High-temperature sintering makes it possible for aerospace components to withstand temperatures that reach 2500°F (1371°C). This is a big deal as it means that modern aircraft engines can operate in extreme conditions. The manufacturing process compacts materials into specific shapes and heats them below their melting point. The result is components that excel in mechanical, thermal, and magnetic properties. This process is vital to produce engine parts like turbine blades, combustion chambers, and bearings that must work in harsh conditions.

Beyond that, advanced materials created through high-temperature ceramic techniques stay strong at operating temperatures from 150°C to over 300°C, based on their use. To name just one example, see how vacuum high-temperature sintering furnaces help create nickel-based alloys. These alloys resist oxidation above 1,000°C while keeping yield strength above 800 MPa. The process also creates ceramic matrix composites that handle temperatures above 2,000°C with minimal wear. This makes them perfect for control surfaces, leading edges. High-pressure high-temperature sintering improves material density, and specialized tools like high-temperature sintering alumina ceramic crucibles ensure precise fabrication.

This piece will help you learn about the basics of high-temperature sintering in aerospace applications. You’ll see how sintered components work in engines and structures, explore techniques that expand material capabilities, and learn the key aspects of furnace setup and process optimization.

Fundamentals of High-Temperature Sintering in Aerospace

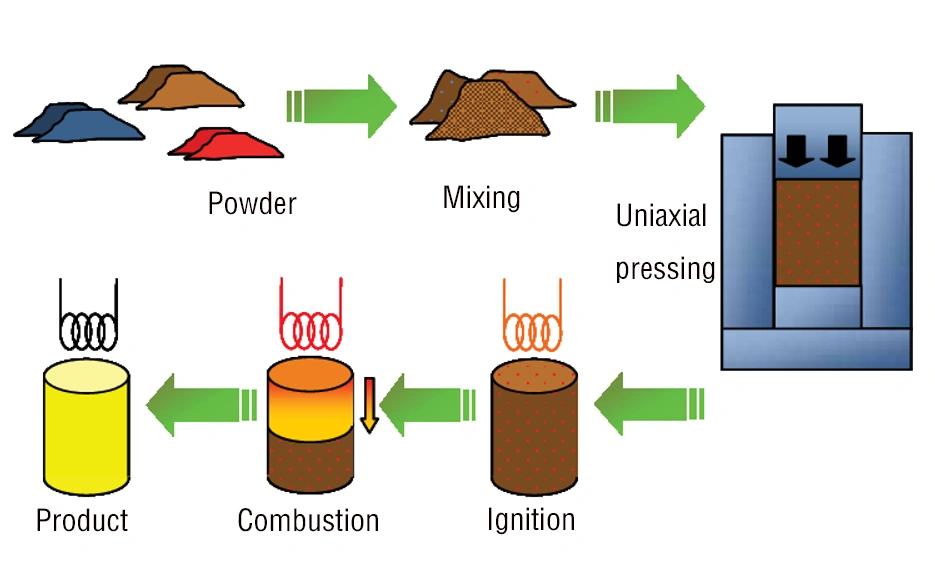

Sintering is a crucial thermal process that compacts and shapes materials through heat without reaching their liquefaction point. Material composition determines the thermal range needed. High-temperature sintering runs about 100-250°F hotter than regular sintering, reaching temperatures near 2050°F for iron-based components. Materials bond more completely because atomic diffusion speeds up at these higher temperatures.

Definition and Thermal Range of High-Temperature Sintering

Different materials need different temperature thresholds. Aerospace applications use sintering temperatures from 1350°F for aluminum up to 3200°F for tungsten. Ultra-high-temperature sintering (UHTS) challenges these limits by operating above 2500°F (1371°C). Thermal protection systems need ceramic components that can handle extreme conditions between 1000-3000°C while maintaining low thermal conductivity (<0.5 W/m·K).

