Sheet metal finishes turn raw materials with imperfections into durable, functional products. Raw material from mills often has minor scratches, identification markings, and cosmetic blemishes. Quality end products need proper finishing.

Metal finishing techniques do more than improve looks. They boost surface properties and substantially improve durability, corrosion resistance, and overall functionality. To cite an instance, galvanizing, powder coating, and anodizing protect steel from corrosion and make it look better. On top of that, these finishes make metal products last longer. Manufacturers can meet specific industry certifications like FDA standards through stainless steel passivation.

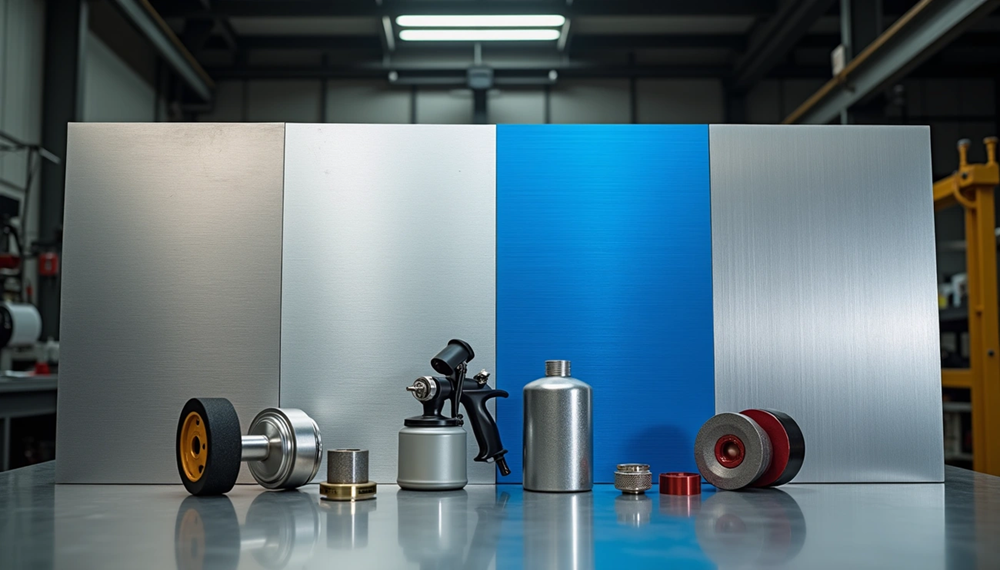

Metal finishing requires choosing from mechanical, chemical, and electrochemical methods that each work differently. Tumbling provides a budget-friendly mass-finishing solution, while electroplating improves corrosion resistance and decorative appeal. The right metal surface finishing technique ensures optimal performance and metal component longevity. Each finish type brings unique advantages – powder coating offers the widest color range among sheet metal finishing options.

This piece compares budget-friendly sheet metal finishes, their applications, durability, and value to help you make smart manufacturing decisions.

Understanding the Role of Sheet Metal Finishing

Surface finish plays a key role in sheet metal fabrication. It goes way beyond just making metal look better. The texture and quality of a metal’s surface directly affect how it performs. Different surface textures can change wear resistance, fatigue properties, lubrication effectiveness, and how vulnerable the metal is to corrosion.

Why surface finishing matters in manufacturing

Sheet metal finishes serve many purposes in industries of all sizes. The right surface finish can change a component’s properties and boost both its performance and how long it lasts. Research shows that specialized high-energy finishing methods can cut down surface profile peaks. These methods create negatively skewed surfaces that have much more surface bearing contact area. These precise changes to surface characteristics affect everything from corrosion resistance to wear performance.

Manufacturers have found something unexpected – parts that get proper finishing work better in real-world use. The surface finish determines how well components perform and how long they last, especially in tough conditions. Getting the right dimensional accuracy and smoothness during manufacturing is crucial. This ensures parts work properly and fit well with other components.

How finishing impacts durability and appearance

Metal surfaces with proper finishing show remarkable improvements in how long they last. High-energy mass finishing can change surface stress conditions. It replaces residual tensile stresses, which can cause early breaks, with uniform residual compressive stresses. Parts with the best surface finishes have lasted longer. One case study shows how this led to fewer maintenance needs and prevented complete failures.

Looks matter too. Surface finishing creates better visual appeal through different textures and appearances – from mirror-like shine to even matte surfaces. People often judge quality by how something looks. This makes surface appearance crucial for products that customers will see.

Manufacturers usually suggest aesthetic finishing like powder coating and silk screening for production parts used in final products, customer-facing components, or trade show demos. These methods make parts look better and protect them from scratches, chips, and rust.

Overview of mechanical, chemical, and electrochemical methods

Sheet metal finishing breaks down into three main types, each with its own benefits:

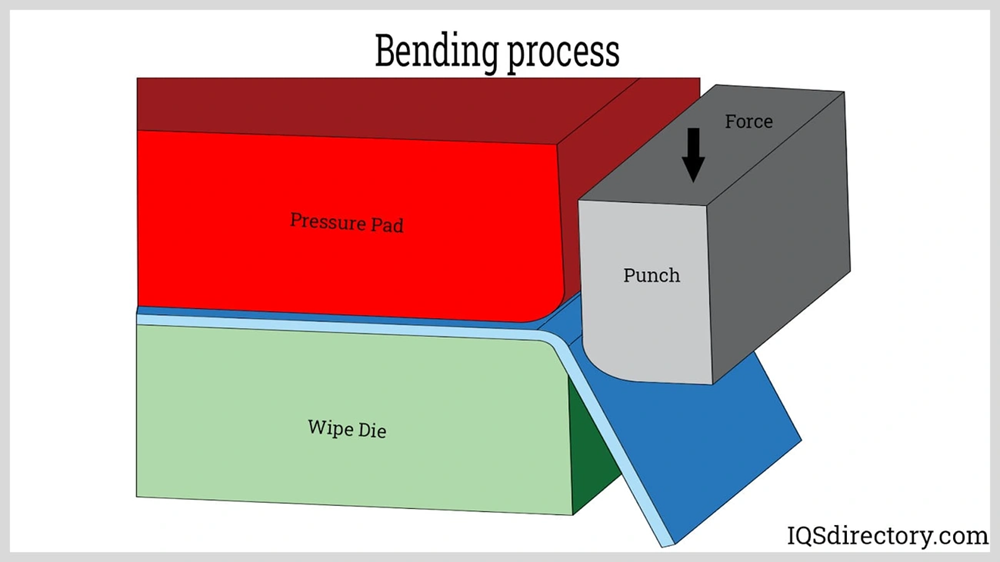

Mechanical methods like barrel, vibratory, centrifugal, and spindle finishing are 15-year-old techniques that create controlled edge and surface finish effects. These methods remove burrs, shape edges, and make parts smooth and polished. You can adjust mass media finishing to help parts last longer and work better. Deburring is crucial for laser-cut parts – it removes dross and burrs while making edges safer to handle.

Chemical methods include processes like passivation that fight corrosion and rust on stainless steel by removing contamination. This cleaning uses citric acid to wash away elements that could cause problems. While not perfect, every stainless steel sheet metal part that needs to handle extreme conditions should get this treatment.

Electrochemical methods like electropolishing work opposite to electroplating. Instead of adding material, electropolishing takes away a thin layer from the metal surface. This can cut surface roughness in half and create a shiny, smooth, super-clean finish. Electropolishing works great for removing tough oxide scale and heat marks that show up on stainless steel after welding.

Knowing these different approaches helps manufacturers pick the best finishing method based on what they need the part to do, what conditions it will face, and their budget limits.

8 Cost-Effective Sheet Metal Finishes You Should Know

Metal components need the right surface treatment to balance cost, performance, and looks. Here are eight economical solutions for sheet metal applications that provide unique benefits without hurting your wallet.

