Introduction

Powder metal 3D printing has revolutionized the manufacturing industry by enabling the production of complex, high-performance components with precision and efficiency. This technology is crucial for producing custom titanium alloy parts, widely used in industries such as aerospace, medical, and automotive. This article delves into the benefits, applications, and technological advancements of powder metal 3D printing services, providing a comprehensive understanding of this cutting-edge manufacturing method.

Benefits of Powder Metal 3D Printing

Enhanced Design Flexibility

Powder metal 3D printing offers unmatched design flexibility, allowing for the creation of intricate geometries that are often impossible with traditional manufacturing methods. This capability is essential for industries that require highly customized parts.

Intricate Designs

Powder metal 3D printing can produce complex structures such as lattice frameworks, internal channels, and overhangs without the need for support structures. This capability is particularly beneficial for industries like aerospace and medical, where intricate designs are crucial for performance and functionality.

Rapid Prototyping

The ability to quickly transition from design to prototype is a significant advantage of powder metal 3D printing. This rapid prototyping capability enables manufacturers to iterate designs swiftly, reducing development time and costs. For example, in the automotive industry, rapid prototyping allows for the quick testing and refinement of new components, accelerating the time-to-market for innovative designs.

Material Efficiency and Sustainability

Powder metal 3D printing is known for its material efficiency, significantly reducing waste compared to traditional subtractive manufacturing processes.

Reduced Waste

In powder metal 3D printing, only the necessary amount of material is used to create a part, minimizing scrap and waste. Unused powder can often be recycled and reused, further enhancing the sustainability of the process. This efficiency is crucial in industries like aerospace, where material costs can be prohibitively high.

| Manufacturing Method | Material Utilization Rate | Material Waste |

| Traditional | 70% | 30% |

| 3D Printing | 95% | 5% |

Cost Savings

The reduction in material waste translates directly into cost savings. Additionally, the energy efficiency of powder metal 3D printing processes helps lower operational costs. These cost benefits are particularly appealing to industries such as consumer electronics, where maintaining competitive pricing is essential.

| Manufacturing Method | Material Cost per Unit | Energy Cost per Unit |

| Traditional | $10 | $5 |

| 3D Printing | $7 | $3 |

High-Performance Material Properties

Powder metal 3D printing produces parts with excellent mechanical properties, making it ideal for demanding applications.

Superior Mechanical Strength

Parts produced through powder metal 3D printing exhibit high tensile strength, durability, and resistance to wear and tear. This is particularly important for aerospace and defense applications, where components must withstand extreme conditions.

| Manufacturing Method | Tensile Strength (MPa) | Wear Resistance |

| Traditional | 500 | Moderate |

| 3D Printing | 700 | High |

Corrosion Resistance

Titanium alloys, commonly used in powder metal 3D printing, offer exceptional corrosion resistance, making them suitable for use in harsh environments. This property is invaluable in industries such as medical and marine, where long-term reliability and performance are critical.

Powder metal 3D printing vs. traditional machinery

Traditional mechanical parts of the finished product, rely on “lathe pliers milling”, which is the process of reducing material;

The finished product of 3D printing technology relies on the melting and casting of metal powder materials, which is an additive process

Powder metal 3d printing can not only improve efficiency and increase accuracy, but also achieve energy saving and emission reduction.

Powder metal 3D printing VS MIM

Many special material applications, such as titanium alloy, MIM and 3D printing technology can be applied, but there are some differences in the specific application. If it involves some special-shaped complex structures, such as hollow, hollow, etc., the MIM process can not be met by the limitations of the mold and 3D printing technology can be realized. If the appearance effect requires a high-gloss or mirror-polished product, 3D printing technology can also be achieved, and the MIM process is relatively suitable for matte, wire drawing and other appearance effects. However, overall, in terms of mass production and comprehensive comparative cost, MIM process has comparative advantages over 3D printing. Therefore, we believe that 3D printing technology and MIM technology is not a substitute or competitive relationship, but on the basis of meeting the different product needs of customers, and effectively complement each other.

Applications of Powder Metal 3D Printing

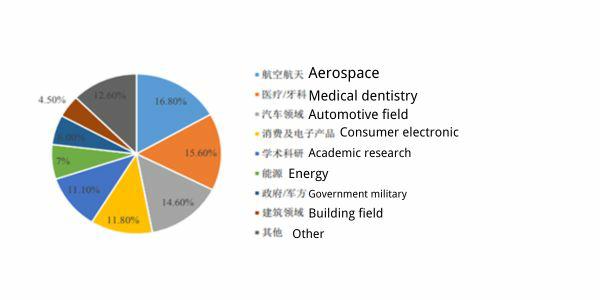

3D printing metal powder materials are the premise to promote the development and progress of 3D printing technology and are also the key to the promotion and development of 3D printing applications. According to the Wohlers Report, 3D printing in 2022 is mainly used in aerospace, automotive, consumer and electronic products, medical/dental, consumer goods, mold manufacturing, electronics and other fields.

Aerospace and Defense

The aerospace and defense industries are among the primary beneficiaries of powder metal 3D printing, leveraging the technology for producing lightweight, high-strength components.

Lightweight Components

Aerospace manufacturers utilize powder metal 3D printing to produce lightweight components, which contribute to fuel efficiency and reduced emissions. For instance, aircraft engine parts made from titanium alloys can achieve a significant weight reduction without compromising strength.

Complex Part Integration

Powder metal 3D printing enables the integration of multiple parts into a single complex component, reducing assembly time and potential failure points. This capability is critical in the defense sector, where reliability and performance are paramount.

Medical and Dental

Powder metal 3D printing has transformative applications in the medical and dental fields, providing custom solutions that enhance patient outcomes.

