Ceramic Molding: Advanced Techniques and Applications

Introduction

Ceramic molding is a crucial manufacturing process in the production of high-performance components used across various industries, including aerospace, automotive, and electronics. This article delves into the advanced techniques employed in ceramic molding, explores the diverse applications of ceramic components, and highlights the technological advancements propelling this field forward.

Advanced Techniques in Ceramic Molding

Slip Casting

Slip casting is a prevalent ceramic molding technique involving the pouring of a liquid clay body slip into a plaster mold, which absorbs the water, leaving a solid layer of clay. This method is renowned for producing complex shapes with high precision.

Process Overview

- Preparation of Slip: The liquid clay body slip is prepared by mixing clay with water and deflocculants.

- Molding: The slip is poured into a plaster mold which absorbs water, forming a solid layer.

- Draining: Excess slip is drained, leaving a hollow shape.

- Drying and Firing: The cast piece is dried and then fired in a kiln to achieve its final hardness.

Advantages

- High Precision and Detail: Capable of producing intricate details and smooth surfaces.

- Complex Geometries: Suitable for creating complex shapes that are challenging with other methods.

- Cost-Effective: Ideal for small to medium production runs with lower costs.

| Feature | Slip Casting |

| Precision | High |

| Geometric Complexity | High |

| Production Cost | Low to Medium |

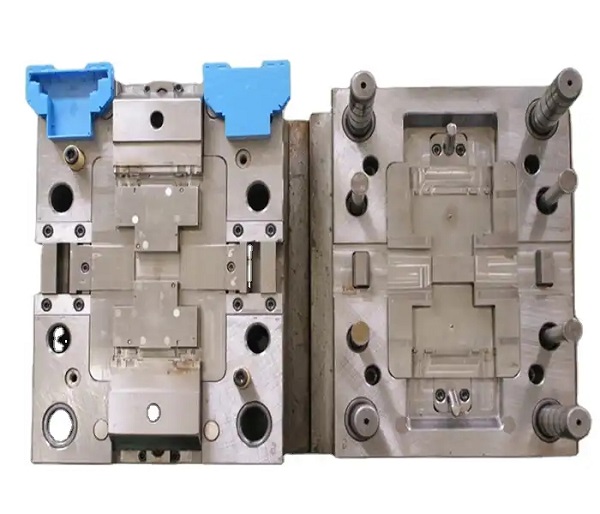

Injection Molding

Injection molding of ceramics is similar to plastic injection molding but involves ceramic powders mixed with a binder to create a feedstock that is injected into a mold under high pressure.

Process Overview

- Feedstock Preparation: Ceramic powders are mixed with a thermoplastic binder to create a feedstock.

- Injection: The feedstock is injected into a mold under high pressure.

- Debinding: The binder is removed through a thermal or chemical process.

- Sintering: The molded part is sintered at high temperatures to achieve final properties.

Advantages

- High Production Rates: Suitable for large-scale production with high efficiency.

- Repeatability and Consistency: Ensures uniformity across all produced parts.

- Precision: Produces highly accurate and detailed components.

| Feature | Injection Molding |

| Production Rate | High |

| Repeatability | Excellent |

| Precision | High |

Ceramic molding compared with other ceramic methods

| Forming method | Forming material | Crystal shape | Diameter | Thickness | Production efficiency | Technical essentials |

| Injection molding | Powder + organic material (10%~25%) | complexity | 30~0.5 | 3.0~1 | Mass production | Additive selection; degrease |

| Mechanical pressing | Powder + organic material (4%~8%) | easy | 20~1.0 | 0.8~1.0 | Intermittent, automatic mass production | Particle adjustment |

| Cold isostatic pressure | Powder + organic material (3%~8%) | More complex cylindrical spheroids | 150~3 | 150~1.9 | Flow production | Particle adjustment, mold production |

| Slurry casting | Powder + various materials + water | complexity | 150~20 | 3.0~0.3 | Batch production | Control particle size and adjust paste |

| Doctor blade | Powder + various materials + organic solvent | easy | 200~15 | 0.2~0.003 | Automatic mass production | Particle size distribution, pulp adjustment, organic matter selection |

| Extrusion | Powder + various materials + water | Rod-shaped tube | 30~20 | 2.5~0.01 | Continuous mass production | Additive selection |

Gel Casting

Gel casting combines the benefits of slip casting and injection molding by using a gelling agent to form a solid, moldable material.

Process Overview

- Slurry Preparation: A ceramic slurry is prepared with a gelling agent.

- Molding: The slurry is poured into a mold and allowed to gel and solidify.

- Drying and Sintering: The solidified part is dried and then sintered.

Advantages

- High Green Strength: Reduces handling damage during processing.

- Large and Complex Shapes: Capable of producing large and intricate components.

- Superior Mechanical Properties: Results in parts with excellent mechanical strength.

| Feature | Gel Casting |

| Green Strength | High |

| Complexity | High |

| Mechanical Properties | Superior |

Applications of Ceramic Molding

Aerospace Industry

Ceramic components are vital in aerospace applications due to their high strength, lightweight, and thermal resistance.

