Metal microinjection molding technology is one of the most effective methods for the mass production of high-precision and high-performance micro metal parts or ceramic parts.

The traditional powder injection molding technology which includes ceramic injection molding and metal powder injection molding (MIM and CIM), is a net-shape technique for producing high volume, high precision components used in a range of industries.PIM can produce parts with the size of 0.1 ~ 1mm, and the minimum parts of 20mg have been produced. However, with the development of micro-systems, including micro-optics, minimally invasive surgery, and micro-jet technology, metal and ceramic parts with complex shapes and sizes in the micron range are required. Micro metal injection molding micro MIM (μ-MIM) is suitable for large-scale manufacturing of micro structural parts.

Germany began to study microinjection molding technology 10 years ago, but the raw material used is thermoplastic, and the micro MIM (μ-MIM) part size has reached 0.2μm. On the basis of this research, Germany is now studying micro metal injection molding and micro-ceramic injection molding technology. The powder used is an average particle size of 15 μm carbonyl iron powder, 4 ~ 5μm stainless steel powder, and 0.6μm aluminum oxide powder. The binders used include self-mixing polyolefin/wax compounds and normal polyaldehyde compounds. The debinders in this study include heating removal of organic matter, catalytic debinders of polyaldehyde compounds, and supercritical carbon dioxide debinders.

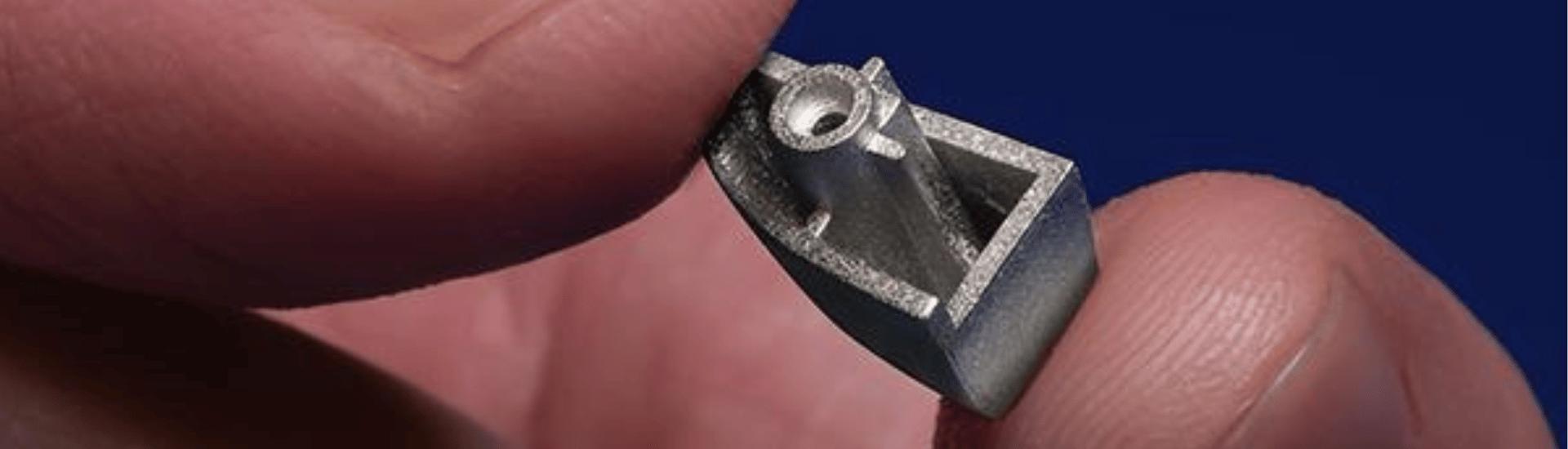

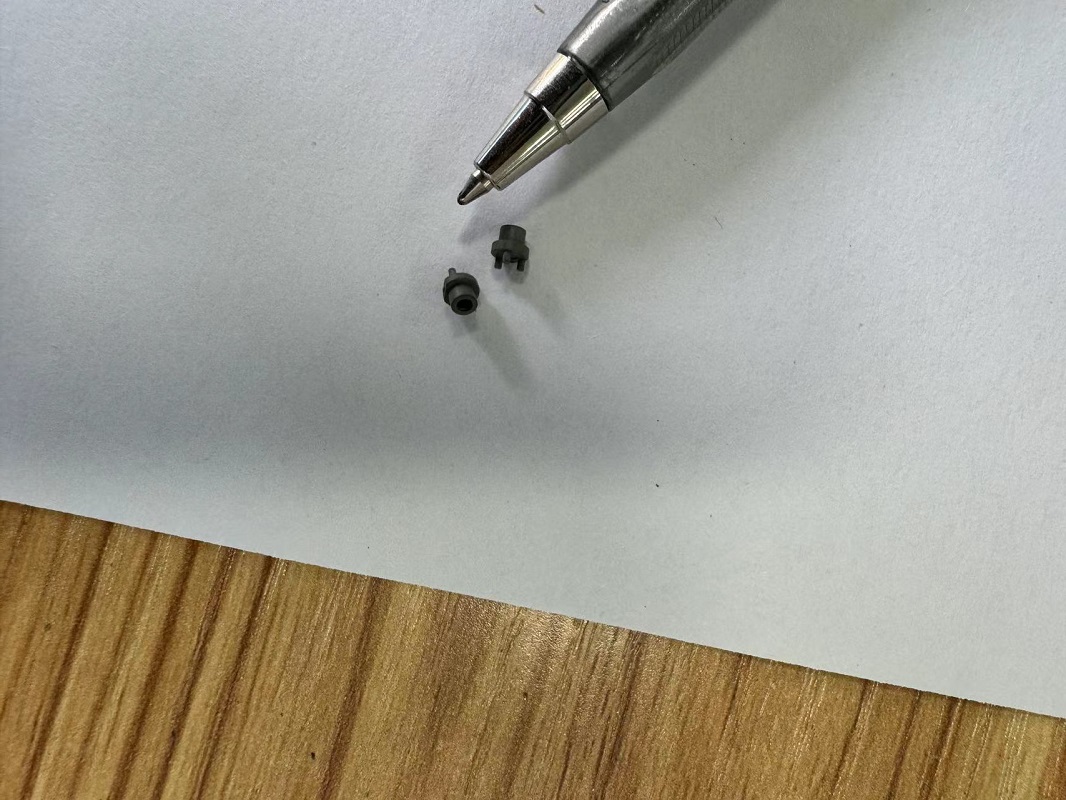

JH MIM μ-MIM Process Produced

In comparison to traditional machine processing, the micro-MIM (μ-MIM) process has several significant advantages, such as the following:

- Parts can be formed with complex features, similar to plastic injection molding; undercuts, threads, and slots can be produced efficiently.

- When two or more components are combined into one, assembly is omitted, saving time and money.

- Compared to traditional machining, there is less waste or scrap because parts can be created in net shape.

- Additionally, no additional machining processes are required.

- Parts can be made with a purity of 98% and have uniformly smooth surface finishes.

- Cost-effectiveness: Customers can experience significant cost reductions over other traditional production techniques, especially for big batches.

μ-MIM Parts

The μ-MIM products have a density of 98% and a linear shrinkage of 15%-22% after repressing. The smallest microceramic injection molded structural part size is 10μm, the weight of the microinjection ceramic gear is only 0 5mg, and the smallest micrometal injection molded part size is 50μm. Microinjection molding is used for micro-pump, micro-gear, micro-turbine, micro-catheter for minimal damage surgery, etc.

Tags: