Introduction

Aluminium 3D printing has revolutionized the manufacturing industry by providing a versatile, efficient, and cost-effective method for producing complex parts and components. The importance of custom solutions in this domain cannot be overstated, as they offer tailored designs that meet specific industry needs. This article delves into the advantages of aluminium 3D printing, the process of customization, and the intricate details of the 3D printing process itself.

Advantages of Aluminium 3D Printing

Lightweight and Strong

One of the most significant advantages of aluminium is its exceptional strength-to-weight ratio. Aluminium parts are lightweight yet incredibly strong, making them ideal for applications where weight reduction is critical. For instance, in the aerospace industry, reducing the weight of components can lead to significant fuel savings and increased payload capacity. Similarly, in the automotive industry, lighter parts contribute to better fuel efficiency and performance.

High Corrosion Resistance

Aluminium naturally forms a thin oxide layer on its surface, which protects it from corrosion. This inherent property makes aluminium an excellent choice for parts exposed to harsh environments, such as marine or industrial applications. The high corrosion resistance of aluminium ensures longevity and reliability, reducing maintenance costs and downtime for industries relying on durable components.

Versatility in Design

The flexibility of aluminium in creating complex geometries is another critical advantage. Aluminium 3D printing allows for the production of intricate designs that would be impossible or highly impractical with traditional manufacturing methods. This capability is particularly beneficial for industries that require precise and custom shapes, such as medical devices, consumer electronics, and architectural components.

Customization in Aluminium 3D Printing

Tailored Design and Prototyping

Custom solutions in aluminium 3D printing begin with tailored designs that meet specific client requirements. The process starts with creating detailed CAD models, which are then used to produce prototypes quickly and efficiently. Rapid prototyping enables businesses to test and refine their designs before committing to full-scale production, ensuring the final product meets all specifications and performs as expected.

Specific Industry Applications

Aerospace

In the aerospace industry, custom aluminium parts are crucial for producing lightweight aircraft components that enhance fuel efficiency and reduce emissions. Aluminium 3D printing enables the creation of complex shapes and structures that are both lightweight and strong, contributing to the overall performance and safety of the aircraft.

Automotive

Custom aluminium designs in the automotive sector lead to performance-enhancing parts such as lightweight engine components, heat exchangers, and structural parts. These custom solutions not only improve vehicle efficiency but also contribute to a reduction in overall vehicle weight, leading to better handling and reduced environmental impact.

Medical Devices

In the medical field, aluminium 3D printing is used to produce patient-specific implants and medical tools. Customization ensures that each part fits perfectly and functions as intended, which is crucial for patient outcomes. The ability to quickly produce and iterate designs also accelerates the development of new medical devices and technologies.

Enhancing Product Performance

Custom aluminium 3D printing enhances product performance by allowing for the creation of parts with optimized geometries and tailored material properties. For example, heat exchangers with complex internal structures can be designed to maximize thermal efficiency. Case studies have demonstrated how custom 3D printed parts outperform their traditionally manufactured counterparts in terms of strength, weight, and durability.

The Aluminium 3D Printing Process

Step-by-Step Overview

The aluminium 3D printing process involves several critical steps, each contributing to the precision and quality of the final product.

Design Phase

The process begins with the design phase, where detailed CAD models are created. These models must be precise and account for all functional requirements of the final part. The design phase is crucial as it lays the foundation for the entire manufacturing process.

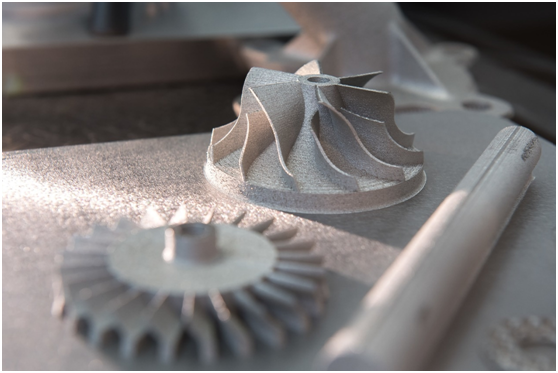

Printing Phase

The next step is the printing phase, which typically involves Selective Laser Melting (SLM) or Direct Metal Laser Sintering (DMLS). In this phase, a high-powered laser melts and fuses aluminium powder layer by layer, building the part from the ground up. The precision of this process allows for the creation of intricate and highly detailed components.

Post-Processing

Post-processing is essential for achieving the desired surface finish and mechanical properties. This phase may include heat treatment, machining, and surface finishing techniques such as polishing or coating. Post-processing ensures that the printed part meets all specifications and performs optimally in its intended application.

