Timing chain sprocket technology has seen remarkable development in the last few years. The industry has moved from traditionally machined cast iron sprockets to sintered powdered metal versions. This advancement represents a major breakthrough in engine component engineering. The new manufacturing process eliminates extra machining steps and produces closer tolerances between components.

Timing chain sets cost much more than belt systems at both OEM and aftermarket levels. Belt applications have steadily declined in the last two decades despite this price difference. Engineers must analyze both material properties and manufacturing techniques to understand worn timing chain sprocket problems. Most mechanics recommend replacing the complete timing chain kit with sprockets instead of individual components. This ensures proper synchronization. JH MIM’s nearly 20 years of experience in Metal Injection Molding and Powder Metallurgy helps deliver precision-engineered products to customers worldwide.

This piece details how sintered timing chain sprockets perform better than their cast iron counterparts. The analysis covers manufacturing processes, performance characteristics, maintenance needs, and future developments in sprocket technology comprehensively.

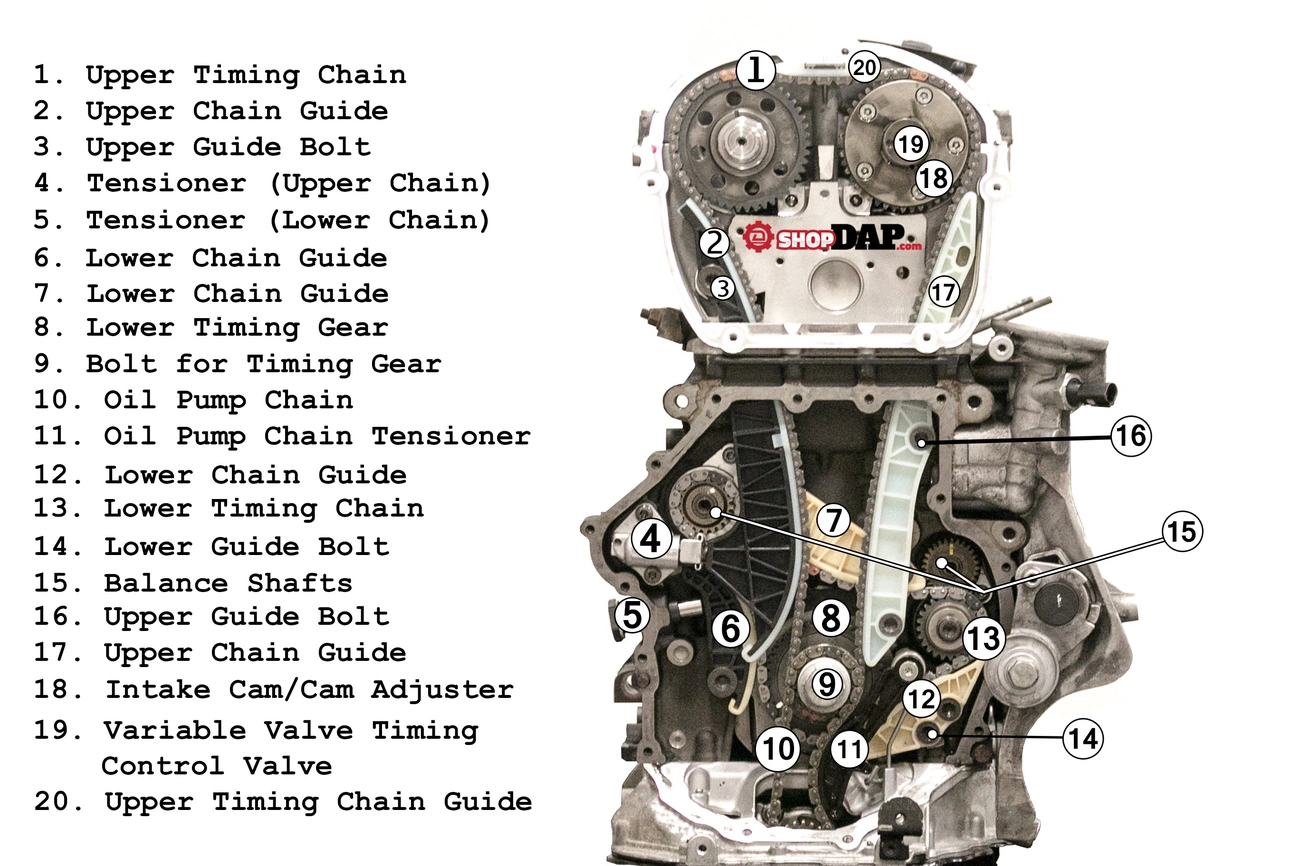

Role of Timing Chain Sprockets in Engine Synchronization

Timing chain sprockets play a vital role in piston engines by synchronizing the rotation of the crankshaft and camshaft. These precision components are the foundation of proper engine operation and ensure valves open and close at exactly the right moment relative to piston position.

Camshaft and Crankshaft Coordination Explained

Engineers call the camshaft and crankshaft “the most famous partnership in the 4-stroke engine world”. These components work together in a synchronized system that optimizes power and efficiency. The timing chain sprocket system links these parts and maintains a precise 2:1 ratio. The crankshaft makes two complete turns while the camshaft makes one full rotation. This happens because four-stroke engines need valves to open and close every other revolution of the crankshaft.

Each cylinder’s valve openings occur about one-fifth of a second apart when the engine idles. This interval drops to about two-hundredths of a second when the engine reaches 5,000 RPM. Even small timing issues can substantially affect engine performance.

