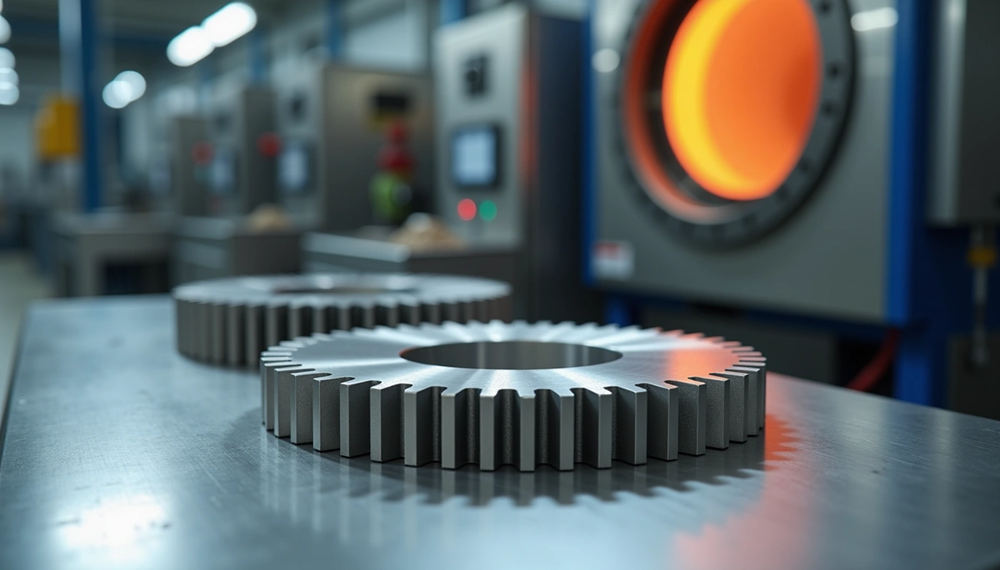

Sintering metal creates parts with outstanding yield strength and fatigue resistance, which makes it perfect for manufacturing high-performance gears. This key stage in powder metallurgy helps create precisely engineered components that can withstand repeated stress without deformation or breaking. Powder metal forging has delivered impressive results by a lot and reduced costs for manufacturers over the past 25 years.

The powder metallurgy process outperforms traditional manufacturing methods with 97% of input materials ending up in the final product. The process also lets manufacturers design intricate parts with excellent dimensional precision. Modern powder metallurgy technology has grown beyond low-load applications and could replace wrought gearing when higher loads are involved. Manufacturers can now create lightweight, porous, self-lubricating, and high-strength components that work great for gears, bushings, and bearings needing continuous lubrication during operation. Manufacturers achieve demanding specifications for modern industrial applications through careful temperature control (typically 2050-2150°F) and specialized techniques.

Understanding Powder Metallurgy and Sintered Metal

Powder metallurgy is a manufacturing method that creates solid metal components from fine metal powders through compression and heat treatment. This technique produces parts with consistent properties and minimal waste. The demand for this process keeps growing, especially when you have precision components like gears.

Definition of sintered metal and powder metallurgy parts

Powder metallurgy involves creating metal parts from powders through a controlled thermal process called sintering. Sintered metal is the solid mass that forms when metal powders are compacted and heated without complete melting. The process bonds powder particles together through diffusion. This creates a homogeneous microstructure with isotropic properties that show similar characteristics in all directions.

Powder metallurgy parts are components made by compressing metal powders into shapes before heat application strengthens the particle bonds. These parts often have controlled porosity, which is ideal for specific uses, such as oil-impregnated bearings that require self-lubrication. Manufacturers aim for very low porosity to maximize strength and durability, especially for high-stress parts like gears.

Overview of the sintering metal process

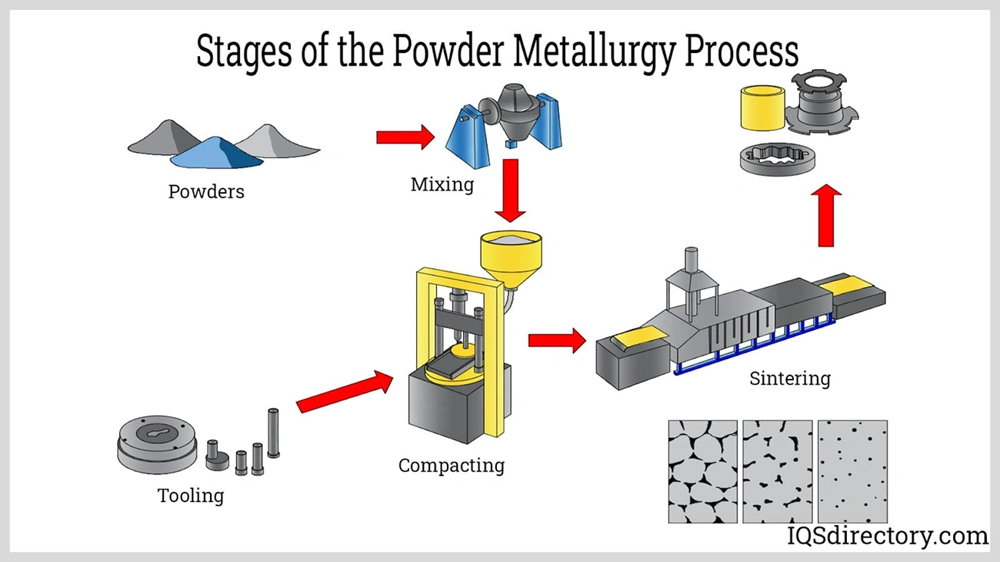

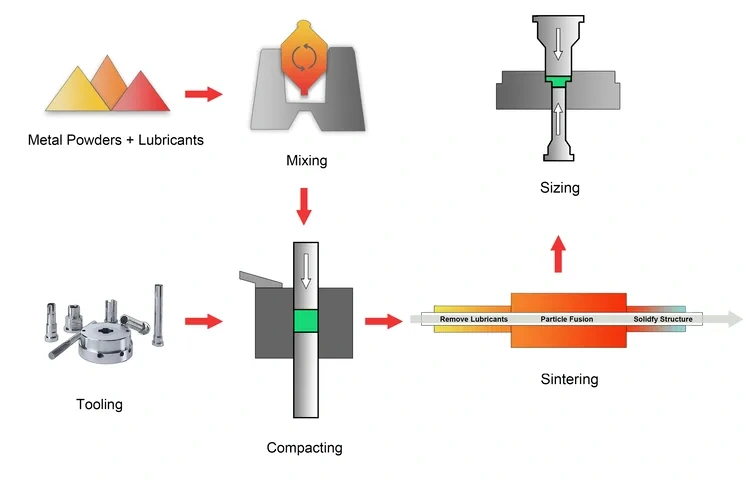

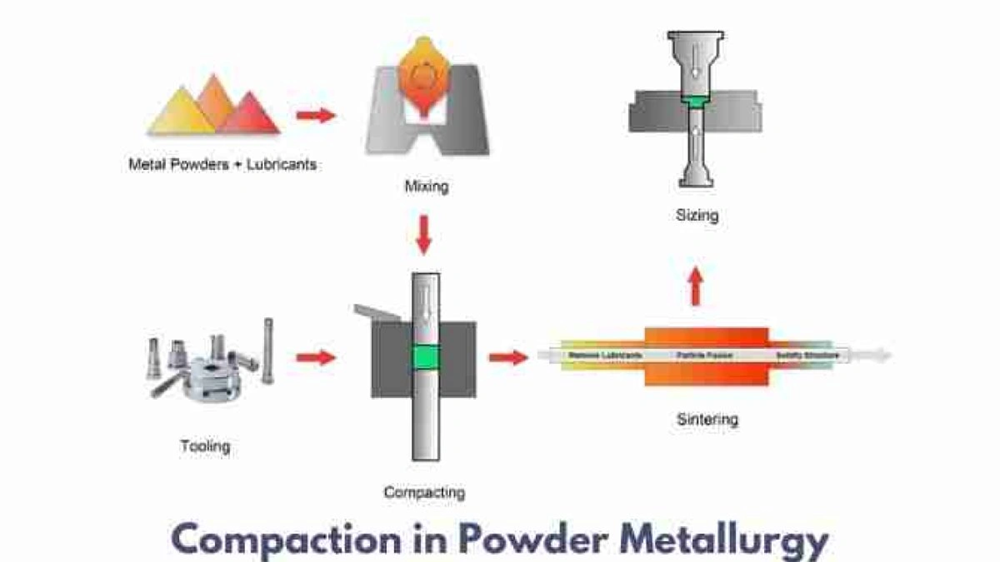

The sintering metal process has three basic stages: powder preparation, compaction, and sintering. Metal powders with specific compositions are mixed with additives and lubricants to help with processing. High pressure (200-1,500 MPa) then compresses this mixture in a die that forms the negative shape of the final part.

The “green compact” that results is strong enough to handle but needs sintering for final properties. During sintering, the compact goes through several changes:

- Delubing phase – The lubricant melts and vaporizes as the temperature rises

- Oxide reduction – The furnace atmosphere reacts with surface oxides and removes barriers between metal particles

- Particle bonding – Particles form “necks” that grow through diffusion at temperatures below the melting point

- Densification – Parts shrink about 15-20% linearly as pores close and density increases

Modern sintering furnaces operate at temperatures between 750 °C and 1300°C, depending on the material composition and desired properties. The controlled atmosphere—often containing hydrogen or carbon monoxide—prevents oxidation and helps particle bonding.

Key advantages of powder metallurgy in gear production

Powder metallurgy brings unique benefits to gear manufacturing. The process achieves material utilization rates above 95%, which is a big deal as it means that waste reduction is compared to traditional machining. The technology creates near-net-shape components that need minimal secondary operations. This cuts production costs while maintaining tight tolerances.