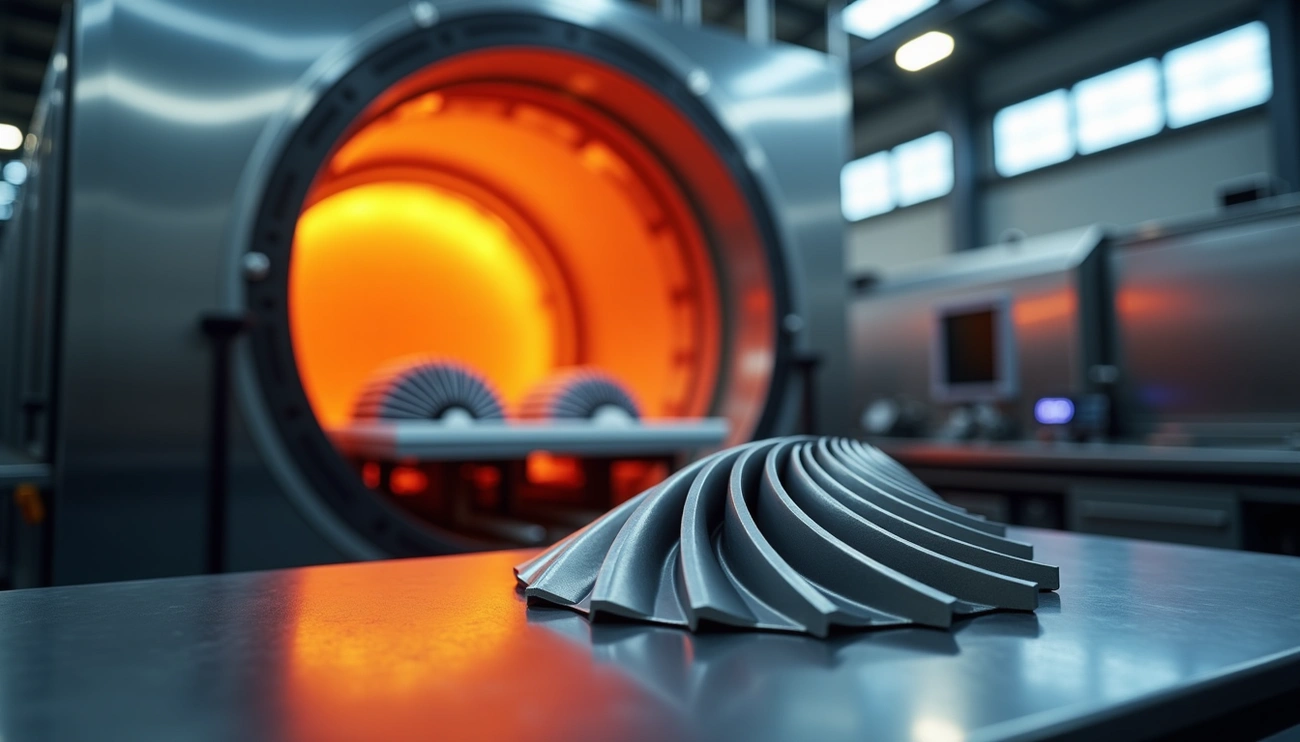

Role of the Vacuum High Temperature Sintering Furnace in Aerospace

Vacuum high-temperature sintering furnaces are specialized ovens that create oxygen-free environments needed for aerospace material processing. Most metals react strongly with atmospheric gases at high temperatures, so these systems prevent oxidation. Products keep their intended chemical makeup and superior mechanical properties because oxygen is absent. This controlled setting works great for making titanium alloys and nickel-based superalloys used in jet engine turbines and structural components.

Material Compatibility: Metals vs High-Temp Ceramic

Some metals are harder to sinter than others, especially aluminum alloys and titanium. Sintering is one of the few ways to manufacture materials with very high melting points like molybdenum, tungsten, and tantalum. High temp ceramic options have unique benefits, especially when using ultra-high temperature ceramics based on borides and carbides of transition metals like hafnium, zirconium, and tantalum. These ceramics might be brittle, but they handle heat remarkably well. Zirconium diboride (ZrB2) can withstand about 2500°C, and hafnium diboride materials last even longer at 3000°C.

Sintered Components in Aerospace Engines and Structures

Powder metallurgy processes create vital aerospace components that meet strict performance requirements in extreme operating environments. These sintered parts work best where traditional manufacturing methods don’t measure up. They provide unique combinations of thermal stability, wear resistance, and strength-to-weight ratios.

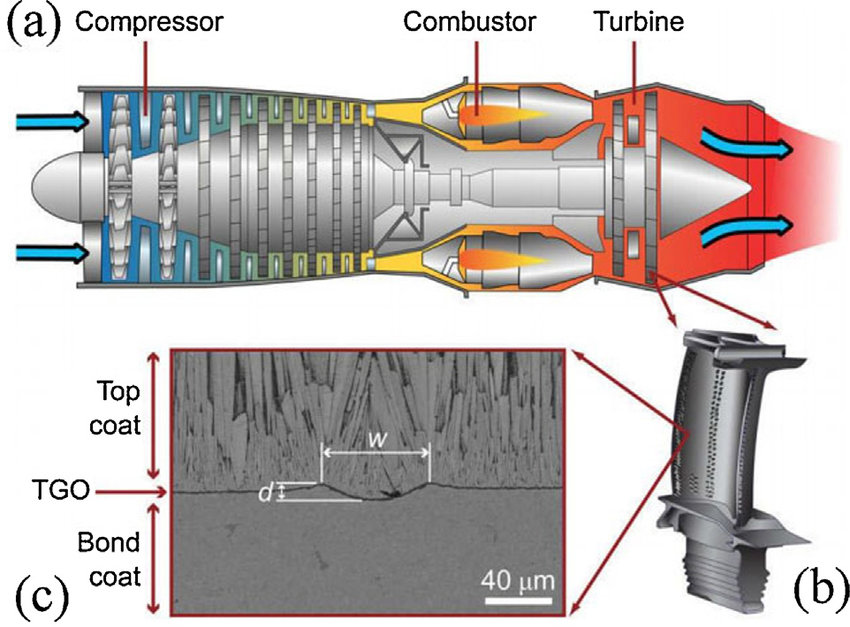

Turbine Blades: Dimensional Stability at 1200°C+

Modern aerospace engines need turbine blades that stay dimensionally stable at temperatures above 1200°C. Nickel-based superalloys with melting points around 1350°C are common, but molybdenum-based materials show promise due to their higher melting temperatures. The biggest problem these materials face above 700°C is a severe pesting phenomenon, which needs protective barrier coatings. Ceramic matrix composites (CMCs) are great candidates for turbine applications and provide better weight-to-thrust ratios than conventional alloys. Oxide CMCs resist oxidation exceptionally well, while non-oxide variants conduct heat better (≈9.8 W m−1 K−1) and have low thermal expansion coefficients (≈4.0 × 10−6 °C−1).

Combustion Chambers: Oxidation Resistance via Sintered Alloys

Combustion chambers work in aggressive gas environments and need exceptional oxidation resistance. C103 niobium alloy combustion chambers are made cost-effectively using cold-spray deposition techniques on removable plastic mandrels. Platinum-iridium coatings make these components better at resisting oxidation – up to 300°F (≈150°C) higher than standard silicide coatings. The iridium component helps minimize reactions with the chamber material at extreme temperatures while protecting against oxidation at the throat section.

Bearings and Shafts: Wear Resistance from Powder Metallurgy

Sintered metal components play vital roles in aerospace bearings and shafts, where durability under extreme conditions matters most. These parts can have customized porosity and mechanical strength while weighing less than conventional materials. The sintering process creates components that resist heat better and have mechanical properties perfect for high-speed rotation and thermal stresses. These bearings work exceptionally well when they need to handle high temperatures and corrosive environments.

Structural Brackets: Lightweight Sintered Titanium Alloys

Lightweight, high-strength brackets are another key application of sintering in aerospace structures. GKN Powder Metallurgy makes sintered components for landing gear assemblies and structural applications with excellent strength-to-weight ratios. Titanium alloy brackets made through additive manufacturing and sintering processes weigh up to 63% less than original designs. These optimized components keep their structural integrity while making aircraft lighter, which helps improve fuel efficiency and reduce carbon footprint. Advanced design techniques that use cellular structures make these benefits even better by replacing solid sections with optimized geometries.

