The manufacturing of magnets is fascinating. Materials must reach temperatures above 1,000°C in controlled environments. The sintering process plays a crucial role in magnet manufacturing and turns powdered materials into powerful magnetic components that power modern technology.

Powder Metallurgy remains the preferred method to create permanent magnets. NdFeB magnets power countless devices in our daily lives. The sintering process causes these magnets to shrink 15-20% linearly. Particles then lock themselves into crystal lattice structures that boost their magnetic properties. This process creates components that power everything from consumer electronics to advanced industrial applications.

Sintered soft magnetic materials deliver remarkable performance benefits. Pure iron, when compacted through powder metallurgy, shows a coercive force of 1.5 A cm⁻¹ and reaches a maximum permeability of 3000. These materials achieve significant improvements in high-efficiency applications. Iron silicon steel shows improvements up to 100%, while pure iron and iron/phosphorus alloys see gains of about 15%.

This piece walks you through the sintering process. You’ll learn about everything from powder preparation to final magnetization and see how manufacturers create these powerful components that meet today’s demanding applications.

Understanding NdFeB Magnets and Their Role in Modern Devices

Neodymium Iron Boron (NdFeB) magnets are the most powerful permanent magnets accessible to more people today. These magnets can attract objects up to 640 times their own weight. This is a big deal as it means that they revolutionize modern electronics with their exceptional strength-to-size ratio.

Nd₂Fe₁₄B Crystal Structure and Magnetic Alignment

NdFeB magnets get their extraordinary magnetic properties from their unique tetragonal crystal structure. The structure shows alternating layers of iron atoms and neodymium-boron compounds. The magnets become exceptionally powerful because neodymium atoms have four unpaired electrons compared to iron’s average of three. These unpaired electrons create a remarkably strong magnetic field when they arrange in the same direction.

The tetragonal Nd₂Fe₁₄B structure (space group P42/mnm) shows high uniaxial magnetocrystalline anisotropy. The material strongly resists demagnetization once magnetized along a specific crystal axis. This resistance gives these magnets their impressive coercivity and magnetic stability.

Why NdFeB Magnets Are Used in Compact Electronics

NdFeB magnets make the miniaturization of electronic devices possible. They create strong magnetic fields from small volumes, making them perfect for compact applications. A typical smartphone contains up to 14 small magnets that serve various functions.

Some critical applications include:

- Speakers and audio equipment: Mobile phone speakers need 3-5 magnets. Headsets need 2-4 magnets to deliver superior sound quality

- Hard disk drives: These magnets control read-write head movements precisely

- Camera autofocus: Each camera needs 2-4 magnets to focus rapidly

- Vibration motors: These create haptic feedback and alerts

These magnets are the foundations of renewable energy systems like wind turbines and electric vehicles. Their high magnetic strength compared to mass improves efficiency and reduces raw material needs.

Comparison: Sintered vs Bonded NdFeB Magnets

Sintered and bonded NdFeB magnets share the same Nd₂Fe₁₄B composition but differ substantially in manufacturing processes and properties. Manufacturers create sintered magnets through powder metallurgy. They pulverize the alloy, press it under a magnetic field, and sinter it at high temperatures.

Bonded magnets combine NdFeB powder with polymers through compression or injection molding. These magnets offer lower magnetic properties but better dimensional precision. Sintered magnets can achieve a maximum energy product (BHmax) above 50 MGOe. Bonded magnets typically stay below 10 MGOe.

Sintered magnets work best in high-performance applications like electric motors and MRI machines. Bonded magnets excel at creating complex-shaped components for office automation equipment and computer peripherals.

Step-by-Step Sintering Process for Permanent Magnets

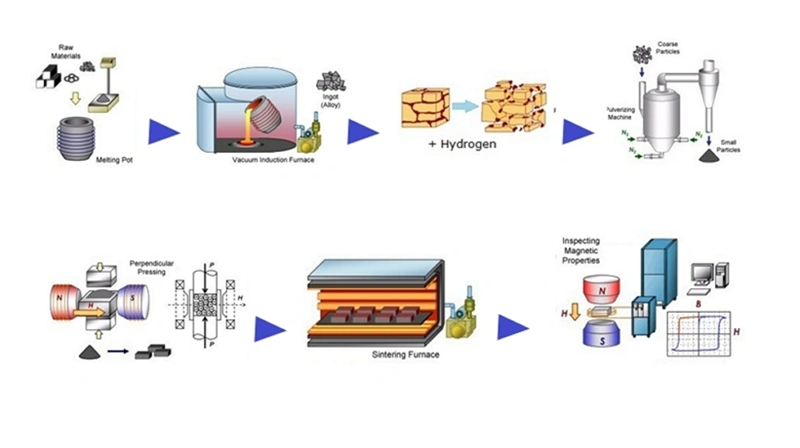

Manufacturing permanent magnets through sintering requires a precise sequence of steps that turns raw materials into powerful magnetic components.

Alloying and Hydrogen Decrepitation Explained

The process starts with precisely measured raw materials—neodymium, iron, and boron. These materials melt in vacuum furnaces at temperatures between 1300-1550°C. The cooled alloy then goes through Hydrogen Decrepitation (HD). During HD, hydrogen gas enters the material and makes it expand and break into smaller particles. This method effectively breaks down the solid mass and creates uniform particles ready for the next steps.

Jet Milling and Magnetic Field Pressing

The material moves to a jet mill where high-velocity air streams reduce particles to 3-5μm in size. A strong magnetic field presses this fine powder into shape and arranges the magnetic domains in a specific direction. Manufacturers use three common methods: membrane pressure, mold pressing with cooling, isostatic pressing, or rubber mold isostatic pressing. The rubber mold method produces higher magnetic energy.

Sintering and Annealing for Grain Boundary Control

A vacuum sintering furnace heats the pressed compact to 1000-1150°C. This heat fuses the particles while keeping their magnetic arrangement intact. The magnet then undergoes tempering at lower temperatures to improve its structure and magnetic properties.

Machining and Surface Coating for Corrosion Resistance

Diamond wheels cut and grind the sintered magnets to exact dimensions. NdFeB magnets need protection from corrosion, so manufacturers apply protective coatings like nickel-copper-nickel, epoxy, or zinc.

Final Magnetization Using High-Field Pulses

The process ends with magnetization through high-field pulses. An electric coil creates a strong magnetic field that permanently arranges the material’s magnetic domains.

JH MIM has nearly 20 years of experience in metal injection molding and powder metallurgy. The company provides precision-engineered products to global customers who need high-performance magnetic components.

Magnetic Properties and Performance Metrics

Four key performance indicators determine how well sintered NdFeB magnets work in ground applications. These parameters show exactly how magnets will perform in actual conditions.

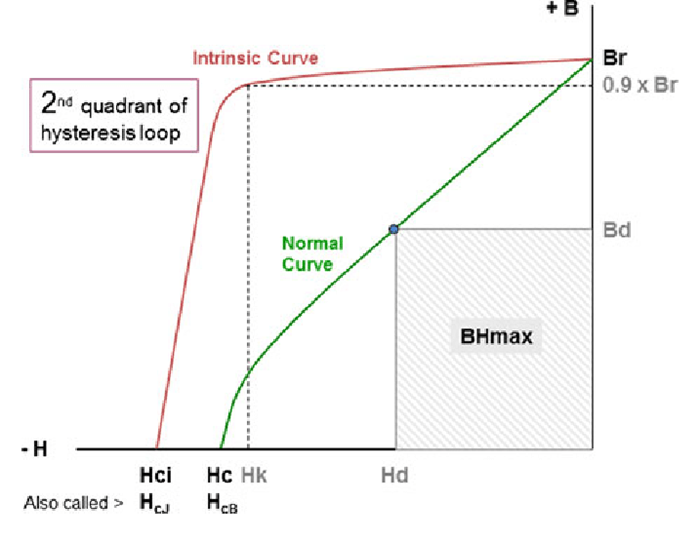

High Remanence (Br) and Coercivity (HcJ) Explained

Remanence (Br) shows the residual magnetic flux density after magnetization and measures a magnet’s strength. Higher Br values show stronger magnetic output. Intrinsic coercivity (HcJ) measures how well magnets resist demagnetization. This becomes crucial to maintain performance when magnets face opposing magnetic fields or high temperatures. Commercial magnets have reached 93% of their theoretical maximum strength. However, their coercivity sits at only 30% of theoretical capacity. This creates ongoing challenges for manufacturers.

