Binder removal stands as a pivotal stage in metal injection molding. This process eliminates the organic binder that holds metal powders together during shaping. Complete binder removal ensures the final part achieves its designed strength and density. If the binder remains, defects such as cracking, distortion, or contamination can occur. Manufacturers must control this step to maintain high part quality and prevent costly failures.

Role of Binders in Metal Injection Molding

Function of Binders in MIM Feedstock

Binders play a central role in the metal injection molding process. They act as a temporary adhesive, holding fine metal powders together during mixing, injection, and shaping. The binder system typically consists of multiple components, each designed to provide specific properties such as flowability, lubricity, and strength. A well-designed binder ensures that the feedstock fills the mold completely and uniformly.

Experimental studies show that a powder-to-binder ratio of 93:7 delivers optimal flowability. This ratio includes a slight excess of binder, which helps prevent separation and supports homogeneity throughout the molded part. Vickers hardness testing and advanced imaging techniques confirm that this composition avoids defects like cracks or surface wrinkles. The binder also reduces interparticle friction, allowing for high particle packing density and improved processing efficiency.

Tip: Consistent binder composition leads to uniform mold filling and minimizes the risk of defects in green parts.

A quantitative analysis of binder function highlights its impact on several key parameters:

| Parameter | Binder Composition Impact | Quantitative Result |

|---|---|---|

| Debinding success | Soluble binder enables successful debinding | Specimens with soluble binder survived thermal and sintering steps |

| Relative density after sintering | Binder composition affects final density | MIM components: ~93-95% relative density |

| Shrinkage after sintering | Adequate shrinkage linked to binder composition | ~10-18% shrinkage observed |

| Microhardness (Vickers HV) | Binder affects hardness of sintered parts | MIM sintered parts: ~36 HV |

| Mechanical strength (max stress) | Binder influences mechanical strength | MIM parts: σmax = 79 ± 3.2 MPa |

Importance of Complete Binder Removal

Complete binder removal is essential for producing high-quality metal injection molding components. Any residual binder can cause defects such as cracking, distortion, or contamination during the sintering stage. These defects compromise the mechanical properties and appearance of the final product.

Manufacturers must carefully control the binder removal process to ensure that all binder components exit the part without causing deformation. Incomplete removal can lead to density inhomogeneities and weak spots, reducing the part’s strength and reliability. Proper binder removal also supports consistent shrinkage and optimal final density, both of which are critical for meeting design specifications.

A well-executed binder removal process ensures that the final component achieves the desired hardness, density, and mechanical strength. This step directly impacts the performance and longevity of metal injection molding products.

Binder Removal Methods in Metal Injection Molding

Thermal Debinding

Thermal debinding stands as one of the most traditional methods for removing binders in metal injection molding. This process uses controlled heating to gradually decompose and vaporize the binder from the molded part. Operators place the green parts in a furnace and slowly raise the temperature. The binder evaporates or breaks down into gases, which then escape through the porous structure of the part.

This method offers simplicity and compatibility with a wide range of binder systems. It does not require special chemicals or catalysts. However, thermal debinding often takes a long time—sometimes up to 24 hours—because rapid heating can cause defects such as cracking or distortion. Careful control of the heating rate and atmosphere ensures that the part maintains its shape and integrity during binder removal. Many manufacturers use thermal debinding as a final step after other debinding methods to ensure complete binder removal.

Note: Slow heating rates and precise temperature control help prevent internal pressure buildup, which can damage the part.

Catalytic Debinding

Catalytic debinding uses a chemical reaction to accelerate binder removal. In this method, the molded part contains a binder component that reacts with a catalyst, usually an acid vapor such as nitric or oxalic acid. The catalyst breaks down the binder at relatively low temperatures, allowing it to diffuse out of the part quickly.

This process offers several advantages. It reduces debinding time compared to thermal methods and operates at lower temperatures, which minimizes the risk of part deformation. Catalytic debinding works best with specific binder systems, such as polyacetal-based binders. The process requires specialized equipment to handle and neutralize the catalyst safely. Operators must monitor the reaction closely to avoid overexposure, which can lead to surface defects or incomplete binder removal.

Manufacturers often choose catalytic debinding for high-volume production because it delivers consistent results and short cycle times. The method supports complex geometries and thin-walled parts, making it suitable for intricate metal injection molding components.

Solvent Debinding

Solvent debinding removes binder by immersing the molded part in a liquid solvent or exposing it to solvent vapor. The solvent dissolves the binder, which then diffuses out of the part. This method stands out for its speed and flexibility.

Key features of solvent debinding include:

- Fast processing times, often reducing total debinding duration compared to thermal methods.

- Debinding rates of several millimeters per hour, enabling higher throughput.

- Use of vapor degreaser systems that recycle solvent, improving sustainability and cost-effectiveness.

- Production of parts with minimal defects such as cracking or distortion.

- Flexibility to accommodate various alloys, binders, and part geometries.

- Enhanced safety through sealed systems that prevent worker exposure to solvents.

A closer look at quantitative benchmarks for solvent debinding:

| Benchmark Parameter | Quantitative Value / Description | Notes / Context |

|---|---|---|

| Activation Energy for Solvent Debinding | 12.4 kJ/mol (PEG extraction) | Easier binder removal by solvent compared to thermal debinding |

| Debinding Rate | Several millimeters per hour (e.g., 2 mm/h in one study) | Rate at which binder is removed by solvent debinding |

| Maximal Open Porosity | 12.6% | Achieved during solvent debinding, critical for optimal debinding duration |

| Optimal Solvent Debinding Duration | Approximately 15-20 hours at 40 °C | Duration to reach maximal porosity and effective binder removal |

| Volume to Surface Ratio | 1.3 to 4.0 | Geometry factor influencing debinding kinetics |

| Thermal Debinding Reduction | 62.5% reduction (from 80 h to 30 h) | Solvent debinding reduces subsequent thermal debinding time significantly |

| Resulting Part Density | ~94.9% relative density | Indicates quality of sintered parts after optimized debinding |

Solvent debinding provides a practical solution for manufacturers seeking to optimize throughput and part quality in metal injection molding. The process supports a wide range of materials and geometries, making it a preferred choice for many applications.

Aqueous Debinding

Aqueous debinding uses water as the primary medium to remove water-soluble binder components from molded parts. This method targets binder systems that include polymers or additives designed to dissolve or disperse in water. Manufacturers often select aqueous debinding for its environmental benefits and compatibility with a wide range of part geometries.

The process begins by immersing the green parts in a water bath at a controlled temperature. Water penetrates the surface and dissolves the soluble binder, which then diffuses out of the part. Operators monitor the process to ensure uniform binder removal and to prevent defects such as swelling or cracking. The duration of aqueous debinding depends on several factors, including part size, binder composition, and bath temperature.

Key advantages of aqueous debinding include:

- Reduced environmental impact compared to organic solvents.

- Lower risk of fire or toxic exposure for workers.

- Cost savings due to the use of water instead of specialized chemicals.

- Compatibility with automated systems for high-volume production.

Aqueous debinding also presents some challenges. The process requires precise control of temperature and agitation to avoid uneven binder removal. Parts with complex shapes or thick cross-sections may experience slower debinding rates. Incomplete removal can lead to defects during subsequent thermal processing.

Note: Operators should use deionized water to prevent contamination and ensure consistent results.

The following table summarizes important parameters for aqueous debinding:

| Parameter | Typical Value/Range | Impact on Process |

|---|---|---|

| Water temperature | 30–60°C | Higher temperatures increase rate |

| Debinding rate | 0.5–2 mm/h | Depends on part geometry |

| Binder removal efficiency | Up to 95% (for soluble phase) | High efficiency with proper control |

| Typical duration | 8–24 hours | Varies with part size and binder type |

| Environmental impact | Low | Water can be recycled |

Aqueous debinding fits well within the broader binder removal process in metal injection molding. Manufacturers often use it as a first step, followed by thermal debinding to remove any remaining binder. This combination ensures complete binder removal and prepares the part for sintering.

Tip: Regularly replace or filter the water bath to maintain high binder removal efficiency and prevent re-deposition of dissolved binder.

Aqueous debinding continues to gain popularity as manufacturers seek safer and more sustainable solutions in metal injection molding. The method supports consistent part quality and aligns with modern environmental standards.

Pros and Cons of Binder Removal Methods

Thermal Debinding: Advantages and Limitations

Thermal debinding offers a straightforward and environmentally friendly approach. Operators only need a kiln and refractory ballast, which keeps costs low. This method works well for many binder systems. However, the process demands careful control of heating rates and equipment size. Small crucibles heat too quickly, causing excessive binder evaporation, high porosity, and distortion. Large crucibles heat too slowly, resulting in incomplete sintering and weak parts. Medium crucibles provide the best balance, reducing porosity and distortion while improving tensile strength and shortening processing time.

| Metric | Small Crucible (1:67) | Medium Crucible (1:19) | Large Crucible (1:10) |

|---|---|---|---|

| Porosity | High (27%) | Reduced (15%) | N/A |

| Tensile Strength | Low (138 MPa) | Increased (186 MPa) | Poor |

| Processing Time | Longest (20.2 h) | Reduced (12.6 h) | N/A |

| Heating Rate | Fast, excessive | Moderate, optimal | Slow, insufficient |

| Distortion | High | Minimized | Increased |

Tip: Medium-sized crucibles and moderate heating rates help achieve the best results in thermal debinding.

Catalytic Debinding: Advantages and Limitations

Catalytic debinding provides rapid binder removal at lower temperatures. This method reduces the risk of part deformation and supports complex geometries. Manufacturers benefit from shorter cycle times and consistent results, especially in high-volume production. However, catalytic debinding requires specialized equipment and strict safety measures to handle acid vapors. The process only works with specific binder systems, such as polyacetal-based binders. Overexposure to the catalyst can cause surface defects or incomplete binder removal.

- Advantages:

- Fast processing and lower energy consumption

- Suitable for intricate and thin-walled parts

- Consistent quality in large-scale production

- Limitations:

- Limited to compatible binder chemistries

- Requires careful monitoring and safety protocols

- Potential for surface defects if not controlled

Solvent Debinding: Advantages and Limitations

Solvent debinding stands out for its speed and flexibility. Operators can remove water-soluble polyethylene glycol (PEG) binder from stainless steel 316L parts within 180 minutes at 40°C. The process relies on dissolution and diffusion, with higher temperatures shifting control to diffusion. Increased sintering temperature and time improve mechanical properties, but excessive soaking can cause grain coarsening. The choice of solvent and temperature affects the efficiency and risk of defects.

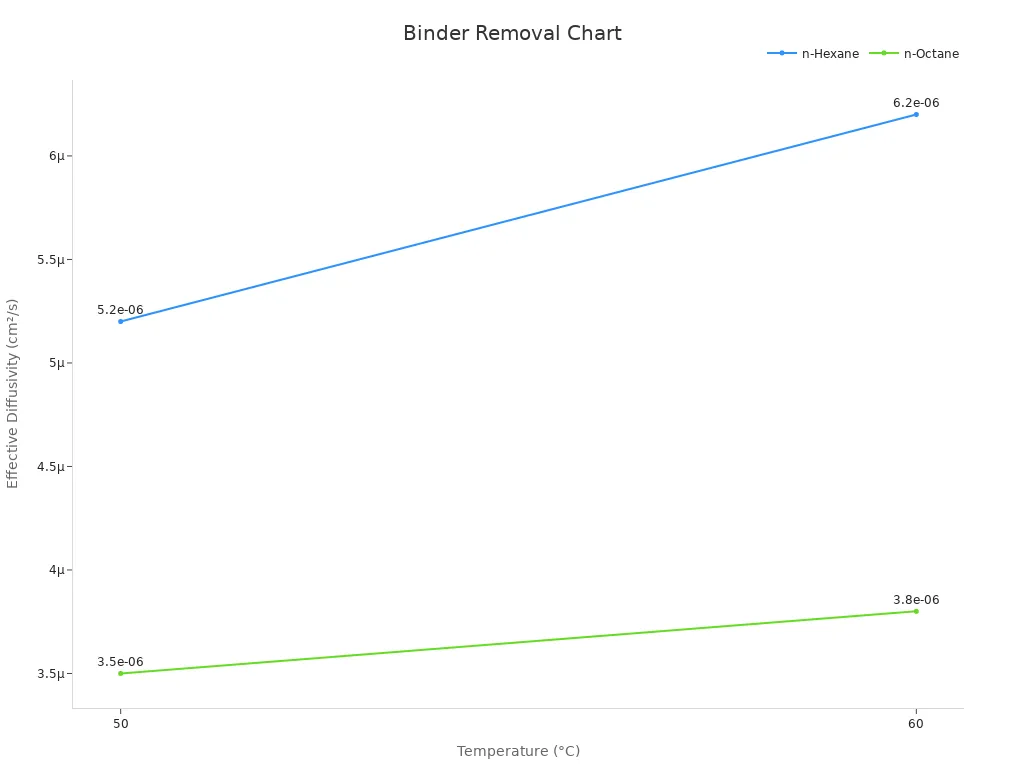

| Solvent (n-C#) | Temperature (°C) | Effective Diffusivity (cm²/s) | Notes |

|---|---|---|---|

| n-Hexane (n-C6) | 50 | 5.2 x 10^-6 | Wax leaching; shrinking core early |

| n-Octane (n-C8) | 50 | 3.5 x 10^-6 | Lower diffusivity with higher carbon number |

| n-Hexane (n-C6) | 60 | 6.2 x 10^-6 | Diffusivity rises with temperature |

| n-Octane (n-C8) | 60 | 3.8 x 10^-6 | Core not removed may cause cracks |

Solvent debinding enables fast binder removal with controlled diffusion. However, if the core remains, cracks may form. Fine or dense powders slow the process, and high temperatures can cause shape distortion. Operators must select the right solvent and control temperature to avoid defects.

Note: Solvent debinding works best with optimized powder size, solvent type, and temperature for each application.

Aqueous Debinding: Advantages and Limitations

Aqueous debinding has become a popular choice in metal injection molding due to its environmental and operational benefits. This method uses water to dissolve and remove water-soluble binder components from green parts. Manufacturers often select aqueous debinding for its safety and sustainability.

Advantages of Aqueous Debinding:

- Eco-Friendly Process: Water serves as a non-toxic, non-flammable solvent. This reduces environmental hazards and aligns with green manufacturing goals.

- Worker Safety: Operators face minimal risk of exposure to harmful chemicals. The process eliminates the need for specialized ventilation or protective equipment.

- Cost Efficiency: Water is inexpensive and widely available. Facilities can recycle water, which lowers operational costs.

- Process Compatibility: Aqueous debinding works well with automated systems. Manufacturers can scale production without significant changes to infrastructure.

- Consistent Results: The method supports uniform binder removal, especially for parts with simple or moderate geometries.

Limitations of Aqueous Debinding:

- Binder System Restrictions: Only binder systems with water-soluble components qualify for this process. Manufacturers must design feedstocks specifically for aqueous debinding.

- Slower Debinding Rates: Water penetrates parts more slowly than organic solvents. Large or complex parts may require extended debinding times.

- Risk of Swelling or Cracking: Water absorption can cause swelling in some polymers. Improper control may lead to surface defects or internal cracks.

- Temperature Sensitivity: The process depends on precise temperature control. Fluctuations can reduce efficiency or cause uneven binder removal.

- Water Quality Management: Impurities in water may contaminate parts. Facilities must use deionized water and maintain filtration systems.

Note: Regular monitoring of water temperature and quality ensures optimal debinding performance and prevents defects.

| Factor | Advantage | Limitation |

|---|---|---|

| Environmental Impact | Low, water-based | Requires water treatment |

| Safety | High, non-toxic | Swelling risk if uncontrolled |

| Cost | Low, recyclable water | Equipment for water management |

| Process Speed | Moderate | Slower for thick/complex parts |

| Binder Compatibility | Water-soluble only | Limited binder options |

Aqueous debinding offers a safe and sustainable solution for many MIM applications. Manufacturers must balance its benefits with careful process control to avoid defects and ensure high-quality results.

Optimizing the Binder Removal Process in Metal Injection Molding

Selecting the Best Method for Materials and Parts

Selecting the optimal binder removal method requires careful consideration of both material properties and part geometry. Each method—thermal, catalytic, solvent, or aqueous—offers unique advantages depending on the specific requirements of the metal powder, binder system, and final component design. Engineers must evaluate several factors before making a decision.

- The presence of nano-powders in a part increases the solvent immersion time and leaves more residual binder. Powder size and shape directly affect how efficiently solvent debinding works.

- Binder composition, powder loading, debinding time, and temperature all play significant roles in the debinding rate when using polyethylene glycol–polyvinyl butyral binders with water as the solvent.

- These variables also influence the porosity and microstructure of the molded parts. Material characteristics dictate which debinding conditions will yield the best results.

Manufacturers often tailor the binder removal process to match the unique properties of each feedstock. For example, parts with complex geometries or thin walls may benefit from catalytic debinding, which operates at lower temperatures and reduces the risk of distortion. In contrast, large or dense parts may require a combination of solvent and thermal debinding to ensure complete binder extraction without compromising structural integrity.

Tip: Always conduct small-scale trials to determine the most effective debinding method for new materials or part designs.

Process Parameters and Their Impact

Process parameters such as temperature, time, atmosphere, and agitation have a direct impact on the success of binder removal. Each parameter must be optimized to prevent defects and achieve consistent part quality.

Temperature control stands as one of the most critical factors. Rapid heating during thermal debinding can cause internal pressure buildup, leading to cracks or distortion. Slow, controlled heating allows gases to escape gradually, preserving the part’s shape. In solvent and aqueous debinding, temperature affects both the solubility of the binder and the diffusion rate. Higher temperatures generally speed up the process but may increase the risk of swelling or surface defects.

Debinding time must match the part’s size and complexity. Shorter times may leave residual binder, while excessive durations can cause unnecessary energy consumption or part degradation. Agitation in solvent or aqueous baths improves binder removal efficiency by enhancing solvent penetration and reducing boundary layers.

Atmosphere also plays a role. Inert or reducing atmospheres during thermal debinding prevent oxidation of metal powders. Proper ventilation and gas flow help remove volatile binder components safely.

| Parameter | Effect on Debinding | Best Practice |

|---|---|---|

| Temperature | Controls rate and safety | Use gradual ramps, avoid overheating |

| Time | Affects completeness | Match to part size and binder type |

| Agitation | Improves efficiency | Use gentle stirring or circulation |

| Atmosphere | Prevents oxidation | Use inert gases when needed |

Careful adjustment of these parameters ensures that each part meets quality standards and performs reliably in its final application.

Safety, Environmental, and Cost Considerations

Safety, environmental impact, and cost remain central concerns in binder removal. Each method presents unique challenges and opportunities for improvement. Life Cycle Assessment (LCA) serves as a valuable tool for evaluating the environmental footprint of different processes. LCA examines energy consumption, carbon emissions, and waste generation, helping manufacturers identify areas for improvement. Lower energy use and reduced emissions not only benefit the environment but also lower operational costs.

The Taguchi design method provides a statistical approach to process optimization. By systematically adjusting parameters, engineers can minimize defects and maximize efficiency. This method supports safer operations by identifying optimal conditions that reduce the risk of accidents or exposure to hazardous substances.

Water-based debinding methods offer significant safety and environmental advantages. They eliminate the need for toxic or flammable solvents, reducing risks for workers and the surrounding community. Facilities can recycle water, further lowering costs and minimizing waste. However, water quality must be monitored to prevent contamination of parts.

Note: Regularly review process data and environmental metrics to ensure compliance with safety regulations and sustainability goals.

Manufacturers who prioritize safety, environmental stewardship, and cost control position themselves for long-term success in the competitive field of metal injection molding.

Effective binder removal ensures high-quality parts and reliable performance. Operators achieve optimal results by controlling heating rates, maintaining uniform temperature, and using multi-stage heating profiles. The following table highlights important process parameters:

| Aspect | Summary of Numerical Data and Process Parameters |

|---|---|

| Powder Loading | 54-60% volumetric loading balances flow and stability |

| Mixing Parameters | 30 rpm rotor speed, 90°C mixing temperature for homogeneity |

| Debinding Control | Slow heating, uniform temperature, laminar gas flow, precise atmosphere, multi-stage heating |

Key recommendations include:

- Monitor temperature and gas flow in real time.

- Use automation for consistency.

- Apply gradual heating to minimize defects.

These practices help manufacturers maintain efficiency and part quality in production.

FAQ

What happens if binder removal is incomplete in metal injection molding?

Incomplete binder removal can cause cracks, distortion, or contamination during sintering. These defects reduce mechanical strength and may lead to part failure. Manufacturers must ensure complete binder extraction to achieve high-quality, reliable components.

Which binder removal method works best for complex part geometries?

Catalytic debinding often suits complex or thin-walled parts. This method operates at lower temperatures and reduces the risk of distortion. It provides consistent results for intricate designs, especially when paired with compatible binder systems.

How do manufacturers control environmental impact during binder removal?

Many facilities use water-based or solvent-recycling systems to reduce emissions and waste. They monitor water quality, recycle solvents, and optimize energy use. These practices help meet environmental standards and lower operational costs.

What safety precautions are necessary during binder removal?

| Method | Key Safety Precaution |

|---|---|

| Thermal Debinding | Monitor furnace temperature |

| Catalytic Debinding | Handle acid vapors carefully |

| Solvent Debinding | Use sealed systems, proper PPE |

| Aqueous Debinding | Maintain water purity |

Operators must follow safety protocols for each method to protect workers and equipment.