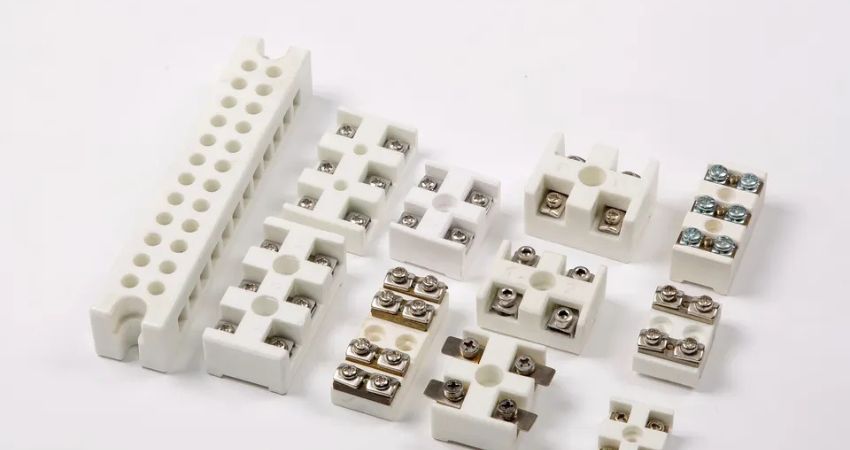

Factory Directly Wholesale Alumina Ceramic Connector Copper Terminal Block

In the field of electronics and electrical engineering, connector selection is crucial as it directly affects the performance, reliability, and cost of the system. Among them, terminal blocks, as a form of connector, are widely used in various devices and systems. With the advancement of technology, the demand for terminal blocks is also constantly changing, requiring them to have higher performance and smaller sizes. Against this background, ceramic terminal blocks, as a new type of high-performance connector, have gradually received widespread attention and application.

- Material properties

The main material of ceramic terminal blocks is ceramic, which has many unique physical and chemical properties. First of all, ceramics have extremely high hardness and wear resistance and can withstand high mechanical stress. Secondly, ceramics have excellent insulation properties and can effectively isolate current and ensure the normal operation of electronic equipment. In addition, ceramics also have properties such as high-temperature resistance, corrosion resistance, and low expansion coefficient, allowing them to maintain stable performance under various harsh environmental conditions.

- Application areas

Due to the excellent properties of ceramic terminal blocks, their application fields are very wide. In the power industry, ceramic terminal blocks are used for high-voltage and high-current connections, which can effectively reduce resistance and heat loss. In the communications industry, ceramic terminal blocks are used to connect optical fiber networks, enabling high-speed, large-capacity data transmission. In the automotive industry, ceramic terminal blocks are used to connect key parts such as engine controls and airbags to ensure the safety and reliability of the vehicle. In addition, ceramic terminal blocks are also widely used in aerospace, rail transit, new energy, and other fields.

- Production process

The production process of ceramic terminal blocks mainly includes raw material preparation, molding, firing and processing. Among them, molding is a key link, and various methods such as grouting, die casting, and isostatic pressing can be used. During the firing process, the firing temperature and atmosphere must be controlled to ensure the performance and appearance quality of the ceramics. Finally, the ceramic terminal blocks also need to be machined and surface treated to meet the needs of different customers.

- Future development

With the continuous development of science and technology, the application prospects of ceramic terminal blocks will be broader. In the future, ceramic terminal blocks will continue to develop towards miniaturization, high density, and high reliability. At the same time, with the popularization and application of 5G communications, the Internet of Things, and other technologies, the demand for ceramic terminal blocks in fields such as high-speed data transmission and smart manufacturing will also continue to increase. In addition, with the improvement of environmental awareness, environmentally friendly ceramic terminal blocks will also become a future development trend.

As a high-performance connector, ceramic terminal blocks have been widely used in various fields. With the continuous advancement of science and technology and changes in market demand, the development prospects of ceramic terminal blocks will be broader. We believe that shortly, ceramic terminal blocks will be applied and developed in more fields, bringing more convenience and beauty to human life.