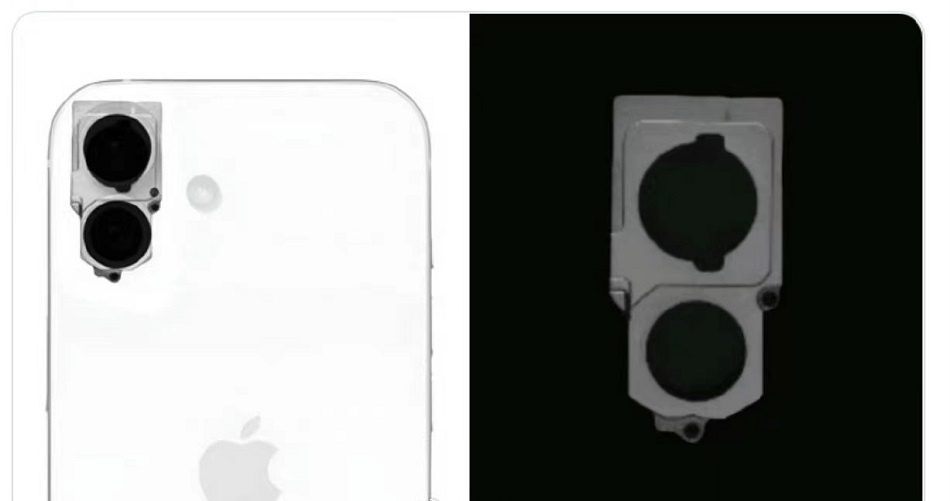

Metal Injection Molding (MIM) is a kind of metal powder and organic binder mixture, through injection molding technology to make the desired shape of the near-clean blank, and then through degreasing, sintering, and other post-processing process to remove organic components, and finally get a certain strength and precision of metal products molding process. Some of the advantages of the iPhone 16 camera module produced by the MIM process and the reasons for choosing this process:

MIM process advantages:

1. High precision and complex structure: The MIM process can achieve high precision and complex structure molding, and the small and complex structure of the camera parts can be accurately copied through this process.

2. Material performance: The MIM process can use a variety of metal powders, such as stainless steel, titanium alloy, etc., these materials have good wear resistance, corrosion resistance, and electromagnetic shielding properties, suitable for the use of camera parts in the environment.

3. Near-net forming type: MIM process can achieve near-net forming type, reduce subsequent machining, and reduce costs and processing time.

4. Mass production: The MIM process is suitable for mass production, which can improve production efficiency and reduce costs, and adapt to the large demand for camera parts in the smartphone market.

5. Design freedom: Because the MIM process can achieve the formation of complex structures, designers have greater freedom when designing camera parts, and can design more unique and innovative products.

Reason for selection :

1. Meet the needs of high precision and complex structure: The structure of the iPhone 16 camera module is complex and requires high precision, and the MIM process can meet these needs. It can realize the vertical positioning of the iPhone camera

2. Excellent material performance: The metal materials used in the MIM process have good wear resistance, corrosion resistance, and electromagnetic shielding properties, which are crucial for camera components.

3. Reduce production costs: The MIM process can achieve near-net formation and mass production, which helps to reduce production costs and improve product competitiveness.

4. Adapt to market demand: With the continuous development of the smartphone market, the demand for camera components is also increasing. The choice of MIM process can meet the market demand for a large number of high-quality camera components.

The metal injection molding process was selected for the production of iPhone 16 camera module components due to its high precision, complex structural molding capabilities, superior material properties, near-net formation, and mass production advantages. This process can not only meet product performance requirements but also effectively reduce production costs and adapt to changes in market demand.