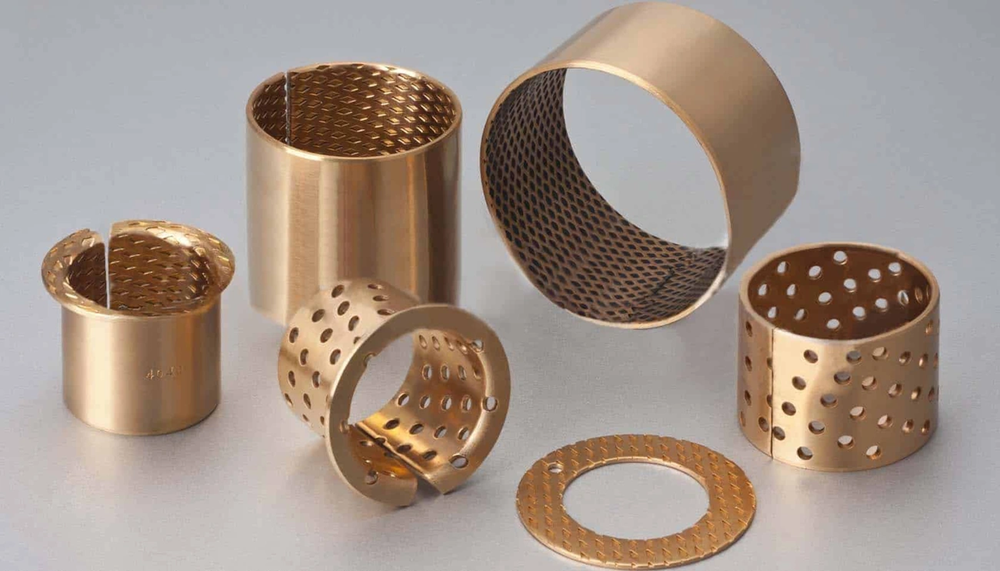

Sintered bronze bushings have become accessible to more people across numerous bearing applications because of their unique self-lubricating properties. These specialized components come to life through a remarkable process. Bronze gets ground into small particles and then hydraulically compressed back together. Sintered bushings provide economical solutions for many industrial applications and come with the added benefit of being marketed as “maintenance-free” or “self-lubricating”.

Bronze bushings’ performance, especially when you have sintered bronze bearings, relies heavily on how the lubricating oil spreads throughout the bearing point. We used sintered bushings mainly in high-frequency or high-speed applications. On top of that, these bearings excel in dirty environments where cleanliness cannot be guaranteed. The oil-impregnated sintered bronze keeps lubricant within its porous structure at times when the bearing is cold or the shaft hasn’t been running, and releases it during operation.

This complete piece gets into the technical differences between sintered bronze bushings and their cast bronze counterparts. You’ll find details about manufacturing methods, lubrication mechanisms, performance characteristics, and cost factors that help determine the best choice for your specific application needs.

Manufacturing Differences Between Sintered and Cast Bronze Bushings

The biggest difference between sintered and cast bronze bushings stems from their manufacturing processes. Their manufacturing methods significantly impact their physical properties and performance.

Powder Metallurgy in Sintered Bronze Bushings

The powder metallurgy process makes sintered bronze bushings. This technique gained popularity in the 1920s when self-lubricating bearings for automobiles emerged. Manufacturers feed bronze powder into a die set that matches the bushing size they want. They press the powder particles under extreme pressure to create the shape. The shaped part then goes into a controlled atmosphere furnace. The temperature stays below bronze’s melting point. This step bonds the particles together without changing the shape. The part becomes stronger while keeping its network of connected capillaries.

The sintering creates parts with about 25% porosity. This forms tiny connected capillaries throughout the material. After sintering, manufacturers adjust the bushings to meet required tolerances. They then use vacuum pressure to force oil into the porous structure.

Centrifugal Casting Process in Cast Bronze Bushings

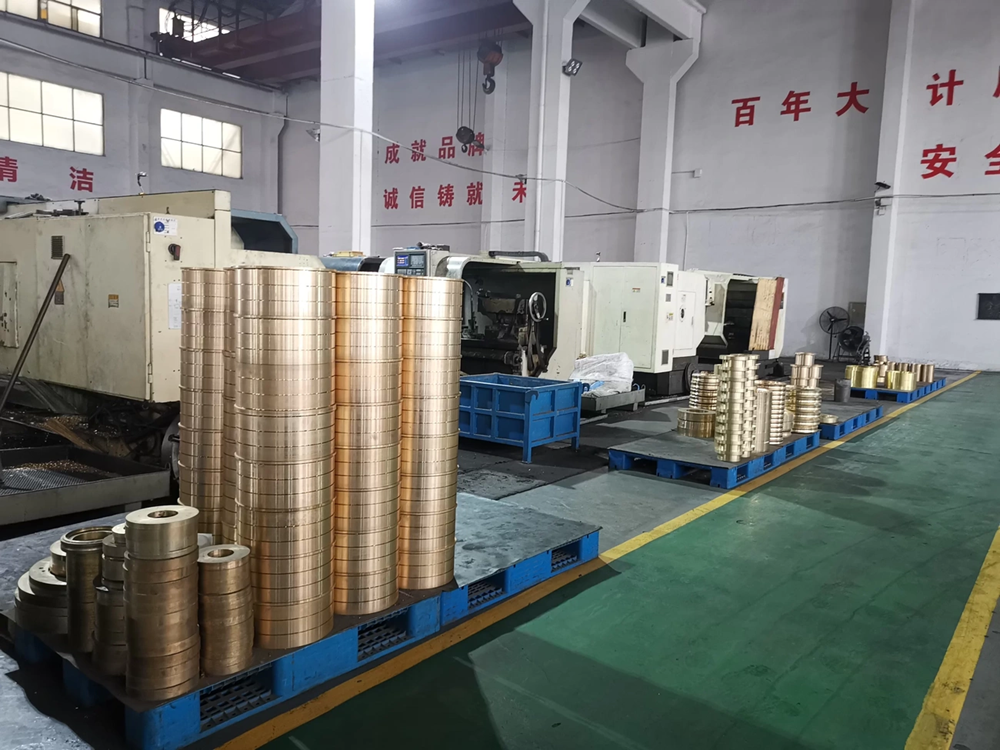

Cast bronze bushings come from traditional casting methods. We used centrifugal casting most often. This method pours molten bronze that meets specific chemical needs into a spinning mold. The process controls rotation speed carefully. Centrifugal force pushes the molten metal against the mold’s inner surface. The mold size determines the outer diameter, while the amount of poured metal sets the inner diameter.

The casting hardens and comes out of the die. It then moves to production, where CNC lathes or other precision equipment machine it to final specs. This creates dense, non-porous parts with excellent mechanical properties and better metallurgical features.

Porosity and Oil Retention Capabilities

These two types differ most in their porosity. Sintered bronze bushings have about 25% porosity. This creates a network of microscopic connected pores that hold lubricating oil. These pores act as oil reservoirs and provide constant lubrication to the bearing surface.

Cast bronze bushings have a solid, uniform, non-porous structure. This density lets them handle greater compressive forces and heavier loads than sintered bushings. But they need external lubrication because they can’t store oil inside like sintered bushings can.

Lubrication Mechanisms and Maintenance Requirements

Bronze bushings’ performance depends on their lubrication mechanisms. These mechanisms vary a lot between sintered and cast types based on their structural properties.

Oil Impregnation in Sintered Bronze Bearings

Oil-impregnated sintered bronze bushings work through an advanced self-lubricating system. The manufacturing process creates porous structures with about 25% porosity. These components can store lubricant within their microscopic network. The internal oil reservoir works through three distinct lubrication mechanisms. Capillary action pulls oil from pores to create a continuous lubrication film between surfaces. This makes it perfect for high-speed, low-load applications. The boundary lubrication forms as higher loads cause a thin oil layer to coat metal surfaces. This protective interface works well for moderate to high-load scenarios. The hydrodynamic lubrication happens when heavy loads push oil into wedge-shaped films between surfaces. This creates cushioning that works best for high-load, low-speed operations.

Grease and Manual Lubrication in Cast Bronze

Cast bronze bushings need external lubrication systems because they aren’t porous. Grease works best as a lubricant for solid bronze bushings. Its thicker consistency helps it stay in place under load conditions. The right amount changes based on specific application factors like load size, operational speed, and environmental conditions. Too much lubrication can cause serious problems. It might lead to operational seizure, more maintenance, and attract unwanted particles. Cast bronze bushings need regular maintenance with consistent application schedules to work at their best and last longer.

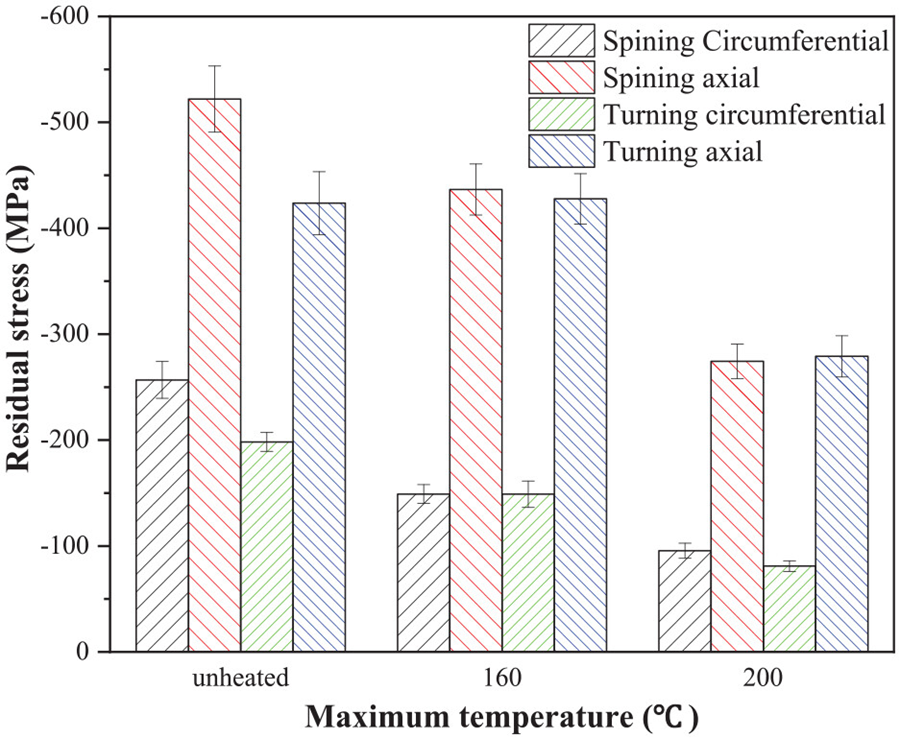

Self-lubricating Behavior at Operating Temperatures

Temperature is vital to how bronze bushings’ lubrication mechanisms work. Sintered bronze components’ self-lubricating properties work best between 10°F and 200°F. Heat from shaft rotation activates the lubricant transfer process. This pulls oil from the bearing’s internal structure to where the bearing meets the shaft. The porous structure reabsorbs extra oil through capillary action as the component cools. This creates an ongoing, self-regulating lubrication cycle. This temperature-dependent behavior lets sintered bushings work with minimal maintenance. Some applications might still benefit from extra lubrication to perform better in challenging environments.

Performance Comparison in Real-World Applications

Bronze bushings show different performance levels on the ground depending on how they’re used. Each type works best under specific conditions.

High-Speed Rotational Use Cases

Power transmission systems with high-speed rotational forces work well with bronze bushings because they create little friction and can handle stress without changing shape. Oil-impregnated sintered bronze bushings handle high-speed loads better than other options. We used them mostly in high-frequency applications where the self-lubricating effect gets better as friction heat increases. Cast bronze bushings work well at high speeds but need external lubrication systems.

Low-Speed and Intermittent Load Scenarios

Cast bronze bushings work best under pressure, which makes them perfect for uses with heavier loads. Yes, cast bronze indeed has a finer grain structure that makes it stronger and more durable. Sintered bronze bushings work better with moderate to low loads. Iron-based oilite bushings provide a solution for very high loads at low speeds where lubrication is hard to apply.

Wear Resistance in Contaminated Environments

Contamination creates problems for both bushing types. When dirt, sand, or chemicals get into bearings, they cause wear and slow things down. Bronze can handle wear and tear well, so it keeps working even with lots of friction. In spite of that, oil-impregnated bronze doesn’t work well when its oil might contaminate nearby parts.

Thermal Expansion and Dimensional Stability

Bronze bearings stay strong at high temperatures compared to other materials. Bronze alloys typically expand at rates between 9-11 × 10⁻⁶ in/in/°F. These rates go up when you add more tin, zinc, or lead. This heat behavior helps keep the right spacing as temperatures change, so parts stay the right size while working.

Cost, Availability, and Material Suitability

Economic and technical specifications determine the choice of bronze bushing options in industrial applications.

Material Cost: Sintered vs Cast Bronze

The powder metallurgy process behind sintered bronze bushings emerged as an economical alternative to standard machining. This manufacturing method enables high-volume production with lower scrap loss, which makes sintered bronze more cost-effective for large production runs. Cast bronze bushings cost more because their manufacturing needs extensive machining that increases production time and labor costs. Bronze raw material costs exceed the metal powders used in sintered components. The original investment might be higher for sintered bronze, but the total ownership cost proves better over time due to less maintenance.