1. Bead Blasting for Uniform Matte Surfaces

Thousands of tiny glass or steel beads shoot at high pressure against metal surfaces to create a consistent, satin-like texture. This versatile technique masks imperfections and keeps the base color of the substrate bright. The beads’ spherical shape creates small dimples that scatter light evenly, which results in an appealing surface with a non-directional texture. You can use bead blasting on aluminum, stainless steel, titanium, brass, and even plastics.

2. Powder Coating for Durable Color Finishes

Powder coating puts a polymer-based colored powder on metal surfaces through an electrostatic process and cures it in an oven. You get a tough 0.002-0.003-inch-thick protective layer that fights scratching and corrosion. This process helps the environment since unused powder can be reclaimed and reused with minimal VOC emissions. The coating comes in gloss, semi-gloss, flat, metallic, and textured finishes in any color you want, which makes it perfect for everything from appliances to outdoor furniture.

3. Anodizing Aluminum for Corrosion Resistance

An electrochemical process creates a controlled oxide layer on aluminum using an acid electrolyte bath and electric current. This treatment makes the natural oxide layer thicker to improve corrosion resistance without adding much weight. The anodic film becomes part of the aluminum surface and creates a hard, insulative layer that resists wear while allowing bright colors. This process works well on titanium and other non-ferrous metals too.

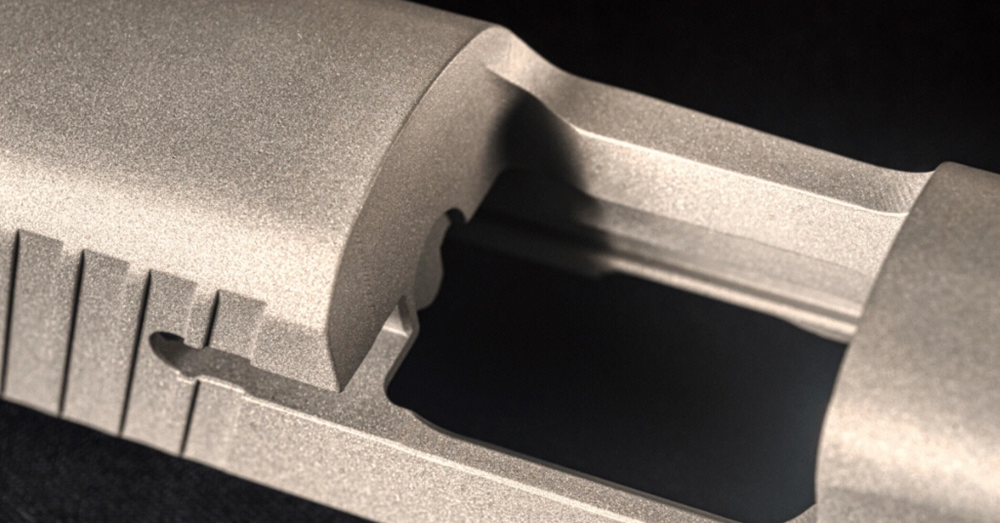

4. Electropolishing for Smooth, Clean Surfaces

Think of electropolishing as reverse electroplating – it removes material instead of adding it to create an ultra-clean, shiny surface. Surface roughness drops by up to 50% as microscopic peaks disappear. Medical, food processing, and semiconductor industries love the smooth, corrosion-resistant surface because it’s easy to clean. The process takes out embedded particles and surface contaminants while boosting stainless steel’s chromium content for better corrosion protection.

5. Vibratory Finishing for Mass Deburring

Mechanical motion helps process multiple parts at once through vibratory finishing. This economical method combines deburring with surface improvement as parts and finishing media move together. Parts get degreased or deoiled at the same time, which eliminates separate pre-washing. Production environments benefit from consistent, repeatable results across component batches.

6. Chemical Film Coating for Paint Adhesion

Chemical film coating puts a chromate conversion coating on aluminum that protects it and helps paint stick better. This coating is so thin you can’t measure it, but it still provides great corrosion protection. Modern versions use trivalent chromium (Type II) instead of hexavalent chromium (Type I) to meet environmental rules while working just as well. Aerospace, defense, and electronics industries value this coating because it provides environmental protection and conducts electricity.

