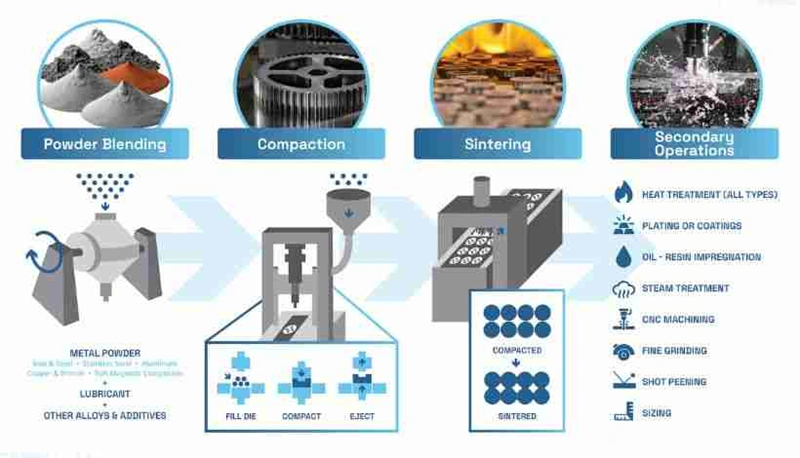

Titanium sintering process cuts powder production costs by over 70% compared to traditional atomized powder methods. This budget-friendly manufacturing technique reshapes the scene of titanium component production. Press and sintering give manufacturers a practical way to meet performance standards in many applications.

Sintered titanium’s benefits go well beyond saving money. These materials’ porous nature helps create lightweight designs with better surface area and filtration properties. The sintering process cuts down material waste when compared to regular manufacturing methods. Traditional machining wastes up to 90% of the original titanium stock through time-consuming and expensive cutting – a step that processes like direct metal laser sintering eliminates completely. The HSPT (Hydrogen Sintering Phase Transformation) process shows great promise to produce high-performance titanium alloys at much lower costs, which opens up new uses in industries of all types.

Powder Morphology and Its Role in Cost Reduction

Powder characteristics are key factors that determine how cost-effective and efficient the titanium sintering process will be. The type of powder you choose affects your production costs, sintering behavior, and the final product’s properties.

Irregular vs spherical particles in sintered titanium

The shape of titanium powder makes a big difference in manufacturing costs and material properties. Spherical particles pack better, flow easier, and create smoother surfaces with evenly distributed pores. These benefits come at a higher price tag. Irregular-shaped particles cost less but have lower creep strength and bulk density. The irregular shapes help powder particles bind better in the green state, which works great for conventional pressing and sintering. Spherical powders show better mechanical properties, but irregular powders are more biocompatible – this matters a lot for medical uses.

Impact of particle size on flowability and tooling wear

The size of particles affects how well your production runs and how long your tools last. Particles smaller than 100μm stick together more and don’t flow as freely as bigger, denser ones. This creates problems during compaction. Small particles can get stuck between the punch and die interfaces and might cause your tools to lock up. Manufacturers try to fix this by reducing die-punch clearance, but this gets tricky with high compaction pressures. That’s why fine powders work better with low compaction pressure. Getting these settings right helps cut manufacturing costs by making tools last longer and processes run smoother.

Why TiH2 is preferred in cost-sensitive applications

TiH2 has changed the game for budget-friendly titanium manufacturing. This powder costs much less than pure titanium powder because it’s an intermediate product in the hydrogenation-dehydrogenation process. TiH2 saves you money throughout the sintering process too. The hard, brittle TiH2 particles break and rearrange during compaction. This gives you high green density and fewer issues with friction and cold welding compared to pure titanium. As it heats up, TiH2 releases hydrogen, which helps with densification and reduces oxygen levels. Smaller TiH2 particles release hydrogen faster thanks to their bigger surface area. This leads to lower sintering temperatures and finer grain structures. The result? Better mechanical performance at a much lower cost.

Green Strength Optimization Using Lubricants

Good lubrication plays a vital role in titanium sintering. It affects manufacturing costs and the quality of final products. The right choice and use of lubricants can boost green strength while keeping the purity needed for high-performance parts.

Internal vs die wall lubrication in titanium compaction

Titanium’s high reactivity makes choosing the right lubrication methods challenging. Die wall lubrication is the preferred method for titanium in lab settings because it stops chemical contamination that would hurt mechanical properties. The original manufacturers used admixed lubricants. These added impurities like carbon and oxygen that titanium quickly absorbed, which led to much lower ductility and fatigue strength.

Stearate-based lubricants applied directly to carbide die walls cut down ejection friction without hurting material quality. Research comparing internal and die wall lubrication showed something unexpected. In stark comparison to this common belief, internal lubrication produced the highest densities despite concerns about contamination. Each application needs careful evaluation to resolve this paradox.

Effect of warm die compaction on green strength

Warm die compaction makes green strength much better. This is a big deal as it means that components stay intact before sintering. The technique doubles green strength when using lower compaction pressures (200 MPa) compared to standard methods. Compacts with 1.5% lubricant show the best strength improvement. Those with 1% lubricant show modest gains of 20-30% across all compaction levels.

You can get enough handling strength (above 5 MPa) using different combinations of pressure and lubricant percentage. This gives manufacturers room to adjust production settings based on cost and performance needs. They can often use less compaction pressure while keeping part quality intact.

Lubricant removal and its impact on titanium purity

Getting rid of lubricants completely is the toughest challenge in titanium powder metallurgy production. Leftover lubricant creates carbon deposits that hurt the final component’s properties. Common lubricants like Acrawax C™ (an N,N’ ethylene bis-stearamide-based synthetic wax) need careful temperature control between 350°F to 1,000°F (177°C to 537°C) to be removed properly.

Temperatures outside this range lead to soot formation, causing carbon contamination inside and out. Titanium grabs onto impurities, so even tiny amounts of residue can cause problems. The atmospheric conditions must be exact. This includes controlled moisture levels that mix with carbon to create hydrogen and carbon monoxide, which burn away in the sintering atmosphere. Careful control helps manufacturers achieve better properties, including 18% higher transverse rupture strength and 6.3% more hardness.

Sintering Parameters That Influence Final Cost

The right selection of sintering parameters helps control costs in the titanium sintering process. Companies can save money through precise control of temperature, shrinkage, and hydrogen dynamics.

Sintering temperature vs densification efficiency

Temperature choice affects energy use and final product quality. Manufacturers achieve an impressive 99.5% relative density at 1150°C. This temperature is much lower than traditional sintering methods that need temperatures above 1300°C. TiH2 powder reaches 96.5-99% densification even at 1150°C, making it an economical choice. The powder’s unique properties mean compaction pressure becomes less important. Complex components can densify evenly with a single punch movement.

Shrinkage behavior and dimensional control

Products need predictable dimensional changes to meet tight tolerances without expensive secondary operations. Linear dimensional change changes smoothly with compaction pressure when using quality powders. Milled powders show more erratic behavior. TiB2 additions make shrinkage happen faster through local melting. This needs careful monitoring to stop cracks from forming.

Hydrogen removal in titanium melting process

Hydrogen plasma arc melting removes oxygen from titanium and meets industry standards in just eight minutes. This method cuts the titanium sponge vacuum separation time by 30% and saves 1000-1400 kWh of power. The recycled titanium alloys show 24.6% higher tensile strength and 90.5% better elongation compared to standard casting.

Cost Savings from Process Efficiency and Material Utilization

Material efficiency stands as a key economic benefit of the titanium sintering process. This process eliminates the wasteful 90% material removal seen in conventional manufacturing.

Reduced machining due to near-net shape

Near-net shape manufacturing changes the “buy-to-fly” ratio dramatically. This ratio shows how much raw material becomes the final component. Traditional titanium manufacturing wastes 90% of material, needing a 10:1 ratio. Powder metallurgy methods use more than 97% of the starting material, which cuts both material and machining costs. The WAAM process saves up to 220 kg of titanium per component. The HSPT (hydrogen sintering phase transformation) process takes these benefits further and reduces overall manufacturing costs by 80-90%.

Lower compaction pressure and tool longevity

TiH2 powder shows unique compaction behavior and needs less pressure to achieve high green density. This brittle material breaks and rearranges during compaction, which leads to better die filling and density distribution. Manufacturers achieve 95-98% theoretical density with modest pressures between 200-800 MPa. Tools last longer as a result. This matters because tool costs make up 60% of manufacturing expenses.