Gear applications benefit from powder metallurgy’s dimensional precision—with tolerances from 0.05% (12.5μm) to 0.08% (20μm) after sizing, matching ISO standard tolerances IT6-IT7. Gears mesh correctly with mating components because of this precision, reducing noise and improving efficiency.

The process lets manufacturers create complex gear geometries that traditional manufacturing methods struggle to achieve. Custom tooth profiles can be made without excess flash or burrs that need removal.

Sintered metal gears dampen vibrations well and can have controlled porosity to retain lubricants longer. Miba’s patented densification process can create powder metal gears with densities above 7.6 g/cm³, making their surface strength close to solid steel.

How the Sintering Process Enhances Gear Strength

The metallurgical transformations during sintering change metal powder particles at a fundamental level. These changes create strong metallurgical bonds that improve gear performance. The process involves several distinct phases that work together. They maximize strength and durability through controlled microstructural progress.

Delubing and oxide reduction in the sintering of metal powders

The path to better gear strength starts with two key stages. The delubing phase removes lubricants and binders used in compaction that would block particle bonding. These compounds break down and escape as vapors at temperatures between 500-900°C. This vital step prevents carbon deposits from forming bubble-like flaws on the workpiece surface.

After delubing, oxide reduction removes thin oxide layers that cover metal powder particles. These oxides block direct metal-to-metal contact between particles. The furnace’s reducing atmosphere, which often contains hydrogen, reacts with oxides to create clean metal surfaces. Removing these oxides is essential because they would limit bonding strength and reduce gear performance.