Custom Implants

Medical professionals can create patient-specific implants tailored to individual anatomies using powder metal 3D printing. This customization leads to better fit, improved functionality, and faster recovery times. For example, custom dental implants and prosthetics can be produced with high precision, ensuring optimal patient comfort and performance.

Rapid Production

The ability to quickly produce surgical instruments and implants is a significant advantage in the medical field. Powder metal 3D printing reduces lead times, ensuring that critical components are available when needed, thereby improving patient care.

Automotive Industry

The automotive sector benefits from powder metal 3D printing through the production of lightweight and durable components, contributing to better fuel efficiency and vehicle performance.

High-Performance Parts

Automotive manufacturers use powder metal 3D printing to produce high-performance parts with superior mechanical properties. These parts can withstand the stresses of high-speed and high-temperature environments, enhancing overall vehicle performance.

Prototyping and Customization

Powder metal 3D printing allows for efficient prototyping of new designs, enabling automotive engineers to test and refine components quickly. Additionally, the technology offers customization options for performance vehicles and limited editions, meeting specific customer demands.

Powder of powder metal 3D printing

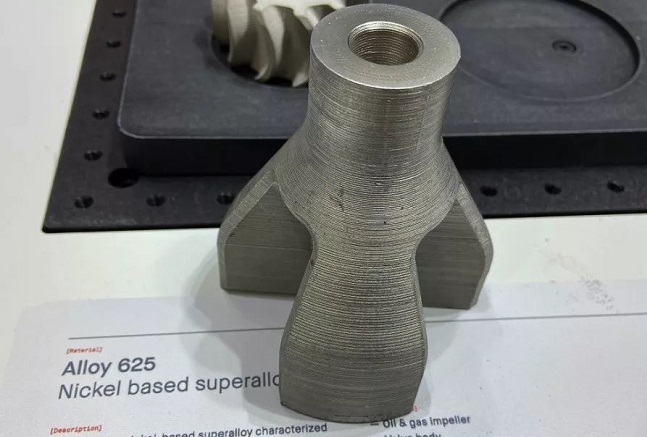

Powder metal 3D printing products cover a variety of high-end metal powders such as superalloy, die steel, high entropy alloy, aluminum alloy, titanium alloy, copper alloy, cobalt chromium alloy and so on.

Superalloy powder:

Superalloy materials are the main materials for aerospace engines. Among them, the superalloy GH5188 and GH3230 need to add lanthanum, because the melting point of lanthanum is only 920, easy to burn and difficult to control, domestic technology has solved this difficulty, GH4169, GH3625, GH3536, GH4099, and other superalloy powder, It meets the demand of high-performance superalloy powder materials in the domestic aerospace field.

Die steel powder:

Die steel 3D printing powder quality requirements are higher, with 18Ni300 powder in high performance, high efficiency and other indicators compared with imported powder, The unique batch stability control method to ensure the stability of printing performance, is very few through the industrial application of the die steel powder verification.

High entropy alloy powder:

In recent years, with the development of 3D printing technology, the demand for high-entropy alloy powder for nuclear power, electric heating, hydrogen storage materials, etc., has gradually increased. For manganese containing high-entropy alloy, due to the volatilization and burning loss of manganese element, smoke is serious, it is difficult to observe the production situation in the furnace, resulting in composition does not meet the ratio requirements, resulting in composition deviation problems, domestic has solved the problem of large loss of Mn element in the production process, to ensure reliable and stable product quality.

Aluminum alloy powder:

The new nano-ceramic reinforced aluminum alloy powder, processed into a workpiece by 3D printing (SLM) technology, has a tensile strength of 530MPa, an elongation of 15.5%, and a microhardness of 193HV, which is much higher than the forged aluminum alloy material (tensile strength 360MPa), and has been successfully applied in domestic large aircraft.

Technological Advancements in Powder Metal 3D Printing

Sintering Techniques

Advancements in sintering techniques have significantly improved the quality and consistency of powder metal 3D printed parts.

Enhanced Precision

Modern sintering techniques provide better control over part dimensions and tolerances, resulting in higher precision and better surface finishes. This improvement is crucial for industries that demand tight tolerances and high-quality finishes, such as aerospace and medical.

Faster Production Times

Improved sintering processes have reduced production cycle times, increasing throughput and efficiency. This advancement is particularly beneficial for industries with high production demands, such as automotive and consumer electronics.

Powder Quality and Material Development

The development of high-quality metal powders and new alloy compositions has expanded the range of applications for powder metal 3D printing.

Consistent Powder Quality

Uniform particle size distribution and high-purity metal powders contribute to better print quality and performance. Consistent powder quality ensures that parts meet stringent industry standards, which is essential for applications in aerospace and medical sectors.

New Alloy Innovations

Ongoing research and development have led to the creation of specialized alloys designed for specific industrial needs. These innovations enhance the performance characteristics of 3D printed parts, enabling new applications and improving existing ones.

Automation and Integration

The integration of automation in powder metal 3D printing processes has streamlined production, reducing human error and improving efficiency.

Automated Quality Control

Real-time monitoring and inspection of parts during production ensure consistent quality and reduce defects. Automated quality control systems are particularly beneficial in industries with stringent regulatory requirements, such as medical and aerospace.

Seamless Workflow Integration

Automation allows for the seamless integration of powder metal 3D printing into existing manufacturing workflows. This integration improves production planning, resource management, and overall operational efficiency.

Conclusion

Powder metal 3D printing services offer transformative benefits across various industries, providing enhanced design flexibility, material efficiency, and superior mechanical properties. With advancements in technology and material development, this manufacturing method continues to evolve, offering innovative solutions for complex design challenges and high-performance requirements. By understanding its benefits, applications, and technological advancements, businesses can leverage powder metal 3D printing to achieve new levels of efficiency and performance.