What is selective laser melting(SLM)?

SLM: Selective laser melting (selective laser melting), is a 3D printing technology for metal materials. Selective laser melting process: uses software to generate 3D CAD slice models for parts orders, and after obtaining the size data of each section, uses a laser as an energy source, combined with the size data, to selectively scan metal powder layer by layer. By spreading powder layer by layer, scanning the melting, solidification, and accumulation methods layer by layer, the effect of metallurgical bonding is achieved, and finally the metal parts designed by the model are obtained.

SLM 3D printing technology

- SLM can produce parts with complex shapes without specific molds, improving production efficiency and saving mold production costs.

- The product has high precision. The laser is used to irradiate the surface of the metal powder to rapidly heat and melt the surface. It can be processed by the movement of the manufacturing platform to produce high-precision parts.

- Wide range of selective laser melting applications: SLM technology is applicable to almost any metal material, including titanium alloy, stainless steel, and aluminum alloy.

- Structures that are difficult to form with some molds can be produced. If cellular type products.

Materials for SLM:

SLM materials: Such as: Titanium alloy, aluminum alloy, stainless steel, high strength steel, copper alloy, tungsten alloy and so on.

| Titanium

TC4,TC4DT,TC6, TC11,TC17 ,TC18,TC21, TA7,TA12,TA15, Ti40,Ti60,TA19

|

Aluminium

AlSi12,AlSi10Mg, AlSi7Mg,AlSi9Cu3, AlMg4.5Mn0.4 |

High strength steel

Aermet100,300M, 30CrMnSiA, 40CrMnSiMoVA |

Copper and copper alloys |

| Stainless steel

304,316L,321,15-5PH, 17-4PH,2Cr13 |

Superalloy

Inconel718(GH4169), Inconel625(GH3625), HastelloyX(GH3536), Haynes188,Haynes230, CoCrW.CoCrMo

|

Die steel

H13,18Ni300,Invar 36,420 |

Tungsten alloy

W-25,TAW |

Selective Laser Melting Advantages

SLM 3d printing technology is widely used in aviation, aerospace, automobile, industrial mold, medical and other fields. SLM technology produces parts with high density, high strength, and high precision, and can print complex-shaped parts such as cams, bases, and thin-walled structures. In the medical field, SLM solutions is applied to manufacture medical devices such as prostheses, which can quickly print out suitable prostheses according to individual needs, greatly improving the efficiency of surgery and the quality of treatment.

JH MIM Selective Laser Melting Machines And Applications

JH MIM introduced advanced selective laser melting 3d printer from 2021 , and completed equipment debugging and mass production. Please check below selective laser melting machines.

- Number of lasers: 1 (A160)/2 (A160D)

- Laser power: 200W/200W*2

- Plant load-bearing requirements: 500Kg

- Power/voltage: 2.5KW/4KW; AC220V

- Layer thickness: 20-40 microns

- Printable materials

Pure titanium, TCA

316L, 17-4. 420, C 300

316L, 17-4. 420, C 300

- Number of lasers: 1 (A160)/2 (A160D)

- Laser power: 200W/200W*2

- Plant load-bearing requirements: 500Kg

- Power/voltage: 2.5KW/4KW; AC220V

- Layer thickness: 20-40 microns

- Printable laser melting materials:

Pure titanium, TCA

316L, 17-4. 420, C 300

316L, 17-4. 420, C 300

Difficult-to-form material structures

Tungsten grating, Material: Pure Tungsten

- Traditional method: use powder metallurgy to manufacture tungsten sheets, and then

Cutting (dense density, low yield rate. Difficult to guarantee accuracy )

- Wall thickness: 0.1±0.025mm

- Performance: 3-point bending strength 285N (international standard>200N)

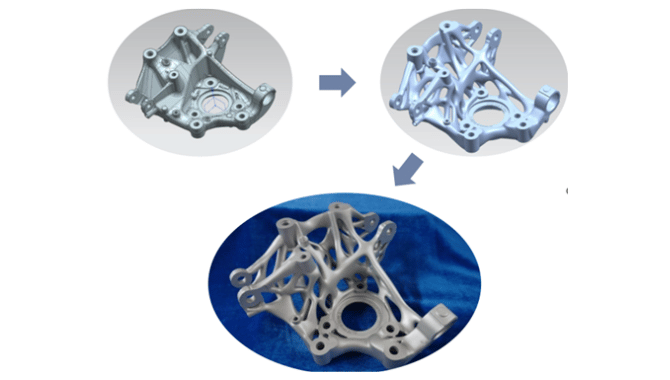

Structural optimization design, reduce product weight

Steering knuckle structure, material: aluminum alloy

Problems: 1. Casting defects are unavoidable and the scrap rate is high

.The product is overweight ·Solution: optimized design + 3D printing ·Effect: a. 33% weight loss

3D printing one-time forming, no metallurgical defects

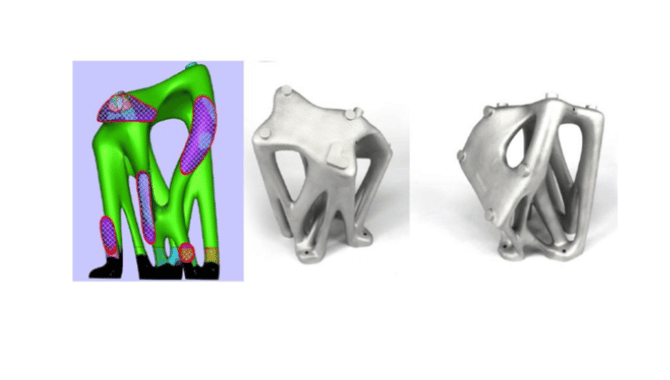

For products with complex structures, molds are difficult to shape, and CNC cannot process them

C724C aviation bracket , material: titanium alloy

Shaped Lightweight Bracket

The exterior is a topological surface

Lightweight lattice structure inside

The whole is formed by titanium 3D printing at one time

76% weight reduction after optimized design

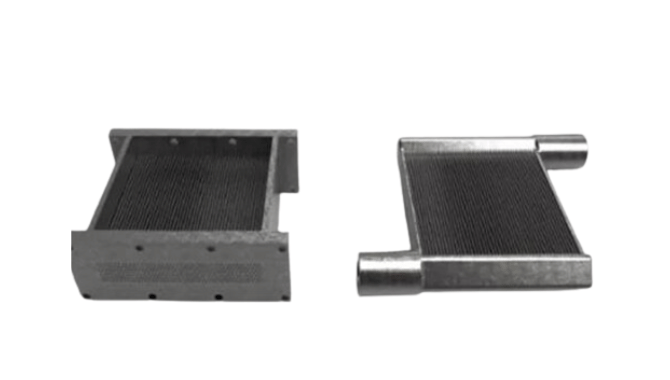

The thermal management of cooling products

Traditional crafts:

Large number of tubes and fins brazed assembly

Internal Straight Channel Splicing

Runner corners are sealed with plugs

SLM:

Spatial distribution of continuous flow channels and internal characteristic flow channels, fins, and complex structures conformal design the installation interface is free and efficient

Mounting Interface Design Restricted