Introduction

In the evolving landscape of manufacturing, Metal Injection Molding (MIM) and 3D Printing are two distinct processes that offer unique benefits. MIM is a well-established method known for its efficiency in mass production, while 3D Printing, an additive manufacturing technique, excels in creating complex and customized parts. This article delves into the differences between these two processes, focusing on their workflows, cost efficiency, applications, quality, and environmental impact. Understanding these distinctions is crucial for manufacturers and engineers in selecting the most suitable process for their specific needs.

Process Comparison

Metal Injection Molding Process

Material Preparation

Metal Injection Molding begins with the preparation of a feedstock composed of fine metal powders and binders. The precise mixing of these components is critical, as it directly influences the quality and consistency of the final parts. The feedstock is then granulated into pellets, ready for the injection molding process.

Molding and Debinding

The prepared feedstock is injected into molds under high pressure, similar to plastic injection molding. This step allows for the production of intricate shapes with tight tolerances. After molding, the parts undergo debinding, a process that removes the binders, leaving behind a porous metal structure. This step is crucial as it prepares the parts for the final sintering process.

Sintering

Sintering involves heating the debound parts to just below the melting point of the metal. This high-temperature process fuses the metal particles together, resulting in a dense, solid part. Quality control during sintering ensures that the parts meet the required mechanical properties and dimensions, making MIM suitable for high-strength applications.

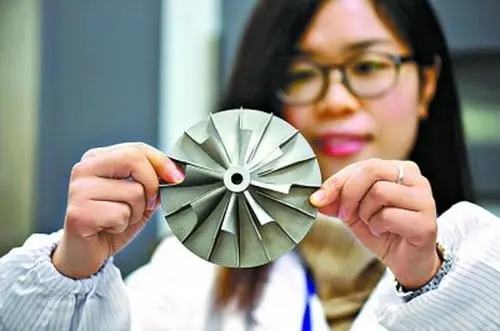

MIM PARTS

3D Printing Process

Additive Manufacturing Techniques

3D Printing, or additive manufacturing, builds parts layer by layer from a digital CAD model. Techniques such as Selective Laser Sintering (SLS) and Direct Metal Laser Sintering (DMLS) use lasers to fuse metal powders. This method is highly versatile, allowing for the creation of complex geometries that are difficult or impossible to achieve with traditional manufacturing.

Material Handling

3D Printing uses a variety of metal powders, each with specific properties tailored to different applications. The ability to switch between materials easily is a significant advantage over MIM. However, the properties of printed materials can vary, and achieving uniformity in mechanical properties can be challenging compared to MIM.

Post-Processing

Post-processing in 3D Printing includes removing support structures, surface finishing, and heat treatment to enhance mechanical properties. These steps are vital to achieving the desired part specifications and performance. Although post-processing can be time-consuming, it is necessary to ensure the final product meets the required standards.

3D PRINTING PARTS

Cost and Efficiency

Cost Analysis

Initial Investment

The initial investment for MIM is substantial, involving the cost of molds and specialized equipment. In contrast, 3D Printing requires less upfront investment, with lower costs for equipment and no need for molds. This makes 3D Printing more accessible for small businesses and prototyping.

Production Costs

MIM is cost-effective for large production runs due to economies of scale. The per-part cost decreases significantly as the volume increases. On the other hand, 3D Printing has a relatively constant per-part cost, which can be higher than MIM for large quantities but advantageous for low-volume or custom production.

Production Speed

Lead Times

MIM has longer lead times due to the need for mold fabrication and preparation. However, once the molds are ready, production can be very fast. 3D Printing offers shorter lead times, especially for prototypes and small batches, as it bypasses the need for molds and tooling.

Scalability

MIM excels in scalability, making it ideal for mass production. The process is designed for high throughput and consistent quality across large volumes. 3D Printing, while scalable to an extent, faces challenges in maintaining efficiency and uniformity when scaled up for mass production.

Applications and Suitability

Ideal Use Cases

MIM Applications

MIM is widely used in industries such as automotive, aerospace, and medical devices, where high strength, precision, and mass production are required. Common applications include gears, surgical instruments, and complex automotive components. The ability to produce parts with excellent mechanical properties makes MIM the preferred choice for these sectors.

3D Printing Applications

3D Printing is favored for prototyping, custom parts, and low-volume production. Industries like aerospace, healthcare, and consumer goods benefit from the ability to quickly produce and iterate on designs. Applications include custom implants, aerospace components with complex geometries, and bespoke consumer products.

