Quality ratings of 4.8 out of 5 stars show how flanged bushings are transforming industrial applications in many sectors. These precision-engineered components deliver self-lubricating performance and smooth operation without extra greasing, especially when made from sintered bronze.

Bronze flanged bushings have become the top choice for self-lubricating bearings in home appliances and automated machinery. The company stocks over 10 million parts and holds ISO 9001 certification. The flanged design handles both radial and axial thrust loads effectively. Oil-impregnated bronze material, with its 0.19 oil content, runs maintenance-free in high-speed, low-load applications. Engineers can choose from more than 350 standard sizes. The inner diameter ranges from 1/8″ to 3″ and the outer diameter from 1/4″ to 3-1/2″, making them adaptable for industrial needs. This piece helps engineers and maintenance professionals select the right flanged bushing for their applications.

Understanding Sintered Bronze in Flanged Bushings

Sintered bronze is the foundation of high-performance flanged bushings. These components blend unique material properties with self-lubricating features. Powdered metal technology creates bearings that work best where maintenance access is limited or regular lubrication isn’t practical.

SAE 841 Material Composition and Properties

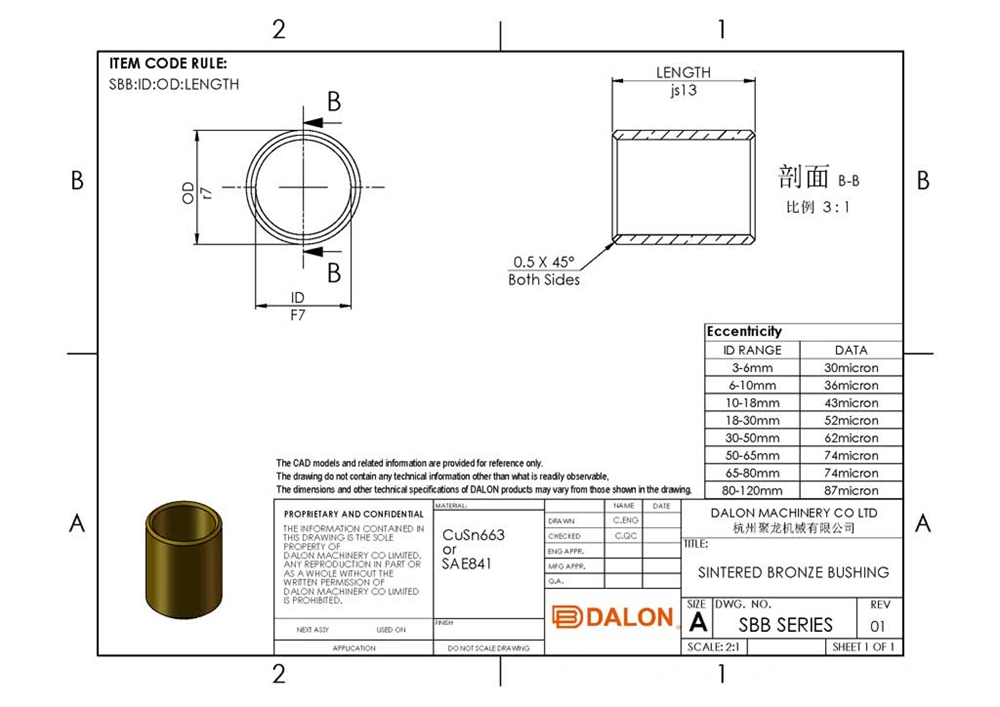

SAE 841 bronze stands as the go-to material for quality flanged bushings. This copper-tin alloy combines 87.5-90.5% copper and 9.5-10.5% tin. Small amounts of other elements like iron (1.0% max) and graphite (0.3% max) complete the mix. This material blend delivers just the right balance of mechanical and tribological properties needed for bearing applications.

