Sintered gears provide a cost-effective solution that runs about ten times cheaper than machined gears when produced in high volumes. The powder metallurgy process creates this major cost advantage by using up to 97% of raw materials, while traditional machining methods only use 60-70%.

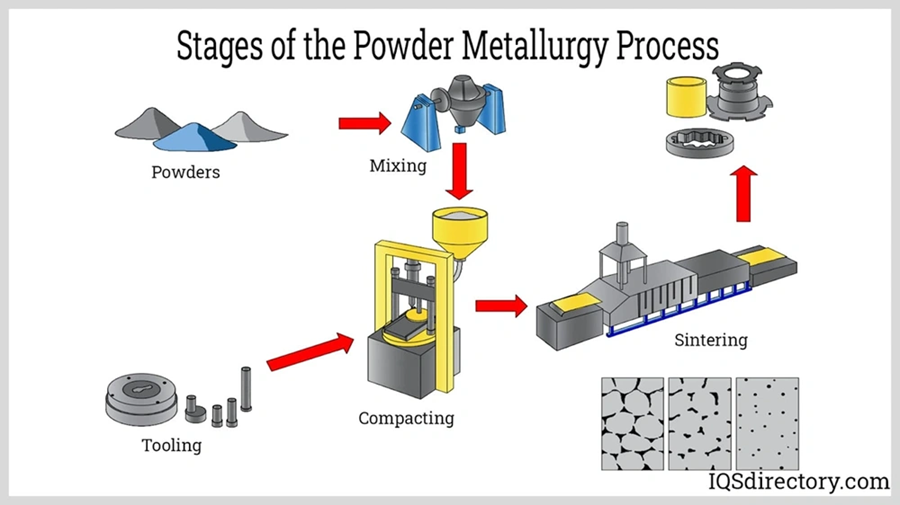

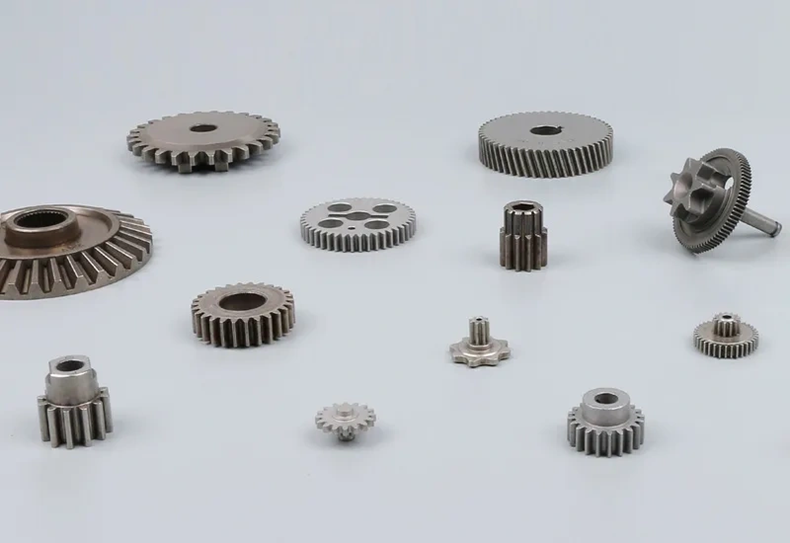

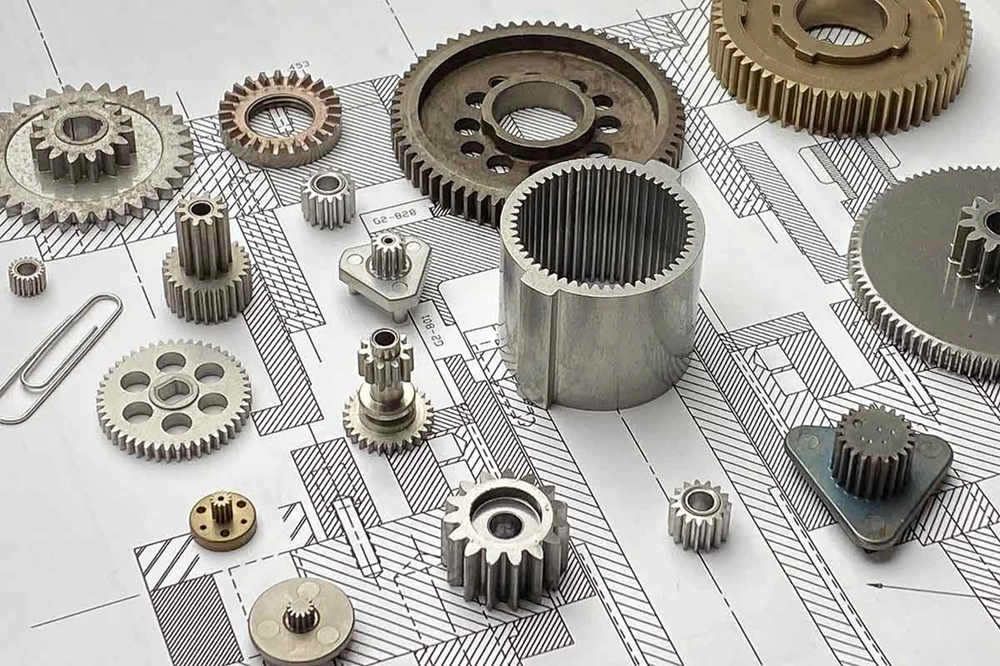

The manufacturing process starts when metal powders are compressed into gear shapes through precision tooling. Iron-based alloys make up most sintered metal gears, including carbon steel, alloy steel, and stainless steel. On top of that, manufacturers can blend powdered metals like iron-nickel steel, pre-alloyed steel, and custom combinations to achieve specific performance targets. The powder metallurgy technique stands out because it shapes tooth geometry directly during compaction, which creates complex features in one step instead of multiple operations.

These gears serve crucial roles in automotive transmissions, power tools, industrial machinery, and consumer appliances. They help boost fuel efficiency and reduce noise levels, which leads to smoother gear changes and better overall performance. While metal remains the primary material, manufacturers also use acetate and nylon resins for molded plastic gears, though these come with limitations in strength, temperature tolerance, and accuracy.

This piece will get into the best materials for manufacturing sintered gears by learning about selection criteria, comparing ferrous and non-ferrous options, and contrasting sintered gears with other manufacturing processes. Readers will gain practical insights to make informed decisions for their specific applications.

Material Selection Criteria for Sintered Gears

You need to think over several key factors to pick the right material for sintered gears. Your choice will affect the gear’s performance, durability, and cost in specific applications.

Load and torque requirements in light-duty applications

Load capacity is the main focus when designing sintered gears for light-duty applications. Right now, international standards don’t cover the load capacity of powder metallurgy (PM) gears as fully as wrought gears. Sinter-hardened PM gears with a density of 7.5 g/cm³ match the endurance limit of quenched and tempered wrought steel (SAE 4140). This makes them a good fit for medium-duty applications.

The material you choose directly affects load-carrying capacity. Iron-based sintered gears are popular because they’re strong and budget-friendly. Copper-based alloys give you great wear and corrosion resistance. These gears work best in moderate load scenarios rather than high-stress applications due to their natural porosity.

Dimensional accuracy and AGMA class expectations

Powder metal gears usually fall within the AGMA class 8 range. This precision works well for many uses, but getting higher accuracy needs special attention and might cost more. High-density PM prototype gears can match hobbed conventional gears from wrought steel in gear-profile, lineup, and pitch quality.

PM prototype gears can have 30% better surface smoothness than wrought prototype gears. Standard powder metallurgy processes might not always give you the same dimensional precision as machining methods. You should keep this in mind when setting design specs, especially if you need very tight tolerances.

Cost-performance tradeoffs in high-volume production

Sintered gears can save you a lot of money in high-volume production—they cost about ten times less than machined gears. These savings come from using less material (3-5% waste for PM versus 40-60% for machining) and needing fewer secondary operations.

Today’s powdered metal gears reach 80-90% of solid steel gear strength while staying cheaper. If you need better performance, density becomes vital—most transmission gears with high contact loads need properties beyond what regular PM gears at 6.9-7.1 g/cm³ can provide.

Manufacturers must balance material choice and processing methods to get the best value. High-performance PM gears need just five processing steps, while regular machined gears often take many more [2].

Ferrous Alloys for Sintered Gear Manufacturing

Ferrous alloys lead the powder metallurgy world in sintered gear production. These materials give manufacturers an ideal balance of performance and economical solutions. They serve as the foundation for gear applications in many industries.

Carbon Steel Powders: Strength and Machinability

Iron-carbon alloys emerge as the most economical choice for sintered gear manufacturing. The FC-0200 series delivers fundamental strength that suits light-duty applications, reaching tensile strengths of 205 MPa to 345 MPa based on density. The mechanical properties get better as density rises from 6.0 g/cm³ to 6.8 g/cm³. Carbon content determines the maximum strength you can achieve in sintered steels, whether as-sintered or heat-treated. Small appliance gears and timing components work well with these materials under moderate loads.

Alloy Steel with Nickel and Molybdenum Additions

Alloy steels containing nickel and molybdenum additions perform better in demanding applications. Adding 2-4% nickel leads to higher density, better ductility, stronger impact resistance, and longer fatigue life. The FN-0200 series shows tensile strength values between 310 MPa and 380 MPa with impact energy ratings of 8-18 J. Molybdenum combined with chromium can push tensile strength up to 1282 MPa. These alloys shine during heat treatment since they resist oxide formation better than iron.

Stainless Steel Powders for Corrosion Resistance

Stainless steel powders add excellent corrosion resistance to sintered gears. Austenitic grades like 304L and 316L achieve tensile strengths from 204 MPa to 520 MPa depending on sintering conditions. Applications needing magnetic properties work best with ferritic grades such as 409LE and 434L, which deliver tensile strengths up to 368 MPa. These materials excel in harsh environments, from marine settings to chemical processing equipment. Standard PM techniques can produce stainless steel gears, though proper atmosphere control during sintering helps maintain their corrosion-resistant properties.

Non-Ferrous and Composite Materials in Powder Metallurgy

Non-ferrous alloys provide remarkable advantages for specialized sintered gear applications. These materials shine in conditions where steel variants might struggle.

Copper and Bronze Alloys for Low-Friction Applications

Copper-based sintered gears stand out when you need reduced friction and exceptional wear properties. Bronze alloys show excellent sliding characteristics and resist wear effectively. C90700, a copper-tin alloy with up to 88.8% copper, has gained popularity as a gear material because of its high tensile, yield, and compression strength. These materials work well in worm gear applications where self-lubricating properties are vital. Oil-impregnated sintered bronze bearings keep their lubricating qualities through a smart system. Heat makes the oil expand to bearing surfaces, while cooling pulls the lubricant back through capillary action.

Aluminum Alloys for Lightweight Gear Design

Aluminum powder metallurgy reduces weight significantly without sacrificing performance. The 7075Al alloy components reach 97.6% relative density when sintered at 610°C, achieving tensile strength of 214.8 MPa. The PM production uses four main aluminum alloy families: 2000-series (Al-Cu-Si-Mg), 4000-series (Al-Si-Cu-Mg), 6000-series (Al-Mg-Si-Cu), and 7000-series (Al-Zn-Mg-Cu). Aluminum sintered gears compete well with wrought-aluminum castings because they have a net-shape advantage, especially in high-volume production.

Beryllium-Copper and Phosphor Bronze for Wear Resistance

Beryllium copper and phosphor bronze excel in applications that need superior wear resistance. Beryllium copper achieves tensile strength between 900-1400 MPa and hardness values of 200-450 HV. These values surpass phosphor bronze’s 350-800 MPa tensile strength and 100-200 HV hardness. Phosphor bronze alloys resist fatigue, wear, and corrosion remarkably well. Plain copper gears without proper alloying elements show plastic flow, material transfer, and high wear rates.

Comparative Analysis of Gear Materials and Processes

Manufacturing methods play a crucial role in gear performance, cost, and their use in industries of all types. Selecting the right process depends on several key factors.

Sintered Gears vs Machined Gears: Cost and Accuracy

Sintered gears provide remarkable cost benefits and are about ten times cheaper than machined versions in high-volume production. The savings come from better material usage, as powder metallurgy reaches 97% efficiency while machining achieves only 60-70%. Production speed favors sintered gears, which take less time to manufacture, especially for bigger orders.

Machined gears shine in applications that need micron-level accuracy. All the same, today’s sintered gears can reach AGMA class 8 quality standards. The surface finish shows a significant difference – sintered gears typically have a 30% smoother surface than machined ones.

Hot-formed vs Sintered Powder Gears: Strength Comparison

Hot-forged gears show 8% more tensile strength and are 27% more resistant to fatigue than their sintered counterparts. Surface-densified powder metallurgy gears perform impressively well, with endurance limits only 5% below hobbed gears. This makes them excellent choices for high-stress applications.