Design Flexibility

Complexity and Customization

3D Printing offers unparalleled design flexibility, allowing for the creation of intricate and customized parts without the constraints of traditional manufacturing. This capability is particularly advantageous for producing prototypes and unique designs. MIM, while less flexible, can still produce complex shapes but requires careful consideration of mold design and manufacturability.

Material Variety

Both MIM and 3D Printing support a wide range of materials. However, 3D Printing provides greater flexibility in experimenting with different metal powders and composites, enabling rapid material changes to meet specific application needs. MIM, while versatile, requires more effort to switch materials due to the complexities of feedstock preparation and mold design.

Quality and Performance

Surface Finish and Tolerances

MIM Surface Finish

MIM typically produces parts with excellent surface finishes and tight tolerances, making it suitable for applications requiring high precision and aesthetic quality. The sintering process further enhances the surface quality, reducing the need for extensive post-processing.

3D Printing Surface Finish

3D Printed parts often require post-processing to achieve the desired surface finish and tolerances. While 3D Printing can produce high-quality parts, the layer-by-layer nature of the process can result in visible layer lines and a rougher surface compared to MIM.

Mechanical Properties

Strength and Durability

MIM parts generally exhibit superior mechanical properties, including high strength and durability, due to the dense, homogenous structure achieved through sintering. 3D Printed parts, while strong, may have inherent weaknesses along the layer lines, impacting their overall mechanical performance.

Performance Under Stress

Under various stress conditions, MIM parts tend to outperform 3D Printed parts, especially in applications requiring high fatigue resistance and long-term durability. The uniformity and density of MIM parts contribute to their superior performance in demanding environments.

Environmental and Sustainability Considerations

Environmental Impact

Material Waste

MIM generates less material waste compared to subtractive manufacturing processes, as the feedstock is fully utilized in part production. 3D Printing also minimizes waste by using only the necessary amount of material for each part. However, both processes benefit from advances in recycling and material reuse technologies.

Energy Consumption

3D Printing typically consumes less energy during the manufacturing process compared to MIM, which involves high-temperature sintering. The lower energy consumption of 3D Printing contributes to its appeal from a sustainability perspective, although the environmental impact of energy sources should also be considered.

Recycling and Reusability

MIM Recycling

Materials used in MIM can often be recycled, and scrap material from the molding process can be reused in future production runs. This recyclability enhances the sustainability of the MIM process.

3D Printing Recycling

Similar to MIM, 3D Printing materials can be recycled, and unused metal powder can be reclaimed and reused. Advances in material science are improving the efficiency and sustainability of both processes.

MIM vs 3D Printing Comparison

Metal Injection Molding and 3D printing boast unique characteristics, necessitating a thorough evaluation of several factors when selecting a manufacturing method. Here is a comparison of these two techniques:

| Material Selection | Metal Injection Molding excels in metal part production, whereas 3D printing is more versatile in terms of material options. | ||||

| Precision and Strength | Metal Injection Molding generally offers superior precision and material strength, while 3D printing’s precision and strength may be influenced by the materials and technology used. | ||||

| Production Volume | Metal Injection Molding is well-suited for large-scale production, whereas 3D printing is optimal for low-volume production and prototyping. | ||||

| Custom Manufacturing | 3D printing uniquely enables custom production, a capability that Metal Injection Molding cannot match. | ||||

| Cost Considerations | Specific costs vary based on several factors, including material expenses, production scale, and required precision. In some cases, Metal Injection Molding may be more cost-effective, while in others, 3D printing may offer a competitive edge. | ||||

In the decision-making process, manufacturers must weigh these factors to determine which method aligns with their specific requirements and budget constraints. With ongoing technological advancements, both Metal Injection Molding and 3D printing will continue to evolve, ushering in opportunities for innovation and progress in the manufacturing sector. Ultimately, both technologies promise boundless potential, driving the manufacturing industry forward.

Conclusion

In summary, Metal Injection Molding and 3D Printing each offer distinct advantages and are suitable for different applications. MIM is ideal for mass production of high-strength, precise parts, while 3D Printing excels in design flexibility and customization. When choosing between these processes, manufacturers must consider factors such as cost, production speed, material properties, and environmental impact. By understanding these differences, businesses can make informed decisions that optimize their manufacturing strategies and meet their specific needs. As both technologies continue to advance, they will play complementary roles in the future of manufacturing, driving innovation and efficiency across various industries.