SAE 841 sintered bronze’s physical characteristics include:

- Density: 6.4-6.8 g/cm³

- Porosity: Minimum 19% by volume

- Ultimate tensile strength: 14,000 psi (97 MPa)

- Yield strength: 11,000 psi (76 MPa)

- Hardness: Approximately H-45 on the Rockwell scale

Sintered bronze differs from solid bronze alloys through its interconnected pores. These microscopic channels take up 19-25% of the total volume and create a natural storage system for lubricants.

Oil Impregnation Process and Self-Lubrication

Manufacturing these flanged bushings requires a precise powder metallurgy process. Bronze powder mixes with lubricants to create an even mixture. Compression happens next, with dies applying pressure between 10-45 tons per square inch. The material then moves to the crucial sintering phase. Heat below the melting point bonds the metal particles through solid-state diffusion while keeping the porous structure intact.

Bushings then go through vacuum impregnation with SAE 30 oil, which fills about 19% of their volume. This oil-filled network of connected pores creates a unique self-lubricating system.

Self-lubrication works through three main ways:

- Capillary Action: Microscopic channels in the porous structure absorb oil, which provides continuous lubrication between surfaces

- Boundary Lubrication: A thin oil layer creates a protective boundary between surfaces under moderate loads, which reduces friction and wear

- Hydrodynamic Lubrication: Friction-generated heat causes thermal expansion that pushes oil to the surface, creating a thin lubricating film. When cooling occurs, capillary action pulls excess oil back into the pores

This continuous cycle removes the need for external lubrication systems. Such features make these bushings perfect for hard-to-reach spots or applications that need minimal upkeep.

Thermal and Load Performance Characteristics

These bushings show impressive thermal and load-bearing abilities. They work well in temperatures from 10°F to 220°F (-12°C to 104°C). This range suits most industrial needs, though special synthetic oils can push these limits further in either direction.

The friction coefficient ranges from 0.02 to 0.06, substantially lower than iron-based alternatives at around 0.08. Lower friction leads to better efficiency, less wear, and longer service life.

Load capacity tests show remarkable results:

- Static loads up to 50 N/mm² (7,250 psi)

- Dynamic loads that change with speed and lubrication conditions

- Great resistance to shock and vibration thanks to oil cushioning

The bushings maintain reliable performance at high speeds up to 69,000 RPM under light loads. Their self-lubrication system creates hydrodynamic conditions with minimal friction.

The flange design adds support for axial loads where regular sleeve bushings fall short. This mix of material properties and structural design makes these bushings versatile components for industries of all types.

Types of Flanged Bronze Bushings and Their Standards

Standard classification systems are crucial for selecting flanged bronze bushings in industries of all sizes. These systems help maintain manufacturing consistency and guide engineers reliably when they specify components for their designs.

BNZF vs BFMF vs BFMS: Dimensional Differences

Part numbers of flanged bushings start with prefixes that show their standardization origins and dimensional traits. You’ll find several standardized variations of sintered bronze bushings with flanges, each following specific national or international guidelines. “BNZ” usually means standard bronze bushings, while “BF” points to flanged versions.

The letters after these simple prefixes tell you key standardization details:

- BFMF – References flanged bushings following French standardization

- BFMG – Indicates flanged bushings conforming to German standards

- BFMS – Designates flanged bushings manufactured to English standardization

- BFAI – References imperial measurement standards

These bushings work like self-lubricating bearings, but their different names help engineers know which national standardization system they follow. So this affects their dimensional specs, tolerances, and material makeup that might vary between standards.

Metric vs Imperial Sizing Standards

The measurement system is key when choosing flanged bronze bushings. Metric bushings show sizes in millimeters, while imperial ones use inches. This difference goes beyond just converting units – each system has its own size steps and tolerances.

Metric bronze flanged bushings typically stick to ISO or DIN standards. Their inner diameters usually range from 3mm to 300mm. These parts keep tight tolerances, often following H7 or H8 specs to fit shafts perfectly. Imperial-sized bushings follow ASME or SAE rules, starting at 1/8″ for inner diameters.

The systems handle standard dimensions differently too. Metric systems use decimal steps, but imperial standards prefer fractions. This matters a lot when you’re looking for replacement parts or mixing components from different regions in existing machines.