Plastic and Die-Cast Alternatives for Low-Load Use Cases

Plastic gears cut costs significantly in light-duty applications. Acetal (POM) serves as the most cost-effective choice for prototypes and low-load scenarios. Delrin® (homopolymer POM) delivers better strength and resists fatigue well, while copolymer varieties like Hostaform® balance good properties with lower costs.

Nylon 6/6 excels at absorbing shock, but moisture affects its dimensional stability. Applications that need better wear resistance can use aluminum-bronze and phosphor-bronze alloys as viable options.

Conclusion

Material choice for sintered gears affects performance, durability, and creates budget-friendly solutions in applications of all types. Ferrous alloys lead the powder metallurgy market because they strike an excellent balance between strength and economic value. Carbon steel powders are the foundations of strength for light-duty applications while staying budget-friendly. Adding nickel and molybdenum to alloy steels improves their performance, which makes them perfect for tougher environments. Stainless steel powders cost more but protect against corrosion exceptionally well in harsh conditions.

You should think over non-ferrous options for specialized uses, too. Copper and bronze alloys work great when you need less friction and self-lubricating properties. Aluminum powder metallurgy cuts weight substantially without sacrificing performance, especially when you have weight-sensitive designs. Beryllium-copper and phosphor bronze are also excellent choices because they resist wear better in high-stress uses.

Looking at sintered gears versus traditional manufacturing shows how powder metallurgy saves money, particularly in high-volume production. Machined gears might be a bit more precise, but modern sintered gears reach impressive accuracy within AGMA class 8 standards and often have better surface finish.

Your specific application requirements and limits will determine what material you end up choosing. Engineers just need to balance load capacity, operating environment, dimensional precision, and production volume to make their final pick. Manufacturing technologies keep advancing, and sintered gears will without doubt become more important in industries of all types – from automotive and power tools to industrial machinery and consumer appliances. Their cost savings, material efficiency, and steadily improving performance make them crucial to modern mechanical design.

Key Takeaways

Understanding the best materials for sintered gears helps manufacturers optimize performance while controlling costs in high-volume production scenarios.

• Sintered gears cost 10x less than machined alternatives in high-volume production while achieving 97% material utilization efficiency compared to machining’s 60-70%.

• Iron-based alloys dominate sintered gear manufacturing with carbon steel for basic applications, nickel-molybdenum alloys for enhanced performance, and stainless steel for corrosion resistance.

• Non-ferrous materials serve specialized needs including copper-bronze for low-friction applications, aluminum for weight reduction, and beryllium-copper for superior wear resistance.

• Modern sintered gears achieve AGMA class 8 accuracy with 30% better surface roughness than machined gears, making them viable for most industrial applications.

• Material selection depends on load requirements and environment with powder metallurgy excelling in moderate-load scenarios while offering significant cost advantages over traditional manufacturing methods.

The key to successful sintered gear implementation lies in matching material properties to specific application demands while leveraging the inherent cost and manufacturing advantages of powder metallurgy processes.

FAQs

Q1. What are the main advantages of sintered gears over machined gears? Sintered gears are approximately ten times less expensive than machined gears in high-volume production. They also utilize up to 97% of raw materials compared to only 60-70% for traditional machining methods, making them more cost-effective and environmentally friendly.

Q2. Which materials are commonly used for manufacturing sintered gears? The most common materials for sintered gears are ferrous alloys, including carbon steel, alloy steel with nickel and molybdenum additions, and stainless steel. Non-ferrous materials like copper, bronze, and aluminum alloys are also used for specific applications.

Q3. How does the accuracy of sintered gears compare to machined gears? Sintered gears typically achieve AGMA class 8 accuracy, which is suitable for many industrial applications. While machined gears may offer slightly better precision, modern sintered gears can have up to 30% better surface roughness compared to their machined counterparts.

Q4. Are sintered gears suitable for high-load applications? Sintered gears perform best in moderate load scenarios. While they can achieve 80-90% of the strength of equivalent solid steel gears, they may not be ideal for extremely high-stress applications due to their inherent porosity. For high-load uses, special considerations in material selection and processing are necessary.

Q5. What are the benefits of using non-ferrous materials for sintered gears? Non-ferrous materials offer unique advantages for specialized applications. Copper and bronze alloys provide excellent wear resistance and self-lubricating properties. Aluminum alloys offer significant weight reduction benefits, while beryllium-copper and phosphor bronze excel in wear-resistant applications.