Metal injection molding (MIM) transforms automotive manufacturing by enabling the production of intricate, high-precision components. Manufacturers achieve significant cost savings and efficiency gains with MIM.

- The process reduces material waste and minimizes finishing operations.

- It lowers development cycles and eliminates costly multistage machining.

- MIM supports the demand for lightweight, high-strength parts, especially for electric vehicles.

The applications of Metal Injection Molding now extend to critical automotive systems, ensuring precision and reliability.

Key Takeaways

- Metal Injection Molding (MIM) produces complex, high-precision metal parts that improve automotive safety, engine, fuel, electronic, and structural components.

- MIM reduces material waste and lowers production costs by combining multiple features into a single part and minimizing secondary machining.

- The process supports lightweight, strong parts that enhance vehicle performance, fuel efficiency, and meet modern design demands.

- MIM parts offer mechanical strength and reliability comparable to forged or machined components, ensuring durability in critical automotive systems.

- Automotive manufacturers benefit from MIM’s design flexibility, high-volume production capability, and consistent quality for advanced vehicle technologies.

What Is Metal Injection Molding?

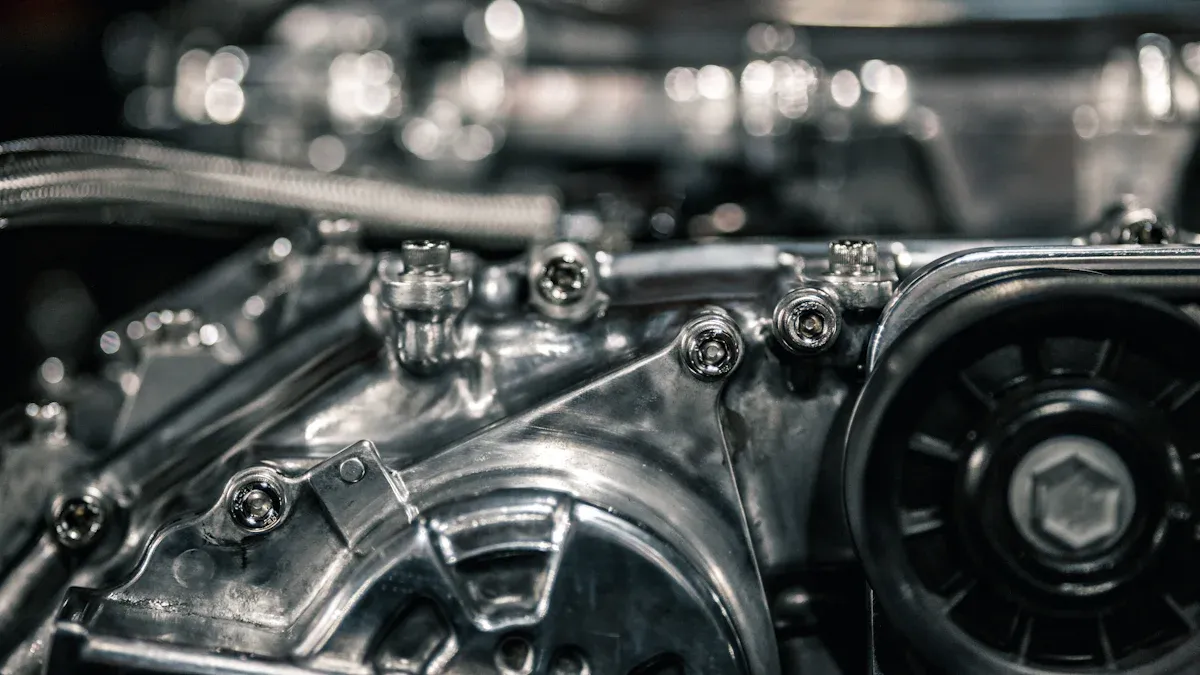

Metal injection molding (MIM) is a manufacturing process that combines the versatility of plastic injection molding with the strength and integrity of metal. This technique enables manufacturers to produce complex, high-precision metal parts in large quantities. Automotive engineers rely on MIM to create components that demand both intricate shapes and robust mechanical properties.

