Hot pressing combines pressing and sintering into one powerful manufacturing step that delivers exceptional results for powder metallurgy applications. Manufacturers achieve over 99.5% of theoretical density with this technique, which substantially outperforms traditional sintering methods reaching only 90-98% density. The process runs at temperatures between 1400°C and 2000°C and applies pressures up to 50 MPa to create strong bonds between particles.

This advanced technique works by applying heat and pressure to powder materials simultaneously. The process boosts mechanical properties and eliminates porosity completely. Components made through hot pressing show superior strength, hardness, and fracture toughness compared to conventional sintering. The process also removes material weaknesses as porosity decreases. Hot pressing machines are crucial to consolidate materials that are difficult to sinter, like non-oxide ceramics and metal matrix composites. Traditional sintering needs long processing times that promote grain growth. Hot pressing cycles are shorter and use lower temperatures, which results in finer microstructures and improved performance.

Process Overview: Sintering vs Hot Pressing

The powder metallurgy process becomes clear when we dissect the key differences between traditional sintering and hot pressing technologies.

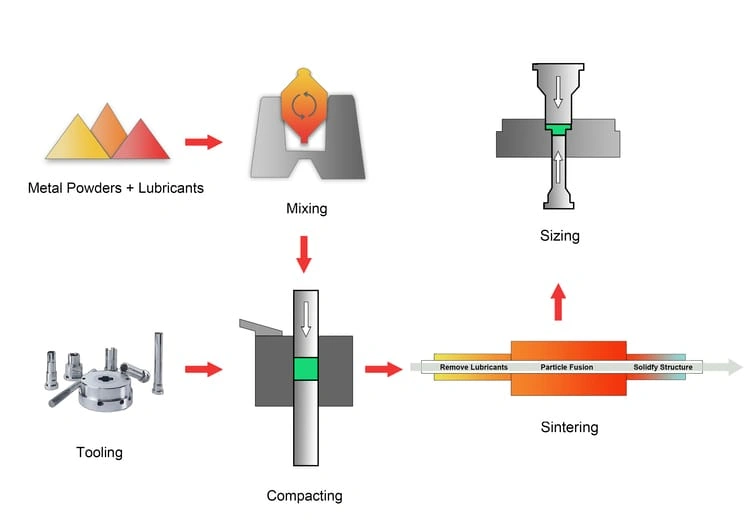

Sintering Process: Cold Compaction + Heat Treatment

Traditional sintering uses a two-step approach. Metal powders are first cold compacted into a “green compact” and then undergo heat treatment. The process moves through three main stages: preheating (500-900°C), main sintering, and cooling. Main sintering temperatures reach about 70-90% of the metal’s melting point. To cite an instance, copper-based parts need 820°C, iron-based parts require 1120°C, and stainless steel demands 1250°C. Particles bond at contact points and form “necks” that grow stronger gradually. The final products usually have 5-25% porosity.

Hot Pressing Process: Simultaneous Heat and Pressure

Hot pressing takes a different approach by applying heat and pressure at the same time to powder materials. Ceramics need temperatures between 1000-2400°C with uniaxial pressures up to 50 MPa. This combined application creates plastic deformation that results in better densification than heat alone. Higher temperatures aid atomic diffusion and rearrangement while reducing material viscosity. The pressure creates close particle contact that eliminates voids and produces more compact products. Modern systems often use induction or resistance heating. Direct hot pressing, where electrical current flows through the die, offers faster heating rates and shorter cycle times.

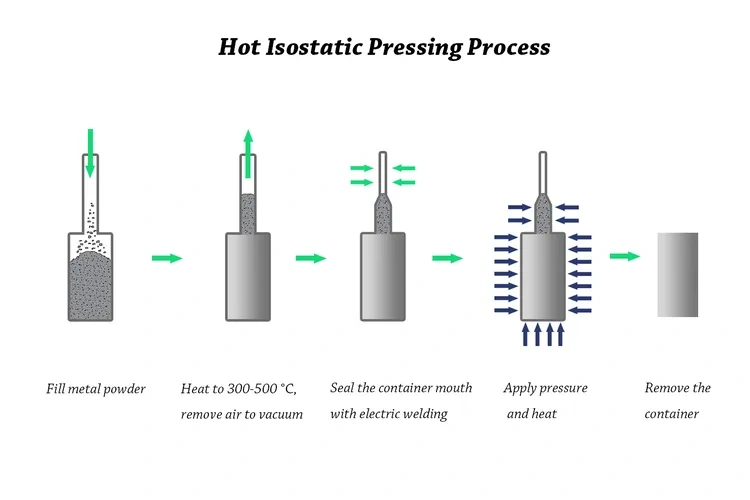

Hot Isostatic Pressing: A Third Option for Full Densification

Hot isostatic pressing (HIP) stands out as an advanced densification method that applies equal pressure from all directions. Unlike uniaxial hot pressing, HIP uses high-pressure gas, usually argon, to create hydrostatic pressure of 100-200 MPa at temperatures between 800-1350°C. This equiaxial compression puts equal pressure on all surfaces while maintaining precise temperature control. HIP can achieve 100% of theoretical material density, which makes it perfect for removing internal porosity in critical components. This process works great for aerospace parts, medical implants, and nuclear applications where materials must be free of pores.

Material Properties and Performance

Processing methods in powder metallurgy affect material performance in many ways. Manufacturers choose specific techniques based on how these methods stack up against each other.

Final Density: 90–98% vs >99.5%

The gap in density between conventional sintering and hot pressing leads to major performance differences. Parts made through hot pressing reach densities above 99.5% of the theoretical maximum. Traditional cold compaction with sintering achieves only 90-98% density. Heat and pressure working together in hot pressing remove residual pores effectively. The external pressure drives densification and cuts the required sintering temperature by 50-150°C.

Porosity and Defect Control

Hot pressing gives better control over internal voids and defects. The parts show porosity below 0.5%. Traditional sintering creates components with higher and uneven porosity. These pores become stress points where cracks start. Some pores stay trapped within the material structure during sintering and weaken the mechanical performance.

Mechanical Strength and Fracture Toughness

Density plays a crucial role in determining mechanical properties. Hot-pressed ceramics perform better than their sintered counterparts. To cite an instance, see hot-pressed Si₃N₄ with specific additives – it reaches flexural strength up to 1250.8 ± 39 MPa. The process also boosts Vickers hardness by 23.78% in some ceramic materials. Fracture toughness values range from 3.4 to 5.0 MPa m^(1/2), and smaller grain sizes in hot-pressed materials help improve fracture resistance.

Grain Growth: Controlled vs Accelerated

Each method develops microstructure differently. Hot pressing uses lower temperatures and shorter cycles to limit grain growth, which creates finer microstructures. These controlled grains make materials stronger and more durable. Traditional sintering needs higher temperatures or longer hold times, which can reduce mechanical performance by promoting grain growth. Studies show that extended exposure to high temperatures can cause irregular grain growth – some grains grow over 100 times larger than others.

Surface Finish and Dimensional Accuracy

Parts made through hot pressing have excellent dimensional control and surface quality. Roughness values range from 3.2 μm Ra for standard finishes to 0.4 μm Ra for high-stress applications. Better surface finishes can make components last up to 20 times longer. Pressure during hot pressing packs particles better and reduces shrinkage. This results in precise dimensional tolerances and a superior surface finish that needs minimal post-processing.

Production Efficiency and Cost Factors

Money drives the choice between sintering and hot pressing techniques in manufacturing. Companies need to weigh upfront costs against future gains.

Cycle Time: Seconds vs Hours

These technologies differ most in their production speed. Hot pressing takes just 3-10 minutes to achieve density, while conventional sintering needs much longer furnace cycles of 1-2 hours. Pressure makes this huge speed difference possible. New technologies like spark plasma sintering have cut processing times even more – now it takes less than 60 seconds from room temperature.