Interchangeability Across Global Standards

Manufacturers and engineers face real challenges with flanged bushing interchangeability across global standards. North America uses multiple standards including IEEE, IEC, and CSA. On top of that, even within these standards, differences in key measurements like flange bolt circle diameters can cause fitting problems.

We have a long way to go, but we can build on this progress toward standard harmony. To cite an instance, see IEC bushings – they lack standard size requirements and usually won’t work with different bushing brands. This means manufacturers must stick with specific suppliers for matching replacement parts.

Industry-specific needs make global standards even trickier. Aerospace needs light but strong materials that meet National Aerospace Standards. Food processing equipment needs non-toxic materials that follow 3-A Sanitary Standards. These special requirements often trump general standards.

Manufacturers often get ISO 9001:2015 certified to ensure quality across these different standards, showing their steadfast dedication to quality and customer satisfaction. Plus, European rules like RoHS and REACH make sure bronze flanged bushings stay free of harmful substances, so they work well in many uses including food processing.

Engineers need to understand both standard names and measurement systems to identify flanged bushings correctly. They should record all five key measurements when specifying parts: inner diameter (ID), outer diameter (OD), overall length (OAL), flange outer diameter (FLOD), and flange thickness (FLTH).

How to Select the Right Bronze Flanged Bushing

The right flanged bushing needs exact measurements and a good grasp of how it will work. Your choice will affect how long it performs and how reliable your system is in all types of applications. Getting the measurements right is the foundation of picking the best bushing.

Measuring I.D., O.D., Flange O.D., and Length

You need to measure five key dimensions to get the right flanged bushing. These are inner diameter (ID), outer diameter (OD), overall length (OAL), flange outer diameter (FLOD), and flange thickness (FLTH). Each measurement has its own role:

- Inner Diameter (ID): Use vernier calipers to measure the hole where your shaft will fit. This needs to give the shaft enough clearance.

- Outer Diameter (OD): Measure the bushing’s body that goes into the housing bore. If you don’t have the original bushing, measure the tube’s inner diameter where you’ll install the new one.

- Overall Length (OAL): Get the full bushing length with the flange. This makes sure it fits in your assembly space.

- Flange Outer Diameter (FLOD): Measure the flange’s widest point. This helps with mounting and alignment.

- Flange Thickness (FLTH): Measure from the base to the flange’s top. This helps the bushing handle axial loads better.

List your measurements as ID, OD, OAL, FLOD, and FLTH when asking for quotes. Manufacturers can respond faster and more accurately this way. A vernier caliper works well for most cases, but you might need micrometers for high-precision work.

Understanding PV and V Value Ratings

The PV value is vital for picking the right bushing. You get this by multiplying pressure (P) and velocity (V). This number tells you how well bronze flanged bushings will perform and last.

To find pressure (P), take your total load in pounds and divide it by the projected area in square inches. For sleeve bearings, multiply the length by the inside diameter to get the projected area. For rotational applications, calculate velocity (V) using:

V = 0.262 × RPM × shaft diameter (inches)

The PV value shows if your material can handle both pressure and speed. Here’s an example with a ¾” shaft spinning at 341 RPM with a 90 lb load in a 1″ long bearing:

- V = 0.262 × 341 × 0.750 = 67 sfpm

- P = 90 lbs ÷ 0.75 sq. in. = 120 psi

- PV = 120 × 67 = 8,040

Cast bronze C93200 flanged bearings can handle up to 4,000 psi (P), 750 sfpm (V), and 75,000 PV. Going beyond these limits can wear out your bushing too fast.

Lower PV values mean your bushing will last longer. Temperature is also a big deal as it changes clearances through thermal expansion, which can cause heavy wear and shorter life.

Choosing Between Sleeve and Flanged Variants

Your application’s needs determine whether you should use sleeve or flanged bushings. Flanged bushings do more than standard sleeve bushings:

- Alignment and Mounting: The flange helps line everything up during installation and gives you a solid mounting surface.

- Installation Ease: The flange works as a built-in stop that keeps the bushing from going in too far.

- Axial Load Support: Unlike sleeve bushings that mainly handle radial loads, flanged versions can take axial thrust forces too.

- Space Efficiency: Flanged bushings work great in tight spaces where you can’t fit separate thrust washers. They handle both radial and thrust bearing jobs.

Electric motors, fan assemblies, and oscillating applications work best with flanged bushings. Self-lubricating flanged bronze bushings are perfect for oscillating jobs because they stay lubricated even when motion stops between cycles – a common issue with regular bearings.

JH MIM’s precision-engineered flanged bronze bushings are great for applications that start and stop often. Their self-lubricating properties and 20 years of powder metallurgy experience mean you get consistent quality for tough industrial jobs.

Reading and Decoding Bushing Part Numbers

Engineers and technicians need to figure out part numbers when working with flanged bushings. These alphanumeric codes pack vital specs needed to select and replace components correctly. Knowing how to read these codes will give a proper fit and help you avoid installation mistakes that can get pricey or lead to early component failure.

BNZF12-16-20-2-16: What Each Number Means

The part number BNZF12-16-20-2-16 makes a great example to understand flanged bushing nomenclature. Each part of this code tells you something specific about the component’s dimensions:

- BNZF – Prefix showing it’s an oil-filled flanged bronze bushing

- 12 – Inside diameter (ID) in millimeters

- 16 – Outside diameter (OD) in millimeters

- 20 – Flange outer diameter in millimeters

- 2 – Flange thickness in millimeters

- 16 – Overall length in millimeters

Selection guides prioritize measurements in this order: ID, OD, Flange OD, Flange Thickness, and Length. Product descriptions state that “The Oil Filled Flanged Bronze Bush known by the reference BNZF12-16-20-2-16 Generic has an inside diameter of 12 mm, an outside diameter of 16 mm and a length of 16 mm”.

Inch-series bushings show dimensions in 16ths of an inch. This creates different numbers but keeps the same sequence structure. Technicians can identify the right component with this consistency, whatever measurement system they use.

Common Prefixes and Their Applications

Part number prefixes tell you about material makeup, design features, and manufacturing standards. Industry experts use these prefixes as quick identifiers:

Bronze Material Prefixes:

- BNZ/BNZF – Standard sintered bronze bushings (F means flanged version)

- BF – General name for flanged bushing types

Standard-Specific Prefixes:

- BFMF – Flanged bushings following French standardization

- BFMG – Flanged bushings matching German standards

- BFMS – Flanged bushings built to English standardization

- BFAI – References imperial measurement standards

The “OR” prefix usually means O-ring seals, not bushings. This shows how prefix systems work for different component types. Take “OR-40X3-NBR90” – here OR shows the product type, 40X3 gives inside diameter and thickness, and NBR90 tells you material and shore hardness.

Many manufacturers create their own numbering systems. These combine standard dimensions with special codes for specs. AST Bearings experts point out that “Most manufacturers have created their own numbering systems that are a combination of the actual part, or bearing, number and a series of codes that define additional specifications”.

Switching bearings between different numbering systems needs careful attention and detailed knowledge of specification codes. JH MIM brings nearly 20 years of powder metallurgy experience. They make precision-engineered flanged bronze bushings with consistent part numbers that match industry standards. This makes identification and replacement easier for maintenance teams.

Standards like ABMA, JIS, and ISO define boundary dimensions for certain bushing series. These standards aim to create consistency among manufacturers. Complete interchangeability remains tough because of differences in tolerances and material compositions.

Application-Specific Use Cases for Oilite Flanged Bushings

Oilite flanged bushings play a vital role in many industries where equipment needs to run reliably with minimal upkeep. These bushings work great in tough environments where regular lubrication is hard to do or just not practical.

