Soft-magnetic-materials play a vital role in modern technology. These materials can be magnetized and demagnetized with ease, making them highly efficient for various applications. You will find their primary purpose lies in improving energy efficiency. They minimize energy losses in magnetic systems, ensuring optimal performance. Their unique properties make them indispensable in devices like transformers and electric motors. By using soft-magnetic-materials, you contribute to creating more sustainable and energy-efficient systems.

Key Takeaways

- Soft magnetic materials are crucial for enhancing energy efficiency in devices like transformers and electric motors, minimizing energy losses during operation.

- Key properties such as low coercivity, high permeability, and low hysteresis loss make these materials ideal for applications requiring frequent changes in magnetic fields.

- Using materials with high electrical resistivity helps reduce eddy currents, further improving the efficiency of magnetic systems and minimizing heat generation.

- Different types of soft magnetic materials, including silicon steel, ferrites, amorphous alloys, and nanocrystalline alloys, offer unique benefits tailored to specific applications.

- Incorporating soft magnetic materials into power electronics and renewable energy systems supports the development of sustainable technologies and reduces environmental impact.

- Choosing the right soft magnetic material can significantly enhance the performance and longevity of devices, leading to cost savings and improved reliability.

Properties of Soft Magnetic Materials

Soft-magnetic-materials possess unique properties that make them essential for various applications. Understanding these properties helps you appreciate their role in improving energy efficiency and device performance.

Low Coercivity

Low coercivity is a defining feature of soft-magnetic-materials. It refers to the minimal effort required to magnetize or demagnetize these materials. You can think of it as the ability of the material to respond quickly to changes in an external magnetic field. This property ensures that energy losses remain low during magnetization cycles. Devices like transformers and electric motors rely on this characteristic to operate efficiently.

High Permeability

High permeability allows soft-magnetic-materials to conduct magnetic fields effectively. This means the material can channel magnetic flux with minimal resistance. When you use materials with high permeability, you enhance the performance of magnetic circuits. This property is particularly valuable in applications where strong magnetic fields are required, such as inductors and magnetic sensors.

Low Hysteresis Loss

Hysteresis loss occurs when a material undergoes repeated cycles of magnetization and demagnetization. Soft-magnetic-materials exhibit low hysteresis loss due to their narrow hysteresis loops. This means less energy is wasted as heat during these cycles. By choosing materials with low hysteresis loss, you contribute to reducing energy consumption and improving the overall efficiency of magnetic systems.

Electrical Resistivity and Its Role in Reducing Eddy Currents

Electrical resistivity plays a crucial role in the performance of soft-magnetic-materials. It determines how well a material resists the flow of electric currents. When magnetic materials operate in alternating magnetic fields, they often experience eddy currents. These currents are loops of electrical current induced within the material due to changing magnetic fields. If left unchecked, eddy currents can lead to significant energy losses in the form of heat.

Soft-magnetic-materials with high electrical resistivity help minimize these losses. The increased resistivity reduces the magnitude of eddy currents, ensuring that less energy is wasted. This property becomes especially important in applications like transformers and electric motors, where alternating magnetic fields are common. By using materials with higher resistivity, you enhance the efficiency of these devices and reduce unnecessary heat generation.

To further reduce eddy currents, manufacturers often design soft-magnetic-materials in thin laminated sheets. These laminations, coated with insulating layers, break the path of eddy currents. This design approach complements the natural resistivity of the material, providing an additional layer of energy efficiency. When you choose materials with high resistivity and proper lamination, you ensure optimal performance in magnetic systems.

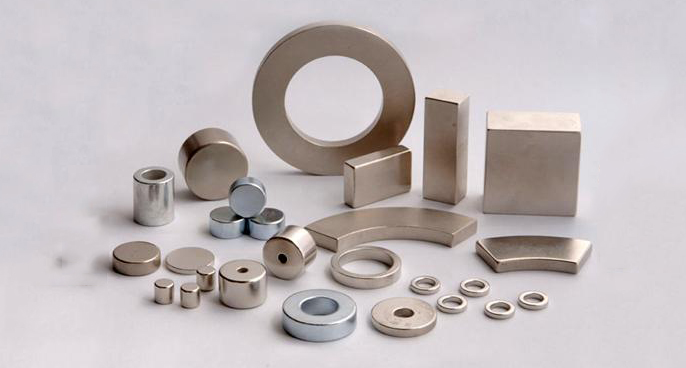

Types of Soft Magnetic Materials

Soft-magnetic-materials come in various types, each offering unique properties and benefits. Understanding these types helps you select the right material for specific applications.

Silicon Steel

Silicon steel is one of the most widely used soft-magnetic-materials. It contains a small percentage of silicon, which enhances its magnetic properties. This material exhibits low hysteresis loss and high permeability, making it ideal for applications requiring efficient energy transfer. You will often find silicon steel in transformers, electric motors, and generators. Its ability to reduce energy losses ensures optimal performance in these devices. Manufacturers also use thin laminations of silicon steel to minimize eddy currents, further improving efficiency.

Ferrites

Ferrites are ceramic compounds made from iron oxide combined with other metallic elements. These materials are lightweight and exhibit high electrical resistivity. Their high resistivity makes them effective in reducing eddy current losses. Ferrites are commonly used in high-frequency applications, such as inductors, transformers, and magnetic cores in electronic circuits. You will notice that ferrites are available in two main types: soft ferrites and hard ferrites. Soft ferrites are specifically designed for applications requiring easy magnetization and demagnetization. Their versatility and cost-effectiveness make them a popular choice in modern electronics.

Amorphous Alloys

Amorphous alloys are metallic materials with a non-crystalline structure. Unlike traditional metals, these alloys lack a regular atomic arrangement. This unique structure gives them exceptional magnetic properties, including low coercivity and low core losses. Amorphous alloys are highly efficient in energy conversion, making them suitable for transformers and power distribution systems. Their thin ribbon-like form helps reduce eddy currents, ensuring minimal energy wastage. By using amorphous alloys, you can achieve significant energy savings in high-performance applications.

Nanocrystalline Alloys

Nanocrystalline alloys represent a breakthrough in the field of soft-magnetic-materials. These materials consist of ultra-fine grains, typically smaller than 100 nanometers. This unique structure gives them exceptional magnetic properties, making them highly efficient for advanced applications.

You will find nanocrystalline alloys exhibit extremely low coercivity. This means they require minimal energy to magnetize and demagnetize, which reduces energy losses during operation. Their high permeability allows them to conduct magnetic fields effectively, ensuring optimal performance in magnetic circuits. These properties make nanocrystalline alloys ideal for use in high-frequency transformers, inductors, and power electronics.

Another key advantage of nanocrystalline alloys is their ability to minimize core losses. Core losses, which include hysteresis and eddy current losses, can significantly impact the efficiency of magnetic systems. The fine grain structure of these alloys reduces hysteresis loss, while their high electrical resistivity limits the formation of eddy currents. This combination ensures that less energy is wasted as heat, improving the overall efficiency of devices.

Manufacturers often produce nanocrystalline alloys in thin ribbon forms. This design further enhances their performance by reducing eddy currents and heat generation. You can rely on these materials for applications requiring compact, lightweight, and energy-efficient solutions. They are particularly valuable in renewable energy systems, electric vehicles, and next-generation power electronics.

By choosing nanocrystalline alloys, you contribute to the development of sustainable and energy-efficient technologies. Their superior magnetic properties and low energy losses make them a cornerstone in modern engineering and innovation.

Applications of Soft Magnetic Materials

Soft-magnetic-materials play a crucial role in various industries by enhancing the efficiency and performance of magnetic systems. Their unique properties make them indispensable in devices that rely on magnetic fields for energy transfer and conversion. Below, you will explore some of the most common applications of these materials.

Transformers

Transformers depend heavily on soft-magnetic-materials to function efficiently. These materials form the core of transformers, enabling the transfer of electrical energy between circuits through magnetic induction. The low coercivity of soft-magnetic-materials ensures minimal energy loss during magnetization and demagnetization cycles. This property is vital for reducing heat generation and improving energy efficiency.

High permeability in these materials allows transformers to channel magnetic flux effectively. This ensures optimal energy transfer, even in high-power applications. Manufacturers often use silicon steel or amorphous alloys for transformer cores due to their ability to minimize hysteresis and eddy current losses. By using these materials, you can achieve better performance and lower operational costs in power distribution systems.

Electric Motors

Electric motors rely on soft-magnetic-materials to convert electrical energy into mechanical energy. These materials form the stator and rotor cores, which are essential for generating the magnetic fields that drive motor operation. The low hysteresis loss of soft-magnetic-materials ensures that less energy is wasted as heat, making motors more efficient.

High electrical resistivity in these materials helps reduce eddy current losses, especially in motors operating at high speeds. This improves the overall performance and longevity of the motor. You will find soft-magnetic-materials like ferrites and nanocrystalline alloys commonly used in electric motors for applications ranging from household appliances to industrial machinery. Their efficiency contributes to energy savings and reduced environmental impact.

Inductors

Inductors use soft-magnetic-materials to store and regulate energy in the form of magnetic fields. These components are essential in electronic circuits for filtering, energy storage, and voltage regulation. The high permeability of soft-magnetic-materials allows inductors to generate strong magnetic fields with minimal energy input.

The low coercivity of these materials ensures quick response to changes in current, making inductors highly effective in dynamic applications. Ferrites are a popular choice for inductor cores due to their lightweight nature and high electrical resistivity. By incorporating soft-magnetic-materials into inductors, you can enhance the performance of electronic devices, including power supplies and communication systems.

Magnetic Sensors

Magnetic sensors rely on soft-magnetic-materials to detect and measure magnetic fields with precision. These sensors play a critical role in various applications, including navigation systems, automotive technologies, and industrial automation. The unique properties of soft-magnetic-materials, such as high permeability and low coercivity, make them ideal for enhancing the sensitivity and accuracy of magnetic sensors.

You will find that these materials enable sensors to respond quickly to changes in magnetic fields. This rapid response ensures accurate readings in dynamic environments. For example, in automotive systems, magnetic sensors monitor wheel speed and position, contributing to the efficiency of anti-lock braking systems (ABS) and advanced driver-assistance systems (ADAS). Their ability to operate reliably under varying conditions makes them indispensable in modern vehicles.

In industrial settings, magnetic sensors equipped with soft-magnetic-materials improve the precision of machinery and equipment. They help monitor rotational speeds, detect metal objects, and ensure the proper alignment of components. By using these sensors, you can enhance productivity and reduce operational errors. Their versatility also extends to consumer electronics, where they are used in devices like smartphones and wearables for features such as compass functionality and motion tracking.

Power Electronics and Renewable Energy Systems

Soft-magnetic-materials are essential in power electronics and renewable energy systems. These materials improve the efficiency of devices that convert and manage electrical energy. Their low hysteresis loss and high permeability make them suitable for applications requiring minimal energy wastage and optimal performance.

In power electronics, you will see soft-magnetic-materials used in components like inductors, transformers, and chokes. These components regulate voltage, filter noise, and manage energy flow in circuits. For instance, in power supplies and inverters, soft-magnetic-materials ensure stable and efficient energy conversion. Their ability to minimize heat generation reduces energy losses, which is crucial for maintaining the reliability of electronic systems.

Renewable energy systems, such as wind turbines and solar inverters, also benefit from the use of soft-magnetic-materials. In wind turbines, these materials enhance the performance of generators by reducing core losses and improving energy transfer. Solar inverters rely on them to convert direct current (DC) into alternating current (AC) efficiently. By incorporating soft-magnetic-materials into these systems, you contribute to the development of sustainable energy solutions.

The role of soft-magnetic-materials extends to emerging technologies like electric vehicles and smart grids. In electric vehicles, they improve the efficiency of motors and charging systems, enabling longer driving ranges and faster charging times. Smart grids use these materials in transformers and sensors to optimize energy distribution and reduce power losses. Their contribution to renewable energy and power electronics underscores their importance in building a sustainable future.

Advantages of Soft Magnetic Materials

Soft-magnetic-materials offer several advantages that make them essential in modern technology. Their unique properties contribute to energy efficiency, reduced heat loss, and enhanced performance in magnetic devices.

Energy Efficiency

Soft-magnetic-materials improve energy efficiency by minimizing energy losses during magnetization and demagnetization cycles. Their low coercivity ensures that less energy is required to magnetize or demagnetize the material. This characteristic reduces wasted energy, especially in devices like transformers and electric motors. High permeability also enhances energy transfer by allowing magnetic fields to flow with minimal resistance. When you use these materials, you optimize energy usage and reduce operational costs.

Reduced Heat Loss

Heat loss occurs when energy dissipates as heat during the operation of magnetic systems. Soft-magnetic-materials address this issue effectively. Their low hysteresis loss ensures that less energy is converted into heat during repeated magnetization cycles. High electrical resistivity further reduces heat generation by limiting eddy currents. These properties make soft-magnetic-materials ideal for applications requiring consistent performance without overheating. By choosing these materials, you enhance the durability and reliability of your devices.

Enhanced Performance in Magnetic Devices

Soft-magnetic-materials significantly improve the performance of magnetic devices. Their ability to respond quickly to changes in magnetic fields ensures efficient operation in dynamic environments. High permeability allows these materials to generate strong magnetic fields, which is crucial for devices like inductors and magnetic sensors. Low energy losses and reduced heat generation also contribute to better device performance. When you incorporate soft-magnetic-materials into your systems, you achieve higher efficiency and reliability in applications ranging from power electronics to renewable energy systems.

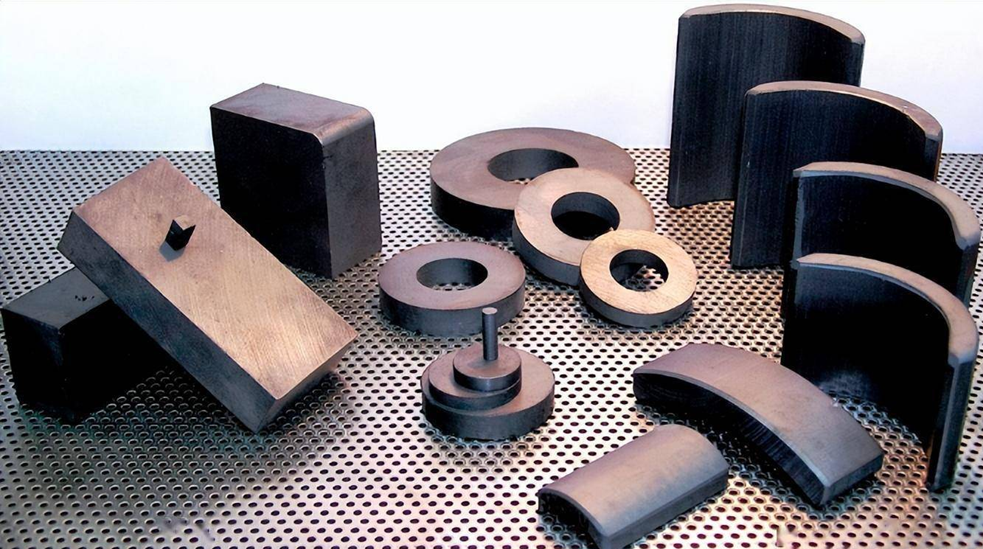

Comparison with Hard Magnetic Materials

Soft-magnetic-materials and hard magnetic materials serve different purposes in magnetic systems. Understanding their differences helps you choose the right material for your specific needs. Below, you will explore key distinctions between these two types of magnetic materials.

Differences in Coercivity

Coercivity measures the resistance of a material to changes in its magnetization. Soft-magnetic-materials have low coercivity, which means you can easily magnetize and demagnetize them. This property makes them ideal for applications requiring frequent changes in magnetic fields, such as transformers and electric motors.

Hard magnetic materials, on the other hand, exhibit high coercivity. They retain their magnetization even when exposed to external magnetic fields. This characteristic makes them suitable for permanent magnets used in devices like speakers, magnetic locks, and generators. If you need a material that maintains a stable magnetic field over time, hard magnetic materials are the better choice.

Differences in Applications

The applications of soft-magnetic-materials and hard magnetic materials differ significantly due to their magnetic properties. Soft-magnetic-materials excel in dynamic systems where magnetic fields change frequently. You will find them in transformers, inductors, and electric motors, where they enhance energy efficiency and reduce losses.

Hard magnetic materials are used in static systems where a constant magnetic field is required. These materials are essential for creating permanent magnets found in everyday items like refrigerator magnets, electric vehicle motors, and wind turbine generators. If your application demands a steady magnetic force, hard magnetic materials are more appropriate.

Differences in Magnetic Retention and Demagnetization

Magnetic retention refers to a material’s ability to maintain its magnetization after the removal of an external magnetic field. Soft-magnetic-materials have low magnetic retention. They lose their magnetization quickly when the external field is removed. This property allows them to respond rapidly to changes in magnetic fields, making them efficient for alternating current (AC) systems.

Hard magnetic materials, however, retain their magnetization for extended periods. They resist demagnetization, even under challenging conditions. This makes them reliable for applications requiring long-lasting magnetic fields, such as magnetic storage devices and industrial lifting magnets. If you need a material that withstands demagnetizing forces, hard magnetic materials are the better option.

