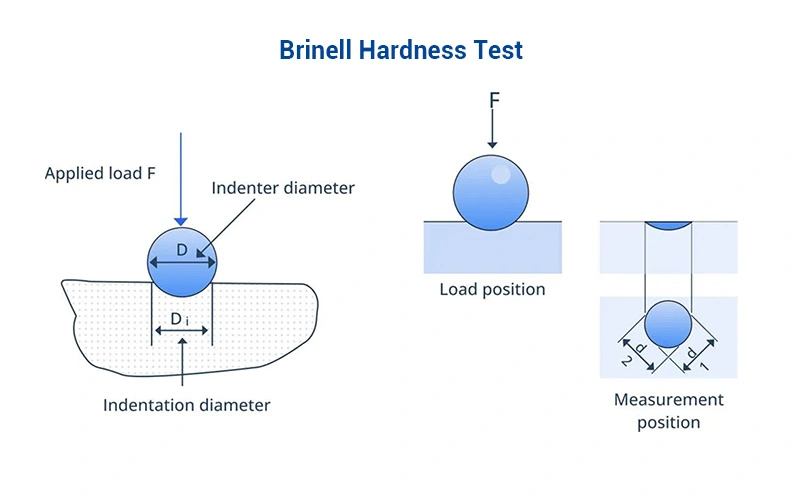

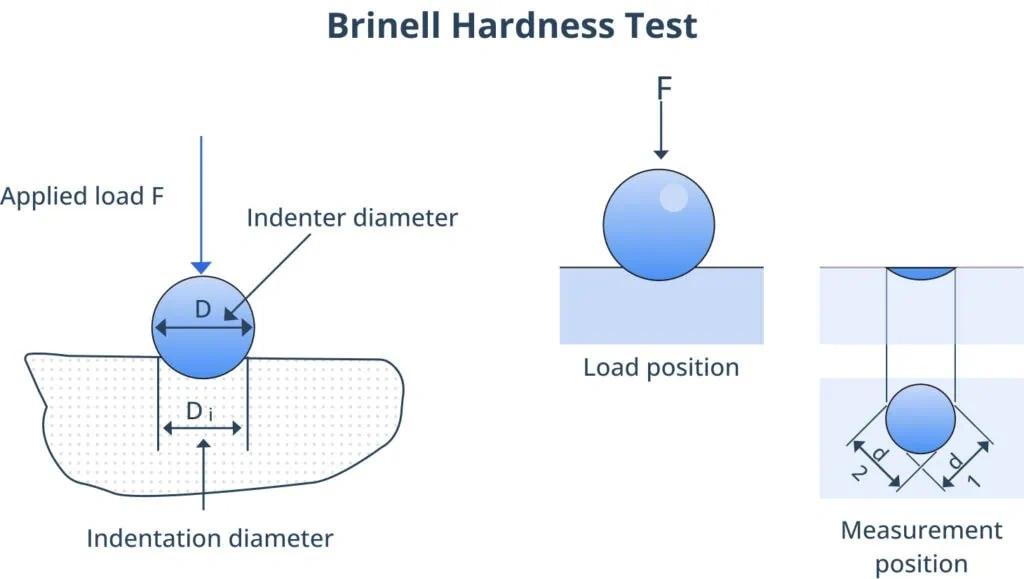

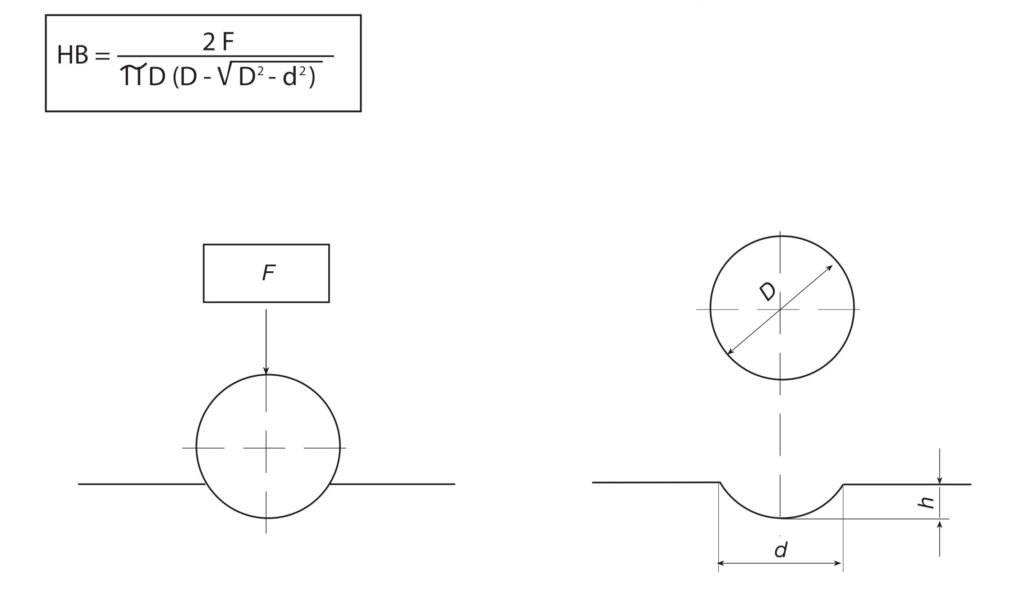

The Brinell hardness test has been a trusted way to measure material hardness since experts standardized it at the 1900 Paris Exposition. This test uses a tungsten carbide ball indenter that applies steady pressure between 500-3000 N on the material’s surface for 10-30 seconds. Materials with coarse-grain structures like rough castings benefit greatly from this method as the indentation reveals crucial data about their strength.

Brinell hardness testing works well with materials of all types, though it leaves large indentations that can damage the surface. The test measures an impressive range of hardness values – from soft pine wood at just 1.6 HBS 10/100 to mild steel at 120 HB. Hardened tool steel measures between 600-900 HB, and remarkable materials like rhenium diboride can reach up to 4600 HB. Engineers and metallurgists find this test valuable because its hardness number (HBW) helps predict a material’s ultimate tensile strength. Standards like ASTM E10 and ISO 6506 maintain testing consistency, but proper surface preparation remains crucial for accurate results.

How the Brinell Hardness Test Works in Practice

The Brinell hardness test uses a systematic process that gives consistent and reliable measurements in materials of all types. This method stands out because it uses a methodical approach and gives representative hardness values, especially with materials that have complex internal structures.

Load application and the indentation process overview

The Brinell test follows a well-laid-out procedure. The test material needs proper preparation through machining, grinding, lapping, or polishing to get accurate measurements. The prepared material then goes through a controlled indentation process.

A tungsten carbide ball indenter (which replaced the older steel balls) pushes against the specimen’s surface with a set force. Here’s how the test works:

- The indenter sits perpendicular to the test surface

- A consistent test force (1 kgf to 3000 kgf) applies within 1 to 8 seconds

- The force stays steady for 10-15 seconds

- The force comes off completely

- The resulting indentation gets measured

The steady period serves a vital purpose – it lets the metal’s plastic flow stop completely before measurement. Once the force is gone, you measure the impression across at least two diameters at right angles, and use the average for hardness calculation.

Test forces usually range from 187.5 to 3000 kgf, though exact ranges change with different materials. To name just one example, see how aluminum and copper alloys just need lower forces, while steels and cast irons work better with higher force ranges. You must pick the right force-to-ball diameter ratio so the indentation diameter falls between 0.24D and 0.6D (D being the ball diameter).

The test works best in specific room temperatures – between 10 to 35°C (50 to 95°F) – because temperature changes can throw off measurements. The material thickness also matters: ISO 6506 says at least 8 times the indentation depth, while ASTM standards call for 10 times.

Why Brinell is preferred for coarse-grained materials

The Brinell method works best with coarse-grain structures and materials that don’t have uniform hardness. This preference comes from several benefits.

The test makes bigger and deeper indentations than other methods. These larger marks (usually 2.4mm to 6mm across) average out any local variations in the material’s structure. A single Brinell test will give a more representative hardness value because it includes multiple grains or structural parts at once.

The Brinell test excels with castings, forgings, and other large components where surface conditions change. While other hardness tests might show problems with small surface irregularities, the Brinell test’s larger indentation makes these effects less important.

You can use this method on rougher surfaces, which makes it practical in industrial settings where perfect surface finish isn’t always possible. This feature, plus its effectiveness on mixed materials like cast iron, explains why quality control teams in foundries and heavy manufacturing still prefer the Brinell test.