Turbine Blades

Ceramic matrix composites are used for high-temperature turbine blades, improving fuel efficiency and performance. These blades can withstand extreme temperatures and pressures.

| Component | Material | Benefit |

| Turbine Blades | Ceramic Matrix Composites | High-temperature resistance |

| Thermal Shields | Ceramics | Extreme temperature protection |

Thermal Shields

Ceramic thermal shields protect critical aerospace components from extreme temperatures, enhancing durability and lifespan.

Automotive Industry

The automotive industry leverages ceramic molding for components requiring high durability and thermal stability.

Engine Components

High-performance ceramic spark plugs and sensors are produced using ceramic molding, leading to enhanced engine efficiency and longevity.

Brake Systems

Ceramic brake discs offer superior heat resistance and longevity, improving braking performance and safety.

| Component | Benefit |

| Spark Plugs & Sensors | Improved efficiency |

| Brake Discs | Enhanced durability |

Electronics Industry

Ceramics are extensively used in the electronics industry for their insulating properties and ability to withstand high temperatures.

Substrates and Insulators

Ceramic substrates are used for electronic circuits due to their superior electrical insulation and thermal management.

Capacitors and Resistors

Ceramic materials are used in capacitors and resistors to ensure stable performance and reliability in high-frequency and high-temperature environments.

| Application | Feature |

| Substrates & Insulators | Electrical insulation |

| Capacitors & Resistors | High stability |

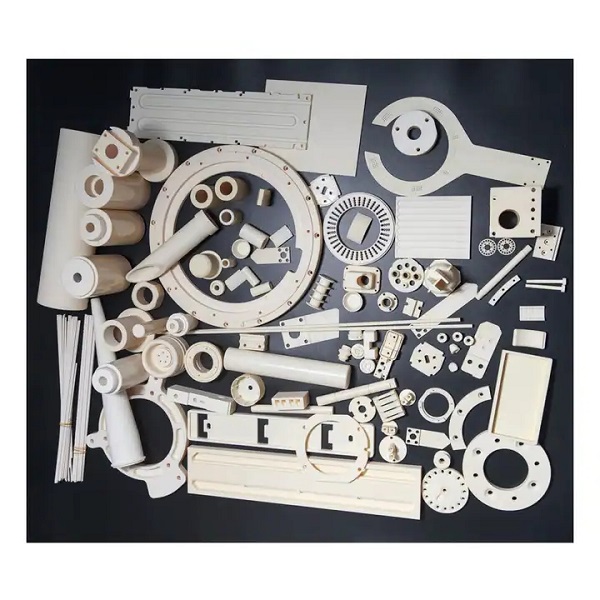

Ceramic molding parts application field

| Application field | Typical product |

| Aerospace industry | Turbine rotor, blade, aircraft spacecraft bearing, accessory rocket nose cone |

| Automobile industry | Spark plug, automotive engine, valve, piston, turbocharger rotor, nozzle |

| Electronics industry | Optical fiber guide, integrated circuit board, resistor, heating element |

| Medical treatment | Artificial bones, artificial joints, artificial gums, dentures, medical knives |

| Daily necessities | Watch case, hair clippers, insulator, spring |

| Machinery industry | Gears, screws, nuts, cutting tools, seals, wire drawing dies, ball grinding parts |

Technological Advancements in Ceramic Molding

Additive Manufacturing

Additive manufacturing, or 3D printing, of ceramics is revolutionizing the production of complex and customized ceramic parts.

Process Overview

- Layer-by-Layer Deposition: Ceramic materials are deposited layer by layer.

- Sintering: The part is sintered to achieve its final properties.

Advantages

- Design Flexibility and Customization: Allows for intricate and unique designs.

- Reduction in Material Waste and Lead Times: Minimizes waste and shortens production cycles.

| Feature | Additive Manufacturing |

| Design Flexibility | High |

| Material Waste | Low |

| Lead Times | Short |

Advanced Materials

The development of new ceramic materials with enhanced properties is expanding the range of applications for ceramic molding.

High-Performance Ceramics

New ceramics with improved toughness and thermal resistance are being developed, allowing for use in more demanding environments.

Composite Materials

Integrating ceramics with other materials creates composites with enhanced mechanical and thermal properties.

| Material Type | Feature |

| High-Performance Ceramics | Toughness, Thermal resistance |

| Composite Materials | Enhanced properties |

Automation and Precision Control

The integration of automation and precision control in ceramic molding processes is improving production efficiency and part quality.

Automated Molding Systems

Robotics and automated systems ensure consistent production, reducing labor costs and human error.

Precision Control Technologies

Advanced control systems enable precise monitoring and adjustment of molding parameters, resulting in improved quality and consistency of ceramic parts.

| Technology | Benefit |

| Automated Systems | Consistent production |

| Precision Control | Improved quality |

Conclusion

Ceramic molding is a vital manufacturing process with diverse applications across multiple industries. Advanced techniques such as slip casting, injection molding, and gel casting enable the production of high-precision and high-performance ceramic components. The ongoing technological advancements in materials, additive manufacturing, and automation are driving the growth and innovation in ceramic molding, offering new possibilities for industrial applications. By understanding the advanced techniques, applications, and technological advancements, businesses can leverage ceramic molding to achieve superior performance and efficiency in their products.