Grain growth and pore shrinkage during sintering

The real strength-building begins once oxides are gone. When temperatures reach 70-90% of the metal’s melting point, particles form “necks” where they touch. These necks grow through various diffusion mechanisms while the pores get smaller.

Pores start connected. As sintering continues, grain boundaries form and grains get bigger. The material becomes denser as porosity decreases. Higher density leads to better mechanical properties. Atoms move toward empty spaces in predictable mathematical patterns during pore shrinkage.

The material’s microstructure gets refined during this phase. Any remaining pores become rounder. Round pores help increase strength because they create fewer stress concentration points.

Impact of sintering temperature and time on strength

Temperature and time are the main factors that control mechanical property improvements. Research shows that raising sintering temperature from 1120°C to 1290°C can increase ultimate tensile strength by 16.5% and yield strength by 25%. Higher temperatures need more processing time but create rounder pores and finer grain structures that make gears more durable.

Each material needs different sintering temperatures – copper-based parts need 820°C, iron-based components need 1120°C, and stainless steel needs 1250°C. Controlled cooling rates play a key role in the final microstructure. Slower cooling makes parts tougher, while rapid cooling (sinter hardening) makes them harder.

Atmosphere control using argon or nitrogen

The sintering atmosphere plays a vital role in gear strength by stopping oxidation and helping oxide reduction. Nitrogen prevents oxidation and keeps powder pure because it’s inert. This makes it perfect for stainless steel and high-speed steel components. Nitrogen provides good protection at high temperatures with dewpoints below -75°F.

Argon works better for reactive metals like titanium and chromium because it’s more inert. These metals might form unwanted compounds during sintering without proper protection. Hydrogen-containing atmospheres reduce oxides most effectively but cost more.

Today’s sintering operations often use precise atmosphere combinations like nitrogen/hydrogen mixtures to get the best protection and reduction. This atmosphere control, combined with an accurate temperature profile, ensures consistent metallurgical bonding throughout complex gear shapes.

Role of Compaction and Material Selection in Durability

Durable powder metallurgy gears need the right compaction pressure and material mix. These foundations determine how well the finished gears will perform, even before sintering begins.

High-pressure compaction and its effect on density

Precise pressure during compaction shapes how durable the gears become. Most conventional compaction uses pressures between 400-800 MPa. This creates green components with densities of 6.6-7.2 g/cm³ for iron-based materials. The porosity distribution throughout the component depends on this stage, which affects the final mechanical properties.

Studies show that higher compaction pressure leads to smaller and fewer pores. The powder particles get more compressed at higher pressures. This creates more contact between particles and reduces overall porosity. Research proves that green density can jump from 63% at 280 MPa to 79% at 840 MPa.

High Velocity Compaction (HVC) offers better density for tough gear applications. A high-speed hammer (2-30 m/s) creates strong stress waves through the powder. HVC achieves densities of 7.4-7.8 g/cm³ through multiple quick impacts. This boosts tensile strength by 20-25% compared to standard methods.

Material blends and alloying elements for strength

Your gear’s performance depends heavily on powder composition. Most powder metallurgy gears use iron-based materials as their base, with specific elements added to boost certain properties. Common additions include:

- Copper: Makes machining easier and fights corrosion

- Nickel: Makes gears stronger and tougher for demanding uses

- Molybdenum: Helps with hardening and fights fatigue

- Carbon (usually as graphite): Added at 0.2-0.8% to control hardness

Powder metallurgy lets manufacturers fine-tune material mixes in ways casting or forging can’t match. This means they can optimize specific properties like fatigue strength, which usually reaches 30-35% of tensile strength.

Lubricants and binders in powder metallurgy parts

Lubricants and binders play key roles despite making up just a tiny part of the mix. Manufacturers add lubricants like zinc stearate at 0.5-0.8%. These reduce friction between powder particles and die walls during compaction. This helps prevent density differences and gives even compaction across complex gear shapes.