Tooling and Equipment Cost

Hot pressing systems cost a lot more upfront, even though they work better. The equipment needs to handle extreme heat and mechanical pressure at the same time. The dies must be made from special materials like graphite, which adds to running costs. Tooling expenses matter because manufacturers have to spread these costs across their production runs.

Energy Consumption and Maintenance

These processes use energy very differently. Old-style sintering furnaces run at about 30% efficiency and waste most energy as heat. Modern hot isostatic pressing systems work better – they’ve cut cycle times by 70% with new cooling technologies. Good maintenance helps machines last longer, no matter which method you pick.

Scalability for Mass Production

Traditional sintering works great for mass production. Hot pressing usually makes just one or a few parts per cycle, so it’s not ideal for high-volume work. We have a long way to go, but we can build on this progress in hot pressing technology. Output has improved even with higher equipment costs.

Hot Pressing Machine Lifespan and Limitations

Hot pressing equipment lasts differently based on how well it’s built and used. Good commercial machines can run for more than 10 years if they’re maintained well. Things that often break include heating elements, controllers, wiring, and pressure systems. Hot pressing works best with simple shapes because complex designs cause problems.

Best Use Cases and Industry Applications

Matching process capabilities with specific applications helps select the right powder metallurgy technique.

High-Performance Ceramics and Composites

Hot pressing creates dense ceramic components with exceptional mechanical properties. We used this technique to manufacture oxide and non-oxide monolithic ceramics in thin-film technology as sputtering targets and semiconductor processes. Hot-pressed ceramics provide superior strength, hardness, and corrosion resistance for cutting tools and industrial applications. The process turns diamond-metal composites and other hard-to-sinter materials into high-performance cutting tools.

Automotive and Aerospace Components

Hot-pressed components create dense composites that improve mechanical wear resistance in automotive brakes and clutches. The aerospace sector uses hot pressing to make lightweight structural components and turbine blades. These parts reduce engine weight by 30-50 kilograms, which is a big deal as it means lower fuel consumption. Powder metallurgy techniques help manufacture heat exchangers and thermal barrier coatings that protect vital components from extreme temperatures.

Medical Implants and Bioceramics

Hot pressing creates bioceramics with excellent mechanical strength and biocompatibility for orthopedic and dental uses. Hot isostatic pressing boosts zirconia dental implants’ strength from 800-900 MPa to 1300-1400 MPa. These materials work as surgical implants in orthopedics, dentistry, and new fields like drug delivery and bioimaging.

When to Choose Hot Pressing over Sintering

Hot pressing is your best choice if you:

- Need maximum strength and performance

- Work with hard-to-press materials or complex shapes

- Must achieve near-zero porosity

- Need high-temperature stability

Comparison Table

| Characteristic | Sintering | Hot Pressing |

|---|---|---|

| Process Details | ||

| Temperature Range | 820-1250°C (depends on material) | 1400-2000°C |

| Pressure Applied | No external pressure | Up to 50 MPa |

| Process Steps | Two-step: cold compaction + heat treatment | Single step: simultaneous heat and pressure |

| Processing Time | 1-2 hours or longer | 3-10 minutes |

| Performance Metrics | ||

| Final Density | 90-98% of theoretical density | >99.5% of theoretical density |

| Porosity | 5-25% | <0.5% |

| Surface Finish | Lower quality | Down to 0.4 μm Ra |

| Grain Structure | Shows accelerated grain growth | Controlled grain growth, finer microstructure |

| Production Factors | ||

| Equipment Cost | Lower upfront investment | Higher upfront investment |

| Mass Production Capability | Excellent for high volume | Limited (one or few components per cycle) |

| Energy Efficiency | ~30% efficiency | Higher efficiency (exact % not specified) |

| Geometric Flexibility | Handles complex shapes better | Works best with simple shapes |

| Best Applications | ||

| Ideal Use Cases | – Standard components | – High-performance ceramics |

| – Mass production items | – Aerospace components | |

| – Less critical applications | – Medical implants | |

| – Complex geometries | – Difficult-to-sinter materials |

Conclusion

Sintering and hot pressing each bring their own strengths to manufacturing, with the best choice depending on specific production needs. Hot pressing stands out when material performance matters most. It achieves densities of over 99.5%, while conventional sintering typically reaches 90-98%. These higher density levels lead to better mechanical properties, tougher materials that resist fracture, and smoother surface finishes.