How MIM Works

The MIM process involves several key steps that transform fine metal powders into finished automotive parts:

- Feedstock Mixing: Technicians blend fine metal powders with a thermoplastic binder to form a uniform feedstock. This mixture ensures proper flow and strength during the molding process.

- Injection Molding: The feedstock is heated and injected into precision molds, forming “green parts” that match the desired geometry.

- Debinding: The molded parts undergo debinding, where the binder is removed using thermal, solvent, or catalytic methods. This step leaves behind porous “brown parts.”

- Sintering: The brown parts are heated to a temperature near the metal’s melting point. This process bonds the metal particles, resulting in dense, strong components.

- Optional Hot Isostatic Pressing (HIP): For critical applications, parts may undergo HIP to eliminate internal voids and further enhance mechanical properties.

- Finishing: Final steps such as polishing and brushing ensure the parts meet surface and dimensional requirements.

Tip: MIM allows for the use of a wide range of metals. The table below highlights common choices for automotive parts:

| Metal Type | Common Grades / Examples |

|---|---|

| Stainless Steel | 304, 316L, 17-4 PH, 420, 440C, 430 |

| Titanium Alloy | Ti-6Al-4V, Ti-6Al-7Nb, Ti-5Al-2.5Fe |

| Low Alloy Steels | MIM 4605, MIM 4140, MIM 4340, MIM 2700, MIM 2200 |

| Tool Steel | A2, M2, M4, D2, S7, H13, T15 |

| Tungsten Alloy | W-Ni-Fe, W-Ni-Cu, W-Cu, W-Ni-Co, W-Fe |

| Cobalt Alloys | CoCrMo, CoCrW, CoNiCrMo, MP35N, Haynes 25 |

Why MIM Is Suited for Automotive Manufacturing

Automotive manufacturing demands parts that are small, complex, and durable. MIM excels at producing components with intricate features and thin walls, such as fuel injector housings and locking mechanisms. The process achieves high density—up to 99% of theoretical density—resulting in mechanical properties similar to wrought metals. Manufacturers benefit from near-net-shape production, which reduces the need for secondary machining and lowers costs.

MIM also generates minimal material waste, making it both cost-effective and environmentally friendly. The process supports high-volume production, which is essential for the automotive industry. Compared to other metal forming techniques, MIM enables the creation of complex geometries that would be difficult or impossible to achieve otherwise. These advantages explain the growing number of applications of Metal Injection Molding in modern vehicles.

Applications of Metal Injection Molding in Safety Components

Automotive safety systems demand components that perform flawlessly under extreme conditions. Metal injection molding (MIM) has become a preferred manufacturing method for these critical parts. The process delivers high-strength, complex components that meet stringent safety standards. Manufacturers rely on MIM to produce parts with precise dimensions, uniform density, and exceptional reliability. These qualities make MIM indispensable in the production of airbag system parts, seatbelt mechanisms, and sensor housings.

Airbag System Parts

Airbag systems protect vehicle occupants during collisions. The reliability of each component directly impacts passenger safety. MIM enables the creation of intricate airbag initiators and inflator housings. These parts require high strength and precise tolerances to function correctly in milliseconds during an accident.

- MIM produces airbag components with uniform density, reducing the risk of defects and ensuring consistent performance.

- The process allows for the use of advanced materials, such as 17-4 PH stainless steel, which offers high yield strength and corrosion resistance.

- Manufacturers can consolidate multiple features into a single part, minimizing assembly steps and potential failure points.

- The ability to create small, lightweight components supports automotive lightweighting goals without sacrificing structural integrity.

Airbag system parts made with MIM demonstrate mechanical properties comparable to wrought metals. This ensures that the components withstand the intense forces generated during deployment.

Seatbelt Mechanisms

Seatbelt systems rely on robust and precisely engineered components to restrain passengers safely. MIM plays a vital role in producing seatbelt anchors, buckles, and locking mechanisms.

- The process enables the manufacture of complex geometries that traditional methods struggle to achieve.

- MIM parts exhibit high mechanical strength and wear resistance, essential for repeated use and long-term reliability.

- Uniform density and tight dimensional tolerances ensure that seatbelt mechanisms operate smoothly and consistently.

- Part consolidation through MIM reduces the number of joints and welds, lowering the risk of mechanical failure.

Automotive engineers value MIM for its ability to deliver seatbelt components that meet or exceed industry safety standards. The process supports the production of smaller, lighter parts, contributing to overall vehicle efficiency.

Sensor Housings

Modern vehicles depend on a network of sensors to monitor and control safety systems. Sensor housings must protect sensitive electronics from harsh environments while maintaining precise alignment and sealing.

- MIM enables the production of micro-precision housings with wall thicknesses as thin as 0.4 mm.

- The process supports the use of stainless steel alloys, providing chemical resistance and mechanical durability.

- Manufacturers can produce single-piece housings, eliminating the need for multi-part assembly and reducing potential failure points.

- Superior surface quality and dimensional accuracy meet the strict requirements of automotive sensor applications.

- Automated MIM production ensures consistent quality and cost-effective mass manufacturing.

- Leak-tightness testing, such as helium leakage tests, guarantees maximum sealing reliability for safety-critical sensors.

The thin walls achieved with MIM improve sensor responsiveness by minimizing the barrier between the sensor and the measured medium. This enhances the performance of safety systems such as airbags, anti-lock brakes, and stability control.

The applications of metal injection molding in safety components continue to expand as automotive technology advances. MIM delivers the precision, strength, and reliability required for next-generation safety systems.

Applications of Metal Injection Molding in Engine and Transmission Parts

Automotive engines and transmissions demand components that deliver both precision and durability. The applications of metal injection molding in these systems have transformed how manufacturers approach complex part production. MIM enables the creation of intricate, high-performance parts that withstand extreme conditions inside modern powertrains.

Turbocharger Components

Turbochargers play a vital role in boosting engine efficiency and power. Variable Geometry Turbochargers (VGTs) require components with complex shapes and tight tolerances. Metal injection molding provides a solution by producing precision parts that resist high temperatures and corrosion. This process allows manufacturers to create aerodynamically shaped vanes and housings that optimize airflow. These features improve engine responsiveness and fuel economy.

MIM parts undergo advanced post-processing, such as heat treatment and surface coatings. These steps enhance strength, hardness, and wear resistance. As a result, turbocharger components maintain optimal performance and reliability over time. The durability of MIM parts directly contributes to longer service life and reduced maintenance needs. Automotive engineers rely on MIM to deliver turbocharger components that meet the demands of modern engines.

Turbocharger components produced by MIM withstand extreme operating conditions, ensuring consistent performance and supporting advancements in engine technology.

Valve Train Parts

Valve train systems control the flow of air and fuel into the engine and manage exhaust gases. These parts must operate with high precision and endure constant mechanical stress. Metal injection molding excels in producing valve train components with intricate geometries and fine surface details. The process achieves tight tolerances, typically around ±0.3%, which ensures dimensional accuracy and repeatability.