The test does have its limits – you’ll get accurate measurements only if you read the indentation correctly. Even skilled technicians might read indentation boundaries differently, and being off by just 0.2mm could mean a 20-point difference in hardness. Modern automatic measurement systems solve this issue by using optical microscopes connected to computers, which give more consistent results.

Choosing the Right Test Parameters for Your Material

The right test parameters play a vital role to get reliable Brinell hardness test results. The test’s accuracy depends on picking the right combination of test force and ball diameter for the material you need to assess.

Test force and ball diameter combinations

Brinell hardness testing uses test forces ranging from 187.5 to 3000 kgf, along with tungsten carbide ball indenters. These balls come in standard diameters of 1mm, 2.5mm, 5mm, and 10mm. The combinations follow specific relationships. Tests that use load/indenter combinations with the same ratio (L/D²) will give equivalent HBW values.

The force-diameter ratio, shown as stress level B = 0.102 × F/D², must stay constant within a testing method to get comparable results. Standard force-diameter ratios are 1, 2.5, 5, 10, and 30. You can’t directly compare test results that use different ratios.

The test load should create a mean indentation diameter within 0.24D < d < 0.6D (D being the ball diameter) for the best accuracy. The Brinell method loses accuracy when this condition isn’t met, whether the penetration depths are too small or too large.

Examples: 500 kgf for aluminum, 3000 kgf for steel

Materials need specific test parameters based on their hardness:

Steel and cast iron testing typically uses a 10mm ball with a 3000 kgf test force (HBW 10/3000). This high force-diameter ratio of 30 works best for hard materials with hardness between 95.5 and 650 HBW. HBW 5/750, HBW 2.5/187.5, and HBW 1/30 are other valid combinations with the same ratio.

Aluminum alloys and other light metals need much lower test forces. A 10mm ball with a 500 kgf test force (HBW 10/500) works well. This force-diameter ratio of 5 suits materials with hardness between 15.9 and 109 HBW. You can also use HBW 5/125, HBW 2.5/31.25, and HBW 1/5.

Copper alloys need medium test forces. Their hardness determines whether they need a force-diameter ratio of 5 (softer alloys) or 10 (harder variants with HBW between 32 and 218).

The ball diameter should be as large as possible to cover more of the sample surface. Larger diameters help average out material variations, which explains why many applications prefer the 10mm ball.

Understanding HBW 10/3000 and similar notations

Brinell test conditions follow a standard format that shows all key parameters. To name just one example, see HBW 10/3000:

- HBW shows the use of a tungsten carbide ball indenter (not the old HBS for hardened steel balls)

- 10 is the ball diameter in millimeters

- 3000 shows the applied force in kilograms force

The notation sometimes includes more details. A complete Brinell hardness result might look like: 310 HBW 2.5/187.2/20, where:

- 310 shows the actual hardness value

- HBW indicates the tungsten carbide ball

- 2.5 is the ball diameter in mm

- 187.2 shows the test force in newtons (N = 9.807 × kgf)

- 20 indicates the application time in seconds (left out if between 10-15s)

This standard notation system helps communicate test conditions. It’s worth mentioning that hardness values from different parameters can’t be directly compared. Tests with the same ball diameter but different force-diameter ratios give results you can’t compare. This makes precise documentation of test parameters crucial to understanding Brinell hardness values properly.

Reading and Representing Brinell Hardness Values

Reading Brinell hardness test results needs a good grasp of the numbers and how they’re written in standard format. Engineers can judge material properties better when they know how to read these values correctly.

How to interpret values like 200 HBW 5/250/15

The Brinell hardness system uses a specific way to write down important test details. Let’s look at what “200 HBW 5/250/15” means:

- “200” shows the actual hardness number

- “HBW” tells us a tungsten carbide ball made the dent (older tests used “HBS” for steel balls)

- “5” is the ball’s width in millimeters

- “250” shows the force applied in kilograms

- “15” tells us how many seconds the force was applied (usually left out if between 10-15 seconds)

This format gives us a complete picture of the test conditions. We need this because you can’t compare hardness values from tests with different settings. If there’s no time mentioned, you can assume it was between 10-15 seconds – that’s the standard way.