Timing chain sprockets transfer rotational force from the crankshaft to the camshaft through their precisely engineered teeth. These parts control when intake valves open and close relative to piston position. They also manage ignition timing, fuel delivery, and engine start-up sequences.

Impact of Sprocket Wear on Valve Timing Accuracy

Timing chains stretch, and sprockets wear down after long periods of use. This wear affects the engine’s timing precision. Worn timing chain sprockets lose their ability to keep the crankshaft and camshaft components in sync.

Worn timing chain sprockets lead to:

- Changes in valve timing relative to piston position

- Lower combustion efficiency and power output

- Higher fuel consumption and emissions

- Engine misfires, backfires, or complete failure

- Starting problems

A worn crankshaft sprocket can cause valves to open at the wrong times. This reduces the air and fuel mixture entering the cylinder. Poor mixing creates partial combustion and reduces power output. Loose valves from worn sprockets also lower cylinder compression pressure, which hurts combustion efficiency.

Most modern vehicles use “interference engines” where valves and pistons share the same space at different times. These engines can suffer catastrophic damage if the timing system fails. Lost synchronization lets valves hit pistons, causing severe internal damage. This risk of expensive repairs shows why proper timing chain sprocket maintenance matters.

JH MIM brings nearly 20 years of powder metallurgy and metal injection molding expertise to produce precision-engineered timing chain sprockets. Their sprockets maintain critical tolerances throughout their service life. The company’s manufacturing expertise helps ensure these essential engine components remain reliable long-term.

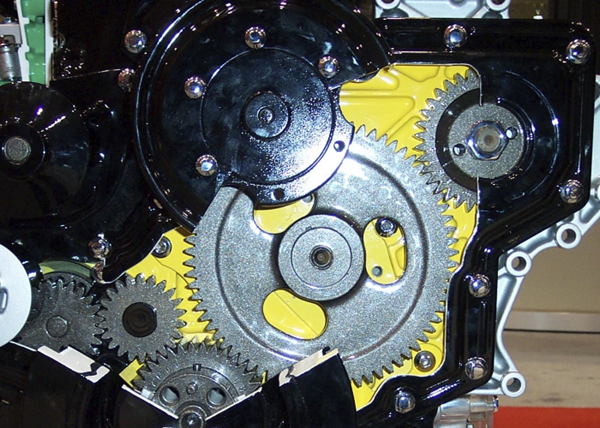

Cast Iron Sprockets: Traditional Manufacturing and Limitations

Traditional cast iron timing chain sprockets are still common in many engine designs. These sprockets have unique properties that make them ideal for specific applications. Their manufacturing process, failure modes, and performance characteristics show both advantages and limitations compared to newer materials.