Advanced Sintering Techniques for Aerospace Applications

Aerospace manufacturing depends on specialized sintering methods that boost component performance under extreme conditions. These techniques tackle unique challenges in aerospace materials processing and balance densification with microstructural control.

Ultra High Temperature Sintering (UHTS) for Ceramic Matrix Composites

Ultra-high-temperature ceramic matrix composites (UHTCMCs) can withstand temperatures above 2000°C with minimal erosion. This makes them perfect for rocket nozzles and thermal protection systems. The materials use ZrB2/SiC matrices processed through hot pressing or spark plasma sintering. UHTCMCs show no measurable erosion even after repeated exposure to propulsion environments. Their oxidation mechanism creates a protective ZrO2 intermediate layer with liquid SiO2 surface coating that protects components from further breakdown.

High-Pressure High-Temperature Sintering for Densification

High pressure sintering techniques solve the densification challenges of refractory ceramics with covalent bonds. Hot pressing at high pressures (16-48 MPa) and temperatures (1250-1350°C) produces Ti/TiB composites with better densification rates and less porosity. High pressure-high temperature (HPHT) processing achieves better densities in boride ceramics compared to standard methods. Pressure application helps with particle rearrangement at first, then promotes grain boundary diffusion over lattice diffusion.

Additive Manufacturing with Laser-Assisted Sintering

Laser-assisted sintering combines additive manufacturing with precise thermal control to create complex aerospace geometries. This method allows quick prototyping of high-temperature components while keeping exceptional material properties. The process builds near-fully dense structures with controlled porosity and microstructure customized for specific aerospace needs.

Two-Step Sintering for Grain Growth Control

Two-step sintering (TSS) stops excessive grain growth during densification. The materials heat up to high temperatures for compaction first, then cool to lower temperatures for longer periods. This approach creates finer, more uniform microstructures without losing density. TSS achieves densities that exceed 98% at temperatures below 2000°C for solid-state sintered silicon carbide. The process keeps grain-boundary diffusion working while limiting grain-boundary migration.

Ceramic Furnace Setters and Process Optimization

Quality aerospace components depend on precision control during the sintering process. Specialized equipment and detailed procedures work together to maintain material integrity at extreme temperatures.

