The powder metallurgy process is a vital part of manufacturing high-performance shock absorber pistons that determine vehicle stability and comfort. Pistons stand out as the most important components in shock absorbers. Small modifications within acceptable dimensions can substantially affect performance characteristics and production efficiency . This manufacturing approach will give consistent quality that directly shapes how shock absorbers work in ground applications.

Sintered parts from powder metallurgy deliver exceptional dimensional precision and stability across production batches . The manufacturing method makes it possible to produce components with complex geometries while maintaining high density—a must-have feature in modern shock absorber designs . Parts created through the powder metallurgy sintering process become the core elements that determine shock absorber lifespan and operational stability . The advantages of powder metallurgy process benefit manufacturers through improved precision, better material properties, and reliable performance in automotive applications. Companies like JH MIM have built unique experience over the last several years in the powder metallurgy industry. They continue to supply precision-engineered shock absorber components to global customers that ensure consistent quality and performance.

Powder Metallurgy Process in Shock Absorber Manufacturing

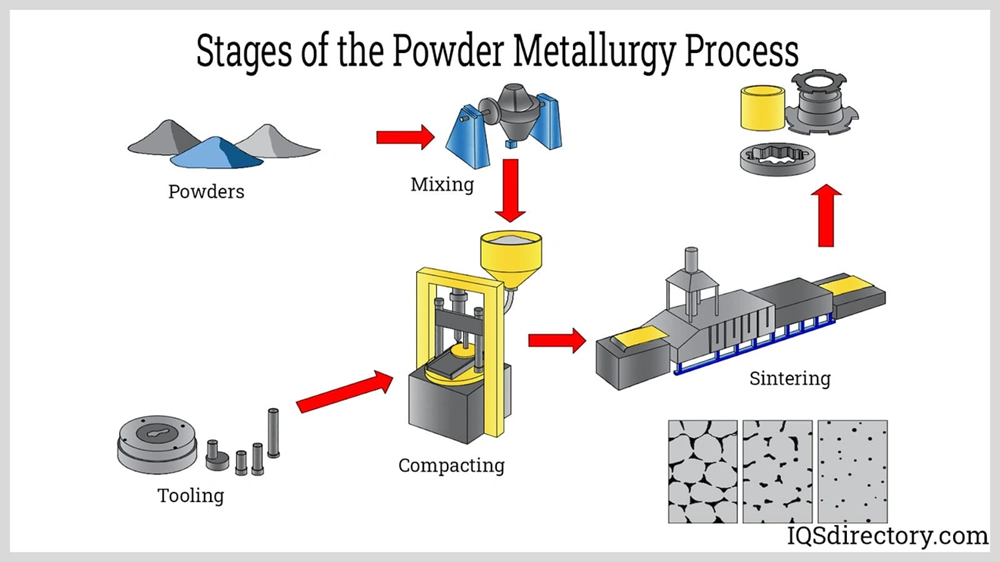

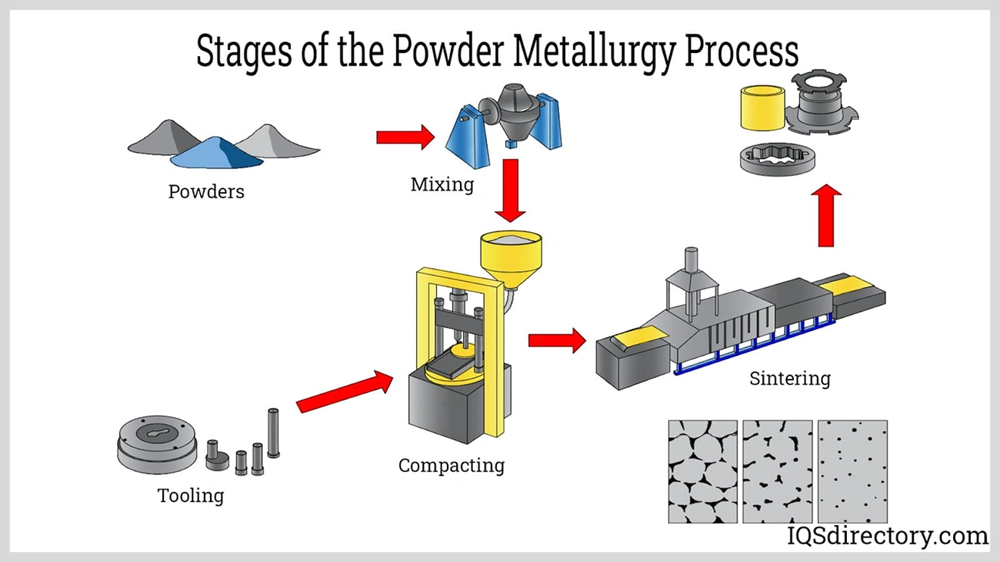

Powder metallurgy manufacturing serves as the foundation of modern shock absorber production. This method gives manufacturers precise control over component properties. Metal powders transform into durable, complex parts through a series of carefully controlled steps.