Quality Control and Testing

Ensuring the accuracy and reliability of 3D printed parts is paramount. Quality control measures include dimensional inspections, mechanical testing, and non-destructive testing methods such as X-ray or ultrasonic inspection. These tests verify that the parts meet all quality standards and are free from defects.

Material Considerations

Various aluminium alloys can be used in 3D printing, each with its unique properties. The selection of the appropriate alloy depends on the specific requirements of the application, such as strength, thermal conductivity, or corrosion resistance. Commonly used aluminium alloys in 3D printing include AlSi10Mg and AlSi12, known for their excellent mechanical properties and suitability for a wide range of applications.

Commonly used aluminum alloy 3D printing raw materials:

- Aluminum alloy powder: Aluminum alloy powder is one of the main raw materials for aluminum alloy 3D printing. It has good fluidity and compactability and is suitable for laser or electron beam melting molding.

- Aluminum alloy wire: Aluminum alloy wire is also commonly used in 3D printing, especially suitable for large-scale printers using pulsed laser deposition (DED) technology.

- Pre-alloy powder: In addition to pure aluminum alloy powder, pre-alloy powder is also widely used in aluminum alloy 3D printing, and aluminum alloy materials with specific properties can be obtained through precise formulation.

- Metal powder alloy: Some aluminum alloy 3D printing technology can also use metal powder alloy, by alloying aluminum with other metals (such as titanium, magnesium, etc.), you can obtain materials with specific properties.

Advantages and disadvantages of aluminum 3D printing

1) Advantages of aluminum 3D printing include:

- High degree of design freedom: Aluminum alloy 3D printing technology can realize the manufacturing of complex geometric shapes, so it has a very high degree of design freedom. Designers have more flexibility to create part structures that meet specific needs.

- Customization: Can directly print complex shaped parts according to customer needs to achieve personalized customization.

- Lightweight: Can produce lightweight and high-strength aluminum alloy parts, which is conducive to improving product performance.

- Simplify the manufacturing process: compared with the traditional casting and processing methods, reduce the manufacturing steps and process flow, improve the production efficiency, do not need to make molds, can save at least 30-40 days.

- Material saving: Waste and material waste are reduced through precise material deposition.

- Fast delivery: The cycle from design to object is greatly shortened. This makes the product development process more efficient. Greatly shorten the product delivery cycle, only 1-2 days to sample.

- Strong production flexibility: suitable for small batch production and customized production, without additional molds or tooling. This makes production planning more flexible and able to respond more quickly to changes in market demand.

2). The disadvantages of aluminum 3D printing include:

- High cost: The cost of equipment and materials is relatively high, which may not be economical for some small businesses.

- Unstable surface quality: The surface quality of some complex structures may not be as good as that of traditional manufacturing methods, requiring additional surface treatment.

- Limited material selection: Currently available aluminum alloy materials are relatively few, for some special requirements of the application may not be enough to meet.

- High equipment technical requirements: professional equipment and technical personnel are needed for operation and maintenance, and the technical threshold is high.

JH advantages

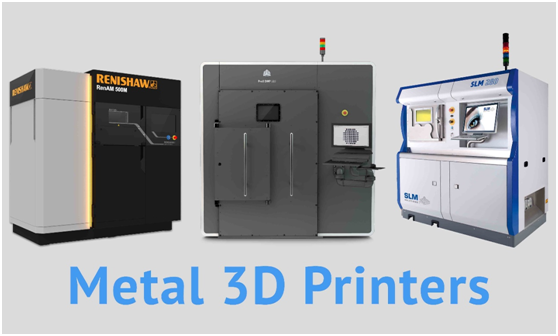

Advanced technology

We use the most advanced aluminum alloy 3D printing technology to ensure product quality and production efficiency. Our equipment is precisely tuned to enable high-precision printing, ensuring that every part meets specifications.

Rich in experience

We have many years of industry experience and have accumulated a wealth of experience and technology in the field of aluminum alloy 3D printing. Our team is composed of professional engineers and technicians who are able to solve a variety of complex production challenges and provide customers with the best solutions.

Customer-first

We always put our customers first and are committed to providing them with the most satisfactory service. We work closely with our customers to understand their needs and provide customized solutions. Whatever the size of your project, we will do our best to meet your requirements and ensure your satisfaction.

conclusion

Aluminum 3D Printing services provide you with a customized solution that can meet your business needs. Whether you need personalized design, rapid prototyping or mass production, we can provide you with a high quality service. Contact us and let us add new life to your project together!

Aluminium 3D printing Service: