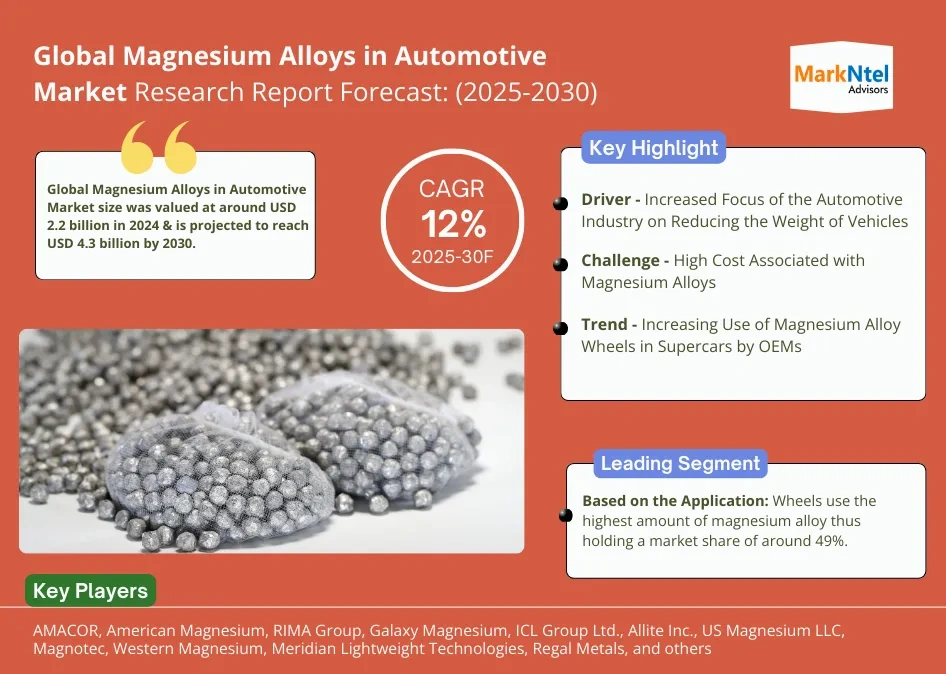

Manufacturers face a significant decision between magnesium vs aluminum for die casting projects that affects product performance and cost. Magnesium alloys weigh about one-third less than aluminum alloys, with a density of about 1.74 g/cm³ compared to aluminum’s 2.7 g/cm³. This weight difference makes magnesium a great choice for applications where weight matters.

Die casting with magnesium runs faster cycles than aluminum, but costs more. Each metal brings its own advantages to the table. To cite an instance, aluminum provides better tensile strength and resists corrosion better . Die cast magnesium shines in machinability and becomes the top choice in automotive and aerospace industries where weight reduction is critical . On top of that, the manufacturing processes differ between these metals – magnesium alloys work best in hot chamber machines, while aluminum needs cold chamber machines .

The best metal for your project ended up depending on cost, performance needs, and application requirements. This piece gets into the main differences between magnesium alloy vs aluminum to help you pick the right metal for your die casting needs in 2025.

Material Properties: Magnesium vs Aluminum Alloys

Engineers need to understand the basic material properties of these metals to make smart choices for their projects.

Density Comparison: 1.74 g/cm³ vs 2.70 g/cm³

The most important difference in the magnesium vs aluminum debate comes down to density. Magnesium alloys weigh about 1.74 g/cm³, which makes them 35% lighter than aluminum alloys at 2.70 g/cm³. This big drop in weight makes all the difference for aerospace and automotive applications, where every gram counts.

Strength and Stability: Tensile Strength and Stress Resistance

Magnesium’s weight advantage comes with some drawbacks in strength. Aluminum alloys are generally stronger and harder. You’ll find aluminum alloys reaching yield strengths above 270 megapascals, while magnesium alloys usually top out at 150-200 megapascals. Aluminum’s higher elastic modulus (around 70 gigapascals) lets it handle bigger loads before it starts to bend.

