Sintering transforms fragile “green” parts into robust, high-density components. This critical process is indispensable for achieving desired mechanical properties and dimensional accuracy in MIM parts. Sintering in Metal Injection Molding unlocks the full potential of MIM for complex, high-performance applications. The Metal Injection Molding market continues to expand rapidly.

| Attribute | Value |

|---|---|

| Market Size in 2024 | USD 4.86 Billion |

| Growth Rate (CAGR) | 8.59% |

| Forecast Period | 2025-2034 |

This growth trajectory highlights the increasing demand for precision components produced via MIM.

Key Takeaways

- Sintering changes weak MIM parts into strong, dense metal parts.

- This process makes MIM parts strong, hard, and resistant to wear.

- Sintering causes parts to shrink, so careful control is important for the correct size.

- Tiny movements of atoms help metal particles join together and remove holes.

- Special methods like vacuum sintering make parts very pure and strong.

- Controlling heat and cooling during sintering stops parts from breaking or bending.

- Sintering makes parts last longer and work well in tough conditions.

Why Sintering in Metal Injection Molding is Essential for Precision

The Transformative Role of Sintering in MIM

From Debound Part to Solid Component

Metal Injection Molding (MIM) produces parts in several stages. Initially, a “green” part forms after molding. This part is fragile. A subsequent debinding process removes the binder material. This leaves a porous, brittle structure. Sintering then transforms this debound part into a dense, solid metal component. This transformation is fundamental for the part’s final performance.

Driving Force for Material Consolidation

Sintering acts as the primary force for material consolidation. This process reduces the total free energy within the material. The change in free energy comes from a decreased surface area. It also results from replacing high-energy solid-vapor interfaces with lower-energy solid-solid interfaces. On a microscopic scale, differences in free energy across curved surfaces also contribute. The power source for solid-state sintering processes is the change in free or chemical potential energy between the neck and the particle surface. This reduction in total surface energy, known as capillarity, drives the particles closer. Externally applied pressure can also enhance these densification forces. Sintering requires a net reduction in free energy between particles to reach a thermodynamic minimum. Initially, this driving force is linked to minimizing surface curvatures. As sintering progresses, the primary driving force shifts. It focuses on reducing interfacial energy. This happens by replacing higher-energy interfaces with lower-energy ones through pore reduction and grain growth. Applied pressure can enhance these densification driving forces by increasing stress at particle contacts.

Sintering’s Unwavering Importance in MIM

Achieving Structural Integrity and Density

Sintering is crucial for achieving the structural integrity and high density of MIM parts. Without sintering, the debound part remains weak and unsuitable for most applications. The high temperatures during sintering cause metal particles to bond together. This bonding eliminates voids and reduces porosity. The result is a component with significantly increased density. This increased density directly contributes to the part’s strength and reliability.

Enabling Optimal Material Performance

Sintering enables optimal material performance in Metal Injection Molding. It significantly improves various mechanical properties. These improvements make MIM parts suitable for demanding applications.

- Density: Sintering significantly increases the material’s density.

- Strength: The process strengthens the metal component, enhancing overall mechanical properties.

- Compression Strength: Improved due to increased density.

- Fatigue Resistance: Enhanced as a result of higher density.

- Wear Resistance: Benefits from the increased density of the MIM part.

- Hardness: Optimized through precise control of sintering parameters, which influence microstructure.

- Toughness: Can be fine-tuned by adjusting sintering parameters to control microstructure.

- Durability: Enhanced, making parts suitable for high-demand applications.

- Surface Finish: Optimized through controlled sintering, contributing to overall quality.

Mechanisms of Sintering in Metal Injection Molding: Building Precision

Sintering transforms a porous, debound part into a dense, functional component. This process involves complex atomic-level mechanisms. These mechanisms work together to build the precision and performance of MIM parts. Sintering in Metal Injection Molding is a complex process. It involves intricate atomic movements and microstructural changes. Understanding these mechanisms allows manufacturers to produce high-precision, high-performance components.

Atomic Diffusion and Neck Growth During Sintering

Atomic movement drives the sintering process. Atoms migrate from high-energy areas to lower-energy areas. This movement leads to the formation and growth of “necks” between adjacent particles.

Surface Diffusion for Initial Bonding

Surface diffusion is one primary mechanism. Atoms move along the surfaces of individual metal particles. This movement facilitates the initial bonding between particles. It forms small contact points, or “necks.” Surface diffusion primarily changes the shape of pores. It does not significantly contribute to overall densification.

Grain Boundary Diffusion for Material Transport

Grain boundary diffusion plays a crucial role in material transport. Atoms move along the interfaces between individual grains. This mechanism contributes significantly to densification during solid-state sintering. In the second stage of sintering, densification continues through material transport mechanisms, including grain boundary diffusion. This process helps shrink interconnected pore channels. It increases the relative density to about 93%. Grain boundary energy drives this process. It minimizes total interfacial energy. This leads to microstructural evolution where pores are located at three-grain edges. At higher sintering temperatures, for example, 1370 °C, grain boundary diffusion is observed. It forms part of a mixture of densifying mechanisms. It contributes to the overall densification rate.

Volume Diffusion for Densification

Volume diffusion involves atomic movement through the bulk of the metal particles. This process is generally slower than surface or grain boundary diffusion. However, it becomes more significant at higher sintering temperatures. Volume diffusion helps fill internal pores. It contributes to the final densification of the material.

Pore Elimination and Densification in Sintering

The various diffusion mechanisms work in concert. They effectively eliminate pores and increase the material’s density. This is a critical aspect of achieving precision in MIM parts.

Reducing Interparticle Voids

As necks grow between particles, the spaces between them, known as interparticle voids, shrink. The reduction of surface energy drives this process. Pores become smaller and more isolated. They eventually transform into spherical shapes within the material.

Maximizing Material Density

Pore elimination directly leads to a significant increase in the material’s density. This increased density is essential for the mechanical performance of the final component. Sintering aims to achieve near-full theoretical density. This maximizes the part’s strength and integrity.

Grain Growth and Microstructure Evolution via Sintering

Sintering not only densifies the material but also modifies its internal microstructure. This involves changes in grain size and overall homogeneity.

Optimizing Grain Size for Properties

Individual metal crystals, or grains, grow during the sintering process. Grain size has a significant influence on the mechanical properties of the final part. For instance, smaller grains often lead to higher strength and hardness. Larger grains can improve ductility and toughness. Manufacturers carefully control sintering parameters to achieve an optimal grain size. This ensures the desired balance of properties for specific applications.

Enhancing Overall Microstructural Homogeneity

Sintering promotes a more uniform internal structure throughout the component. This homogeneity ensures consistent material properties. It prevents localized weak spots or variations in performance. A well-sintered part exhibits a consistent and predictable microstructure. This is vital for reliable operation in demanding environments.

How Sintering in Metal Injection Molding Impacts Part Precision

Sintering directly influences the precision of Metal Injection Molding (MIM) parts. This critical process determines dimensional accuracy, surface quality, and the absence of internal flaws. Manufacturers carefully control sintering parameters to achieve the tight tolerances and high performance required for advanced applications.

Controlled Shrinkage and Dimensional Accuracy in Sintering

Sintering causes significant shrinkage as the material densifies. Managing this shrinkage is paramount for dimensional accuracy.

Predicting and Managing Shrinkage Rates

MIM parts undergo substantial shrinkage during sintering. This shrinkage is a primary factor in the dimensional reduction from the mold cavity to the finished part. Typically, MIM parts shrink by 15% to 20% linearly. For example, 316L stainless steel, a common MIM material, exhibits a shrinkage rate of 16.5%. Predicting and managing these rates accurately is crucial for producing parts within specified tolerances.

| Material | Shrinkage Factor (Mold to Final Part) | Shrinkage Factor (Green Part to Final Part) |

|---|---|---|

| Carbon/Low Alloy Steel | 1.2165 | 1.205 |

| Stainless Steel | 1.160 | 1.166 |

Engineers use these shrinkage factors to design molds that compensate for the material reduction. This ensures the final sintered part meets the required dimensions.

Minimizing Distortion and Warpage

Distortion and warpage present significant challenges in MIM sintering, especially for complex geometries. Uneven shrinkage often causes these issues. Manufacturers employ several strategies to minimize these defects:

- Maintaining a stable thermal environment ensures all parts experience uniform temperatures. This prevents differential shrinkage and warping.

- Using support fixtures minimizes warping, particularly when uneven shrinkage occurs.

- Properly designed support furniture allows uniform shrinkage and reduces distortion.

- Carefully managing heating and cooling rates prevents rapid temperature changes. Such changes introduce thermal stresses, cracking, or warping. Gradual heating and cooling reduce deflection rates and volumetric shrinkage.

- Implementing appropriate support structures or fixtures during sintering is essential for complex geometries or thin-walled sections. This reduces warping or distortion.

- Choosing support materials with thermal expansion properties similar to the MIM part minimizes stress and deformation.

- Ensuring uniform heating throughout the sintering furnace provides consistent part quality and dimensional accuracy.

- Optimizing temperature ramp rates balances sintering kinetics and part integrity, thereby reducing deformation.

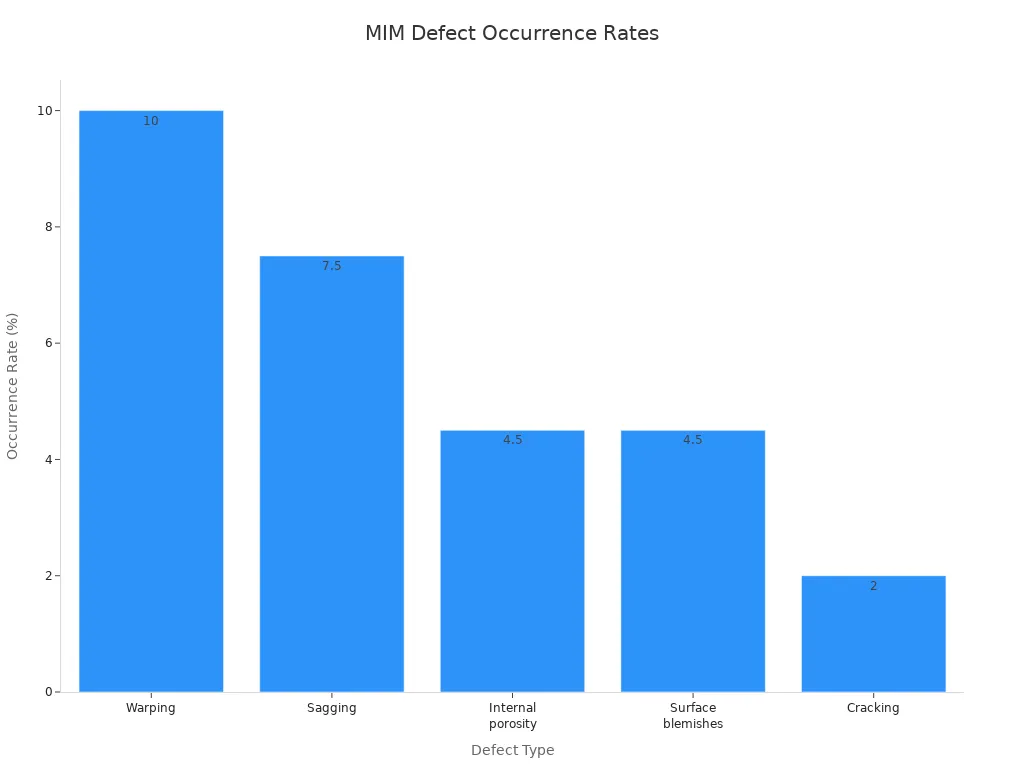

Manufacturers actively address common defects during sintering. Warping, for instance, has an occurrence rate of 8-12% and primarily results from uneven shrinkage. Support fixtures effectively prevent this.

Achieving Superior Surface Finish and Quality through Sintering

Sintering significantly impacts the final surface finish and overall quality of MIM components.

Reducing Surface Roughness Post-Sintering

Sintering transforms the rough surface of the debound part into a smoother, denser finish. MIM parts typically achieve a surface finish of 32 µin Ra after the sintering process. Many MIM applications frequently achieve Ra values below 0.8 micrometers for superior surface finishes. Some parts can even achieve surface roughness values below Ra 1.6 µm. This level of smoothness often eliminates the need for extensive post-sintering machining or finishing operations.

Attaining Desired Aesthetic and Functional Surfaces

Beyond numerical roughness values, sintering contributes to the aesthetic and functional quality of the part’s surface. A well-sintered surface appears uniform and free from visible defects. This is crucial for components requiring a specific visual appeal or those interacting with other parts where surface friction or wear is a concern. The controlled atmosphere during sintering also prevents surface oxidation, maintaining the material’s inherent properties and appearance.

Minimizing Defects and Flaws with Effective Sintering

Effective sintering is crucial for minimizing internal defects and flaws, ensuring the structural integrity of MIM parts.