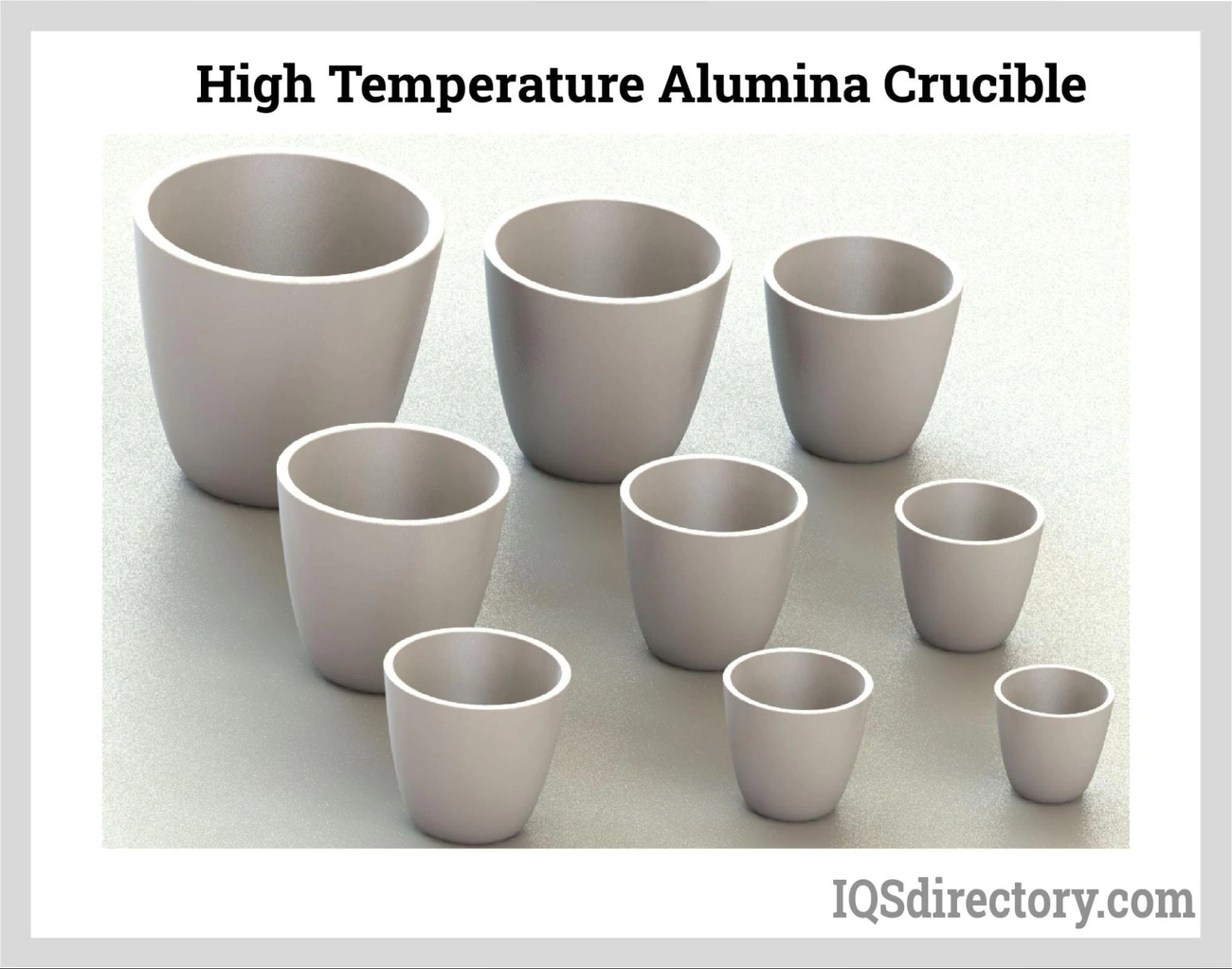

Precision Control in High Temperature Sintering Alumina Ceramic Crucible

High temperature sintering alumina ceramic crucibles are the foundations of aerospace material processing. These crucibles can withstand temperatures up to 1800°C. Made from 99.8% pure aluminum oxide, they resist corrosive melts and maintain dimensional stability】. Alumina purity above 99.5% prevents contamination when heated in semiconductor or metallurgical applications. Their heat distribution properties boost thermal efficiency, which infrared thermography confirms.

Furnace Calibration for Uniform Thermal Profiles

Consistent performance across sintering cycles requires regular furnace fine-tuning. The System Accuracy Test (SAT) checks temperature control accuracy and spots potential errors in thermocouple readings. Temperature Uniformity Surveys (TUS) ensure even heat distribution. Sensors placed at strategic locations—center, corners, and edges—detect variations. This uniformity is vital for processes with annealing and sintering, where temperature changes affect material integrity.

Quality Assurance through In-Situ Monitoring

Real-time monitoring systems track process characteristics at sampling rates up to 50 kHz. Advanced coaxial sensors track melt pool emissions during fabrication and identify key parameters, including melt pool area and intensity. Position-related signals generate three-dimensional data landscapes similar to CT scans, which enable quick post-process analysis.

Collaboration Between Engineers and Furnace Operators

Ceramic furnace setters expertise drives successful sintering operations as they configure and operate specialized furnaces. These professionals fine-tune heating cycles based on material needs to ensure optimal processing conditions. Their strategic collaborations with engineers help refine techniques and implement breakthroughs that advance aerospace manufacturing capabilities.

Conclusion

High-temperature sintering is the life-blood of modern aerospace manufacturing. This technology helps components withstand extreme thermal and mechanical stress in aircraft engines. Sintering temperatures above 2500°F create exceptional mechanical properties that are crucial for mission-critical parts. It also uses specialized processes like vacuum sintering to protect reactive materials from oxidation. Ultra-high-temperature techniques produce ceramic matrix composites that survive temperatures beyond 2000°C.