Achieving >99% density with minimal post-processing

Several methods now help titanium components reach near-full density without extensive secondary operations. Pressureless sintering at 1300°C creates densities above 99%. Two-step pressureless sintering produces 99.0% density and a refined grain structure. Field Assisted Sintering Technology (FAST) creates ultra-high-density components at lower temperatures than conventional methods. These advances create quick, one-step processing routes that save manufacturing time while keeping excellent mechanical properties.

Conclusion

Titanium sintering technology brings a 40% cost reduction through several connected benefits. The right powder choice, especially TiH2 for cost-sensitive needs, cuts down original material costs but keeps the performance intact. On top of that, it optimizes green strength through proper lubrication that protects structural integrity during processing without affecting product purity.

Smart control of sintering parameters leads to even more savings. The process needs only 1150°C to achieve excellent densification, which uses nowhere near the energy of older methods that need 1300°C or more. This gives manufacturers lower energy bills and better material properties.

The biggest advantage comes from near-net shape capabilities. Old titanium manufacturing methods waste about 90% of raw materials. Modern sintering employs over 97% of the starting material. These savings help both the bottom line and the environment.

JH MIM shows how these technical benefits create ground success in manufacturing. With almost 20 years in powder metallurgy, they deliver precision-engineered products to customers worldwide that illustrate what titanium sintering can do.

New breakthroughs like HSPT and FAST technologies will without doubt boost the economical production of titanium parts. These advances make titanium viable in aerospace, medical, automotive, and consumer products where cost was once too high. Titanium sintering has become more than just another manufacturing method – it’s changing how industries build high-performance metal components.

Key Takeaways

The titanium sintering process revolutionizes manufacturing economics by dramatically reducing costs while maintaining high-performance standards through optimized material utilization and process efficiency.

• TiH2 powder reduces material costs by 70% compared to traditional atomized titanium powder while enabling lower sintering temperatures and superior densification.

• Near-net shape manufacturing eliminates 90% material waste typical in conventional machining, achieving >97% material utilization versus traditional 10% efficiency.

• Optimized sintering at 1150°C achieves 99.5% density while consuming significantly less energy than conventional methods requiring temperatures above 1300°C.

• Die wall lubrication prevents contamination while warm compaction doubles green strength at lower pressures, extending tool life and reducing equipment costs.

• Lower compaction pressures with TiH2 extend tooling lifespan significantly, as tool costs typically represent 60% of total manufacturing expenses.

The combination of advanced powder selection, precise parameter control, and near-net shape capabilities makes titanium components economically viable across aerospace, medical, and automotive applications that were previously cost-prohibitive.

FAQs

Q1. How does titanium sintering reduce manufacturing costs? Titanium sintering can cut manufacturing costs by up to 40% through improved material utilization, lower energy consumption, and reduced machining. The process achieves near-net shape production, utilizing over 97% of the starting material compared to traditional methods that waste up to 90%.

Q2. What are the advantages of using TiH2 powder in titanium sintering? TiH2 powder offers significant cost benefits, reducing material expenses by up to 70% compared to traditional atomized titanium powder. It also enables lower sintering temperatures, superior densification, and requires less compaction pressure, extending tool life and improving overall process efficiency.

Q3. How does the sintering temperature affect the final product? Optimal sintering temperatures around 1150°C can achieve 99.5% relative density, which is significantly lower than conventional methods requiring temperatures above 1300°C. This results in energy savings and improved material properties, contributing to overall cost reduction.

Q4. What role does lubrication play in the titanium sintering process? Proper lubrication is crucial for optimizing green strength and maintaining product purity. Die wall lubrication is preferred for titanium to prevent chemical contamination, while warm compaction techniques can double green strength at lower pressures, extending tool life and reducing equipment costs.

Q5. Is titanium sintering suitable for complex component manufacturing? Yes, titanium sintering is well-suited for producing complex components. The process allows for near-net shape manufacturing, reducing the need for extensive machining. Additionally, techniques like Field Assisted Sintering Technology (FAST) can produce ultra-high density components with excellent mechanical properties, making it viable for various industries including aerospace, medical, and automotive.