Machinability and Customization Options

Machining sintered bronze components requires tungsten carbide tools because they keep a sharp cutting edge longer than standard tools. The process needs slower speeds and feeds compared to cast C93200 bearing bronze. The cutting surface needs a high polish to stop metal from sticking to the cutting tip. Bushings need re-impregnation after machining and should soak in hot oil for about an hour. Manufacturers can create custom sintered bronze bushings with special geometries, specific alloy compositions, and tailored porosity levels. Sintered bronze bar stock in 6-1/2″ lengths works well for smaller quantities, though this method adds to the final cost.

Compliance with PFAS-Free Requirements

Environmental regulations in global markets have made PFAS-free requirements crucial. Regulators have tightened restrictions on PFAS compounds, including PTFE (polytetrafluoroethylene), because they persist in the environment. Both sintered and cast bronze bushings are PFAS-free alternatives that work well in industrial applications. Bronze bushings outperform some polymer bearings containing these substances, especially in applications that need environmental compliance. These bushings deliver the required performance without raising environmental concerns.

Conclusion

Sintered bronze and cast bronze bushings serve different industrial needs through their unique technical characteristics. Powder metallurgy creates sintered bronze bushings that self-lubricate through their porous structure. These work best in high-speed applications where access is difficult. Cast bronze bushings have a solid structure with better compressive strength. They shine in high-load situations where you can apply external lubrication regularly.

Engineers need to think about several key factors to choose between these options. The application’s speed, load, and accessibility determine which bushing type works best. Environmental factors like temperature range and contamination risk affect how long these bushings last. A facility’s maintenance capabilities help decide if self-lubricating features matter more than cast components’ higher load capacity.

Cost plays a big role in the final decision. Sintered bronze offers affordable solutions for high-volume production. Cast bronze costs more but delivers exceptional results under heavy loads and harsh conditions that make the extra investment worthwhile.

These bushings are PFAS-free alternatives that work well in industrial settings. They meet environmental standards without sacrificing performance. Companies that specialize in powder metallurgy and metal injection molding are a great way to get guidance about choosing the right bronze bushing.

The best choice between sintered and cast bronze bushings comes down to understanding your operational needs, environment, and budget. Neither option stands as the universal solution. Each type excels in its intended use, giving engineers expandable solutions to tackle various industrial challenges.

Key Takeaways

Understanding the fundamental differences between sintered and cast bronze bushings helps engineers select the optimal bearing solution for their specific industrial applications.

• Sintered bronze bushings excel in high-speed applications due to their self-lubricating porous structure (25% porosity) that stores oil internally, reducing maintenance needs.

• Cast bronze bushings handle heavy loads better with their solid, non-porous structure providing superior compressive strength for demanding industrial conditions.

• Manufacturing methods drive performance differences – powder metallurgy creates cost-effective sintered bushings while centrifugal casting produces stronger cast components.

• Lubrication requirements vary significantly – sintered bushings self-lubricate through capillary action while cast bushings need external grease or oil systems.

• Cost considerations favor sintered bronze for high-volume production runs, though cast bronze justifies higher costs in heavy-load applications requiring maximum durability.

The selection ultimately depends on balancing operational requirements (speed vs. load), maintenance capabilities, environmental conditions, and budget constraints. Both options provide PFAS-free solutions that meet modern environmental compliance standards while delivering reliable performance in their respective application niches.

FAQs

Q1. What are the main differences between sintered bronze and cast bronze bushings? Sintered bronze bushings are porous (about 25% porosity) and self-lubricating, making them ideal for high-speed applications. Cast bronze bushings are solid and non-porous, offering superior strength for heavy-load scenarios but requiring external lubrication.

Q2. Which type of bronze bushing is more cost-effective? Sintered bronze bushings are generally more cost-effective, especially for high-volume production runs. While cast bronze bushings typically have a higher initial cost, they may be justified in applications requiring maximum durability under heavy loads.

Q3. How do the lubrication mechanisms differ between sintered and cast bronze bushings? Sintered bronze bushings self-lubricate through oil stored in their porous structure, released via capillary action during operation. Cast bronze bushings require external lubrication systems, typically using grease applied at regular intervals.

Q4. Are bronze bushings environmentally friendly? Yes, both sintered and cast bronze bushings offer PFAS-free alternatives for industrial applications, making them environmentally responsible choices compared to some polymer bearings that may contain these substances.

Q5. What factors should be considered when choosing between sintered and cast bronze bushings? Key factors include application requirements (speed, load, accessibility), environmental conditions (temperature, potential contamination), maintenance capabilities, and budget constraints. The choice depends on balancing these factors for the specific industrial application.