These technologies have transformed numerous aircraft systems. Advanced sintering processes help turbine blades stay stable at temperatures above 1200°C. Sintered alloys give combustion chambers better oxidation resistance. Powder metallurgy techniques create bearings and shafts with exceptional wear resistance. Structural brackets made from sintered titanium alloys cut aircraft weight substantially without losing structural integrity.

The field keeps expanding with advanced sintering methods. Two-step sintering keeps grain growth in check while maintaining density. This creates finer, more uniform microstructures. High-pressure techniques speed up densification for hard-to-process refractory ceramics. These approaches combined with additive manufacturing create complex geometric designs that were impossible before.

Precision control and expertise are the foundations of these technological breakthroughs. Alumina ceramic crucibles stay stable at temperatures up to 1800°C. Proper furnace calibration creates uniform thermal profiles during sintering cycles. Immediate monitoring systems detect process characteristics and allow quick quality checks.

The aerospace manufacturing’s future depends on refined high-temperature sintering technology. These processes will stay vital to create next-generation aircraft components that perform better under tough conditions. Through collaboration with materials scientists, engineers, and furnace operators will adopt state-of-the-art methods in this critical field. This ensures continued growth in aerospace capabilities.

Key Takeaways

High-temperature sintering is revolutionizing aerospace manufacturing by creating components that can withstand extreme conditions exceeding 2500°F while maintaining structural integrity and performance.

• High-temperature sintering enables aerospace components to operate at temperatures above 1200°C, creating turbine blades and engine parts with exceptional thermal stability and oxidation resistance.

• Vacuum sintering furnaces prevent oxidation of reactive materials like titanium and nickel alloys, ensuring superior mechanical properties essential for jet engine applications.

• Advanced techniques like ultra-high-temperature sintering produce ceramic matrix composites capable of surviving temperatures beyond 2000°C with minimal degradation.

• Two-step sintering controls grain growth while preserving density, creating finer microstructures that enhance component durability and performance.

• Precision control through specialized equipment like alumina ceramic crucibles and real-time monitoring systems ensures consistent quality across aerospace manufacturing processes.

The collaboration between materials scientists, engineers, and furnace operators continues to drive innovation in this critical field, enabling the development of lighter, stronger, and more heat-resistant aerospace components that push the boundaries of flight performance and safety.

FAQs

Q1. What are the key benefits of high-temperature sintering in aerospace manufacturing? High-temperature sintering enables the creation of aerospace components that can withstand extreme temperatures exceeding 2500°F (1371°C) while maintaining structural integrity. This process is crucial for producing parts like turbine blades and combustion chambers that operate in demanding environments, offering exceptional thermal stability and oxidation resistance.

Q2. How does vacuum sintering contribute to aerospace component quality? Vacuum sintering furnaces create oxygen-free environments essential for processing reactive materials like titanium and nickel alloys. This prevents oxidation during the sintering process, ensuring that the final products maintain their intended chemical composition and superior mechanical properties, which are critical for jet engine applications.

Q3. What are ultra-high temperature ceramics (UHTCs) and their significance in aerospace? Ultra-high temperature ceramics are advanced materials, typically based on borides and carbides of transition metals, that can withstand temperatures above 2000°C with minimal degradation. They are crucial for applications such as thermal protection systems and rocket nozzles, offering exceptional heat resistance and low thermal conductivity.

Q4. How does two-step sintering improve aerospace material properties? Two-step sintering is an advanced technique that controls grain growth while maintaining high density in materials. It involves heating to a high temperature for initial compaction, followed by cooling to a lower temperature for an extended period. This process results in finer, more homogeneous microstructures, enhancing the durability and performance of aerospace components.

Q5. What role do ceramic furnace setters play in aerospace manufacturing? Ceramic furnace setters are skilled professionals who configure and operate specialized furnaces for sintering aerospace materials. They meticulously calibrate heating cycles based on specific material requirements, ensuring optimal conditions throughout the sintering process. Their expertise is crucial for achieving the precise thermal profiles needed to produce high-quality aerospace components.

Pingback: Why Technical Ceramics Will Double Manufacturing Efficiency by 2025 - 10+ years China Customzied Shop Fittings manufacturer