What is Fe-Si in metal production?

Fe-Si, known as ferrosilicon, is the life-blood of modern metallurgy. This metallic ferro-alloy contains iron and silicon as its main elements. The silicon content in Fe-Si ranges from 15% to 90% by weight, while iron makes up most of the remainder with trace amounts of other elements.

Manufacturers classify Fe-Si by silicon percentage, with standard grades of 15%, 45%, 65%, 75%, and 90% silicon. On top of that, it contains small amounts of aluminum, calcium, carbon, manganese, phosphorus, and sulfur. Industry standards define Fe-Si as a ferro-alloy with at least 4% iron, 8-96% silicon, 3% or less phosphorus, 30% or less manganese, less than 3% magnesium, and 10% or less of any other element.

Fe-Si’s physical form is silver-gray, brittle solids that come in lump or granular form. Its appearance might seem simple, but its substantial functional properties make it valuable in metallurgical applications. The alloy shows magnetic properties, especially in grades made for electrical applications.

Producers use two main methods to make Fe-Si, depending on silicon content. They make grades with about 15% silicon in blast furnaces lined with acidic fire bricks. Higher silicon percentages need electric submerged arc furnaces (SAF). The process uses carbothermic reduction of silicon dioxide (SiO₂) with carbon and iron. Raw materials include quartzite lumps for silicon, iron ore or scrap for iron, and carbon sources like coal or petroleum coke.

Fe-Si serves many significant functions in metal production. It acts as a powerful deoxidizing agent in steelmaking. Silicon’s strong attraction to oxygen makes Fe-Si excellent at removing dissolved oxygen from molten metal—a vital step that prevents defects and improves steel quality. The alloy also enhances properties like strength, hardness, and wear resistance in the final product.

Fe-Si is a revolutionary force in cast iron production as an inoculant that speeds up graphitization. Added to molten iron before casting, it helps form graphite nuclei and controls graphite flakes or nodules’ structure and size. This prevents brittle iron carbides from forming and substantially improves the casting’s machinability and ductility.

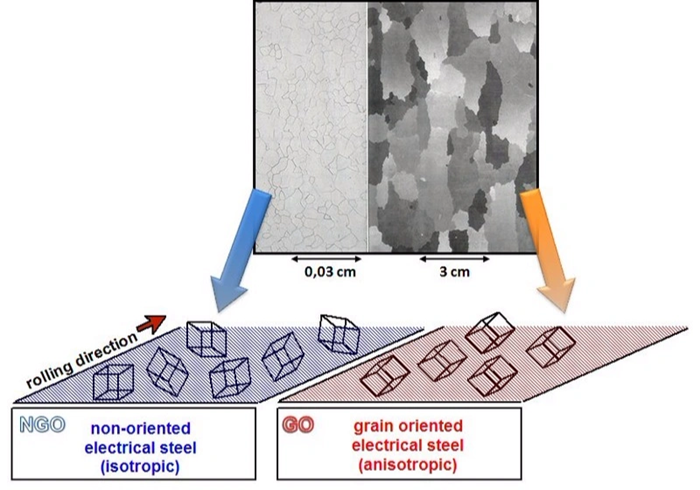

Fe-Si alloys are the prominent soft ferromagnetic materials used today. Adding silicon to iron decreases coercivity, slightly reduces saturation magnetization, and increases electrical resistivity. These properties make Fe-Si essential in electrical steels for transformers, motors, and generator cores.

Metal injection molding (MIM) applications benefit from Fe-Si powders’ unique magnetic and mechanical properties. These alloys can form complex shapes with exact dimensions while keeping their magnetic characteristics. The process utilizes Fe-Si’s ability to make metal mixtures flow better during casting.

Fe-Si’s phase diagram shows how temperature and composition relate, revealing silicon percentages’ effects on the alloy’s structure and properties. This knowledge helps optimize Fe-Si alloys for various uses, from welding electrodes to precision electromagnetic parts.

Why is Fe-Si important in modern metallurgy?

Modern metallurgical processes rely heavily on Fe-Si alloys as key materials for many industrial applications. The steel industry has changed to become more eco-friendly, which makes Fe-Si a vital part of green steel production. Steel manufacturers of all sizes are investing in eco-friendly upgrades – over 70% globally. Fe-Si demand keeps growing thanks to low-emission steel projects.

Fe-Si works as a powerful deoxidizing agent in steelmaking. It reduces oxygen content during production, which improves product quality and cuts down waste. This stops carbon loss from molten steel – what experts call “blocking the heat”. The silicon in Fe-Si combines with oxygen to create silica gas through a stable chemical reaction that removes impurities from the melt.

Fe-Si helps control slag by reducing chromium oxides in stainless steel production. This improves metallic chromium recovery and boosts steel purity by cutting impurities and letting us recycle waste slag. Modern steelmaking wants to maximize furnace availability by tapping in the “open” condition and using ladle deoxidation with Fe-Si.

Fe-Si does more than just deoxidize – it improves energy efficiency in metal production. The heat balance stays stable during furnace operations, which cuts energy use. Adding 1 ton of FeSi75 raises ladle temperature by about 4.73°C, based on the largest longitudinal study of industrial ladle refining processes.

Silicon steels need Fe-Si for electrical applications. Adding up to 3.5 wt% Si improves magnetic properties. This allows quick magnetization and demagnetization while reducing energy losses from hysteresis and eddy currents. Silicon content at 6.5 wt% creates zero magnetostriction and small magnetocrystalline anisotropy, giving us superior soft magnetic properties. These features make Fe-Si essential for electrical transformer cores, motors, and generators.

Metal injection molding technology benefits from Fe-Si too. Fe-Si powders are great because they combine magnetic and mechanical properties. The Fe-Si phase diagram helps manufacturers optimize alloy structures for specific molding applications. Some Fe-Si alloys processed this way reach impressive flexural strength – 1428 ± 107 MPa.

Cast iron production needs Fe-Si as an inoculant to speed up graphitization. It stops iron from forming carbides and helps graphite precipitate and form spheres. This makes the final casting easier to machine and more ductile.

Recent research shows Fe-Si creates amazing new composite materials. Fe-Si intermetallic phases in zinc matrices improve mechanical properties through Orowan strengthening, where tiny phases block dislocation movement.

How does Fe-Si improve steel and cast iron properties?

Silicon content in Fe-Si alloys revolutionizes the microstructural and performance characteristics of steel and cast iron. Silicon added to electrical steels boosts magnetic properties as it enables rapid magnetization and demagnetization. This reduces energy losses from hysteresis and eddy currents. Materials with up to 3.5 wt% silicon are the foundations of electrical applications where magnetic efficiency matters most.

Fe-Si plays a dual role in steel production as a deoxidizer and an alloying agent. The ferritic phase becomes stronger with silicon, which makes Si-killed steels harder and stiffer than their aluminum-killed counterparts. Silicon also improves the atmospheric corrosion properties of weathering steel and boosts its tensile properties. Duplex stainless steel with 1.5-2% silicon can develop nanoscale Si-enriched oxide films on steel surfaces that substantially increase critical pitting temperature.

Silicon additions bring substantial mechanical benefits. It increases yield strength in aluminum-killed low-carbon steel and boosts tensile strength through solid solution strengthening in low-carbon bainite steel. All the same, silicon does more than just strengthen—it changes microstructural development and promotes transformation from ferrite to granular bainite as content increases.

Fe-Si stops carbides from forming and changes graphite morphology in cast iron production. Research comparing silicon carbide (SiC) and ferrosilicon (FeSi) as silicon carriers shows that SiC leads to higher liquidus and eutectic temperatures, more A-type graphite content, and refined eutectic cells. SiC creates more evenly distributed A-type graphite than FeSi, which directly affects cast iron’s mechanical performance.

Fe-Si inoculation substantially affects graphite parameters in cast iron, as confirmed by microstructural analyzes. Ca,Ba-FeSi inoculation works better than simple Ca-FeSi to improve graphite parameters, while Ca,RE-FeSi shows fewer benefits. Your choice of inoculant directly affects graphite particle size, area, perimeter, and shape factors—key factors that determine mechanical properties.

High-silicon steels (Si content ≥4.5 wt%) show exceptional soft magnetic properties. Fe-6.5 wt% Si steel outperforms conventional Fe-3.2 wt% Si steel with better magnetic characteristics, lower iron loss, higher permeability, good saturation magnetization, and near-zero magnetostriction coefficient. These improved magnetic properties optimize efficiency in electrical applications, with silicon steel energy losses making up 2.8-4.9% of global power generation.

Silicon makes biodegradable materials better too. Fe-Mn-Si alloys with added silicon show excellent microstructural homogeneity. Different heat treatment strategies can adjust relative amounts of austenitic and martensitic phases. This modification boosts mechanical resistance by 70% compared to base alloys while keeping good ductility.

Fe-Si powders bring unique advantages to metal injection molding through their combined magnetic and mechanical properties. The process makes use of Fe-Si’s fluidity characteristics, which allows controlled flow behavior during casting—especially when creating complex components that need precise dimensions.

The biggest problem with increasing silicon content is increased brittleness. High silicon content makes ordered phase formation (B2, DO3) easier, which substantially reduces ductility. Rapid solidification techniques can effectively stop these ordered phases and improve mechanical properties. Understanding the Fe-Si phase diagram helps optimize these properties for different applications.

Types of Fe-Si alloys and their uses

Ferrosilicon alloys are grouped by their silicon content. Each grade has unique properties that make them useful in different industries. The grades range from low to high silicon percentages, and each serves specific functions in metallurgical processes.

15% Si Fe-Si

Companies produce commercial grade 15% Si Fe-Si in blast furnaces with acidic fire brick linings. This lower-silicon version is a budget-friendly option when minimal silicon introduction is needed. The grade works as a simple deoxidizer in steelmaking operations. The production of 15% Fe-Si for dense medium applications differs from higher-silicon grades. It needs remelting of 75% Fe-Si with steel scrap in an electric arc furnace before casting into a high-pressure water spray. In metal injection molding, this grade provides good fluidity while keeping structural integrity. This makes it perfect for components that need moderate silicon content.

45% Si Fe-Si

The 45% Si Fe-Si grade strikes a balance between silicon content and processability. Manufacturers use this alloy to make silicon steel for transformer cores and electromotors. Its silicon percentage makes it valuable especially when you need moderate magnetic properties without too much brittleness. This grade is a great way to get results in cast iron production. It speeds up the graphitization process and enhances the final product’s mechanical properties.

75% Si Fe-Si

The 75% silicon content variant is the most accessible grade in the ferrosilicon family. Steelmakers prefer FeSi 75 because it delivers high silicon efficiency with lower impurity levels. This grade’s aluminum levels max out at 1.5%, carbon at 0.1%, and both sulfur and phosphorus at 0.02%. It works well to deoxidize molten steel and improve mechanical properties, making it the top choice for many metallurgical applications. The 75% Fe-Si grade also serves as raw material in magnesium production through the Pidgeon process.

90% Si Fe-Si

The 90% Si Fe-Si grade has the highest silicon content among common ferrosilicon alloys. This grade’s maximum silicon efficiency makes it ideal for specialized areas that need minimal iron content. The impurity profile shows maximum aluminum at 1.0%, carbon at 0.05%, and both sulfur and phosphorus at 0.01%. High-performance alloy production and industries like electronics and semiconductors benefit from this grade. Its exceptional purity is perfect for metal injection molding applications where precise silicon content control determines the final component’s magnetic or mechanical properties.

How Fe-Si is used in metal injection molding

Metal injection molding (MIM) provides a precise way to create complex Fe-Si components that traditional manufacturing methods struggle to produce. The process lets manufacturers create net-shaped parts from hard and brittle Fe-Si materials that resist standard machining techniques.

Fe-Si powder characteristics

Fe-Si powders for MIM applications have unique properties that shape their processing abilities and end-product performance. Gas-atomized pre-alloyed Fe-Si powders with 3% to 9% silicon content make up the main raw materials. The powders’ spherical shape creates high packing density and helps produce feedstocks with better powder loading.

Particle sizes range from under 5 μm to 38 μm, with controlled distributions that optimize how well they flow. Quality Fe-Si powders maintain low oxygen content, which helps control carbon consistency during sintering and speeds up densification. These features become crucial for soft magnetic alloys where impurities directly shape magnetic performance.

Injection molding process steps

The MIM process starts as Fe-Si powder mixes with a multicomponent binder system. A blend of 65 vol% Fe-Si alloy powders combines with 35 vol% binder that contains polypropylene, polyethylene, paraffin wax, and stearic acid. The mixture blends thoroughly at 200°C for 120 minutes.

The prepared feedstock gets injected into mold cavities at specific temperatures (around 205°C) and pressures (180 MPa). Green parts then go through debinding—first solvent debinding in substances like heptane at 50°C for 20 hours, then thermal debinding in controlled atmospheres.

The final sintering happens at temperatures between 1300-1375°C for 2-14 hours, usually in hydrogen atmosphere. Parts shrink up to 20% as metal particles fuse together during this phase. The completed components show excellent soft magnetic properties, and their permeability and magnetic induction get better with increased sintering time and temperature.

Fe-Si in advanced applications and future trends

Fe-Si alloys now find their way into many high-tech industries, showing their value beyond traditional metallurgy. These materials prove invaluable in sectors that need precision engineering and better performance.

Fe-Si and magnetism in electronics

Fe-Si alloys play a key role in electromagnetic energy conversion technologies that power many electrical and electronic devices. The industrial sector uses nearly one-third of total electricity. Electric motors make up about 65% of this usage. Small efficiency gains can create big environmental benefits. A tiny 1% improvement could cut CO₂ emissions by several million metric tons.

Scientists now focus on Fe-Si-Al magnetic alloys with better multi-property optimization. These materials show excellent magnetic permeability and stronger mechanical properties through new manufacturing methods. Fe-6.5 wt% Si alloys are typically brittle with standard processing. However, they show remarkable magnetic properties through additive manufacturing. The benefits include better magnetic permeability, stronger magnetization, and power losses cut by more than half compared to Fe-3.0 wt% Si options.

Fe-Si in solar and semiconductor industries

Fe-Si compounds show great promise in green photovoltaic technology. Scientists have created heterostructure solar cells using metallic alpha-phase aluminum alloyed iron silicide (FeSi(Al)) on n-type silicon. Interface engineering has helped boost efficiency from 0.8% to 5.1%. These devices achieve open circuit voltage of 425 mV, short-circuit current of 18.5 mA/cm², and fill factor values of 64%.

Fe-Si serves as a crucial material for silicon-based technologies in semiconductor applications. Research shows that ferromagnetism in SiC with Fe atoms at 2% concentration comes from two sources. It stems from Fe-Si magnetic nanoparticles and magnetic Fe atoms spread through the semiconductor matrix. Metal injection molding helps shape Fe-Si components precisely for advanced electronic applications. The dimensional accuracy of these components directly affects their performance.

Key Takeaways

Fe-Si (ferrosilicon) is a critical iron-silicon alloy that transforms modern metal production through multiple essential functions, from basic steelmaking to advanced electronics manufacturing.

• Fe-Si serves as a powerful deoxidizer in steelmaking, removing oxygen impurities and improving steel quality while preventing carbon loss during production.

• Silicon content determines application: 15% for basic deoxidizing, 45% for transformer cores, 75% for general steelmaking, and 90% for high-performance electronics.

• Fe-Si enhances magnetic properties in electrical steels, reducing energy losses by up to 50% in transformers and motors through improved magnetization efficiency.

• Metal injection molding with Fe-Si powders enables complex component manufacturing with precise dimensions while maintaining magnetic and mechanical properties.

• Advanced applications span from solar cells to semiconductors, with Fe-Si achieving 5.1% efficiency in photovoltaic devices and superior performance in additive manufacturing.

Fe-Si’s versatility makes it indispensable across industries—from traditional steelmaking requiring basic deoxidation to cutting-edge electronics demanding precise magnetic properties. Understanding silicon percentages and processing methods enables manufacturers to optimize Fe-Si alloys for specific applications, driving innovation in both established and emerging technologies.

FAQs

Q1. How is ferrosilicon (Fe-Si) manufactured? Ferrosilicon is produced by reducing silica (sand) with carbon (coke or coal) in the presence of iron. This process is typically carried out in electric arc furnaces or blast furnaces, depending on the desired silicon content.

Q2. What are the primary applications of Fe-Si in the steel industry? Fe-Si is primarily used as a powerful deoxidizer in steelmaking, removing dissolved oxygen to improve steel quality. It also serves as an alloying component, enhancing properties like strength and wear resistance in the final product.

Q3. How does the silicon content in Fe-Si affect its uses? The silicon content determines the alloy’s application. Lower percentages (15%) are used for basic deoxidizing, while higher percentages (75-90%) are utilized in specialized applications like electrical steels and high-performance electronics.

Q4. What role does Fe-Si play in improving the properties of cast iron? Fe-Si acts as an inoculant in cast iron production, accelerating graphitization. It promotes the formation of graphite nuclei, controlling the structure and size of graphite flakes or nodules, which improves the machinability and ductility of the final casting.

Q5. How is Fe-Si utilized in advanced applications beyond traditional metallurgy? Fe-Si is increasingly used in advanced applications such as soft magnetic materials for electronics, solar cell technology, and semiconductor manufacturing. In these fields, it contributes to improved energy efficiency, enhanced magnetic properties, and the development of novel photovoltaic devices.