Eliminating Internal Voids and Porosity

The sintering process actively works to eliminate internal voids and porosity. These defects can compromise a part’s mechanical properties. Common types of internal voids include interconnected or open pores, prevalent in green parts, and closed pores, which become isolated during sintering. Sintering reduces the overall volume of pores. It also isolates interconnected pores, transforming them into closed pores by cutting them off from the external environment. Liquid phase sintering, a specific method, eliminates porosity, leading to parts with superior material properties. This densification process ensures the final component has minimal internal flaws.

Preventing Cracks and Delamination

Properly controlled sintering prevents the formation of cracks and delamination. Rapid heating or cooling rates can induce thermal stresses, leading to cracks. Inadequate binder removal during debinding can also leave residues that cause delamination during the high-temperature sintering process. Manufacturers carefully manage temperature profiles and furnace atmospheres to avoid these issues. This ensures the part maintains its structural integrity throughout the process.

Enhancing Performance Through Sintering in Metal Injection Molding

Sintering is a pivotal process that significantly elevates the performance characteristics of Metal Injection Molding (MIM) components. It transforms a fragile, porous structure into a robust, high-density part, ready for demanding applications.

Improving Mechanical Strength and Hardness via Sintering

Sintering directly contributes to the superior mechanical properties of MIM parts. This process ensures components can withstand significant operational stresses.

Increasing Tensile and Yield Strength

The high temperatures during sintering cause metal particles to bond strongly, eliminating voids and increasing the material’s density. This densification directly translates into higher tensile and yield strengths. Parts can endure greater pulling forces and resist permanent deformation more effectively. Manufacturers achieve specific strength targets by carefully controlling the sintering temperature and time.

Enhancing Hardness and Wear Resistance

Sintering also significantly enhances the hardness of MIM components. Increased density and optimized microstructure contribute to this improvement. Harder surfaces resist scratching, abrasion, and indentation. This makes sintered MIM parts ideal for applications requiring high wear resistance. The process creates a uniform, dense structure that stands up to continuous friction and contact.

Boosting Fatigue and Wear Resistance with Sintering

Sintering plays a crucial role in extending the operational lifespan of MIM parts, particularly under cyclic loading and abrasive conditions.

Extending Component Service Life

Sintered parts exhibit good resistance to wear and fatigue. Sintering increases bend fatigue strength by 15%. This improvement stems from increased material density, which causes metal particles to bond and reduces porosity. Reduced porosity enhances fatigue resistance by delaying crack initiation. Sintering optimizes material properties by allowing control over microstructure, including grain size, phase transformation, and porosity, through adjustments to temperature, time, and atmosphere. Furthermore, sintering removes binders used during molding, ensuring structural integrity and reducing stress that could lead to deformation or cracking.

Reducing Material Degradation Under Stress

Hot Isostatic Pressing (HIP), an advanced sintering technique, can further decrease pore size and quantity, thereby improving fatigue by delaying crack initiation. The initial powder particle size and sintering temperature significantly influence the pore distribution and grain size of sintered components. Appropriate particle-size powders and low sintering temperatures can promote recrystallization during HIP while maintaining a small grain size. This enhances relative density, static mechanical properties, and fatigue performance, ultimately reducing material degradation under stress.

Optimizing Corrosion Resistance and Chemical Stability through Sintering

Sintering in Metal Injection Molding also improves the chemical resilience of components.

Improving Environmental Durability

The densification achieved through sintering reduces the surface area exposed to corrosive environments. This minimizes pathways for corrosive agents to penetrate the material. A dense, uniform microstructure provides a more effective barrier against chemical attack, enhancing the part’s overall environmental durability.

Enhancing Chemical Inertness in Harsh Conditions

By eliminating porosity and creating a homogeneous structure, sintering helps parts maintain their chemical inertness. This is particularly important for components exposed to harsh chemicals or extreme temperatures. A well-sintered part resists degradation, ensuring reliable performance even in aggressive chemical environments.

Advanced Sintering Techniques for Metal Injection Molding

Manufacturers employ advanced sintering techniques to push the boundaries of Metal Injection Molding (MIM) part performance. These methods offer enhanced control over microstructure, density, and purity, leading to superior components for demanding applications.

Vacuum Sintering for High-Purity MIM Parts

Vacuum sintering represents a crucial advancement for producing high-quality MIM components. This technique involves processing parts in a vacuum environment.