Thermal Conductivity: Heat Dissipation Capabilities

Aluminum alloys shine when it comes to managing heat. These alloys move heat better than magnesium ones, which makes aluminum the go-to choice for heat exchangers and parts that need to stay cool. Some magnesium alloys like AZ31B can move heat at 96 W/mK, but that’s nowhere near what aluminum can do.

Corrosion Resistance: Oxide Layer vs Coating Requirements

Aluminum has a clear edge in fighting corrosion. A natural oxide layer forms on aluminum that blocks rust. Magnesium needs extra help because it reacts more easily. You’ll need special coatings or surface treatments on magnesium alloys to stop corrosion, especially around salt water or humid air

Machinability: Cutting Pressure and Tool Wear

Working with magnesium alloys is a machinist’s dream. Tools last longer and need less pressure to cut. These alloys let you cut at amazing speeds—up to 5000 ft per minute in some cases. This makes magnesium great for complex parts that need precise machining.

Environmental Reactivity: Oxidation and Surface Protection

Engineers must think carefully about how magnesium reacts to its environment. Magnesium alloys oxidize more easily [1], and you might need special fire safety measures when machining them. Notwithstanding that, the right surface treatments and coatings can handle these challenges in most cases.

Die Casting Process Differences

The manufacturing processes for magnesium vs aluminum show fundamental differences in several key areas.

Casting Method: Hot Chamber vs Cold Chamber

Magnesium alloys work best with hot chamber die casting, where a built-in furnace stores and connects molten metal to the machine. Aluminum needs cold chamber die casting because of its higher melting point, which requires a separate furnace. This difference affects both production efficiency and equipment costs.

Cycle Time: Faster Solidification in Magnesium

Magnesium’s faster solidification leads to cycle times of 15-20 minutes for hot chamber processes. Production rates for magnesium reach 400-900 cycles per hour, while aluminum achieves only 50-90 cycles. This speed advantage gives magnesium alloy vs aluminum operations better productivity.

Wall Thickness Capabilities: Thin-Wall Casting in Magnesium

The excellent fluidity of magnesium allows for more complex features and thinner walls. Magnesium can maintain uniform thickness between 1.5-3 mm, unlike aluminum. This makes it perfect for complex, lightweight components.

Surface Finish Quality: Smoother Finish in Magnesium

Die cast magnesium parts often need no coating because of their smooth surface finish. They need less post-processing work than aluminum components.

Dimensional Accuracy: Stability During Cooling

Magnesium die casting delivers precise dimensional accuracy ranging from 0.25 mm in 100 mm to 0.6 mm in 500 mm [10]. Most parts meet size specifications with tolerances of ±0.1 mm.

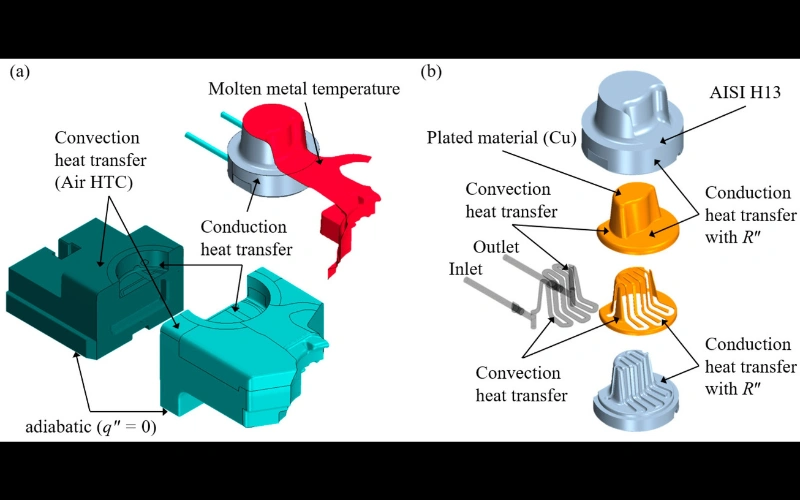

Tooling and Equipment Requirements

Both metals need high-quality tool steel dies that can handle extreme temperatures and pressures. Magnesium dies typically use H13 steel (45-50 HRC hardness) and 4140 steel (28-32 HRC hardness), which work well at temperatures around 600°C.

Cost and Sustainability Factors

Material selection for die casting projects depends more on economics than technical specs.

Raw Material Cost: Aluminum vs Magnesium Pricing

The cost difference between these metals is quite noticeable. Magnesium alloys cost $3.00-$6.00 per kilogram, which is about double aluminum’s price of $2.00-$4.00 per kilogram. This price difference comes from magnesium’s complex extraction and processing methods.

Production Efficiency: Cycle Time and Tool Life

Magnesium makes up for its high costs with better operations. The tooling for magnesium die casting lasts 2-3 times longer than aluminum’s. The material’s natural slickness stops it from sticking to molds, which leads to better dimensional consistency.

Recyclability: Energy Use in Reprocessing

These metals can be recycled forever, but their processes are different. Magnesium needs just 5% of the energy used in primary production for recycling, which is similar to aluminum’s requirements. Aluminum has a more reliable recycling infrastructure, though.

Post-Processing Needs: Coatings and Finishing

Magnesium just needs extra protection because it reacts easily. Manufacturers use treatments like anodizing, chromate conversion coating, and powder coating, which add to the final cost.

Environmental Impact: Emissions and Energy Use

Making magnesium creates more emissions than aluminum. SF6 (sulfur hexafluoride) used to prevent oxidation during magnesium casting is a big environmental concern. Manufacturers now use low-global-warming-potential cover gasses, which cut emissions from several kilograms to 10-20g CO2/kg processed [4].

Applications Across Industries

Both magnesium vs aluminum die casting metals have unique applications in major industries. Each metal shows its strengths in different scenarios.

