Carbon’s density exhibits remarkable differences among its various allotropes. The values range from 1.8 to 2.1 g/cm³ for amorphous carbon to 3.5 g/cm³ for diamond. This variation makes carbon-based materials incredibly versatile in engineering applications, and they have become vital to modern materials science.

The density profiles of carbon materials change based on their structure and composition. Material selection decisions by engineers depend a lot on carbon’s density in its various forms. Carbon fiber’s density of about 1.8 g/cm³ makes it perfect for lightweight applications. Carbon black’s density (1.7-1.9 g/cm³) helps reinforce polymers effectively. Carbon fiber composite materials have density values between 1.4-1.7 g/cm³, which gives them an excellent strength-to-weight ratio. Scientists and engineers measure carbon density in g/ml or g/cm³. These units are numerically the same despite different notations.

This piece explores carbon density in different forms, along with measurement methods and real-world uses. Engineers will find how carbon’s density affects performance characteristics. They’ll also learn what matters most to pick the right carbon-based materials for advanced engineering projects.

Fundamentals of Carbon Density in Material Science

Carbon is the sort of thing I love in material science because it knows how to form various allotropes with dramatically different densities. The fundamental properties and structural characteristics of carbon-based materials help us understand these density variations.

What is the density of carbon? (g/cm³ and g/mL units)

Pure carbon’s density varies depending on its allotropic form. Graphitic carbon has an average density of 2.266 g/cm³. These measurements stay the same whether expressed in g/cm³ or g/mL, though their notations differ.

Carbon’s allotropes show remarkable density variations:

- Graphite: 2.267 g/cm³

- Diamond: 3.515 g/cm³

- Amorphous carbon: 1.8-2.1 g/cm³

These values show carbon’s remarkable density range in its different forms. Carbon steel, which uses carbon as an alloying element, has much higher densities from 7.75 g/cm³ to 8.05 g/cm³, showing how other elements in the alloy change the density.

Atomic structure and its influence on density

Different atomic arrangements create substantial density variations between carbon allotropes atomic arrangements. Graphite’s carbon atoms bond trigonally to three others in a plane and create a two-dimensional network of fused hexagonal rings. Flat sheets stack and bond loosely through weak van der Waals forces, which explains graphite’s lower density and softness.

Diamond’s higher density comes from its three-dimensional tetrahedral bonding structure. Each carbon atom connects to four others and forms a compact network of puckered six-membered rings. This tight packing makes diamond’s density (3.515 g/cm³) nearly 55% higher than graphite’s.

Amorphous carbon shows intermediate density values between 1.9 and 2.1 g/cm³ due to its less ordered atomic structure.

Why carbon density matters in engineering applications

Carbon’s density substantially changes several vital material properties that determine its engineering uses. Materials become more durable as carbon’s density increases. Diamond proves this relationship as the hardest naturally occurring material with the highest density among carbon allotropes.

On top of that, it affects porosity – denser carbon materials have lower porosity because particles pack more tightly. This property becomes vital when applications need gas impermeability or strength.

Thermal conductivity associates with carbon density. Denser carbon structures conduct heat better, making them valuable for thermal management. Higher density also improves electrical conductivity as particles create better electrical connections.

Carbon’s density-to-performance ratio density-to-performance ratio offers great ways to get value in a variety of industries, from aerospace parts needing lightweight strength to energy storage systems where density changes capacity and efficiency.

Comparative Densities of Carbon-Based Materials

Carbon-based materials show unique density profiles that shape their engineering applications. Materials engineers use these differences to make better choices about which materials suit specific needs.

Density of carbon fiber vs carbon fiber composite

Raw carbon fiber has density values between 1.75 to 1.93 g/cm³. Carbon fiber reinforced polymer (CFRP) composites show lower values at about 1.55 g/cm³. The difference exists because composites contain resin systems that change the overall density. A typical mix contains 30% epoxy resin and 70% carbon fiber. The composite’s density stays nowhere near most metals – about 2 times less than aluminum (2.7 g/cm³) and 5 times less than steel (7.9 g/cm³). So, replacing aluminum parts with carbon fiber composites cuts weight by about 42%.

Density of carbon black in polymer matrices

Adding carbon black to polymer matrices creates composites with electrical properties that depend on carbon black particle concentration. The composite shows unique electrical conductivity profiles at carbon black volume fractions between 0.16-0.28. The matrix polymer’s density affects these properties a lot. High-density polyethylene matrices boost current density about three times compared to low-density options. This shows how the base polymer’s density affects carbon black composite properties directly.

Graphite vs amorphous carbon: structural impact on density

Graphite’s layered crystalline structure creates density values from 2.1 to 2.3 g/cm³. Amorphous carbon has lower densities, around 1.8-2.1 g/cm³. Both materials contain carbon atoms, but their structural arrangement causes this density difference. The number of defects in the carbon structure is associated inversely with density – more defects mean lower density values. Pure graphite reaches 2.28 g/cm³. This value drops as defects appear, sometimes falling to 1.9 g/cm³ in materials like activated carbon.

Density of carbon g ml: unit conversions and context

The density units g/ml and g/cm³ mean the same thing since 1 ml equals 1 cm³. Engineers use both units when talking about carbon materials. Yes, it is crucial to understand proper unit context when comparing different carbon materials. Densities range from ultralight carbon nanostructures (about 0.8-0.9 g/cm³) to diamond (3.5 g/cm³).

Measurement Techniques and Standards

Scientists need specific techniques to measure carbon density in different material forms. Material scientists use time-tested methods that give accurate and repeatable results for carbon materials of all types.

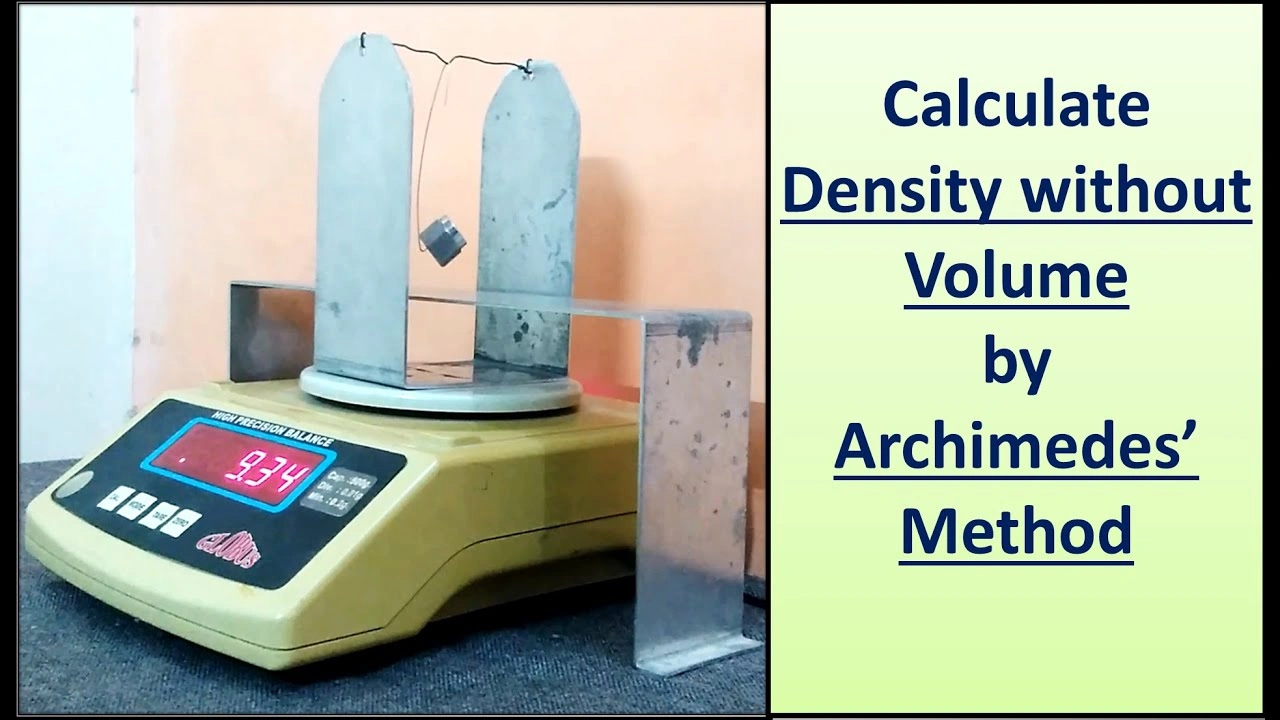

Archimedes’ Principle for solid carbon materials

Archimedes’ Principle is the foundation for determining solid carbon materials. The method works through buoyancy force, which equals the displaced fluid’s weight when an object is submerged. Scientists weigh carbon materials that are denser than water first in air and then in distilled water at 23°C. The density calculation is straightforward: density (kg/m³) = (specific gravity) × (997.6). Materials lighter than water need a sinker with known mass and volume to stay submerged during measurement.

Pycnometry for powdered carbon, like carbon black

Gas pycnometry proves most effective to measure powdered carbon materials’ density, especially carbon black. Helium gas works best for this technique, though nitrogen can substitute when helium reacts with certain materials. The MultiVolume Pycnometer measures sample volumes from 0.5 to 150 cm³ with ±0.1 to 0.2% accuracy. The process involves pressurizing a sample chamber with gas. The gas then expands into a measured volume, creating a pressure drop that reveals volume and density calculations.

ASTM D792 and ISO 1183 standards for density testing

ASTM D792 and ISO 1183 offer standard methods to determine materials’ density and specific gravity. ASTM D792 requires weighing specimens in air and water at 23±2°C. This test shows how specific gravity varies between specimens. ISO 1183-1 adds flexibility by allowing tests at 27±2°C alongside ASTM D792’s temperature range.

Temperature and pressure effects on density readings

Temperature changes density measurements by a lot, with variations of 0.001 to 0.1 per °C affecting the third decimal place. Liquid measurements show even greater sensitivity—0.1 to 1‰ per °C. Therefore, stable temperature conditions are crucial to determine carbon density accurately.

Applications and Engineering Implications

Engineers take advantage of carbon’s variable density properties in many industries, from lightweight structures to thermal management systems. They create materials with custom performance characteristics by manipulating carbon density.

Lightweight design using carbon fiber composites

Carbon fiber composites provide an exceptional strength-to-weight ratio that cuts down weight in structural components. These materials weigh much less than conventional metals – carbon fiber density ranges from 1.75-1.93 g/cm³, while carbon fiber reinforced polymer (CFRP) composites typically measure around 1.55 g/cm³. Switching from aluminum to carbon fiber composites reduces component weight by 42%, which optimizes fuel efficiency and performance.

Carbon fiber composites help aerospace companies boost fuel economy, increase payload capacity, and cut manufacturing costs. Car manufacturers also benefit from carbon fiber’s lightweight properties in body panels, chassis, and interior components. This leads to better fuel efficiency and handling.

Thermal insulation and conductivity trade-offs

The link between carbon density and thermal conductivity creates interesting engineering choices. Dense carbon materials usually conduct heat better, but engineers can change this through structural modifications. They can reduce thermal conductivity while keeping mechanical properties intact by adding closed pores in carbon-graphite materials.

Studies show that increasing thermosetting phenolic resin from 10% to 35% boosts compressive strength from 7.083 MPa to 19.735 MPa. This also raises thermal conductivity from 0.974 W·m⁻¹K⁻¹ to 2.743 W·m⁻¹K⁻¹. Engineers can create carbon-graphite insulation materials with both high compressive strength (16.432 MPa) and low thermal conductivity (0.743 W·m⁻¹K⁻¹) through careful design.

Density-driven material selection in aerospace and automotive

Modern aircraft use record amounts of carbon-based materials. The Boeing 787 Dreamliner contains about 50% carbon composites by weight, while the Airbus A350 XWB uses 53%. This smart material choice improves fuel efficiency by 10-12% and cuts weight by up to 20%.

Carbon fiber’s high strength, stiffness, and low coefficient of thermal expansion make it perfect for spacecraft structures, aircraft components, and high-precision applications. Its negative thermal expansion coefficient lets engineers design composite materials with near-zero overall thermal expansion.

Carbon density in additive manufacturing and 3D printing

3D printing carbon fiber composites offers better design freedom and faster, cheaper production. All the same, current technologies struggle with porosity. Traditional carbon fiber manufacturing achieves 1% porosity compared to 18-25% in 3D printed versions.

New advances in composite fiber additive manufacturing (CFAM) show a clear link between compaction pressure and porosity/fiber volume fraction. This method creates parts with just 1.5% porosity and 15% fiber volume content, which results in 97 MPa tensile strength and 8.9 GPa elastic modulus. Fiber orientation and layer position in 3D printing play a crucial role in mechanical properties. Fiber angle affects 54.13% of overall performance while infill density contributes 16.25%.

Conclusion

Material engineers need to grasp carbon density to achieve optimal performance in a variety of applications. This piece shows how atomic structure shapes material properties through carbon allotropes’ remarkable density spectrum—from 1.8 g/cm³ in amorphous forms to 3.5 g/cm³ in diamond. Such variability creates exceptional versatility in engineering applications.

Carbon’s atomic arrangements shape both density and many performance characteristics. Materials with higher density show better durability, less porosity, improved thermal conductivity, and better electrical connections. These relationships help engineers pick the right carbon-based materials for specific uses with precision.

Quality control and material validation rely heavily on precise density measurement techniques like Archimedes’ Principle and gas pycnometry. These standard methods, combined with careful temperature and pressure control,l deliver consistent results for different carbon forms.

Carbon density’s impact goes way beyond the reach and influence of theory. To name just one example, carbon fiber composites cut weight by up to 42% compared to aluminum while keeping exceptional strength. On top of that, they provide customizable thermal properties through structural changes, which creates options for both insulation and conduction based on engineering needs.

Carbon’s density advantages have, without doubt, transformed aerospace and automotive industries. Modern aircraft using 50-53% carbon composites achieve 10-12% better fuel efficiency and significant weight reductions. Advanced manufacturing technologies continue to evolve and tackle porosity challenges by optimizing fiber orientation and infill density.

Carbon density serves as the lifeblood of modern materials engineering. Engineers who really understand these density-property relationships can pick, design, and use carbon-based materials in countless ways. Manufacturing techniques will definitely keep advancing, and carbon materials will keep offering groundbreaking solutions to complex engineering challenges.

FAQs

Q1. What is the typical density range for different forms of carbon? The density of carbon varies widely depending on its form. Graphite has a density of about 2.26 g/cm³, diamond is around 3.51 g/cm³, amorphous carbon ranges from 1.8-2.1 g/cm³, and carbon fiber is typically between 1.75-1.93 g/cm³.

Q2. How does carbon’s atomic structure affect its density? The atomic arrangement of carbon directly influences its density. For example, diamond’s tightly packed tetrahedral structure results in a higher density compared to graphite’s loosely bonded layered structure. This variation in atomic arrangement explains the significant density differences among carbon allotropes.

Q3. Why is carbon density important in engineering applications? Carbon density is crucial in engineering because it directly impacts material properties such as strength, thermal conductivity, and electrical conductivity. Understanding these relationships allows engineers to select the most appropriate carbon-based materials for specific applications, from lightweight aerospace components to thermal management systems.

Q4. How is the density of carbon materials measured accurately? The density of solid carbon materials is often measured using Archimedes’ Principle, which involves weighing the sample in air and then in water. For powdered carbon like carbon black, gas pycnometry is preferred. These methods, along with standardized procedures like ASTM D792 and ISO 1183, ensure accurate and reproducible density measurements.

Q5. What advantages do carbon fiber composites offer in terms of weight reduction? Carbon fiber composites provide significant weight reduction benefits compared to traditional materials. For instance, replacing aluminum components with carbon fiber composites can reduce weight by approximately 42%. This weight savings leads to improved fuel efficiency and performance in industries like aerospace and automotive.