What a high or low Brinell number means

The Brinell scale shows how well materials resist permanent dents. Materials with higher numbers are harder, while lower numbers mean softer materials. The scale covers everything from very soft to super hard materials.

Hardness numbers help predict other material properties. To name just one example, we can use these numbers to figure out how much force it takes to break metals. Each type of material has its hardness range, though, so comparing different materials directly doesn’t work well without more context.

Common Brinell values for copper, aluminum, and steel

Hardness values are quite different for various materials:

| Material | Typical Brinell Hardness |

|---|---|

| Pure aluminum | 15 HB |

| Copper | 35 HB |

| Soft brass | 60 HB |

| Hardened aluminum | 75 HB |

| Mild steel | 120-130 HB |

| Annealed chisel steel | 235 HB |

| White cast iron | 415 HB |

| Hardened tool steel | 600-900 HB |

These numbers work as guidelines rather than strict rules. The exact hardness changes based on what’s in the material, how it’s made, and how it’s heat-treated. Yes, it is common to see big differences even in the same type of material. Steel’s hardness, for example, ranges from 120 HB in mild steel to more than 700 HB in hardened tool steels.

Applications of Brinell Hardness Testing in Industry

Brinell hardness testing is crucial for quality assurance and material verification in heavy industrial sectors. This method stands out because it works exceptionally well in specific applications where other testing approaches fall short.

Use in castings, forgings, and weld zones

Quality control teams rely on Brinell hardness testing for cast and forged components during manufacturing. The method works great with large, heavy, and coarse-grained metal parts because it creates large indentations that average out surface irregularities. This makes it perfect for materials with rough or uneven surfaces, which leads to more accurate hardness values.

Manufacturing facilities use Brinell testing to ensure consistent quality and verify materials meet hardness requirements. The test shines when checking heavy-duty components like engine blocks, large-diameter pipes, machine frames, and industrial valves.

Weld testing with Brinell has both strengths and limitations. The large indenter size isn’t ideal for narrow heat affected zones (HAZ), but it’s great at measuring hardness values on larger areas like weld faces. Some teams adapt HAZ testing by checking base material within 1/2″ or 1″ of the weld to make sure welding heat hasn’t affected base metal properties.

Field testing with portable Brinell machines

Portable Brinell testers let teams check hardness on-site without moving heavy parts to labs. These units come with hydraulic cylinders that put controlled force on the indenter. Modern portable equipment is incredibly flexible – it tests metal specimens of any size and shape and works in any position, whether upright, upside down, or sideways.

Chain adapters make these tools even more versatile. Technicians can apply full 3000 kgf loads to parts with different diameters wherever they need to. This makes portable testing perfect for checking pipes, drill bits, and critical infrastructure components in the field. Welding crews love the lightweight portable systems under ten pounds that help them verify quality quickly.

Limitations in small or curved components

Brinell hardness testing has its drawbacks. The method doesn’t work well with small or thin samples because the large indentation might deform or damage them. Materials that are too thin for proper indentation measurement need different approaches, like Rockwell or Vickers testing.

Testing curved surfaces presents challenges since Brinell testing needs a flat surface. The large indenter size also makes it tough to test narrow areas like traditional heat-affected zones in welds.

The testing process takes more time than other methods because it involves multiple steps. This factor, combined with the need for special reading microscopes to measure indentation diameters, makes Rockwell and Vickers better choices for smaller, precision components.

Standards, Accuracy, and Error Margins

Standards help labs worldwide get consistent hardness measurements. Two international standards guide Brinell hardness testing. These standards give detailed guidelines that cover equipment specs and how to interpret results.

ASTM E10 and ISO 6506 compliance

Brinell hardness testing follows two main standard frameworks: ASTM E10 and ISO 6506. ASTM E10 sets testing methods for metallic materials and explains equipment specs, testing steps, and calculation methods. ISO 6506 works as four connected parts. These parts cover test methods (ISO 6506-1), equipment checks (ISO 6506-2), reference block calibration (ISO 6506-3), and hardness value tables (ISO 6506-4). Testing labs need to keep their documentation up to date because these standards change regularly.

The standards spell out key requirements like ball indenter specs, test force selection, and measurement techniques. Labs that follow these standards can compare their results reliably. This gives manufacturing sectors better quality control.