Energy Product (BHmax) Across NdFeB Grades

Maximum energy product (BHmax) is the definitive indicator of a magnet’s performance. It represents the magnetic energy density between poles. This parameter determines how well a magnet works. Two similar-sized magnets with different BHmax values show proportionally different strengths. Current grades range from N35 (35 MGOe) to N52 (52 MGOe). Higher numbers mean stronger magnets. Letters following these numbers (M, H, SH, UH, EH, TH) show increasing temperature resistance.

Thermal Stability and Curie Temperature Range

Each NdFeB magnet grade shows different temperature sensitivity. The Curie temperature, where magnets lose their magnetic properties, ranges from 310°C to 400°C. Magnets experience reversible performance loss below this threshold. Temperature coefficients govern this loss: approximately -0.12%/°C for remanence and -0.6%/°C for coercivity.

Effect of Dysprosium and Terbium Additions

Dysprosium and terbium help magnets perform better at high temperatures. These heavy rare earth elements boost coercivity by enhancing the material’s magnetocrystalline anisotropy. While effective, these elements are rare. Neodymium is five times more common than dysprosium and 36 times more common than terbium. Advanced grain boundary diffusion techniques have helped manufacturers cut DyTb content from 30% to about 4% in modern magnets.

Applications of Sintered Magnets in Industry

Sintered NdFeB magnets power many critical applications in a variety of industries and change how modern technologies operate through their exceptional magnetic properties.

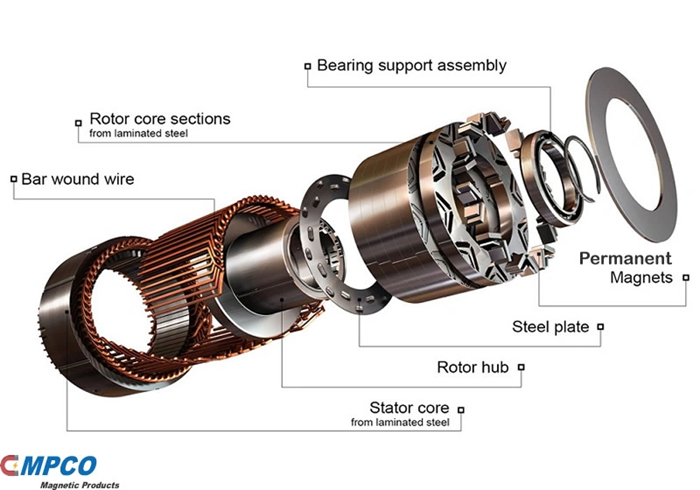

Electric Motors and EV Powertrains

Sintered NdFeB magnets make electric vehicle motors smaller and lighter without power loss. Their high energy density leads to more efficient motors that extend battery life and boost performance. These magnets reduce EV’s overall weight while maximizing energy conversion efficiency. The automotive industry now depends on them for its transition toward electrification.

Wind Turbines and Renewable Energy Systems

Modern wind turbines use permanent magnet synchronous generators (PMSG) that contain up to three tons of high-performance magnets. The magnetic strength of sintered NdFeB magnets creates more compact and efficient turbine generators. These components are essential to produce greater power in smaller wind turbine designs. Magnet content varies from 80 kg/MW to 650 kg/MW based on drivetrain configuration, which substantially improves renewable energy production.

Medical Imaging Devices like MRI

Magnetic Resonance Imaging (MRI) systems need strong, stable magnetic fields to generate detailed images of internal body structures. NdFeB magnets deliver the magnetic strength and stability needed for precise MRI scans that produce clearer diagnostic results. These magnets’ exceptional performance has revolutionized medical imaging technology.

Consumer Electronics: Speakers and HDDs

NdFeB magnets control read/write head positioning in hard disk drives with incredible precision. They guide the heads over spinning disks to ensure reliable data retrieval and storage. These magnets also improve sound quality in audio equipment like headphones and speakers by increasing the speaker’s diaphragm sensitivity for clearer output.

JH MIM’s unique experience spans nearly 20 years in metal injection molding and powder metallurgy. The company provides precision-engineered magnetic components used in these critical applications worldwide.

Conclusion

The sintering process is a remarkable manufacturing technique that turns powdered materials into powerful permanent magnets we need for modern technologies. Manufacturers use precise temperature control and specialized metallurgical processes to create NdFeB magnets with extraordinary strength-to-size ratios. These magnets can attract objects up to 640 times their own weight, and they have revolutionized how engineers design devices in many industries.

Let’s take a closer look at Nd₂Fe₁₄B magnets’ complex crystal structure and unique properties that deliver exceptional magnetic performance. The sintering process starts with alloy preparation and moves through hydrogen decrepitation, jet milling, pressing, sintering, and final magnetization. This creates components with precise magnetic properties. Each manufacturing stage’s careful management affects final performance metrics like remanence, coercivity, and maximum energy product.

Electric vehicles, wind turbines, medical imaging equipment, and consumer electronics need these sintered magnets to work efficiently. Their high energy density helps manufacturers build smaller, lighter, and more efficient devices without compromising performance. As technology moves toward miniaturization and energy efficiency, sintered NdFeB magnets will remain crucial components in future innovations.

JH MIM’s 20 years of experience in metal injection molding and powder metallurgy helps deliver precision-engineered magnetic components to customers worldwide. This expertise means that even as manufacturing processes evolve, the sintering principles discussed here will remain the foundation for producing powerful magnets that revolutionize technology in a variety of applications.

Key Takeaways

Understanding the sintering process reveals how modern technology’s most powerful magnets are manufactured through precise metallurgical techniques that transform raw materials into essential components.

• Sintered NdFeB magnets undergo 15-20% linear shrinkage during manufacturing, creating components 640 times stronger than their weight through controlled crystal alignment.

• The five-step sintering process—alloying, hydrogen decrepitation, jet milling, magnetic field pressing, and high-temperature sintering—transforms powdered materials into permanent magnets.

• Performance metrics like remanence (Br), coercivity (HcJ), and energy product (BHmax) determine magnet effectiveness, with grades ranging from N35 to N52 MGOe.

• Sintered magnets power critical applications from electric vehicle motors and wind turbines to MRI machines and consumer electronics through exceptional strength-to-size ratios.

• Temperature stability and corrosion resistance are enhanced through dysprosium/terbium additions and protective coatings, ensuring reliable performance in demanding environments.

The sintering process represents a perfect blend of materials science and precision manufacturing, enabling the creation of magnets that have revolutionized everything from renewable energy systems to medical imaging technology.

FAQs

Q1. What is the sintering process for manufacturing magnets? The sintering process involves pulverizing a magnetic alloy into fine powder, compacting it under a magnetic field, and then heating it to high temperatures (1000-1150°C) to cause densification. This process aligns and fuses the particles, creating a strong, organized crystal structure that enhances the magnet’s properties.

Q2. Why is sintering important in magnet production? Sintering is crucial because it strengthens the material and significantly enhances its magnetic properties. The process locks particles into an organized crystal lattice structure, which maximizes the magnet’s strength and performance characteristics like remanence and coercivity.

Q3. How do sintered NdFeB magnets compare to bonded ones? Sintered NdFeB magnets are produced through a complex powder metallurgy process involving high-temperature sintering, resulting in stronger magnetic properties. Bonded magnets, made by mixing NdFeB powder with polymers, have lower magnetic strength but offer better dimensional precision and are suitable for complex shapes.

Q4. What are the key performance metrics for sintered magnets? The main performance metrics for sintered magnets include remanence (Br), which indicates magnetic strength; coercivity (HcJ), which measures resistance to demagnetization; and maximum energy product (BHmax), which represents overall magnetic energy density. These factors determine a magnet’s effectiveness in various applications.

Q5. Where are sintered NdFeB magnets commonly used? Sintered NdFeB magnets are widely used in electric vehicle motors, wind turbine generators, MRI machines, and consumer electronics like speakers and hard disk drives. Their high strength-to-size ratio makes them ideal for applications requiring powerful, compact magnetic components.