Electric Motors and Fan Assemblies

Electric motors use flanged bronze bushings to support rotating shafts while keeping friction and wear low. The bushings help absorb the strong vibrations that happen during operation. This makes motors run more smoothly and quietly. The noise drops by 3-6 dB compared to ball bearings – enough to let equipment run overnight without bothering anyone. Air conditioner fan assemblies benefit from these bushings too, as they last longer and run quietly. The self-lubricating properties keep everything running smoothly at speeds over 1,500 RPM.

Home Appliances and Consumer Electronics

Home appliances need Oilite flanged bushings to work consistently. These bushings keep washing machine motor shafts stable through countless spin cycles. Refrigerators and AC systems love these parts because they don’t need maintenance stops that would interrupt service. This is a big deal in places where uptime directly affects output. JH MIM makes precision-engineered flanged bushings that are perfect for consumer products with long warranty periods, backed by their 20 years of powder metallurgy expertise.

Material Handling and Conveyor Systems

Sintered bronze flanged bushings work perfectly in non-stop conveyor systems. Food processing conveyors running at 2 m/s can go five years without needing lubrication stops – saving 120 to 150 hours of downtime. These bushings last 3 to 5 times longer than plain bearings in industrial conveyor systems. That’s why manufacturing, packaging, and logistics operations use them so much.

Automotive and Fitness Equipment

Automotive applications put sintered bronze bushings through their paces. They handle temperatures up to 120°C while supporting rotor assemblies with 15-20 N/mm² loads. You’ll find them in suspension systems, control arms, and sway bars. Fitness equipment makers choose bronze flanged bushings for weight machines and stationary bikes because they handle sweat and moisture while working smoothly. Custom flanged Oilite bushings show up in weightlifting barbells and other gear where self-lubrication matters. They keep performing through thousands of cycles without maintenance, making them perfect for equipment that needs to last for years of heavy use.

Custom Manufacturing and Machining Options

Manufacturers offer several options beyond their standard catalog to produce custom flanged bushings that meet specific requirements.

Pressed-to-Specification Sintered Bronze Bushings

The manufacturing of custom pressed sintered bronze components starts with a homogeneous mixture of metal powders and lubricants. This mixture gets compressed in dies at pressures between 10-45 tons per square inch. The material enters a protective atmosphere furnace in its “green state” for sintering below the melting point. This creates a solid form that stays about 20% porous. Vacuum impregnation with oil then creates maintenance-free self-lubricating properties. JH MIM brings nearly 20 years of powder metallurgy expertise to these precision-engineered flanged bushings.

Machining from Sintered Bronze Bar Stock

Sintered bronze bar stock works better for smaller quantities. The stock comes in 6-1/2″ lengths – the maximum length P/M presses can compact while maintaining required density. Tungsten carbide tools prove best since they keep sharp cutting edges longer. Notwithstanding that, machining needs careful technique to preserve the porous structure. Sharp cutting tools must be used to prevent smearing pores and blocking oil flow. The bushings need re-impregnation after machining by soaking them in hot oil for one hour.

When to Choose Custom vs Standard Sizes

Volume requirements and application specifics determine the choice between custom and standard flanged bushings. Standard sizes cost less and ship right away. Custom options become essential for non-standard shaft diameters, housing sizes, or specialized material needs. Quantities below mass production levels work better with machined bar stock, while high-volume applications make more sense with pressed-to-specification components.

Conclusion

The right flanged bronze bushing selection depends on several factors that affect performance and durability. This piece explores the unique properties of sintered bronze bushings – from self-lubricating capabilities to thermal and load-bearing characteristics. These components work best when maintenance access is limited or regular lubrication isn’t practical.

SAE 841 bronze’s material composition explains why these bushings perform reliably in a variety of industrial settings. Oil impregnation creates a continuous lubrication mechanism that reduces maintenance needs and extends component life. The interconnected porous structure helps these bushings run smoothly even in challenging conditions.

Standard classifications are vital for specifying these components. Engineers must know different designation standards in global markets, whether using metric or imperial systems. Five key measurements form the foundations for proper selection: inner diameter, outer diameter, overall length, flange outer diameter, and flange thickness.