Preventing Oxidation During High-Temperature Processing

High temperatures during sintering can cause metal parts to oxidize, especially when oxygen is present. Vacuum sintering effectively removes oxygen and other reactive gases from the furnace atmosphere. This prevents oxidation, which can degrade material properties and surface finish. Manufacturers ensure the integrity of reactive metals by using a vacuum environment.

Achieving Exceptional Material Purity

The absence of atmospheric contaminants in a vacuum furnace helps maintain the purity of MIM parts. This is particularly important for applications requiring stringent material specifications, such as medical implants or aerospace components. Vacuum sintering minimizes the introduction of impurities, resulting in components with superior chemical and mechanical properties.

Pressure-Assisted Sintering Methods in MIM

Pressure-assisted sintering techniques combine high temperatures with external pressure. This combination promotes even greater densification and improved material properties.

Hot Isostatic Pressing (HIP) for Full Densification

Hot Isostatic Pressing (HIP) applies high pressure uniformly from all directions while simultaneously heating the material. This process effectively eliminates residual porosity within sintered MIM parts. ASTM F-3049 provides a standard guide for HIP for metal injection molded materials. Typical HIP parameters include:

| Process Parameter | Typical Ranges |

|---|---|

| Temperature | 1000 – 2000°C (1830 – 3630°F) |

| Pressure | 15,000 – 30,000 PSI |

| Time | 1 – 6 hours |

| Heating & Cooling Rates | 100 – 500°C/hour (180 – 930°F/hour) |

HIP significantly improves density, strength, ductility, and other mechanical properties. Key benefits include increased load-bearing capacity, higher fracture toughness, improved fatigue life, enhanced corrosion resistance, reduced variability in material performance, leak-proofing for gas or fluid containment, and restoration of ductility in embrittled alloys.

Spark Plasma Sintering (SPS) for Rapid Consolidation

Spark Plasma Sintering (SPS) is another pressure-assisted technique. It uses pulsed direct current to rapidly heat and consolidate powder compacts. SPS offers very fast heating and cooling rates. This allows for rapid densification and fine-grained structures. Manufacturers use SPS for materials requiring precise microstructural control and shorter processing times.

Controlled Sintering Atmosphere in Metal Injection Molding

Controlling the atmosphere inside the sintering furnace is critical for achieving desired material properties and preventing unwanted reactions.

Hydrogen Atmospheres for Reduction

Hydrogen atmospheres are frequently used during MIM sintering. They prevent oxidation and contamination. Hydrogen acts as a reducing agent, effectively removing oxides from the metal powder surfaces. This promotes the sintering process and enhances the bonding between particles.

Inert Gas Atmospheres for Protection

Inert gases, such as argon or nitrogen, provide a protective environment during sintering. They prevent reactions between the metal and atmospheric oxygen or other reactive gases. Manufacturers use inert atmospheres for materials that do not require a reducing environment but still need protection from oxidation or nitridation.

Optimizing Sintering Parameters for Specific MIM Applications

Manufacturers precisely control sintering parameters to tailor Metal Injection Molding (MIM) parts for specific applications. This optimization ensures components meet exact performance requirements.

Temperature and Time Control in Sintering

Temperature and time are critical factors in the sintering process. They directly influence the final properties of MIM components.

Impact on Densification Kinetics

Higher sintering temperatures generally lead to improved density and mechanical properties in MIM components. Sintering causes significant linear shrinkage, typically 15-20%. Both temperature and holding time influence this shrinkage. To achieve maximum densification, manufacturers optimize sintering temperatures, often setting them above 900°C. This ensures the material reaches its full potential density.

Influence on Grain Structure and Properties

Sintering temperature and time also dictate the grain structure of the material. The duration at peak temperature allows grains to grow. This affects properties like strength, hardness, and ductility. Manufacturers carefully balance these parameters to achieve an optimal grain size. This ensures the final part possesses the desired mechanical characteristics for its intended use.

Heating and Cooling Rates in the Sintering Process

The rates at which parts heat and cool during sintering are crucial for preventing defects and controlling microstructure.

Managing Thermal Stresses and Cracking

A controlled heating rate helps minimize thermal stresses and prevent defects. The rate at which the material heats affects the final properties of the sintered parts. Slow and controlled heating rates are crucial during debinding. They allow gradual binder escape without causing internal stresses, preventing cracks, voids, or blisters. Controlled heating rates also prevent thermal shock and uneven densification during sintering. Similarly, controlled cooling is essential after the primary sintering cycle. It prevents thermal shock and cracking, allows proper microstructural development, and minimizes residual stresses. Rapid cooling can cause uneven shrinkage, leading to residual stresses and an increased risk of cracking.

Controlling Microstructure Development

Heating and cooling rates significantly influence the microstructure. Decelerating heating rates in specific temperature ranges stimulate beneficial phase transformations. This enhances sintered density and improves overall part structure. Adjusted heating rates of 1°C/min during thermal debinding prevent defects. Temperature ramps under careful control ensure uniform necking. This allows sufficient time for binder decomposition before necking begins, preventing trapped volatiles and internal defects. Slower cooling promotes uniform stress distribution and reduces the likelihood of defects.

Furnace Design and Uniformity for Consistent Sintering

Furnace design plays a vital role in achieving consistent and high-quality MIM parts.

Ensuring Homogeneous Heating Throughout the Batch

Accurate temperature control is essential for uniformity and throughput in production sintering operations. Achieving uniform heating during sintering is critical for consistent and controlled shrinkage and densification of MIM parts. Non-uniform heating can lead to variations in part properties and dimensional inaccuracies. Constant speed and consistent profiles in furnaces, such as pusher or walking beam designs, ensure every part experiences the exact same conditions. This leads to guaranteed throughput and repeatability.

Minimizing Temperature Gradients and Their Effects

Proper furnace design minimizes temperature gradients. The CM-400 series furnace design, featuring an open hearth and exposed elements, effectively maintains temperature uniformity, even when processing large quantities of material. Uniform temperature profiles, achieved through symmetrically arranged heating elements and sealed retorts, minimize deviations. This ensures consistent shrinkage and density across all parts in a batch.

Challenges and Solutions in MIM Sintering

Addressing Dimensional Control Issues in Sintering

Strategies for Predicting and Compensating for Shrinkage

MIM parts experience significant shrinkage during sintering. Predicting and managing this shrinkage is crucial for achieving dimensional accuracy. Engineers use advanced numerical approaches based on phenomenological models of sintering. These models capture creep deformation during free sintering. This method utilizes a calibrated material model. Metallographic studies, dilatometry experiments, and viscosity measurements qualify this model. It does not rely on empirical models. The approach aims to predict final sintering distortions in industrial-relevant parts. For improved accuracy in sintering predictions for Metal Binder Jetting (MBJ) components, considering anisotropic shrinkage and heterogeneous density distribution of green parts in the simulation is essential.

Mitigating Warpage and Distortion

Warpage and distortion pose significant challenges, especially for complex MIM geometries. Uneven shrinkage often causes these issues. Manufacturers employ several strategies. They maintain a stable thermal environment. This ensures uniform temperatures for all parts. It prevents differential shrinkage and warping. Using support fixtures minimizes warping. Properly designed support furniture allows uniform shrinkage. Carefully managing heating and cooling rates prevents rapid temperature changes. Such changes introduce thermal stresses. Gradual heating and cooling reduce deflection rates.

Overcoming Microstructural Defects During Sintering

Preventing Abnormal Grain Growth

Abnormal grain growth can compromise the mechanical properties of MIM parts. Manufacturers employ various methods to prevent this. They add grain growth inhibitors to the feedstock. They implement specific heating profiles. They use alloying elements that restrict grain boundary movement. Pressure-assisted sintering methods also help. Precise temperature control during sintering cycles is vital. Specialized sintering atmospheres are beneficial. Rapid sintering techniques can also prevent abnormal grain growth. Incorporating specialized additives and advanced material formulations, such as sintering aids and phase stabilizers, also helps. Honeywell has developed an integrated approach to MIM sintering. It focuses on predictive modeling and process control. This manages shrinkage and distortion. Their technology incorporates finite element analysis (FEA) models. These models simulate the entire sintering process. They account for thermal gradients, gravitational effects, and material-specific behavior. They employ a multi-stage sintering protocol. This protocol has precisely controlled temperature ramps and holds. They use specialized sintering atmospheres with controlled oxygen partial pressures. This inhibits abnormal grain growth. Honeywell also utilizes proprietary feedback control systems. These systems provide real-time monitoring and adjustments. They conduct post-sintering characterization. This refines their models and parameters.