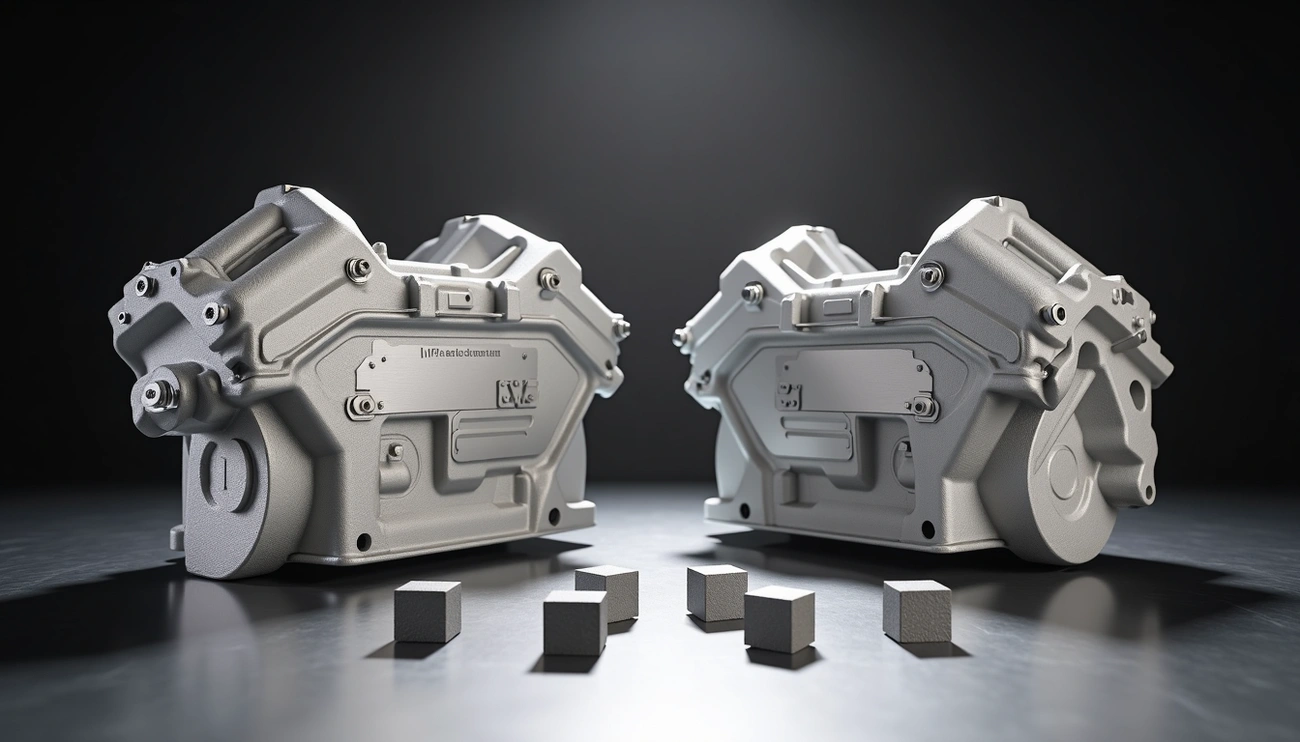

Automotive: Engine Blocks vs Seat Frames

Car manufacturers use magnesium to make seat frames, steering wheels, console brackets, and door handles where weight reduction is significant. Aluminum costs less and dominates engine blocks, transmission cases, and body panels. Magnesium engine blocks are 50% lighter than traditional cast iron alternatives. This weight reduction leads to better fuel efficiency.

Aerospace: Structural vs Interior Components

Aluminum is essential for aircraft structures and fuselage panels. Magnesium works best in non-structural components like seat frames. The metal’s density (66% of aluminum) saves considerable weight. This makes magnesium a valuable choice for aircraft seating and interior panels.

Electronics: Heat Sinks vs EMI Shielding

Aluminum stands out in heat sinks and housing cases due to its better thermal conductivity. Magnesium provides excellent EMI/RFI shielding for sensitive electronic components. This makes it perfect for laptop frames, camera bodies, and mobile phone frames.

Consumer Goods: Luggage Frames vs Cookware

Magnesium alloys work well for lightweight luggage frames. Aluminum’s resistance to corrosion and durability makes it the top choice for cookware.

Medical Devices: Implants vs Diagnostic Tools

Magnesium brings unique benefits to medical applications through biodegradable implants that dissolve safely without surgery. Aluminum finds its place in hospital equipment, medical carts, and diagnostic devices.

Comparison Table

| Characteristic | Magnesium Die Casting | Aluminum Die Casting |

|---|---|---|

| Physical Properties | ||

| Density | 1.74 g/cm³ | 2.70 g/cm³ |

| Tensile Strength | 150-200 megapascals | >270 megapascals |

| Thermal Conductivity | 96 W/mK (AZ31B alloy) | Superior to magnesium |

| Corrosion Resistance | Lower, needs protective coating | Higher, natural oxide layer protection |

| Manufacturing Process | ||

| Casting Method | Hot chamber | Cold chamber |

| Cycle Time | 15-20 minutes, 400-900 cycles/hour | 50-90 cycles/hour |

| Wall Thickness | 1.5-3 mm uniform thickness | Higher minimum thickness |

| Surface Finish | Superior, often uncoated | Needs more post-processing |

| Economic Factors | ||

| Raw Material Cost | $3.00-$6.00 per kg | $2.00-$4.00 per kg |

| Tool Life | 2-3 times longer than aluminum | Shorter than magnesium |

| Recyclability | 5% energy of primary production | 5% energy of primary production |

| Key Applications | ||

| Automotive | Seat frames, steering wheels, door handles | Engine blocks, transmission cases, body panels |

| Aerospace | Non-structural components, seat frames | Structural components, fuselage panels |

| Electronics | EMI shielding, laptop frames, phone frames | Heat sinks, housing cases |

| Performance Characteristics | ||

| Weight Reduction | 35% lighter than aluminum | Base reference |

| Machinability | Excellent, up to 5000 ft/min cutting speed | Lower than magnesium |

| Dimensional Accuracy | ±0.1 mm tolerance | Not specified |

Conclusion

The choice between magnesium and aluminum for die casting projects depends on your specific needs – there’s no clear winner. Magnesium weighs 35% less than aluminum (1.74 g/cm³ vs 2.70 g/cm³), making it ideal for weight-critical applications in automotive and aerospace sectors. Aluminum makes up for this with better tensile strength, corrosion resistance, and heat conductivity.