PV value calculations are essential to select the right bushing. These values show if a specific bushing can handle the combined pressure and velocity effects in your application. Staying within manufacturer limits will prevent early failure and give a better performance.

Flanged bronze bushings excel in versatility. These components provide reliability in electric motors, fan assemblies, home appliances, and material handling systems. They support both radial and axial loads while offering self-lubrication – a great advantage in demanding environments.

Custom manufacturing expands possibilities for specialized applications. Tailored solutions, whether pressed-to-specification or machined from bar stock, meet unique requirements beyond standard offerings.

JH MIM brings 20 years of powder metallurgy expertise to manufacturing these precision-engineered flanged bushings. Their exceptional experience ensures quality that meets global customer needs in industries of all types.

The knowledge in this piece helps engineers and maintenance professionals choose the right flanged bronze bushing for their applications. This choice affects equipment reliability, maintenance needs, and operational efficiency in industrial systems worldwide.

Key Takeaways

Understanding these critical factors will help you select the optimal flanged bronze bushing for your specific application needs and ensure long-term performance.

• Measure five critical dimensions accurately: Inner diameter (ID), outer diameter (OD), overall length (OAL), flange outer diameter (FLOD), and flange thickness (FLTH) using precise tools like vernier calipers.

• Calculate PV values before selection: Multiply pressure (P) and velocity (V) to ensure your application stays within manufacturer limits—exceeding ratings leads to premature failure and excessive wear.

• Choose flanged over sleeve bushings for dual load support: Flanged variants handle both radial and axial thrust forces simultaneously while providing easier installation and proper alignment.

• Decode part numbers systematically: Standard nomenclature follows ID-OD-Flange OD-Flange Thickness-Length sequence, with prefixes indicating material type and manufacturing standards.

• Leverage self-lubricating properties for maintenance-free operation: SAE 841 sintered bronze with 19% oil impregnation eliminates external lubrication needs through continuous capillary action and thermal cycling.

The key to successful flanged bushing selection lies in understanding both the technical specifications and application requirements. With proper measurement, calculation, and material knowledge, these components deliver exceptional performance across industries from electric motors to conveyor systems, providing years of reliable, maintenance-free operation.

FAQs

Q1. What are the key advantages of sintered bronze flanged bushings? Sintered bronze flanged bushings offer self-lubrication, eliminating the need for external greasing. They provide excellent thermal and load-bearing capabilities, support both radial and axial loads, and perform well in high-speed, low-load applications. Their porous structure allows for continuous lubrication, making them ideal for locations with limited maintenance access.

Q2. How do I select the correct size for a flanged bronze bushing? To select the correct size, measure five critical dimensions: inner diameter (ID), outer diameter (OD), overall length (OAL), flange outer diameter (FLOD), and flange thickness (FLTH). Use precise tools like vernier calipers for accurate measurements. When ordering, provide these dimensions in the sequence ID-OD-FLOD-FLTH-OAL for quick and accurate responses from manufacturers.

Q3. What is the PV value, and why is it important for bushing selection? The PV value is the product of pressure (P) and velocity (V), crucial for determining a bushing’s performance capabilities and service life. It helps ensure the bushing can withstand the combined effects of load and speed in your application. Staying within manufacturer-specified PV limits prevents premature failure and excessive wear, thus extending the bushing’s operational life.

Q4. In which industries are flanged bronze bushings commonly used? Flanged bronze bushings find wide application across various industries. They are commonly used in electric motors, fan assemblies, home appliances (like washing machines and refrigerators), material handling and conveyor systems, automotive components, and fitness equipment. Their self-lubricating properties and ability to handle both radial and axial loads make them versatile for many industrial applications.

Q5. When should I consider custom manufacturing for flanged bushings? Consider custom manufacturing when standard sizes don’t meet your specific requirements, such as non-standard shaft diameters, unique housing sizes, or specialized material needs. Custom options become economically viable for high-volume applications, while machining from sintered bronze bar stock is suitable for lower quantities. The choice between custom and standard sizes depends on volume requirements and the specifics of your application.