The following table highlights the key benefits of MIM for valve train parts:

| Aspect | Evidence Summary |

|---|---|

| Precision | Typical tolerances around ±0.3%, enabling high dimensional accuracy and repeatability. |

| Design Complexity | Supports intricate geometries, fine surface details, small holes, threads, and engravings. |

| Part Density | Achieves 95–99% density, leading to strong and reliable mechanical performance. |

Valve train components produced by MIM exhibit excellent mechanical properties. The table below summarizes these attributes:

| Mechanical Property | Description |

|---|---|

| Tensile Strength | High tensile strength comparable or superior to forged or cast parts. |

| Hardness | Excellent hardness ensures durability. |

| Fatigue Resistance | Strong resistance to fatigue, important for valve train longevity. |

| Wear and Corrosion Resistance | Enhanced resistance when using stainless or tool steels, critical for valve train environments. |

MIM also supports a wide range of materials, including stainless steel, titanium, and low-alloy steels. This flexibility allows engineers to optimize valve train parts for specific engine requirements. The controlled environment of MIM reduces contamination and defects, ensuring high-quality, reliable components.

Gear Assemblies

Gear assemblies in automotive transmissions require strength, precision, and wear resistance. Metal injection molding streamlines the production of these critical parts. The process combines the efficiency of plastic injection molding with the material advantages of powdered metallurgy. Manufacturers can produce high volumes of small, detailed gears with minimal waste.

MIM supports the use of advanced alloys, such as stainless steel and titanium. These materials provide the necessary strength, corrosion resistance, and heat tolerance for transmission gears. The process enables the creation of complex gear geometries and integrated features, reducing the need for secondary machining and assembly.

- MIM reduces waste and eliminates secondary machining, lowering production costs and accelerating manufacturing.

- It enables complex gear geometries and integrated features, enhancing design flexibility and reducing assembly complexity.

- Stainless steel alloys used in MIM provide strength, corrosion resistance, and heat resistance, ensuring gear durability.

- High-volume production capability with consistent quality supports scalability and productivity in gear manufacturing.

Gear assemblies produced by MIM offer mechanical properties comparable to wrought materials. This ensures durability and long service life, even under demanding transmission conditions. The applications of metal injection molding in gear manufacturing continue to expand as automotive designs evolve.

Applications of Metal Injection Molding in Fuel System Components

Fuel Injector Housings

Automotive fuel injector housings require exceptional precision and durability. Manufacturers choose metal injection molding for these parts because it delivers consistent quality and tight tolerances. The process produces components with high density, often reaching 95% to 99% of wrought metal. This density ensures that fuel injector housings can handle high pressures and resist wear over time. MIM technology also supports a wide range of metal alloys, allowing engineers to select materials with excellent corrosion resistance and hardness. The ability to create intricate shapes and fine details reduces the need for secondary machining, which improves both reliability and performance. Automotive companies rely on MIM for fuel injector housings because it offers repeatability and structural integrity, both critical for reliable engine operation.

- MIM achieves excellent dimensional accuracy, supporting consistent tolerance control.

- The process enables the production of complex geometries and smooth surface finishes.

- High-performance alloys enhance corrosion resistance and mechanical strength.

Pump Components

Fuel pumps play a vital role in delivering fuel efficiently to the engine. These components must withstand constant exposure to fuel and operate under demanding conditions. Metal injection molding enables the production of pump parts with complex internal features and uniform material properties. The process allows for the consolidation of multiple features into a single component, reducing assembly steps and potential failure points. MIM technology ensures that pump components meet strict industry standards for strength and precision. Automotive manufacturers benefit from the ability to produce high volumes of reliable, high-strength pump parts at a competitive cost.

Nozzle and Valve Parts

Nozzle and valve parts in automotive fuel systems demand high precision and consistent quality. Metal injection molding excels in producing these components with tight tolerances and intricate features. The table below highlights how MIM enhances the precision of nozzle and valve parts:

| Aspect | Description |

|---|---|

| Dimensional Control | Achieves tight tolerances down to ±0.005 inches, enabling precise, small, and complex parts. |

| Geometrical Complexity | Capable of molding intricate features like thin walls, micro-sized holes, and undercuts. |

| Process Efficiency | Consolidates multiple production steps, reducing secondary machining and ensuring uniformity. |

| Surface Finish | Provides superior surface finishes essential for functional automotive components. |

| Material Consistency | Automated process ensures uniform material composition and mechanical properties across batches. |

| Tooling & Sintering | Advanced tooling and optimized sintering maintain dimensional accuracy and repeatability. |

Automotive engineers use MIM to produce fuel injector nozzles and valve parts that meet strict requirements for dimensional accuracy and surface quality. These components contribute to improved fuel efficiency and reliability in modern vehicles. The applications of metal injection molding in fuel system components continue to expand as automotive technology advances.

Applications of Metal Injection Molding in Electronic and Electrical Connectors

Sensor Connectors

Automotive sensor connectors require high precision and reliability to ensure accurate data transmission. Metal injection molding enables manufacturers to produce connectors with intricate geometries and tight tolerances, sometimes as precise as ±0.003 inches. This level of accuracy ensures a secure fit and optimal alignment, which is critical for sensor performance. MIM supports a range of metals, including stainless steel and silver. Silver feedstock, in particular, enhances electrical and thermal conductivity, which improves signal integrity and thermal management in automotive electronics. Surface treatments such as PVD coatings and heat treatments further increase wear resistance and corrosion protection. By consolidating multiple features into a single component, MIM reduces assembly points and potential failure modes. These advantages make MIM a preferred choice for sensor connectors in modern vehicles.

Terminal Housings

Terminal housings in automotive electrical systems must withstand harsh environments and maintain consistent performance. Metal injection molding offers several benefits for these components:

- High precision and repeatability with tight dimensional tolerances.

- Design flexibility for complex shapes and features.

- Cost-effectiveness for high-volume production.

- Material versatility, including stainless steel, titanium, and copper alloys.

- Environmentally friendly processes that generate less waste.

MIM allows the integration of multiple features into a single housing, simplifying assembly and improving reliability. Automated production ensures consistent quality and reduces labor costs. These factors make MIM especially suitable for terminal housings that demand durability, lightweight construction, and intricate geometry.

Shielding Components

Automotive electronics require effective electromagnetic interference (EMI) shielding to protect sensitive circuits. Traditional plastic parts lack conductivity and do not provide adequate EMI protection. Metal injection molding addresses this challenge by embedding conductive metal elements into connector housings. Manufacturers can use MIM to create lightweight, cost-effective components that meet EMI shielding requirements. Techniques such as electroplating and the use of conductive fillers enhance the shielding effectiveness of these parts. By combining the lightweight properties of polymers with the conductivity of metals, MIM enables the production of advanced shielding components for automotive applications. This approach ensures reliable operation of electronic systems in increasingly complex vehicle architectures.

Note: MIM 316L stainless steel is often selected for connectors and external components due to its excellent corrosion resistance and mechanical strength.

The applications of metal injection molding in electronic and electrical connectors continue to expand as vehicles become more reliant on advanced electronics.

Applications of Metal Injection Molding in Structural and Functional Elements

Door Lock Parts

Automotive door lock systems require components that deliver both security and longevity. Metal injection molding produces door lock parts with high density and dimensional stability. Manufacturers often select materials such as 17-4 PH stainless steel and titanium alloys for their strength and corrosion resistance. The process enables direct molding of metal inserts, which eliminates the need for additional fasteners and increases assembly efficiency. Surface treatments like passivation and heat treatment further enhance durability and wear resistance.

| Aspect | Description | Contribution to Strength and Reliability |

|---|---|---|

| Metal Injection Molding Process | Uniform feedstock, precision molding, debinding, sintering | Dense, stable parts with enhanced hardness and tensile strength |

| Materials Used | Stainless steel, titanium, cobalt-chrome alloys | High tensile strength, corrosion, and wear resistance |

| Surface Treatments | Passivation, heat treatments, and electroplating | Improved corrosion resistance, hardness, and durability |

| Integration with Plastic | Metal inserts with plastic in actuators | Accurate motion, fewer parts, better sealing, and waterproofing |

| Assembly Efficiency | Direct molding without fasteners | Increased precision, reduced errors |

Metal inserts in door lock actuators disperse load, prevent deformation, and ensure reliable operation. The combination of metal and plastic improves motion transmission and extends service life, even in harsh environments.