These metals need different manufacturing approaches. Magnesium offers faster solidification, better surface finishes, and lets you create thinner, more precise walls. You’ll see production gains despite magnesium’s higher cost ($3.00-$6.00 per kg vs aluminum’s $2.00-$4.00 per kg). Magnesium’s tooling lasts 2-3 times longer than aluminum’s, which helps offset the original cost difference.

Both metals excel in different industries. Magnesium works best where weight reduction boosts performance, like in car seat frames and electronic device cases. Aluminum remains the top pick for parts needing more strength, better heat dissipation, and natural corrosion resistance – think engine blocks and heat sinks.

The environmental aspect adds another layer to consider. Both metals can be recycled forever, but magnesium production creates more emissions. Recent manufacturing improvements have narrowed this gap substantially.

Your choice between magnesium and aluminum should balance weight needs, mechanical properties, production efficiency, budget, and environmental impact. Companies like Ningbo Jiehuang Chiyang, with their complete metal parts solutions including die casting, can guide you through these material choices. Whatever metal fits your application best in 2025, knowing these key differences will give you optimal component design and performance.

Key Takeaways

Understanding the fundamental differences between magnesium and aluminum die casting helps manufacturers make informed material choices based on specific application requirements and performance priorities.

• Magnesium offers 35% weight reduction over aluminum (1.74 vs 2.70 g/cm³), making it ideal for weight-critical automotive and aerospace applications.

• Aluminum provides superior strength and durability with higher tensile strength (>270 vs 150-200 MPa) and natural corrosion resistance through oxide layer formation.

• Magnesium enables faster production cycles with 400-900 cycles/hour vs aluminum’s 50-90 cycles, plus superior surface finish requiring less post-processing.

• Cost considerations favor aluminum initially at $2-4/kg vs magnesium’s $3-6/kg, but magnesium tooling lasts 2-3 times longer, offsetting some expenses.

• Application-specific selection is crucial – choose magnesium for weight-sensitive components like seat frames and electronics housings, aluminum for high-strength parts like engine blocks and heat sinks.

The optimal choice depends on balancing weight requirements, mechanical properties, production efficiency, and cost constraints rather than declaring one material universally superior. Both metals offer unique advantages that make them valuable for different manufacturing scenarios in 2025.

FAQs

Q1. What are the main differences between magnesium and aluminum in die casting? The key differences include density (magnesium is 35% lighter), strength (aluminum is generally stronger), corrosion resistance (aluminum is superior), and manufacturing processes (magnesium uses hot chamber casting while aluminum uses cold chamber).

Q2. Which material is better for automotive applications? It depends on the specific component. Magnesium is preferred for weight-critical parts like seat frames and steering wheels, while aluminum is commonly used for engine blocks and body panels due to its strength and cost-effectiveness.

Q3. How do the costs of magnesium and aluminum die casting compare? Magnesium is typically more expensive, with raw material costs of $3-$6 per kg compared to aluminum’s $2-$4 per kg. However, magnesium offers faster production cycles and longer-lasting tooling, which can offset some costs over time.

Q4. What are the environmental considerations when choosing between magnesium and aluminum? Both metals are infinitely recyclable, but magnesium production generally has higher emissions. Recent advancements have reduced this gap, and magnesium’s lighter weight can lead to fuel savings in transportation applications, potentially offsetting its higher production emissions.

Q5. How do magnesium and aluminum compare in terms of machinability and surface finish? Magnesium offers superior machinability with higher cutting speeds and less tool wear. It also provides an excellent surface finish that often doesn’t require additional coating, unlike aluminum which typically needs more post-processing.