Overview of Powder Metallurgy Process Steps

The quality of final products depends heavily on powder production – the first phase of manufacturing shock absorber components through powder metallurgy. The process continues with blending, where metal powders mix with lubricants or alloying elements to create uniform mixtures. Manufacturers can choose between pre-alloyed powders with consistent microstructure or mixed powders that compact easily.

The prepared powder becomes a “green compact” through high-pressure application in specialized molds during compaction. This vital step determines the component’s shape, size, and density before sintering begins.

Parts might need secondary treatments after sintering to improve dimensional accuracy and surface finish. Common treatments include CNC machining for complex features, sizing to restore dimensions, and resin impregnation to fill pores.

Sintering Process for High-Density Components

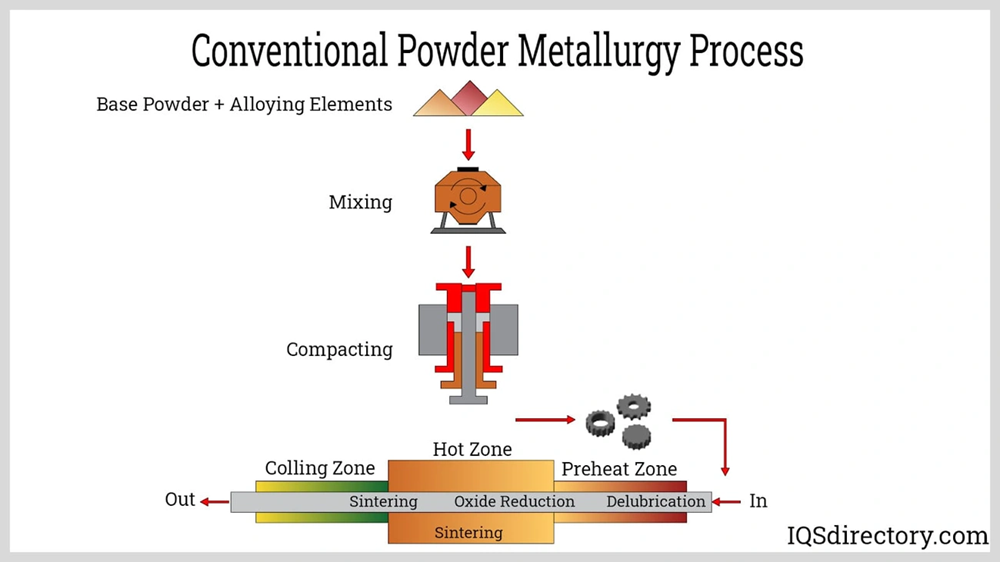

Sintering stands at the core of powder metallurgy production. The metal undergoes thermal treatment at 70-90% of its melting point, which makes powder particles fuse without fully melting. The process happens in three distinct phases:

- Initial Stage: Atoms diffuse at contact points, forming “necks” between particles

- Intermediate Stage: Diffusion increases, necks enlarge, porosity decreases

- Final Stage: Interconnected pores become isolated as density increases

Material properties depend on careful control of temperature, time, and atmosphere during sintering. Shock absorber pistons need precise management of this process to withstand continuous cyclic loading without failing.

Advantages of Powder Metallurgy Process in Automotive Applications

Automotive shock absorber production benefits remarkably from powder metallurgy. The process achieves material utilization of 95% – this is a big deal as it means that it surpasses traditional manufacturing techniques. Parts come out with minimal waste and near-final dimensions, which reduces or eliminates expensive secondary operations.

Production efficiency adds another advantage – automatic compacting presses produce hundreds to thousands of units hourly with minimal operator intervention. The process also creates complex geometries that would be impossible through traditional methods.

JH MIM showcases the power of this technology with its 20 years of industry experience. The company maintains consistent quality standards worldwide through automated measurement systems and 100% in-line vision inspection.

