What benefits of the MIM process for medical equipment and devices?

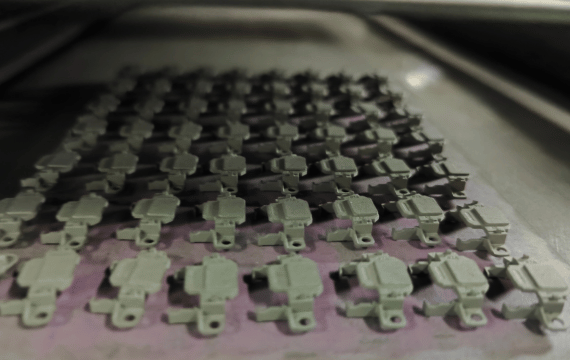

More and more medical equipment and devices parts have been chosen to use the MIM process to produce. To meet the technical needs of medical devices, we can provide rigorous durability materials and high-quality components. Metal injection molding technology, products manufactured by powder metallurgy have high precision, and mass production of precision, high-density, high-performance parts. Manufacturing in this way increases production efficiency and ultimately reduces the cost per component. to increase the final value.

What medical material selection?

Medical devices are divided into therapeutic devices and implanted devices

The choice of material needs to consider the specific use environment. Especially the implant material, size, function, lifespan, rejection of the patient, etc. The main materials used are stainless steel, titanium alloy, magnesium alloy, cobalt-chromium alloy, etc. Usually stainless steel and titanium alloy are made by metal injection molding.

What is JH MIM medical manfucaturing experience?

In nearly 20 years since the establishment of JH MIM, we have provided medical equipment partners with a variety of medical accessories, mainly made of stainless steel and titanium alloy. The final medical product is sold in large volumes in North America and Europe. The main products are brackets de ortodoncia, scalpel handle, grip parts, and dental nozzle….

Why Chose JH MIM technology

JHMIM: Advanced MIM Solutions for the Medical Sector

JHMIM is at the forefront of Metal Injection Molding (MIM) for the medical industry, delivering specialized capabilities that meet the intricate demands of contemporary medical device production. Our expertise enables us to manufacture components that are complex, robust, and finished to the highest quality.

Expert Medical Device Manufacturing

With extensive experience in MIM technology, JHMIM offers tailored design and manufacturability solutions for a diverse range of medical applications:

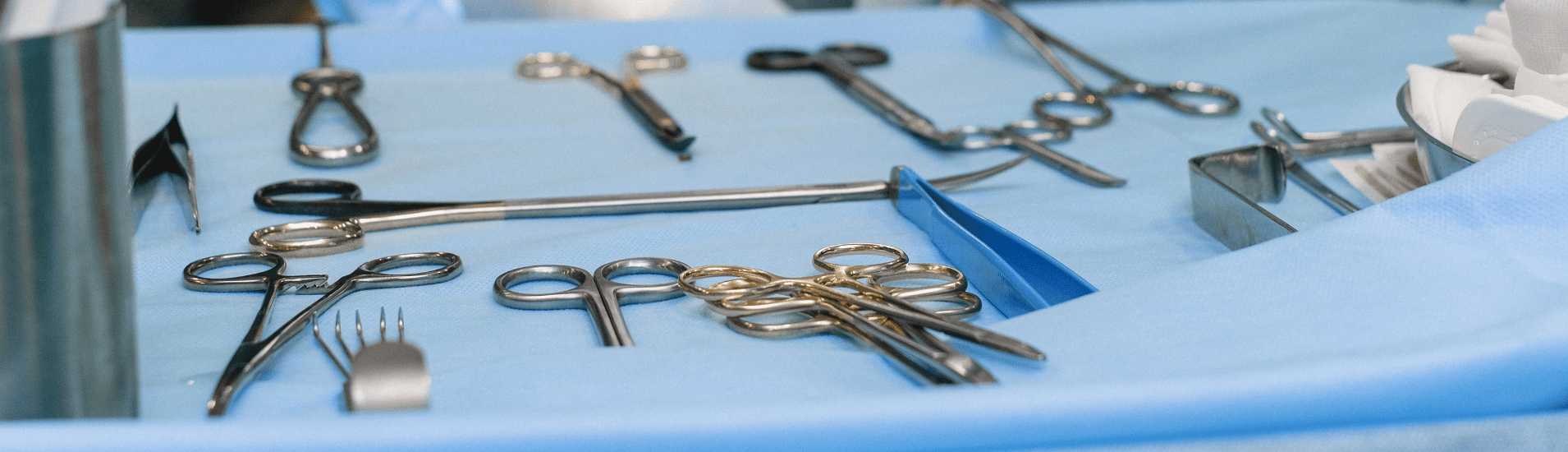

- Surgical Instruments: We produce essential tools such as ablation electrodes, endoscopic graspers and scissors, forceps, instrument bodies, and scalpel handles, ensuring each meets the highest surgical standards.

- Orthopedic Devices: Our capabilities include the production of orthopedic surgery tools, screws, spine implants, external fixation devices, and trauma plates, all crafted with precision.

- Hearing Devices: We create detailed housings and implants that are critical for the functionality and reliability of various auditory devices.

State-of-the-Art Manufacturing and Comprehensive Services

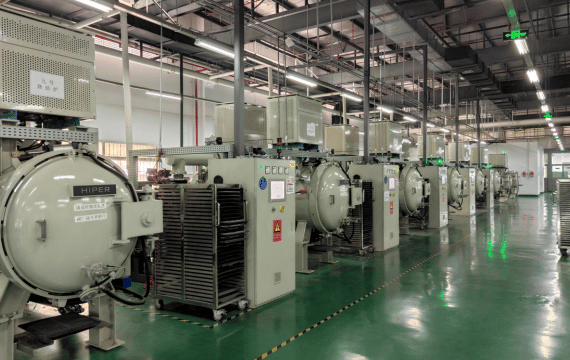

Our facility spans over 65,000 square feet of cutting-edge manufacturing space, utilizing advanced MIM processes to ensure top-quality production. JHMIM’s “Part Program Management” encompasses everything from process engineering and design automation to quality assurance, assembly, packaging, and distribution.

Engage with JHMIM

We encourage you to send us your CAD file or drawings for a detailed assessment of MIM’s viability for your existing or future medical projects. At JHMIM, we combine deep industry insight with innovative MIM technology to deliver unparalleled results.

Choose JHMIM as your trusted MIM partner and elevate the standard of your medical device manufacturing. Together, we can drive medical advancements and improve patient care with superior-quality components.