Machined Cast Iron: Process Overview

Cast iron sprockets usually start with green sand or shell molding processes before precise machining. The manufacturing experience begins by creating the simple sprocket form through casting. CNC machining then helps achieve the final dimensions and tooth profiles. Gray iron’s natural machinability lets manufacturers create complex, highly customized designs quickly and cost-effectively.

Most foundries only do simple metal casting, so customers need to find third-party CNC machine shops to finish the process. In spite of that, facilities that combine casting and machining are a great way to get advantages. They reduce transportation between locations, minimize delays, and shorten overall lead times from raw material to finished product.

Quality control measures ensure dimensional accuracy and structural integrity during production. These combined manufacturing solutions also eliminate logistical complications that could arise from coordinating multiple manufacturers.

Common Failure Points in Cast Iron Sprockets

Cast iron timing chain sprockets show several common failure modes despite their widespread use. The biggest problem involves chain stretch, which usually results from poor lubrication. The chain’s rollers and links wear against each other excessively when engine oil maintenance is neglected.

There’s another reason for failure that occurs when slack develops in the system. This allows the chain to ride up the sprocket and potentially stretch or break it completely. The timing chain tensioner works as the system’s heart—complete system failure becomes inevitable without proper tension.

NVH Reduction vs. Durability Trade-offs

Cast iron provides excellent vibration-damping characteristics. This makes it valuable, especially when you have to reduce noise, vibration, and harshness (NVH) in engine applications. This natural dampening represents one of cast iron’s key advantages over other materials.

Cast iron offers superior noise reduction but has durability limitations compared to steel components. Engineers must balance NVH performance against longevity needs. Cast iron remains a budget-friendly solution for moderate load applications like industrial pumps and compressors, even with its lower durability.

Severe chain noise often occurs around resonant engine speeds, particularly with dual-mass flywheel systems and standard build solid balancer drive sprockets. Torsional oscillation at the crankshaft nose under full load creates unwanted impact noise during chain-sprocket meshing.

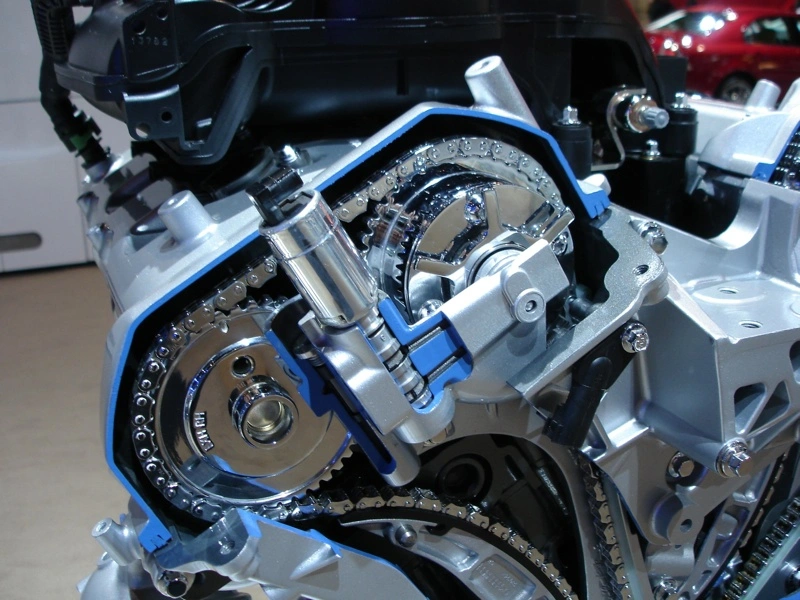

Sintered Sprockets: Powder Metallurgy and MIM Advantages

Powder metallurgy represents a major step forward in timing chain sprocket manufacturing. This technique creates properties that conventional casting methods cannot achieve. Modern engine designs now commonly use this approach because it offers better performance through precise material control.

Sintering Process in Timing Chain Sprockets

The sintering process starts with fine metal powders (typically less than 20 micrometers) mixed with binding agents. High-pressure compaction forms the simple sprocket shape. These “green” components then heat up below the metal’s melting point in controlled atmospheres. Metal atoms move across particle boundaries at these higher temperatures. This solid-state diffusion creates a cohesive microstructure. Manufacturers can achieve sintered densities over 6.7 g/cm³ and tooth profile accuracies better than ISO grade 8 for timing chain sprockets.

Dimensional Accuracy from Metal Injection Molding

Metal Injection Molding (MIM) delivers unmatched dimensional precision for complex sprocket geometries. MIM parts have dimensional tolerances of ±0.05 mm to ±0.10 mm. Some applications can even achieve tolerances as tight as ±0.01mm. Parts shrink by 15-20% after sintering. Engineers can design molds precisely because this shrinkage is predictable. Sizing operations can improve dimensional accuracy to IT6-IT7 for critical applications. Small parts can achieve tolerances as tight as ±5 μm.

Material Density and Strength Improvements

Sintered sprockets show remarkable mechanical properties compared to cast components. Surface hardness can reach HRC 60 or above. This provides excellent wear resistance. High-density sintering processes achieve core densities up to 7.0-7.4 g/cm³. Tooth flank densities can reach 7.8 g/cm³ through surface densification methods. Such density profiles boost both bending fatigue resistance and contact fatigue strength.

JH MIM’s advanced sintering processes, backed by nearly 20 years in powder metallurgy, have produced sprockets with endurance strength over 300 MPa. This is a big deal as it means that it doubles conventional products’ strength. These improvements lead to better performance characteristics. Benefits include 10-15% weight reduction, reduced meshing clearance, and tooth profile accuracy errors below 0.02mm. These changes streamline processes and reduce energy losses.

Performance Comparison: Sintered vs Cast Iron Sprockets

A direct comparison between sintered and cast iron timing chain sprockets reveals notable differences in longevity, operational characteristics, and overall value. These differences stand out in modern high-performance engines.

Wear Resistance in High RPM Conditions

Lab tests show that standard powder metallurgy (PM) sprockets with 6.8 g/cm³ density serve as the baseline for wear resistance measurements. High-density PM sprockets (7.2 g/cm³) show about 30% better wear resistance. The carburized PM versions perform even better with 60% improved wear resistance compared to standard options. Sintered hard iron bearings have a hardness of 45-50 Rc, while cast hard iron bearings measure 55-60 Rc. This difference explains why cast versions last longer than sintered components in very abrasive applications.

Thermal Expansion and Fatigue Resistance

Powder metallurgy components have a basic limitation due to their porosity, which can create crack initiation sites. Manufacturers tackle this issue through reduced pore size, increased material density, and specialized alloying elements. Both tensile strength and fatigue strength increase almost linearly with sintered density. The structured porosity of sintered components proves beneficial for timing chain applications that need thermal stability. These components can handle thermal expansion without distortion.

Noise and Vibration Characteristics

Conveyor trough noise mainly comes from impact forces that occur during the chain system and sprocket meshing. Cast iron components dampen vibrations well, which helps reduce noise and harshness. Sintered components provide better dimensional accuracy that minimizes the polygonal effect—a major source of chain drive noise. Field tests show that a 10 dB reduction in cab noise can optimize operator efficiency by over 25%.

Cost Efficiency Over Lifecycle

Sintered sprockets might cost more upfront than cast iron options. However, they need replacement three times less often than cast versions in demanding applications. Data shows that conveyor troughs under severe vibration have about 40% shorter chain service life compared to those running smoothly. High-quality materials from experienced manufacturers like JH MIM ensure reliable performance throughout the sprocket’s extended service life.

Failure Modes and Maintenance Considerations

Early detection of timing chain sprocket failures helps you avoid engine repairs that can get pricey. The right maintenance approach extends your component’s life, especially for critical synchronization systems.

Bad Timing Chain Sprocket Symptoms in Interference Engines

Interference engines suffer catastrophic damage if timing components fail. You’ll notice warning signs like rattling noises during cold starts, engine misfires, and metal shavings in engine oil. The valves and pistons share the same space at different times, which makes component collision inevitable if the timing chain fails.

Timing Chain Fell Off Sprocket: Why It Happens

A failed tensioner usually leads to chain displacement. Regular wear, maximum capacity operation, and poor oil maintenance create additional problems. The chain develops damaging slack in the system and eventually jumps teeth or completely detaches.

Using a Timing Chain Sprocket Removal Tool Safely

The right tools help prevent damage during removal. Specialty pullers with full thread engagement work best to minimize risks for crankshaft sprockets. You should never hit the crankshaft end or use the crankshaft pulley bolt to force sprocket removal – these methods can damage thrust tolerances.

When to Replace: Worn Timing Chain Sprocket Indicators

Replace components after:

- Visible chain stretch or tensioner wear

- Persistent rattling sounds

- Metal particles in oil

- Check engine light that indicates camshaft/crankshaft correlation issues

Timing Chain Kit with Sprocket: What to Look For

Experienced manufacturers like JH MIM offer complete kits to ensure all interdependent parts work together. Quality kits come with chains, tensioners, guides and sprockets designed to maintain precise synchronization.

Future Trends in Timing Sprocket Engineering

Automotive timing systems continue to evolve faster as manufacturers work toward greater engine efficiency and improved durability. These breakthroughs change how manufacturers design and produce timing chain sprockets.

Integration with Camshaft Sensors and Reluctor Wheels

Modern engines depend heavily on precise crankshaft position data that reluctor wheels transmit—toothed rings working with magnetic sensors identify the exact crankshaft position. Late model LS engines use either 24-tooth (Gen III) or 58-tooth (Gen IV) reluctor wheels. The 58-tooth version provides more precise crank position data. Technicians must heat the reluctor to approximately 450°F to achieve a proper interference fit without component damage. Professional technicians now use specialized indexing tools that arrange the wheel precisely to the crankshaft because of these complexities.

Material Innovations in Powder Metallurgy

Powder metallurgy creates net-shape parts with precise tooth profiles, high core strength, and exceptional wear characteristics. Materials science breakthroughs allow manufacturers like JH MIM—with nearly 20 years in powder metallurgy—to customize density and strength for specific applications. This customization creates optimal weight-to-strength ratios while making parts more durable.

OE Design Alignment and Aftermarket Challenges

Variable valve timing components create unique engineering challenges that require specialized knowledge of VVT, cam phasers, and solenoids. Hydraulic tensioners now feature internal check valves and oil screens to extend component life. These systems need increased technical education, especially when you have electronics integration .

Conclusion

This detailed analysis shows sintered timing chain sprockets have major advantages over traditional cast iron components. The rise from machined cast iron to powder metallurgy marks real progress in engine component engineering and delivers better performance in several key areas.

Material density stands out as the key difference between these manufacturing methods. Sintered sprockets reach excellent density profiles up to 7.4 g/cm³ at their core, while tooth flank densities hit 7.8 g/cm³ through surface densification. These improved densities lead to exceptional mechanical properties, with surface hardness values reaching HRC 60 or above.

Dimensional accuracy sets sintered components apart from cast versions. Metal Injection Molding hits tolerances as tight as ±0.05 mm and creates precise tooth profiles with errors below 0.02mm. This precision reduces the polygonal effect, which leads to less noise and vibration during operation.

Performance tests reveal clear benefits for sintered sprockets, especially at high RPMs. High-density PM sprockets last 30% longer than standard options, while carburized versions perform 60% better. On top of that, the structured porosity of sintered components helps with thermal stability and handles expansion without distortion.

Though they get pricey upfront, sintered sprockets are worth more over their lifecycle. These parts need replacement three times less often than cast alternatives in tough applications. Their precision manufacturing also reduces chain stress, which can extend the whole timing system’s life.

Whatever material you choose, good maintenance will prevent catastrophic engine damage, especially in interference engines. You can avoid expensive repairs by catching timing chain system problems early – watch for rattling noises, engine misfires, or metal shavings in oil.

The field of timing sprocket engineering keeps growing with new advances in materials science and electronic integration. Modern systems are more complex than ever, from variable valve timing to reluctor wheels and camshaft sensors, and they need specialized knowledge from both manufacturers and technicians.

JH MIM utilizes nearly 20 years of powder metallurgy experience to create precision-engineered timing components that stay accurate throughout their service life. This expertise will give reliable performance while meeting modern engine design’s tougher demands.

Sintered timing chain sprockets are the best choice for engineers who want maximum engine performance, efficiency, and reliability. Their better material properties, dimensional accuracy, and longer service life make them worth the higher upfront cost, which is why they’re the go-to option for modern automotive applications.

Key Takeaways

This engineering analysis reveals why sintered timing chain sprockets are becoming the preferred choice over traditional cast iron components in modern engines:

• Superior Material Properties: Sintered sprockets achieve 7.4 g/cm³ core density with surface hardness reaching HRC 60+, delivering exceptional wear resistance and durability.

• Precision Manufacturing Advantage: Metal Injection Molding produces tolerances as tight as ±0.05mm with tooth profile errors below 0.02mm, ensuring optimal engine synchronization.

• Enhanced Performance Under Stress: High-density sintered sprockets show 30% better wear resistance than standard options, with carburized versions performing 60% better in demanding applications.

• Long-term Cost Efficiency: Despite higher initial costs, sintered sprockets require replacement three times less frequently than cast iron alternatives, providing superior lifecycle value.

• Critical Maintenance Awareness: Early detection of timing system issues—rattling noises, engine misfires, or metal shavings in oil—prevents catastrophic damage in interference engines.

The shift from cast iron to sintered powder metallurgy represents a significant advancement in engine component engineering, offering improved performance, reliability, and efficiency that justifies the investment for modern automotive applications.

FAQs

Q1. What are the advantages of sintered timing chain sprockets over cast iron ones? Sintered sprockets offer superior wear resistance, higher material density, and better dimensional accuracy. They typically last three times longer than cast iron sprockets in demanding applications, providing better long-term value despite higher initial costs.

Q2. How do sintered sprockets improve engine performance? Sintered sprockets achieve tighter tolerances and more precise tooth profiles, which helps maintain accurate engine timing. This precision reduces noise, vibration, and wear, leading to improved engine efficiency and longevity.

Q3. What are some signs that a timing chain sprocket needs replacement? Common indicators include rattling noises during cold starts, engine misfires, metal shavings in the oil, and persistent check engine lights related to camshaft/crankshaft correlation issues.

Q4. Are sintered sprockets suitable for all types of engines? While sintered sprockets offer advantages for most modern engines, they are particularly beneficial in high-performance and interference engines where precision timing and durability are critical. However, the choice depends on specific engine design and requirements.

Q5. How is the manufacturing process different for sintered sprockets? Sintered sprockets are made using powder metallurgy techniques like Metal Injection Molding (MIM). This process allows for precise control of material composition and density, resulting in components with superior mechanical properties compared to traditional casting methods.