7. Zinc Plating for Budget-Friendly Protection

A thin zinc layer (up to 1 mil/25 μm thick) protects steel components from corrosion. Small parts like fasteners, hardware items, and indoor components work great with this electro-deposition process. Zinc sacrifices itself to protect the metal underneath – it corrodes first and can extend steel’s life by up to 30 years. You won’t find a more affordable way to protect against corrosion.

8. Brushed Finish for Esthetic Appeal

Abrasive brushes moving in one direction create distinctive linear patterns on metal surfaces. This satin-like texture hides fingerprints and minor scratches while looking sophisticated and modern. Consumer electronics, cars, and kitchen appliances now feature brushed finishes more often because they look good and work well. Device casings with brushed finishes show 80% fewer fingerprints and last 40-60% longer.

Comparing Sheet Metal Finishing Techniques by Application

Sheet metal finishes must match specific techniques to their intended uses. The right finish depends on environmental factors, functional needs, and base materials. These elements help determine which finish will work best while staying budget-friendly.

Best finishes for indoor vs outdoor use

The environment plays a key role in choosing the right finish. Outdoor applications need extra protection against harsh weather. Galvanizing works great in humid or coastal areas and can withstand over 500 hours of salt spray testing. Zinc plating acts as a protective barrier that corrodes first to shield the steel underneath. This makes it perfect for indoor parts or those with minimal outdoor exposure. PVDF coatings are another option that prevents color fading and lasts 20+ years in UV-exposed areas.

Indoor applications give you more options. Raw finishes are often good enough when the base material suits the environment. Stainless steel might not need any extra finishing for indoor use because it resists corrosion naturally. Most fabrication shops use Class C finishes. These provide good protection for interior parts that will later be painted or powder-coated.

Finishes for high-wear vs decorative parts

Parts that see heavy wear need finishes that last longer than they look good. Electroplating and hard anodizing work well for moving parts that face friction. Phosphate coatings resist corrosion and stick well to surfaces. They create gray or black finishes that car manufacturers often use. Vibratory finishing helps with mass deburring when parts need smooth edges all around.

Decorative metal sheets focus on looks without sacrificing function. Buff polishing creates attractive surfaces that pharmaceutical and food companies love. Class A finishes look the best and are perfect for visible parts like medical devices. Brushed finishes offer a modern look while hiding fingerprints and small scratches.