Repeatability and maximum allowable error

A testing machine’s repeatability shows how well it gives the same results under similar conditions. Brinell hardness measurements have different maximum allowable repeatability (R) based on hardness levels:

| Reference Block Hardness | Maximum Repeatability R (% of d) | Maximum Error E (% of H) |

|---|---|---|

| HBW ≤ 125 | 3.0 | 3.0 |

| 125 < HBW ≤ 225 | 2.5 | 3.0 |

| HBW > 225 | 3.0 | 3.0 |

These values show the highest percentage range allowed for diameter measurements compared to their average. The maximum error in hardness values must stay within 3% for all hardness levels. Even skilled operators might get slightly different readings from the same indentation.

Spacing and temperature conditions for valid tests

Brinell hardness testing needs specific conditions to work right. Room temperature should stay between 10 to 35°C (50 to 95°F). Temperature changes can affect measurements by a lot. The test material and machine need time to reach these temperatures before testing.

Spacing rules are crucial too. Centers of adjacent indentations need at least three times the mean indentation diameter between them. The distance from an indentation’s center to the specimen’s edge must be at least two and a half times the mean diameter. These rules keep work-hardened zones from overlapping and messing up later measurements.

The specimen’s thickness matters just as much. ISO 6506 says it should be at least 8 times deeper than the indentation. Specimens that are too thin might bulge on the other side and give wrong hardness readings.

Conclusion

Brinell hardness testing serves as the life-blood of material strength assessment and proves valuable in a variety of heavy industrial sectors. This century-old technique continues to help metallurgists and engineers utilize reliable data about material performance. The test creates larger indentations which makes it perfect for coarse-grained materials like castings and forgings. It averages out structural variations that might skew results when using other testing methods.

Getting the test parameters right plays a crucial role in accurate measurements. The relationship between ball diameter and applied force must match the tested material. Softer materials like aluminum work well with lower forces (typically 500 kgf), while harder materials such as steel just need much higher loads (usually 3000 kgf). The standardized notation system (such as 200 HBW 5/250/15) will give a clear picture of test conditions so results can be properly interpreted and compared.

Brinell testing comes with its share of limitations. Small components or narrow regions don’t work well with this method because of the large indentation size. Curved surfaces also create problems since the test needs flat testing surfaces. These constraints have improved with technological advances like portable testing machines. Now field verification happens without moving heavy components to labs.

Standards like ASTM E10 and ISO 6506 keep testing consistent worldwide. These guidelines are the foundations of critical requirements including proper spacing between indentations, minimum specimen thickness, and acceptable temperature ranges. Following these standards helps maintain the 3% maximum allowable error rate in Brinell measurements.

Brinell hardness testing stays relevant because it’s reliable and correlates well with other material properties. While newer hardness testing methods exist, Brinell testing remains irreplaceable in many applications due to its effectiveness with heterogeneous materials. Engineers who grasp both the strengths and limitations of this fundamental testing method can pick the right testing protocols that their specific material evaluation needs.

FAQs

Q1. What are the basic steps involved in performing a Brinell hardness test? The Brinell hardness test involves applying a specific force to a tungsten carbide ball indenter pressed against the material surface for 10-15 seconds. After removing the force, the resulting indentation is measured to calculate the hardness value.

Q2. How do you interpret a Brinell hardness number like 200 HBW 5/250/15? In this notation, 200 is the hardness value, HBW indicates a tungsten carbide ball indenter, 5 is the ball diameter in mm, 250 is the applied force in kgf, and 15 is the application time in seconds.

Q3. What types of materials are best suited for Brinell hardness testing? Brinell testing is ideal for coarse-grained materials like castings, forgings, and materials with non-uniform hardness distributions. It’s commonly used for ferrous metals, with different force-ball diameter combinations for materials ranging from soft aluminum to hardened steel.

Q4. What are the key standards governing Brinell hardness testing? The two primary standards for Brinell hardness testing are ASTM E10 and ISO 6506. These standards provide detailed guidelines on testing procedures, equipment specifications, and result interpretation to ensure consistency across different testing facilities.

Q5. What are some limitations of the Brinell hardness test? The Brinell test is not suitable for small or thin components due to its large indentation size. It also requires flat testing surfaces, making it challenging to use on curved specimens. Additionally, the test process can be more time-consuming compared to other hardness testing methods.