Steering System Components

Steering systems demand lightweight yet durable parts. Metal injection molding enables the production of strong components with thinner walls, reducing overall weight while maintaining performance. The process allows for the consolidation of multiple parts into a single, complex component, which simplifies assembly and reduces potential failure points. Manufacturers use corrosion-resistant alloys like stainless steel and titanium to enhance longevity.

- MIM produces lightweight components without sacrificing strength.

- Complex geometries optimize functionality and reduce weight.

- Corrosion-resistant materials increase durability.

- Parts maintain integrity under harsh conditions due to high fatigue resistance.

- Tight tolerances and excellent surface finish ensure long service life.

Compared to traditional machining or casting, MIM offers higher precision, less material waste, and improved mechanical properties. These advantages support both weight reduction and durability in modern steering systems.

Small Brackets and Mounts

Small brackets and mounts in vehicles often feature intricate shapes and require high strength. Metal injection molding combines the versatility of plastic injection molding with the strength of metal, enabling the production of complex parts with tight tolerances. Manufacturers use MIM to produce sensor housings, gears, and fasteners that demand durability and precision.

- MIM enables intricate shapes and consistent quality.

- The process supports high-volume production with cost-effectiveness.

- Reduced material waste and integrated manufacturing steps lower labor costs.

- Parts exhibit high strength and durability, essential for automotive applications.

The applications of Metal Injection Molding in structural and functional elements continue to expand as automotive designs evolve. This technology supports the creation of reliable, high-performance components that meet the demands of modern vehicles.

Benefits of Metal Injection Molding for the Automotive Industry

Cost Savings

Metal injection molding delivers significant cost advantages for automotive manufacturers. The process uses nearly all the raw material, minimizing waste compared to traditional machining, which removes excess metal. By consolidating multiple features into a single component, MIM reduces the need for assembly and secondary operations. This streamlined approach lowers labor costs and shortens production cycles. High-volume production becomes more economical, as MIM molds can produce thousands of identical parts with consistent quality. Manufacturers also benefit from reduced tooling costs over time, especially when producing complex or small components.

MIM’s efficient material usage and process integration help automotive companies achieve competitive pricing without sacrificing quality.

Design Flexibility

MIM stands out for its exceptional design freedom. Engineers can create parts with complex internal structures, thin walls, and intricate shapes that traditional metalworking methods cannot easily achieve. The process maintains tight tolerances, often within ±0.3% to ±0.5%, ensuring each part fits and functions as intended. MIM supports a wide range of metals, such as stainless steel, titanium alloys, and hard metals, allowing for tailored material selection.

- Produces components with complex geometries and undercuts.

- Maintains high precision and excellent surface quality.

- Supports merging multiple features into a single part, reducing assembly steps.

- Enables the use of advanced alloys for specific automotive needs.

This flexibility empowers automotive designers to innovate, optimize part performance, and reduce overall vehicle weight.

Performance and Reliability

Automotive parts produced by MIM demonstrate outstanding performance and reliability. Fine powder blending during feedstock preparation ensures material homogeneity, resulting in uniform wear resistance throughout each component. The sintering process creates a porous structure that enhances lubricant retention, providing a self-lubricating effect ideal for friction-intensive environments. MIM parts achieve excellent surface finishes and tight tolerances, which reduce friction and extend part life.

- Superior precision and dimensional accuracy support critical automotive functions.

- Enhanced strength, toughness, and reliability withstand harsh operating conditions.

- Surface treatments, such as heat treatments and coatings, further improve wear and corrosion resistance.