Performance Role of Sintered Shock Absorber Pistons

Sintered shock absorber pistons made through powder metallurgy show exceptional performance that affects vehicle stability and ride comfort. The way these components are manufactured creates unique advantages over traditional production methods.

How Piston Geometry Affects Damping Characteristics

A shock absorber piston’s main job is to control how a vehicle’s suspension handles road irregularities. The piston moves inside the cylinder when it hits bumps or dips. This movement forces hydraulic fluid through carefully designed orifices. The controlled fluid movement manages suspension compression and rebound, and turns energy into heat. Powder metallurgy lets manufacturers create complex geometric designs with precise tolerances (±0.01 mm). This precision gives them better control over damping characteristics.

Material Density and Its Effect on Wear Resistance

The piston’s density plays a crucial role in its performance. Fe-Cu powder metallurgy alloys reach about 90% of theoretical density (7.0 g/cm³) and show ultimate tensile strengths between 300-430 MPa right after sintering. Yes, it is possible to engineer specific strength levels by adjusting porosity. Shock absorbers with lower porosity (around 10%) achieve higher density (7.0 g/cm³) and better wear resistance.

Steam treatment of sintered iron pistons boosts performance by:

- Creating surface hardness of 180-250 HV

- Forming a protective oxide layer 5-15 mm thick

- Reducing the coefficient of friction to 0.15-0.25

Thermal Stability of Sintered Pistons Under Load

These pistons handle heat well and keep their structural integrity at temperatures up to 300°C. This heat resistance matters because damping generates significant heat. Aircraft landing gears face high-stress conditions with dynamic loading, yet sintered components maintain their dimensions despite temperature changes.

JH MIM brings 20 years of powder metallurgy expertise to create pistons that deliver these performance benefits. The company achieves this through careful control of density, geometry, and material properties.

Design and Manufacturing Challenges in Piston Production

Manufacturing shock absorber pistons through powder metallurgy comes with unique challenges that need precise engineering solutions. These challenges shape the quality and performance of final components.

Maintaining Dimensional Tolerances in Complex Shapes

Shock absorber pistons need extraordinary precision. Manufacturers must maintain accuracy up to 0.01mm. These tight tolerances are crucial because small changes can drastically affect shock absorber performance. Notwithstanding that, complex geometries like sintered rod guides make this precision hard to achieve.

Deep-positioned surfaces and discontinuous shapes make it hard for tactile measurement systems to deliver consistent results. So manufacturers must stick to strict tolerances for shape and surface parameters, even with high production volumes. The complex geometry of pistons ended up needing perfect dimensional precision and surface finish to ensure strength and dynamic durability.

Machining Requirements Post-Sintering

Powder metallurgy creates near-net shapes, but some features need post-processing. Machining helps achieve complex shapes you can’t press directly, such as transverse holes and screw threads. Sizing operations help fix dimensional deviations after sintering and enhance product accuracy through a simpler set of molds.

Parts that need more complex shapes while keeping high density often go through additional machining processes. This extra step helps meet final specifications for critical features that affect performance.

Powder Selection and Compaction Pressure Optimization

Even pressure throughout the powder metallurgy die plays a vital role. Pressure variations can lead to uneven density and create weak spots and internal cracks. The compaction pressure directly affects both pore size and number of pores in the final component.

Iron-based materials with a density of 6.5g/cm³ and hardness of 70-90HRB work best for shock absorber applications. But optimal results depend on careful control of compaction parameters to ensure even density distribution throughout the part.

JH MIM brings nearly 20 years of powder metallurgy expertise to tackle these manufacturing challenges while delivering quality components consistently.

Quality Control and Functional Testing in PM Manufacturing

Quality control is the life-blood of powder metallurgy production for shock absorber components. Each manufacturing stage needs systematic monitoring to prevent defects and ensure reliable performance in critical applications.

Batch-to-Batch Consistency in Powder Metallurgy Manufacturing Process

Even minor variations in powder composition can affect final product quality a lot. Manufacturers use ISO 9001:2015 certified quality management systems to keep minimum tolerances within ±0.01 mm after sizing. This precision depends on several critical control points throughout production:

- Raw material verification (particle size, flowability, density)

- Compaction pressure monitoring for optimal strength

- Sintering atmosphere control for mechanical properties

- Dimensional verification to ISO 2768 standards

The team might need to reject whole production batches if they spot any deviation during these stages.

Client-Specific Testing Protocols for Piston Performance

Through collaboration with clients, manufacturers develop customized testing protocols. These protocols serve as measures to ensure shock absorber components meet specific application requirements. The testing protocols include a detailed evaluation of:

- Damping force characteristics

- Temperature cycling capabilities

- Noise evaluations

Use of Independent Verification for Finished Components

Third-party verification provides an objective assessment of component quality beyond internal checks. Advanced technologies improve detection capabilities—magneto-inductive testing allows 100% automatic inspection and spots parts that don’t meet specifications right away. These strict verification procedures, combined with JH MIM’s nearly 20 years of powder metallurgy expertise, help shock absorber pistons deliver exceptional performance consistently.

Conclusion

Powder metallurgy revolutionizes how manufacturers produce shock absorber pistons. This breakthrough approach delivers better performance and solves major production challenges. The advanced process gives manufacturers complete control over component geometry, and pistons maintain dimensional precision within ±0.01 mm. The carefully managed sintering process creates parts with ideal density-to-strength ratios. These parts show better wear resistance through controlled porosity levels.

Parts made through powder metallurgy substantially outperform traditional manufacturing methods. The components remain stable at temperatures up to 300°C and deliver reliable performance in tough conditions. Near-net shapes reduce material waste and allow complex geometries that traditional methods can’t achieve.

Quality control drives successful powder metallurgy applications. Strict testing protocols throughout production ensure consistent batches. Advanced methods like magneto-inductive testing verify that components meet exact performance specifications. This complete approach stops potential defects before parts go into service.

Vehicle manufacturers worldwide see real benefits: better stability, smoother rides, and longer-lasting shock absorbers. Powder metallurgy proves itself as more than just a manufacturing method – it’s a strategy that boosts the performance of crucial suspension parts.

JH MIM stands out in this specialized field with almost 20 years of powder metallurgy expertise. The company’s steadfast dedication to strict quality standards and ability to tackle complex manufacturing challenges ensures reliable performance in automotive markets worldwide.

Key Takeaways

Powder metallurgy revolutionizes shock absorber piston manufacturing by delivering superior performance, precision, and efficiency compared to traditional methods.

• Exceptional Precision Control: Powder metallurgy achieves dimensional tolerances within ±0.01mm, enabling precise damping characteristics that directly impact vehicle stability and ride comfort.

• Superior Material Properties: Sintered pistons reach 90% theoretical density (~7.0 g/cm³) with enhanced wear resistance and thermal stability up to 300°C under continuous loading.

• Manufacturing Efficiency: The process achieves 95%+ material utilization with near-net shapes, reducing waste and eliminating expensive secondary operations while enabling complex geometries.

• Rigorous Quality Assurance: Advanced testing protocols including 100% magneto-inductive inspection and ISO 9001:2015 certification ensure batch-to-batch consistency and reliable performance.

• Cost-Effective Production: Automated compacting presses produce hundreds to thousands of units hourly with minimal operator intervention, making it ideal for high-volume automotive applications.

The powder metallurgy process transforms shock absorber manufacturing from a traditional machining operation into a precision engineering solution that delivers consistent quality, enhanced performance, and improved production efficiency for automotive applications worldwide.

FAQs

Q1. What are the main benefits of using powder metallurgy for shock absorber pistons? Powder metallurgy offers exceptional dimensional precision, enhanced material properties, and the ability to create complex geometries. It also provides high material utilization, reduced waste, and improved production efficiency for shock absorber pistons.

Q2. How does powder metallurgy improve the performance of shock absorber pistons? Powder metallurgy enables the production of pistons with optimal density-to-strength ratios, enhanced wear resistance, and excellent thermal stability. These properties result in improved damping characteristics, longer lifespan, and consistent performance under various operating conditions.

Q3. What challenges are involved in manufacturing shock absorber pistons through powder metallurgy? Key challenges include maintaining tight dimensional tolerances (within ±0.01mm) for complex shapes, optimizing powder selection and compaction pressure, and addressing post-sintering machining requirements to achieve final specifications for critical features.

Q4. How is quality control ensured in powder metallurgy manufacturing of shock absorber components? Quality control involves implementing ISO 9001:2015 certified systems, maintaining batch-to-batch consistency, conducting client-specific testing protocols, and using advanced verification methods like 100% magneto-inductive inspection to ensure components meet strict performance specifications.

Q5. What makes powder metallurgy a preferred method for producing automotive components? Powder metallurgy is preferred for its ability to produce near-net shape parts with minimal waste, achieve complex geometries, and maintain consistent quality in high-volume production. It also offers cost-effectiveness through automated processes and reduced need for secondary operations.