Reducing Residual Porosity

Residual porosity significantly impacts the mechanical performance of sintered parts. Manufacturers aim to minimize it. They optimize sintering temperature and time. Higher temperatures and longer durations promote densification. They use finer powder particles. Finer particles have higher surface energy. This enhances the driving force for sintering. Pressure-assisted sintering techniques, like Hot Isostatic Pressing (HIP), effectively eliminate closed pores. This achieves near-full theoretical density.

Material-Specific Sintering Considerations

Sintering Stainless Steels

Sintering stainless steels requires careful control of the furnace atmosphere. Stainless steels rely on chromium for corrosion resistance. Oxidation of chromium during sintering forms stable oxides. These oxides hinder densification. Manufacturers use reducing atmospheres, such as hydrogen, or vacuum sintering. This prevents chromium oxidation. They also control carbon content. Carbon can react with chromium. This forms carbides. Carbides reduce corrosion resistance.

Sintering Low Alloy Steels

Sintering low alloy steels often involves specific heat treatment steps. These steps achieve desired mechanical properties. Manufacturers control carbon and alloying element diffusion. This forms specific microstructures, like martensite or bainite. They use controlled cooling rates. This achieves the desired phase transformations. Sintering temperatures are typically lower than for stainless steels. This prevents excessive grain growth.

Sintering Titanium Alloys

Sintering titanium alloys presents unique challenges due to titanium’s high reactivity. Titanium readily reacts with oxygen, nitrogen, and carbon at elevated temperatures. This forms brittle compounds. Manufacturers use high vacuum furnaces or inert gas atmospheres (e.g., argon). This prevents contamination. They also control sintering temperatures precisely. This avoids excessive grain growth. The high cost of titanium powder also influences process economics.

| Challenge | Solution |

|---|---|

| High reactivity with atmospheric gases | Sintering in high vacuum or ultra-high purity inert gas (argon) atmospheres. |

| High cost of raw titanium powder | Optimizing powder characteristics and minimizing material waste. |

| Controlling oxygen and nitrogen pickup | Strict control of furnace atmosphere purity and leak integrity. |

| Achieving high density without excessive grain growth | Precise temperature control and optimized heating/cooling rates. |

| Maintaining mechanical properties (e.g., ductility) | Preventing contamination and controlling microstructure. |

Quality Control and Inspection of Sintered Metal Injection Molding Parts

Manufacturers implement rigorous quality control measures. These measures ensure sintered Metal Injection Molding (MIM) parts meet stringent performance and precision standards. Inspection methods range from non-destructive evaluations to detailed destructive analyses.

Non-Destructive Testing for Sintered Components

Non-destructive testing (NDT) methods evaluate parts without causing damage. They are crucial for maintaining product integrity.

Visual Inspection for Surface Flaws

Visual inspection is a fundamental NDT method. Inspectors carefully examine the surface of sintered MIM parts. They look for visible defects. These include cracks, pits, discoloration, or incomplete sintering. This initial check identifies obvious surface imperfections.

X-ray Computed Tomography for Internal Defects

X-ray Computed Tomography (CT) offers powerful insights into internal structures. It provides a non-destructive way to inspect MIM components.

| Feature | X-Ray/CT Scanning | Manual Inspection |

|---|---|---|

| Non-destructive testing | Yes | No |

| 3D visualization | Yes | No |

| Quantification of defects | Yes (volume, location, size) | No |

| Fast feedback to production | Yes | No |

| Early defect detection | Yes | Limited |

| Ability to analyze internal defects | Yes (cracks, voids, porosity, inclusions) | Limited |

| Time-saving opportunities | Yes (faster analysis) | No |

X-Ray and CT scanning detect various defects. These include porosity, inclusions, voids, cracks, and anomalies. Their comprehensive analysis capabilities ensure MIM components meet stringent quality standards. CT scanning identifies micro-defects as small as a few microns. This level of detail is crucial for ensuring the integrity of complex components. X-Ray and CT scanning offer rapid analysis. Low-resolution images are available in about 12 seconds. This efficiency supports quick decision-making in manufacturing processes.

CT scanning provides several benefits:

- Internal Defect Detection: Industrial CT scanning inspects internal structures. It detects defects like porosity, voids, or micro-cracks early in production. Hidden defects significantly impact mechanical properties and longevity.

- Dimensional Stability Assessment: CT scanning enables accurate measurements of internal and external geometries. It helps verify parts meet design tolerances after sintering. This is crucial for precision.

- Process Optimization and Material Flow Analysis: CT scanning visualizes metal particle distribution. It identifies inconsistencies in material flow or density during sintering. This aids in optimizing process parameters.

- Prototype Validation and Mold Verification: CT scans provide a comprehensive view of prototype internal structures. Manufacturers confirm mold accuracy and correct sintering processes early. This reduces redesign risks.

- Failure Investigation: CT scanning is an indispensable tool for root cause analysis when MIM parts fail. It provides detailed imaging to identify specific defects and take corrective action.

- Minimizing Waste and Enhancing Sustainability: CT scans detect defects early. This reduces scrap rates, rework, and material waste. It improves production efficiency and sustainability.

Destructive Testing for Mechanical Properties

Destructive testing methods assess the mechanical properties of MIM parts. They provide quantitative data on material performance.

Tensile and Hardness Testing

Tensile testing measures a material’s strength and ductility. It determines yield strength, ultimate tensile strength, and elongation. Hardness testing evaluates a material’s resistance to indentation. These tests confirm the sintering process achieved the desired mechanical properties.

Microstructural Analysis

Microstructural analysis involves examining the internal structure of a material. Technicians use microscopy to observe grain size, porosity, and phase distribution. This analysis verifies the sintering process created a homogeneous and optimized microstructure.

Dimensional Verification of Sintered MIM Parts

Dimensional verification ensures sintered parts conform to design specifications.

CMM Measurements for Accuracy

Coordinate Measuring Machines (CMMs) provide highly accurate dimensional measurements. CMMs use probes to precisely map the part’s geometry. This verifies critical dimensions and tolerances.

Optical Metrology for Surface Features

Optical metrology uses light to measure surface features. It assesses surface roughness, flatness, and other geometric characteristics. This method ensures the part’s surface quality meets functional and aesthetic requirements.

Sintering is an indispensable stage in MIM. It transforms fragile green parts into robust, high-performance components. The precision and reliability of MIM parts directly attribute to the controlled mechanisms of sintering. Understanding and optimizing Sintering in Metal Injection Molding is paramount for unlocking MIM’s full potential in advanced manufacturing. This includes developing new materials like composite ceramics and integrating 3D printing for greater design freedom. It also involves intelligent manufacturing and sustainable practices, ensuring MIM continues to meet evolving industry demands.

FAQ

What is sintering in Metal Injection Molding (MIM)?

Sintering transforms fragile “green” MIM parts into dense, strong components. High temperatures cause metal particles to bond together. This process eliminates voids and reduces porosity. It is a critical step for achieving desired material properties.

Why is sintering essential for MIM part precision?

Sintering ensures MIM parts achieve high structural integrity and density. It enables optimal material performance, including strength, hardness, and wear resistance. This process also controls shrinkage and minimizes defects, which directly impacts dimensional accuracy.

How does sintering affect the dimensions of MIM parts?

MIM parts experience significant shrinkage during sintering, typically 15-20%. Manufacturers predict and manage these shrinkage rates. They design molds to compensate for material reduction. This careful control minimizes distortion and warpage, ensuring dimensional accuracy.

What mechanisms drive the sintering process?

Atomic diffusion drives sintering. Atoms move along particle surfaces, grain boundaries, and through the material’s volume. This movement forms “necks” between particles. It also eliminates pores and consolidates the material, increasing density.

How do manufacturers prevent defects during sintering?

Manufacturers control heating and cooling rates to manage thermal stresses. They use specific furnace atmospheres, like hydrogen, to prevent oxidation. They also add grain growth inhibitors to the feedstock. These strategies minimize warpage, cracking, and microstructural defects.

What are advanced sintering techniques?

Advanced techniques include vacuum sintering, which prevents oxidation and ensures high purity. Pressure-assisted methods like Hot Isostatic Pressing (HIP) achieve full densification. Spark Plasma Sintering (SPS) offers rapid consolidation and fine grain structures. These methods enhance part performance.

How does sintering improve the mechanical properties of MIM components?

Sintering significantly increases tensile strength, yield strength, and hardness. It boosts fatigue and wear resistance by increasing material density and optimizing microstructure. This process also improves corrosion resistance and chemical stability, extending component service life.

Pingback: A Review of the Top 5 High-Precision China Sintered Parts Factories