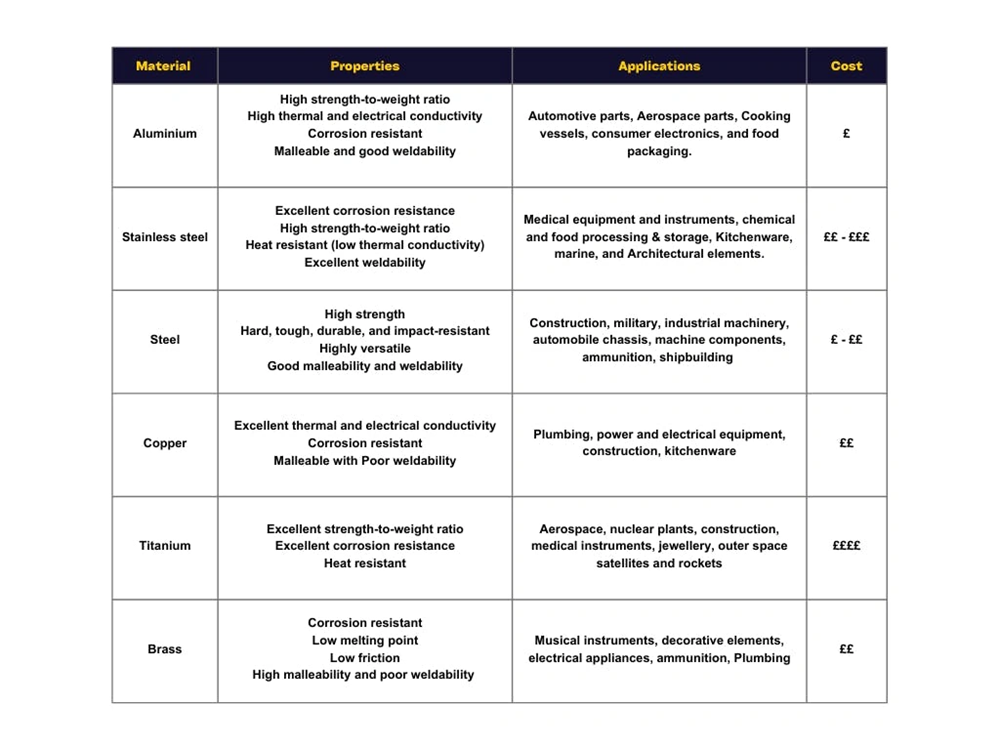

Matching finish to base metal: aluminum, steel, brass

Your choice of base metal limits which finishes will work. Aluminum takes well to anodizing. This creates colored, corrosion-resistant surfaces, but won’t work with galvanizing or black oxide treatments. Carbon steel accepts many finishes, including electroplating, paint, and phosphating. Brass usually gets polished to show off its natural beauty. A lacquer coating then protects it from tarnishing.

Some finishes make metals work even better. Electropolishing helps aluminum resist corrosion better. Powder coating works well on most metals. The compatibility chart shows some important limits. You can only anodize aluminum and titanium, but paint and powder coating work on almost any common metal.

Cost vs Performance: How to Choose the Right Finish

Smart decisions about sheet metal finishes need a balance between original costs and long-term benefits. The right choices can save you money while your components still work as needed.

Material cost and process complexity

Raw material choice affects finishing costs by a lot. Aluminum costs less than stainless steel, and mild steel is even more affordable. The complexity of the process changes the price—powder coating and galvanizing are affordable for bigger batches. Manual polishing needs skilled workers, which makes it more expensive. Automated systems cost more to set up but ended up cutting labor costs in mass production.

Durability and maintenance trade-offs

Maintenance needs directly shape lifetime costs. Stainless steel products keep their look with basic cleaning—mild detergent solutions are enough. Powder-coated surfaces last longer and need less maintenance than regular wet paint. Zinc plating gives budget-friendly protection for outdoor use by acting as a protective barrier. However, it needs more frequent care than premium options.

Premium finishes are worth their cost in certain cases. Parts that customers see often need better looks. Yes, it is worth spending more on parts exposed to harsh environments. Sometimes mixing finishes gives better results—combining anodizing with powder coating creates excellent aluminum protection that’s worth the extra cost.

Common Mistakes and How to Avoid Them

Sheet metal manufacturers face finish-related challenges despite their experience because they miss key technical details. Understanding these common mistakes helps them avoid expensive rework and maintain component performance.

Overlooking thickness changes from coatings

The finishing process adds material that affects final dimensions. Powder coating adds 0.003″-0.005″ per side to overall dimensions, which can cause interference in precision assemblies. Hot-dip galvanizing thickness varies with the base steel material. Standards like ASTM A123 and ISO 1461 specify coating requirements. Manufacturers need to include these thickness allowances in their designs early. Parts often fit incorrectly because these dimensional changes were not considered.

Ignoring tolerance shifts in polishing processes

Surface finishing changes part dimensions beyond just coating additions. Electropolishing removes material instead of adding it, which can alter vital dimensions. The simple formula of electroplating shows deposit thickness relates to electrical current and time. This relationship changes a lot across different plating baths. Material variations create more problems. Sheet thickness can differ between sections even within the same sheet, which affects stack-ups and precision assemblies.

Choosing finishes incompatible with base metal

Galvanic corrosion happens when different metals touch in the presence of an electrolyte. The Galvanic Series shows metals in the same group stay compatible while metals from different groups cause corrosion. To name just one example, aluminum ranks among the more anodic metals and becomes vulnerable when paired with cathodic materials like gold or silver finishes. Real-world testing sometimes contradicts theory. Studies reveal similar corrosion effects between tin/lead, immersion silver, and ENIG finishes despite their different EMF potentials.