Binders work differently by holding particles together temporarily until sintering. They give green strength through matrix binding or chemical binding. Matrix binding embeds particles in a continuous phase, while chemical binding creates reactions between components. These additives must burn off completely before sintering starts. Any leftover additives would stop particles from bonding properly.

The right mix of compaction pressure, materials, and additives creates powder metallurgy gears that last longer and perform better.

Post-Sintering Treatments That Boost Performance

Powder metallurgy gears need several treatments after sintering to boost their mechanical properties and durability. These secondary operations help turn standard sintered components into high-performance machine elements that can handle demanding applications.

Repressing and coining for increased hardness

The sizing process makes sintered parts more accurate and smoother by re-pressing them. This reduces surface irregularities. The surface improves through controlled plastic deformation that seals pores at the same time. Repressing helps fix dimensions that might have changed due to uneven heating or cooling.

Heat treatments: quenching, tempering, annealing

Heat treatments make a big difference in material properties like hardness, strength, and fatigue resistance of sintered gears. Carburizing creates a tough, wear-resistant surface while the core stays flexible—perfect for low carbon alloy steels. Medium to high carbon steels benefit from induction hardening that toughens specific areas with minimal distortion. Steam treating forms a protective oxide layer about 0.0001″-0.0002″ thick with hardness up to HRC50, which works well for sintered parts needing toughness with local high-load capacity.

Infiltration with copper or bronze for higher density

Infiltration seals porous sintered components, which makes them denser and more resistant to corrosion. Copper-based materials penetrate and fill the pore network through capillary action during this treatment. This process boosts mechanical properties like tensile strength, ductility, and impact resistance.

Surface finishing: carburizing and nitriding

Surface treatments such as carburizing push carbon into the part surface, creating a hard carbide layer that resists wear better. Nitriding offers another option, creating an even nitride layer with minimal distortion—this works especially well for stainless steels and tool steels. Ion nitriding produces parts with better surface lubricity while keeping precise dimensions, and no post-nitriding machining is needed.

Comparing Powder Metallurgy with Traditional Methods

Traditional manufacturing methods now face tough competition from powder metallurgy. This process brings clear advantages for gear production. A closer look at these differences shows why many manufacturers now choose sintering metal processes for precision components.

Sintered metal vs casting: precision and material efficiency

Powder metallurgy gives better dimensional accuracy than casting. The casting process needs draft angles and parting line adjustments. Casting works well with non-ferrous materials like aluminum and zinc. The sintering metal process uses materials more effectively and creates minimal waste. Powder metallurgy’s near-net-shape capability drives this efficiency and eliminates the big material losses common in cast parts.

Sintered metal vs forging: complexity and cost

Forged gears show 8% higher tensile strength and 27% greater fatigue resistance than their sintered counterparts. Yet powder metallurgy shines when making complex geometries that would be hard to forge. The powder metallurgy process cuts costs by up to 68% in specific automotive applications during high-volume production. Surface-densified powder metallurgy gears perform almost as well as hobbed gears, with endurance limits just 5% lower. This makes them a solid choice for high-stress applications.

Sintered metal vs machining: waste reduction and net-shape capability

Machining uses only 60-70% of materials effectively, while powder metallurgy reaches 97%. Powder metallurgy creates parts that are 90% close to final dimensions from the start. All the same, CNC machining proves more affordable for small production runs because of lower tooling costs.

Conclusion

Powder metallurgy is a game-changer in manufacturing high-performance gears that excel in strength and durability. The sintering process creates resilient metallurgical bonds and controls porosity, grain structure, and densification. These elements boost the mechanical properties that gears need in demanding applications.

Superior gear performance comes from combining precise compaction techniques with the right material compositions. High Velocity Compaction, an advanced method, achieves densities close to solid steel. This breakthrough has narrowed the gap between powder metallurgy and traditional manufacturing.

Post-sintering treatments take gear capabilities to the next level. Repressing, heat treatment, infiltration, and surface finishing transform standard sintered parts into high-performance machine elements. These components can handle extreme conditions without losing their dimensional precision.

Powder metallurgy outshines traditional manufacturing with material utilization rates above 95%. This is a big deal as it means less waste in production. Complex geometries need fewer secondary operations, which cuts production costs while keeping tight tolerances. On top of that, recent advances have expanded this technology beyond low-load uses, making it a viable replacement for wrought gearing in high-load scenarios.

Companies with decades of powder metallurgy experience keep expanding technological limits. They deliver precision-engineered products that meet tough specifications. Their expertise ensures sintered metal gears deliver consistent quality and performance that modern industrial applications demand.

The future looks bright for powder metallurgy in gear production. Its unique mix of strength, durability, dimensional accuracy, and production efficiency makes it perfect for next-generation gear systems. This technology will become even more crucial as manufacturing continues to evolve.

Key Takeaways

Powder metallurgy revolutionizes gear manufacturing by creating stronger, more durable components through precise control of material properties and microstructure.

• Exceptional material efficiency: Powder metallurgy achieves 97% material utilization compared to 60-70% in traditional machining, significantly reducing waste and production costs.

• Superior dimensional precision: The process delivers tolerances as tight as 0.05-0.08% (IT6-IT7 standards), ensuring perfect gear meshing and reduced noise.

• Enhanced strength through sintering: Controlled temperature (2050-2150°F) and atmosphere create metallurgical bonds that boost tensile strength by 16.5% and yield strength by 25%.

• Customizable performance properties: Material blends with specific alloying elements (copper, nickel, molybdenum) enable tailored gear characteristics for demanding applications.

• Advanced post-processing capabilities: Heat treatments, infiltration, and surface finishing transform standard sintered gears into high-performance components rivaling traditional forged parts.

The technology has evolved beyond low-load applications to potentially replace wrought gearing in high-stress environments, making it a game-changing solution for modern industrial gear systems requiring both precision and durability.

FAQs

Q1. What are the main benefits of using powder metallurgy for gear production? Powder metallurgy offers exceptional material efficiency (97% utilization), superior dimensional precision (tolerances as tight as 0.05-0.08%), and the ability to create complex geometries with minimal secondary operations. It also allows for customizable material properties through specific alloying elements, resulting in high-performance gears for demanding applications.

Q2. How does the sintering process enhance gear strength? Sintering creates strong metallurgical bonds between metal particles through controlled temperature (typically 2050-2150°F) and atmosphere. This process reduces porosity, refines grain structure, and increases density, leading to improved mechanical properties. Studies show that optimizing sintering temperature can boost tensile strength by 16.5% and yield strength by 25%.

Q3. What post-sintering treatments can improve gear performance? Several treatments can enhance gear properties after sintering. These include repressing for increased hardness and dimensional accuracy, heat treatments like carburizing and nitriding for improved wear resistance, infiltration with copper or bronze for higher density, and various surface finishing techniques to optimize specific characteristics like lubricity or corrosion resistance.

Q4. How does powder metallurgy compare to traditional gear manufacturing methods? Compared to casting, forging, and machining, powder metallurgy offers superior material utilization, better dimensional accuracy, and the ability to produce complex shapes cost-effectively. While forged gears may have slightly higher strength, powder metallurgy gears can achieve comparable performance with proper post-processing, making them viable alternatives even for high-stress applications.

Q5. Can powder metallurgy gears be used in high-load applications? Yes, recent advancements in powder metallurgy have expanded its applications beyond low-load scenarios. With techniques like surface densification, powder metallurgy, gears can now achieve endurance limits within 5% of traditionally manufactured gears. This makes them increasingly suitable for high-load applications, potentially replacing wrought gearing in demanding industrial environments.

Pingback: The Process in Powder Metallurgy A 2025 Look at Its Advantages