In spite of that, sintering proves more practical for mass production. Its lower equipment costs, flexible geometry options, and well-established manufacturing base make it ideal for producing large volumes of standard components. Time also plays a crucial role – hot pressing completes the densification process in minutes, while traditional sintering takes hours.

The choice of material often points to the right process. Hot pressing techniques work exceptionally well with materials that resist traditional sintering, such as non-oxide ceramics, metal matrix composites, and diamond-metal combinations. High-end applications like aerospace parts, cutting tools, and medical implants justify hot pressing equipment’s higher investment costs.

Manufacturers need to weigh their production needs, intended uses, and budget constraints carefully. Most experienced powder metallurgy producers have both capabilities, which lets them match each customer’s specific needs with the right process. This strategy helps them deliver precision-engineered products to industries of all types while optimizing both performance and efficiency.

Both technologies will keep shaping modern powder metallurgy’s future. Hot pressing’s remarkable performance benefits complement sintering’s essential role in mass production. We can expect both technologies to advance as manufacturers look to streamline processes and meet tougher performance standards in global markets.

Key Takeaways

Understanding the fundamental differences between sintering and hot pressing helps manufacturers select the optimal powder metallurgy technique for their specific applications and production requirements.

• Hot pressing achieves superior density (>99.5%) compared to conventional sintering (90-98%), resulting in stronger, more durable components with minimal porosity

• Processing time differs dramatically: hot pressing completes densification in 3-10 minutes while traditional sintering requires 1-2 hours or more

• Choose hot pressing for high-performance applications like aerospace components, medical implants, and cutting tools where maximum strength is critical

• Conventional sintering remains ideal for mass production due to lower equipment costs, greater geometric flexibility, and established manufacturing infrastructure

• Hot pressing excels with difficult-to-sinter materials like non-oxide ceramics and metal matrix composites that conventional methods struggle to densify effectively

The decision ultimately depends on balancing performance requirements against production volume, cost constraints, and component complexity. High-performance applications justify hot pressing’s higher investment, while mass production scenarios favor conventional sintering’s economic advantages.

FAQs

Q1. What are the main differences between sintering and hot pressing in powder metallurgy? Sintering involves cold compaction followed by heat treatment, while hot pressing applies heat and pressure simultaneously. Hot pressing achieves higher densities (>99.5%) compared to sintering (90-98%) and has shorter processing times, but requires more expensive equipment.

Q2. When should manufacturers choose hot pressing over sintering? Hot pressing is preferable when maximum strength and near-zero porosity are critical, when working with difficult-to-press materials, or when high-temperature stability is required. It’s ideal for high-performance applications like aerospace components and medical implants.

Q3. How does hot pressing affect the final product’s properties compared to sintering? Hot-pressed products typically have superior mechanical properties, including higher strength, hardness, and fracture toughness. They also have finer grain structures, better surface finish, and significantly lower porosity compared to sintered parts.

Q4. Is hot pressing suitable for mass production? Hot pressing is generally less suitable for mass production compared to sintering. It typically produces one or few components per cycle, making it more appropriate for specialized, high-performance parts rather than high-volume manufacturing.

Q5. What are some key applications for hot-pressed components? Hot pressing is widely used in producing high-performance ceramics, aerospace components, cutting tools, medical implants, and bioceramics. It’s particularly valuable for manufacturing dense composites, turbine blades, and components that require exceptional mechanical properties and wear resistance.