Metal Injection Molding (MIM) complements Additive Manufacturing (AM) by significantly enhancing the efficiency of its processes. While MIM excels in producing complex geometries at high speeds, AM offers unparalleled design flexibility, allowing for intricate and customized shapes. Together, these technologies create a more robust production system that addresses the evolving needs of modern industries. Notably, the MIM market is projected to grow at a CAGR of 9.90% from 2024 to 2032, underscoring its increasing relevance in sectors like automotive, where lightweight components are in high demand.

Key Takeaways

- Metal Injection Molding (MIM) and Additive Manufacturing (AM) work together to improve production efficiency.

- MIM is great for making many identical parts quickly, while AM allows for unique and complex designs.

- Using MIM can lower costs for mass production after a certain number of units are made.

- AM can create detailed parts but may require extra steps to achieve a smooth finish.

- Combining MIM and AM can lead to stronger and more precise components for various industries.

- Hybrid production methods can save time and reduce waste, making manufacturing more sustainable.

- Cross-disciplinary teams enhance collaboration, leading to better designs and faster production.

- Software tools help streamline the design process, making it easier for teams to work together.

Understanding MIM and AM

Overview of Metal Injection Molding

Metal Injection Molding (MIM) is a manufacturing process that combines the versatility of plastic injection molding with the strength of metal. This technique allows for the production of complex metal parts with high precision. The fundamental steps in MIM include:

- Feedstock Creation: Manufacturers mix fine metal powders with thermoplastic binders to create a feedstock.

- Injection: The feedstock is injected into a mold, forming a ‘green part.’

- Debinding: This step removes the binder material, resulting in a ‘brown part.’

- Sintering: Finally, the brown part undergoes heating to densify the metal particles, achieving the desired mechanical properties.

MIM finds applications across various industries, including:

- Automotive

- Aerospace

- Medical

- Electronics

- Defense

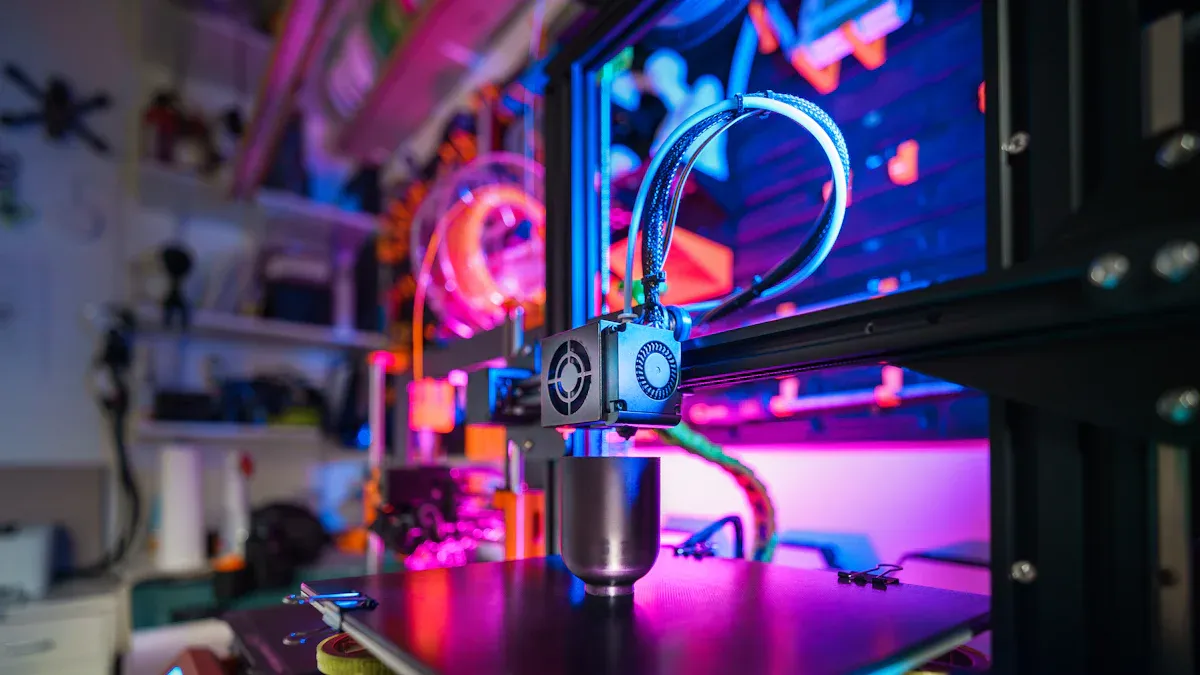

Overview of Additive Manufacturing

Additive Manufacturing (AM) refers to a group of technologies that create parts layer by layer from digital models. This process allows for the production of intricate designs that traditional methods cannot achieve. Several types of AM technologies exist, each with unique characteristics and applications. The following table summarizes some of the most common AM technologies:

| Additive Manufacturing Technology | Description | Primary Industrial Uses |

|---|---|---|

| Vat Photopolymerization | Cures liquid resin into solid parts using light. | Prototyping intricate designs. |

| Material Extrusion | Heats thermoplastic filament to create layers. | Consumer-grade and industrial manufacturing. |

| Powder Bed Fusion | Uses a laser to fuse powdered material in layers. | Metal and polymer part production. |

Key Differences Between MIM and AM

MIM and AM serve different purposes and have distinct characteristics. MIM excels in high-volume production, making it ideal for mass manufacturing. However, it presents design challenges, as altering molds can be costly and time-consuming. In contrast, AM offers greater design flexibility, allowing for rapid prototyping and customization without the need for new molds.

The following table highlights key differences between MIM and AM:

| Feature | Metal Injection Molding (MIM) | Metal Additive Manufacturing (AM) |

|---|---|---|

| Production Volume | High-volume production | Lower production volumes |

| Tooling Costs | High tooling costs | Lower tooling costs |

| Design Flexibility | Limited design flexibility | Greater design flexibility |

| Update Design | Difficult (new mold needed) | Easy (no new mold needed) |

Understanding these differences helps industries choose the right technology for their production needs. The combination of MIM and AM can lead to innovative solutions, enhancing overall production efficiency.

Efficiency of MIM in Hybrid Production

Speed of Production

Metal Injection Molding (MIM) significantly enhances production speed in hybrid manufacturing environments. Once the mold is prepared, MIM can produce parts in less than a minute. This rapid output allows manufacturers to create hundreds or even thousands of identical parts per hour. In contrast, Additive Manufacturing (AM) typically employs a layer-by-layer approach, which can take hours or even days to complete a single part, depending on its complexity. The integration of AM into MIM processes can further improve production efficiency, particularly in mold creation and tooling. This synergy allows for faster turnaround times and a more streamlined workflow.

Cost-Effectiveness

Cost considerations play a crucial role in manufacturing decisions. MIM offers high upfront tooling costs but achieves lower per-part costs at high volumes. This makes it particularly economical for mass production, especially beyond a break-even point of approximately 1,025 units. In comparison, Metal Additive Manufacturing (AM) is more cost-effective for low-volume production of small, detailed parts. Hybrid processes that utilize printed patterns find themselves positioned between metal AM and investment casting in terms of cost-effectiveness. While investment casting remains the most efficient for large, simple designs, advancements in metal AM technologies are rapidly reducing costs, making it competitive even for larger runs.

Material Utilization

MIM excels in material utilization, which is vital for efficient production. The process minimizes waste by using precisely measured amounts of metal powder in the feedstock. This efficiency is particularly beneficial in hybrid production settings, where the integration of AM can further enhance material properties. For instance, AM allows for the creation of intricate mold geometries and features like conformal cooling channels. These enhancements improve cooling efficiency and reduce cycle times, ultimately leading to higher productivity. The combination of MIM and AM not only optimizes material usage but also contributes to overall cost savings and environmental sustainability.

Constraints of Additive Manufacturing

Material Limitations

Additive Manufacturing (AM) faces several material limitations that can impact the production of metal parts. These limitations include:

- Material Availability: Limited access to certain metal powders restricts the types of parts that manufacturers can produce.

- Porosity: This issue is common in processes like Directed Energy Deposition (DED) and Powder Bed Fusion (PBF). Porosity can lead to reduced density and negatively affect mechanical properties, such as corrosion resistance and tensile strength.

- Mechanical Properties: AM parts often exhibit anisotropic properties. This means their strength varies with build direction, which can affect durability under cyclic loading.

These material constraints highlight the challenges that AM must overcome to compete effectively with traditional manufacturing methods like Metal Injection Molding (MIM).

Surface Finish Challenges

Surface finish quality is another area where Additive Manufacturing struggles compared to MIM. The precision of MIM typically results in minimal post-processing requirements. In contrast, AM often necessitates additional steps to achieve the desired surface finish. Common post-processing methods include:

- Sanding

- Polishing

- Coating

These extra steps can increase production time and costs, making AM less efficient for applications where surface finish is critical. The need for extensive post-processing can deter manufacturers from fully embracing AM for high-precision applications.

Production Speed Issues

Production speed remains a significant challenge for Additive Manufacturing. While the Powder Bed Fusion (PBF) process is known for its precision and ability to produce complex geometries, it suffers from limitations in build speed. This slow build speed can hinder high-volume production, making it difficult to scale operations effectively.

The challenges of scaling AM processes become particularly evident in larger builds, which can lead to inconsistencies and defects. As a result, while AM holds great potential, the transition from prototypes to mass production presents a significant hurdle. Manufacturers must weigh these speed limitations against the benefits of design flexibility that AM offers.

Bridging Gaps with Hybrid Production

Combining Strengths of MIM and AM

Hybrid production systems leverage the strengths of both Metal Injection Molding (MIM) and Additive Manufacturing (AM) to create a more efficient manufacturing process. By integrating these technologies, manufacturers can overcome the limitations of each method. For instance, MIM provides high-volume production capabilities, while AM offers design flexibility. This combination allows for the production of complex geometries that would be challenging or costly to achieve with traditional methods alone.

The hybrid approach enhances surface quality and dimensional accuracy. Machining processes can refine the roughness and tolerance of 3D printed parts, improving their performance and aesthetics. Additionally, hybrid systems can enhance mechanical properties by removing defects and residual stresses inherent in 3D printed metal parts. This results in stronger, more durable components that meet the rigorous demands of various industries.

Case Studies in Hybrid Production

Several industries have successfully adopted hybrid production methods involving MIM and AM. The aerospace and defense sectors lead this trend, showcasing innovative applications. A notable case study involves Alpine Advanced Materials, which utilized 3D printed tooling for injection molded composites. This approach allowed for rapid prototype production, demonstrating significant efficiency gains.

Another example is the Freeform Injection Molding process, which combines AM and MIM techniques. This method enables manufacturers to create complex molds quickly, reducing lead times and costs. Such advancements highlight the potential of hybrid production to revolutionize manufacturing practices across multiple sectors.

Industry Applications

Hybrid production finds applications in various industries, including:

- Aerospace: Lightweight components produced through hybrid methods enhance fuel efficiency and performance.

- Automotive: Custom parts created using MIM and AM improve vehicle design and functionality.

- Medical: Tailored implants and devices benefit from the precision and customization offered by hybrid techniques.

- Electronics: Complex geometries in electronic components are achievable through the integration of MIM and AM.

These applications illustrate how MIM complements Additive Manufacturing, creating innovative solutions that address the evolving needs of modern manufacturing.

Technologies Enhancing Hybrid Production

Binder-Jet 3D Printing

Binder-Jet 3D printing has emerged as a transformative technology in hybrid production. This method utilizes MIM-grade powders and binding agents, allowing for seamless integration with Metal Injection Molding (MIM). Notably, Indo MIM has developed a Tool Steel M2 grade material specifically for this process. The printing speed of Binder-Jet 3D printing is approximately five times faster than the Laser Powder Bed Fusion (LPBF) method. Currently, more than 800 mold inserts for MIM are actively used in production, showcasing the technology’s effectiveness.

The process begins with the creation of a ‘green’ part, which is larger than the final component. After printing, the part undergoes sintering in MIM production furnaces to achieve the desired mechanical properties. This combination of speed and efficiency makes Binder-Jet 3D printing a valuable asset in hybrid manufacturing environments.

Advances in Prototype Tooling

Recent developments in prototype tooling have significantly improved the efficiency of hybrid production systems. These advancements combine additive and subtractive processes, enhancing component strength and functionality. By minimizing waste and energy consumption, manufacturers can achieve lower production costs.

Key benefits of these advances include:

- Faster Prototyping: Hybrid systems enable same-day turnaround for functional prototypes.

- Accelerated Design Validation: Quick real-world feedback allows for timely adjustments.

- Reduced Bottlenecks: Streamlined design and development timelines lead to significant time savings.

Additive manufacturing enhances the efficiency of hybrid production systems by allowing for rapid iteration and faster prototyping. Engineers can create functional prototypes quickly, facilitating early design evaluations and revisions. This approach shortens the overall production cycle and minimizes the risk of costly late-stage redesigns.

Integration of Software Solutions

The integration of software solutions plays a crucial role in enhancing hybrid production. Advanced software tools facilitate the design, simulation, and optimization of parts produced through MIM and AM. These tools enable engineers to analyze performance metrics and identify potential issues before physical production begins.

Moreover, software solutions streamline communication between teams, ensuring that designers and engineers work collaboratively. This collaboration fosters innovation and leads to the development of more efficient production processes. As industries continue to evolve, the integration of software solutions will remain essential for maximizing the benefits of hybrid production technologies.

Collaboration in the Production Process

Importance of Cross-Disciplinary Teams

Cross-disciplinary teams play a vital role in the success of hybrid production projects that involve Metal Injection Molding (MIM) and Additive Manufacturing (AM). These teams enhance mold design optimization, which is crucial for integrating both technologies. By collaborating across different fields, team members can improve production efficiency and cost-effectiveness, particularly in low-volume and customized production scenarios.

Key contributions of cross-disciplinary teams include:

- Innovative Solutions: Collaboration fosters the development of 3D-printed molds that complement traditional injection molding techniques. This leads to better product quality and faster time-to-market.

- Enhanced Knowledge Sharing: Team members share insights and skills, which enriches the overall project.

- Diverse Perspectives: Different viewpoints contribute to informed decision-making and strategic alignment.

Companies with strong cross-functional teams are twice as likely to be profitable, demonstrating the significant impact of collaboration on business success.

Communication Between Engineers and Designers

Effective communication between engineers and designers is essential in hybrid production environments. Clear communication minimizes errors and ensures that projects adhere to international standards. Best practices for enhancing communication include:

- Developing Communication Personas: Understanding the communication styles of team members can improve interactions.

- Adopting Asynchronous Video Updates: This method allows team members to share progress without needing to coordinate schedules.

- Gamifying Communication Training: Engaging training methods can enhance team dynamics and collaboration.

Involving designers early in the design process is crucial. Using design collaboration tools and documenting design guidelines can streamline workflows. Regular communication and practicing empathy further strengthen relationships between engineers and designers, leading to more successful outcomes.

Continuous Improvement Practices

Continuous improvement practices are fundamental to optimizing hybrid production processes. Organizations should foster a culture of innovation and adaptability. This involves regularly assessing workflows and identifying areas for enhancement.

Key strategies for continuous improvement include:

- Feedback Loops: Implementing regular feedback sessions allows teams to learn from successes and failures.

- Data-Driven Decision Making: Utilizing data analytics can help identify inefficiencies and inform strategic adjustments.

- Training and Development: Investing in employee training ensures that teams remain knowledgeable about the latest technologies and best practices.

By embracing continuous improvement, organizations can enhance their hybrid production capabilities, leading to better quality products and increased customer satisfaction.

The synergy between MIM and Additive Manufacturing leads to innovative solutions in manufacturing. By integrating metal additive technology with traditional processes, manufacturers can drive advancements that enhance production capabilities. This collaboration fosters the development of complex mold features and improves tooling types, offering alternatives to conventional methods.

Looking ahead, trends indicate a significant shift towards hybrid production systems. For instance, projections suggest that by 2034, hybrid vehicles will account for 34% of U.S. sales, translating to over 3 million units.

| Trend | Description |

|---|---|

| Advancements in Alloy Development | Innovations in metal alloys that enhance performance and application in MIM and AM. |

| Sustainable Strategies | Approaches aimed at reducing environmental impact in production processes. |

| Integration of Industry 4.0 | Adoption of smart technologies to improve efficiency and connectivity in manufacturing. |

| Additive Manufacturing in MIM | Use of AM to improve mold production speed and complexity, complementing traditional MIM. |

| Hybrid Tooling Solutions | Development of tools that utilize both MIM and AM technologies for enhanced production. |

As these trends evolve, the collaboration between MIM and AM will continue to enhance production outcomes and drive innovation in the manufacturing landscape.

FAQ

What is the primary advantage of combining MIM and AM?

Combining MIM and AM enhances production efficiency. MIM provides high-volume capabilities, while AM offers design flexibility. This synergy allows manufacturers to produce complex parts quickly and cost-effectively.

How does MIM improve production speed?

MIM significantly boosts production speed by allowing manufacturers to produce parts in under a minute once the mold is ready. This rapid output supports high-volume manufacturing.

What industries benefit most from hybrid production?

Industries such as aerospace, automotive, medical, and electronics benefit greatly from hybrid production. These sectors require complex geometries and high-quality components, which MIM and AM can deliver effectively.

Are there any limitations to using AM?

Yes, AM faces limitations such as material availability, surface finish challenges, and slower production speeds compared to MIM. These factors can hinder its effectiveness in high-volume production.

How does Binder-Jet 3D printing enhance hybrid production?

Binder-Jet 3D printing accelerates the production process by using MIM-grade powders. It allows for faster mold creation, improving overall efficiency in hybrid manufacturing environments.

What role does software play in hybrid production?

Software solutions streamline design, simulation, and optimization processes in hybrid production. They facilitate communication between teams, enhancing collaboration and innovation in manufacturing.

How can companies ensure effective collaboration in hybrid production?

Companies can foster collaboration by forming cross-disciplinary teams, enhancing communication between engineers and designers, and implementing continuous improvement practices. This approach leads to better project outcomes.

What future trends should we expect in hybrid production?

Future trends include advancements in alloy development, sustainable production strategies, and the integration of Industry 4.0 technologies. These trends will further enhance the capabilities of hybrid production systems.