These qualities lead to longer service intervals, reduced maintenance, and improved safety for modern vehicles.

Lightweighting and Material Efficiency

Automotive manufacturers face increasing pressure to reduce vehicle weight while maintaining strength and safety. Metal injection molding (MIM) addresses these challenges by enabling the production of lightweight, high-performance components. This technology supports the automotive industry’s drive toward fuel efficiency, lower emissions, and sustainability.

MIM offers several advantages for lightweighting and material efficiency:

- Reduces component weight without sacrificing mechanical strength, which improves vehicle performance and fuel economy.

- Minimizes material waste compared to traditional metalworking methods, enhancing overall material efficiency.

- Enables the creation of complex geometries, such as lattice structures and thin-walled parts, that are difficult to achieve with other manufacturing processes.

- Supports the use of advanced lightweight materials, including high-strength stainless steel, titanium, and even fiber-reinforced composites.

- Provides a cost-effective solution for mass production, making lightweight parts accessible for a wide range of automotive applications.

Advanced injection molding systems, such as low-constant-pressure technologies, allow manufacturers to produce thinner-walled, lighter-weight parts. These innovations can reduce part weight by up to 25% or more, decrease material waste, and lower energy consumption. As a result, automakers achieve improved part quality and support sustainability goals.

The table below highlights how MIM contributes to lightweighting and material efficiency in automotive manufacturing:

| Aspect | Explanation |

|---|---|

| Design Optimization | Uses topology optimization to place material only where needed, enabling complex, weight-saving geometries. |

| Porous Structures | Produces porous parts that reduce weight and improve properties like heat dissipation. |

| Material Options | Supports high strength-to-weight materials, broadening choices for lightweight parts. |

| Material Efficiency | Minimizes waste through optimized designs, reducing costs and environmental impact. |

| Performance & Durability | Maintains strength and durability despite weight reduction. |

| Industry Impact | Contributes to better fuel efficiency, lower emissions, and sustainability in automotive manufacturing. |

By leveraging MIM, automotive engineers design parts that are lighter, stronger, and more efficient. This approach not only meets industry standards but also supports the ongoing evolution of modern vehicles.

Metal injection molding stands as a cornerstone in automotive manufacturing. Engineers use MIM to create complex, high-quality parts for safety, engine, fuel, electronic, and structural systems. This technology drives improvements in cost, design, and performance.

- Manufacturers achieve greater efficiency and reliability.

- Automotive innovation accelerates with MIM’s versatility.

As automotive technology evolves, MIM will continue to support industry advancements and set new standards for precision and efficiency.

FAQ

What types of metals can manufacturers use in metal injection molding for automotive parts?

Manufacturers often select stainless steel, titanium alloys, low alloy steels, and tool steels. These materials provide strength, corrosion resistance, and durability. The choice depends on the specific requirements of each automotive component.

How does MIM improve cost efficiency in automotive manufacturing?

MIM reduces material waste and minimizes secondary machining. Manufacturers can produce complex parts in large volumes, which lowers unit costs. The process also allows for part consolidation, reducing assembly steps and labor expenses.

Are MIM automotive parts as strong as forged or machined components?

Yes. MIM parts achieve densities up to 99% of wrought metals. They offer mechanical properties comparable to forged or machined components. This ensures reliability and performance in demanding automotive applications.

Can MIM produce parts with complex shapes and fine details?

Absolutely. MIM excels at creating intricate geometries, thin walls, and small features. Engineers can design parts that traditional metalworking methods cannot easily achieve.

Why do automotive manufacturers prefer MIM for small, high-precision components?

MIM delivers tight tolerances and consistent quality. The process supports high-volume production of small, detailed parts. This reliability makes MIM ideal for safety, engine, and electronic components in modern vehicles.

Tip: For custom automotive MIM solutions, experienced manufacturers like JH MIM provide expert guidance and advanced production capabilities.