What are interchangeable inserts in metal injection molding?

JH MIM, have 15 years of experience in the production of metal injection molding parts. We often encounter the situation of producing two or more very similar products, for example, one has a logo, while the other two have no logo; one with holes, one without holes, etc… To save the cost of mold design and mold manufacturing, JH MIM’s mold engineers will work in the mold design stage. From the customer’s perspective, it provides users with a faster and lower-cost mold design model – interchangeable molding inserts.

Why produce molds with interchangeable mold inserts?

In manufacturing, the ability to quickly adapt to changing production needs is critical. This is where insert molding comes into play. This innovation provides solutions that increase the flexibility, efficiency, and cost-effectiveness of the manufacturing process.

Advantages of mold inserts:

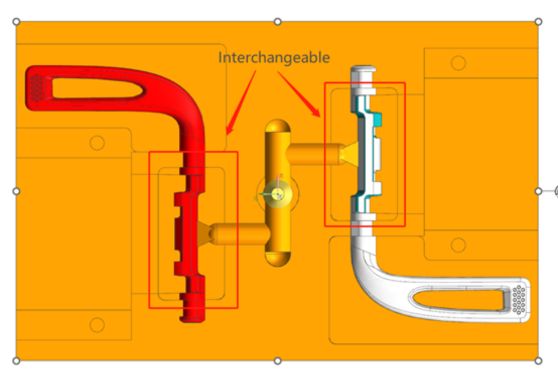

Interchangeable insert molded are removable components that can be easily interchanged within a mold to produce products of different shapes, sizes, or configurations. Traditionally, manufacturers had to create individual molds for each product, resulting in increased costs and a time-consuming process. However, with interchangeable mold inserts, manufacturers can quickly and easily replace inserts in a single mold, allowing for the rapid production of different product variations.

One of the main benefits of interchangeable molding inserts is their ability to enhance manufacturing flexibility. By using a single mold with interchangeable inserts, manufacturers can produce a variety of product designs without the need for multiple molds. This flexibility enables faster responses to market demands and enables manufacturers to easily introduce new product variants or customizations.

Improve efficiency. With traditional injection molds, going from one product change to another requires disassembling, cleaning, and reassembling the mold, a time-consuming and costly process. However, the process can be simplified using an insert mold. Manufacturers can simply replace the blades, significantly reducing downtime and increasing productivity.

This also speeds up prototyping and testing, allowing manufacturers to quickly iterate and refine their product designs.

Using injection molded inserts can help save costs during the manufacturing process. By eliminating the need for multiple molds, manufacturers can reduce mold costs and save storage space. Additionally, the ability to quickly make product changes allows for better inventory management because manufacturers can produce products on demand, reducing the risk of overproduction or obsolete inventory. These cost-saving advantages make replaceable injection molding tools an attractive option for manufacturers looking to optimize their production processes.

Interchangeable insert molding process

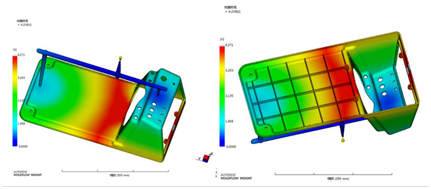

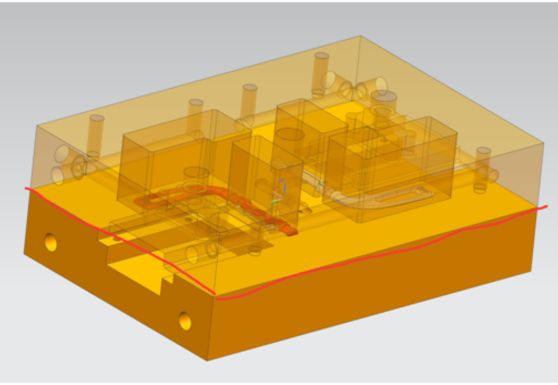

- Mold design and provision of DFM report. Including injection analysis, mold flow analysis, gate design, and parting line design of metal injection molds. Draft angle analysis, etc.

Mold flow analysis

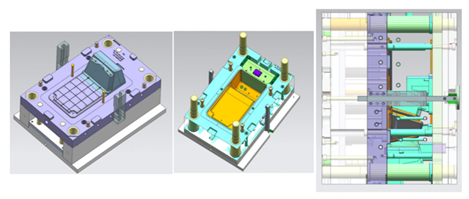

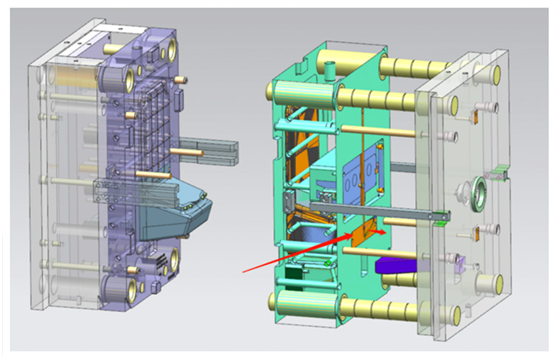

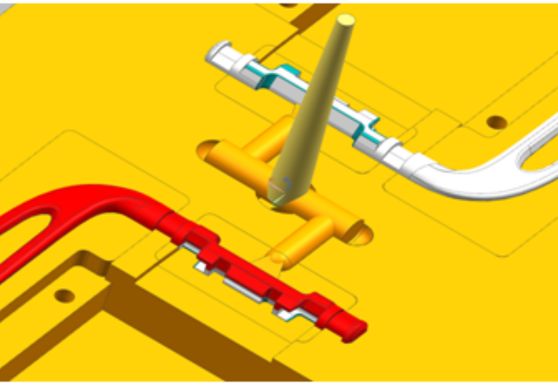

- Inset molding manufacturing. These include mold core making, EDM, slider making, etc.

- Fit the mold and polish the mold.

- Insert moulding assemble and test samples, including installation testing of replaceable

Actual case

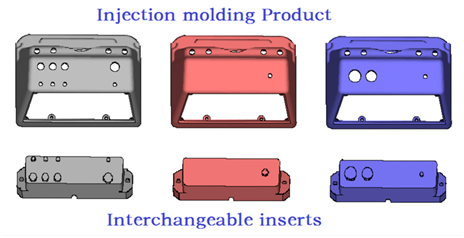

JH MIM can use interchangeable inserts to manufacture products with similar product structures, saving costs for buyers.

Mass production case:

This project is a MIM mold we made for a German customer. It ended up producing two structural products of MIM316L with a similarity of 80%.

Downloaded is the mold design drawing. Just by replacing the interchangeable inserts of the mold, customers can save 80-90% of the mold cost.

In summary, interchangeable insertion molding offers a game-changing solution for manufacturers looking to increase the flexibility, efficiency, and cost-effectiveness of their production processes. By enabling quick and easy interchangeability within a single mold, these inserts enable manufacturers to produce a variety of products without using multiple molds. This means faster response times, greater efficiency, and cost savings. As manufacturing continues to evolve, interchangeable mold inserts will play a vital role in driving manufacturing process innovation and productivity.

JH MIM has rich experience and a professional engineering team. We can provide you with metal injection molding molds and product support with less cost and time.