Conclusion

The right sheet metal finish depends on several key factors. You need to weigh mechanical, chemical, and electrochemical methods that affect how the final product works and looks. Each technique – bead blasting, powder coating, anodizing, or electropolishing – works best for specific uses and materials.

Affordable finishing options need to balance upfront costs with long-term benefits. Powder coating gives great durability and color choices for most metals. Aluminum components work best with anodizing for better corrosion resistance. Zinc plating serves as a budget-friendly protective layer indoors, while galvanizing protects outdoor materials reliably.

Manufacturers must factor in size changes when they apply finishes. The coating’s thickness affects tolerances, and polishing takes material off the surface. Metal and finish compatibility is vital since mismatched combinations can trigger galvanic corrosion and early failure.

Sheet metal projects soar when finishing techniques match specific needs rather than using standard options. The best finish depends on environmental conditions, wear patterns, base materials, and looks. Companies that grasp these details get better results while keeping costs in check.

Surface treatments change basic components into lasting, practical, and attractive products. These treatments are the foundations of metal fabrication that boost product life, performance, and quality. This knowledge helps manufacturers make smart choices that balance costs with performance needs in their applications.

Key Takeaways

Master these essential insights to select cost-effective sheet metal finishes that balance performance, durability, and budget constraints for your manufacturing projects.

• Match finish to environment: Outdoor applications need galvanizing or PVDF coatings for UV/corrosion resistance, while indoor parts can use simpler finishes like zinc plating or raw stainless steel.

• Account for dimensional changes: Powder coating adds 0.003″-0.005″ thickness per side, while electropolishing removes material—factor these changes into design tolerances early.

• Choose compatible metal-finish combinations: Aluminum works with anodizing but not galvanizing; steel accepts most finishes; brass requires polishing with protective lacquer coating.

• Balance cost vs performance: Zinc plating offers budget-friendly protection for low-wear indoor parts, while premium finishes like hard anodizing justify costs for high-wear applications.

• Consider batch processing for savings: Vibratory finishing and powder coating become more economical with larger quantities due to setup costs and automated processing capabilities.

Understanding these fundamentals helps manufacturers avoid costly rework while achieving optimal component performance. The key is selecting finishes based on specific application requirements rather than defaulting to standard options, ensuring both functional success and cost efficiency in your sheet metal projects.

FAQs

Q1. What are the most cost-effective sheet metal finishes for outdoor use? For outdoor applications, galvanizing and PVDF coatings are highly cost-effective. Galvanizing can withstand over 500 hours of salt spray testing, making it ideal for humid or coastal environments. PVDF coatings offer excellent UV resistance, retaining color for 20+ years in outdoor settings.

Q2. How does powder coating compare to traditional wet paint? Powder coating offers superior durability and reduced maintenance compared to traditional wet paint. It provides a thick, protective layer (0.002-0.003 inches) that resists scratching and corrosion. Additionally, powder coating is more environmentally friendly, with minimal VOC emissions and the ability to reclaim and reuse unused powder.

Q3. What finishing technique is best for aluminum components? Anodizing is an excellent choice for aluminum components. This electrochemical process creates a controlled oxide layer that significantly improves corrosion resistance without adding much weight. Anodizing also allows for vibrant coloring options and creates a hard, insulative layer that resists wear.

Q4. How can manufacturers avoid common mistakes when choosing sheet metal finishes? To avoid common mistakes, manufacturers should account for dimensional changes caused by finishes (e.g., powder coating adds 0.003″-0.005″ per side), consider tolerance shifts in polishing processes, and ensure compatibility between the base metal and chosen finish to prevent galvanic corrosion.

Q5. What factors should be considered when balancing cost and performance in sheet metal finishing? When balancing cost and performance, consider factors such as material costs, process complexity, batch size, durability requirements, and maintenance needs. For example, zinc plating offers budget-friendly protection for indoor use, while premium finishes like hard anodizing may justify higher costs for high-wear applications or customer-facing components.