By understanding these differences, you can make informed decisions about which material best suits your application. Both soft-magnetic-materials and hard magnetic materials play vital roles in modern technology, each offering unique advantages based on their properties.

Soft-magnetic-materials offer unique properties that make them essential in modern technology. Their low coercivity, high permeability, and low hysteresis loss enhance energy efficiency and device performance. You can find these materials in transformers, electric motors, and renewable energy systems, where they reduce energy losses and improve functionality. By using soft-magnetic-materials, you support advancements in industries like power generation, electronics, and transportation. These materials play a key role in creating sustainable and energy-efficient solutions, making them indispensable for the future of technology.

FAQ

What are soft magnetic materials?

Soft magnetic materials are materials that you can easily magnetize and demagnetize. They exhibit properties like low coercivity, high permeability, and low hysteresis loss. These characteristics make them ideal for applications where magnetic fields need to change frequently, such as in transformers and electric motors.

How do soft magnetic materials differ from hard magnetic materials?

Soft magnetic materials have low coercivity, meaning they lose their magnetization quickly when the external magnetic field is removed. This makes them suitable for dynamic systems. Hard magnetic materials, on the other hand, have high coercivity and retain their magnetization for long periods. You would use hard magnetic materials for permanent magnets, while soft magnetic materials work best in devices like inductors and transformers.

Why is low coercivity important in soft magnetic materials?

Low coercivity ensures that soft magnetic materials require minimal energy to magnetize or demagnetize. This reduces energy losses during operation, making these materials highly efficient for applications like transformers and electric motors. It also allows for quick responses to changes in magnetic fields.

What role does electrical resistivity play in soft magnetic materials?

Electrical resistivity helps reduce energy losses caused by eddy currents. Eddy currents are loops of electrical current induced within a material by changing magnetic fields. High resistivity in soft magnetic materials minimizes these currents, ensuring less energy is wasted as heat. This property is especially important in devices like transformers and motors.

What are some common types of soft magnetic materials?

You will find several types of soft magnetic materials, including:

- Silicon Steel: Known for its low hysteresis loss and high permeability.

- Ferrites: Lightweight materials with high electrical resistivity, ideal for high-frequency applications.

- Amorphous Alloys: Metallic materials with a non-crystalline structure, offering low core losses.

- Nanocrystalline Alloys: Materials with ultra-fine grains, providing exceptional magnetic properties.

Each type serves specific applications based on its unique properties.

Where are soft magnetic materials commonly used?

Soft magnetic materials are widely used in:

- Transformers: For efficient energy transfer between circuits.

- Electric Motors: To convert electrical energy into mechanical energy.

- Inductors: For energy storage and voltage regulation in electronic circuits.

- Magnetic Sensors: To detect and measure magnetic fields.

- Power Electronics: In devices like inverters and renewable energy systems.

These materials enhance the efficiency and performance of these devices.

How do soft magnetic materials improve energy efficiency?

Soft magnetic materials improve energy efficiency by minimizing energy losses during magnetization and demagnetization cycles. Their low coercivity and low hysteresis loss ensure that less energy is wasted as heat. High permeability also allows for effective magnetic flux conduction, optimizing energy transfer in devices.

Can soft magnetic materials be used in renewable energy systems?

Yes, soft magnetic materials play a crucial role in renewable energy systems. In wind turbines, they enhance generator performance by reducing core losses. Solar inverters use these materials to efficiently convert direct current (DC) into alternating current (AC). By using soft magnetic materials, you support the development of sustainable energy solutions.

What are the advantages of using nanocrystalline alloys?

Nanocrystalline alloys offer several advantages:

- Extremely low coercivity, reducing energy losses.

- High permeability, ensuring effective magnetic flux conduction.

- Low core losses, including reduced hysteresis and eddy current losses.

- Compact and lightweight design, ideal for advanced applications like electric vehicles and power electronics.

These properties make nanocrystalline alloys a preferred choice for high-performance systems.

How can you reduce eddy current losses in soft magnetic materials?

To reduce eddy current losses, you can use soft magnetic materials with high electrical resistivity. Manufacturers often design these materials in thin laminated sheets coated with insulating layers. This breaks the path of eddy currents, further minimizing energy losses. By choosing materials with proper lamination and high resistivity, you enhance the efficiency of magnetic systems.