Application of powder metallurgy and metal injection molding processes to planetary gears

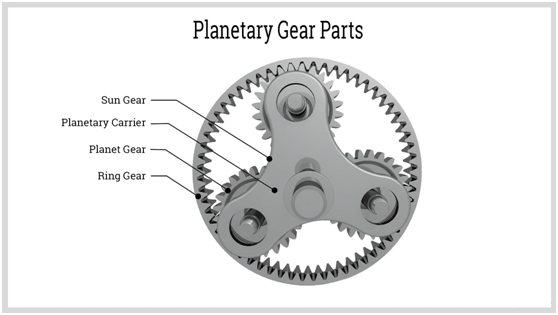

What is a planetary gear?

A planetary gear, also known as an epicyclic gear system, is a type of gear arrangement that consists of several key components:

- Sun gear: A central gear that acts as the input and driver of the system.

- Planet gears: Three or more gears that rotate around the sun gear. They are typically mounted on a movable carrier.

- Ring gear: An outer gear with internal teeth that meshes with the planet gears from the inside.

- Carrier: Also called an arm, it holds the planet gears and allows them to orbit around the sun gear.

Key features of planetary gears include:

- Compact design: They can provide high torque and speed reduction in a smaller package compared to traditional gear systems.

- Even load distribution: The planet gears distribute the load evenly, making the system more robust and able to handle higher torques.

- Versatility: Planetary gears can be easily configured for different ratios by changing the carrier and sun gears.

- Efficiency: They can handle higher shock loads and are known for their ruggedness.

Planetary gears are used in various applications, including:

- Automotive transmissions

- Industrial machinery

- Construction equipment

- Turbine engines

- Electric screwdrivers

The unique arrangement of gears in a planetary system allows for complex motion and power transmission, making it a versatile and widely used gear configuration in many industries

The main uses of planetary gears include:

Main Uses of Planetary Gears

Automotive Transmissions

Planetary gears are integral to most modern automatic transmissions in vehicles. They provide various gear ratios, allowing smooth and efficient power transfer from the engine to the wheels.

Industrial Machinery

Planetary gears are used in various industrial applications such as guided robots, laser cutting machines, and hospital operating tables. Their compact size and high efficiency make them ideal for precision equipment.

Power Tools

Electric screwdrivers and other power tools often utilize planetary gears. Their ability to provide high torque in a compact form factor makes them suitable for handheld devices.

Wind Turbines

In wind turbine systems, planetary gears are essential for converting the slow rotation of the turbine blades into higher-speed rotation suitable for electricity generation.

Aerospace

Planetary gears are used in helicopter and aircraft engine drive systems, providing reliable power transmission and speed reduction.

Speed Reduction

Planetary gears are commonly employed as speed reducers to slow down motors and increase torque, making them crucial for various machinery and equipment.

Compact Power Transmission

Their compact design allows for high torque and speed reduction in a small package, making planetary gears ideal for applications where space is limited.

High-Torque Applications

Planetary gears can handle higher torque loads efficiently, making them suitable for applications that require substantial power transmission.

Consumer Electronics

Planetary gears are used in devices like mobile phone camera actuators and photo printers, where precise movement and compact size are critical.

Smart Home Devices

In appliances such as hand-held washing machines, vacuum cleaners, and sweeping robots, planetary gears provide reliable and efficient power transmission.

Industrial Automation

Planetary gears are used in valve drive systems, vending machines, and other automated equipment, ensuring smooth and precise operation.

Automotive Systems

Beyond transmissions, planetary gears are found in electric parking brakes, tailgate drives, and other automotive systems, providing reliable and efficient power transmission.

Planetary gears play a crucial role in various industries due to their compact size, efficiency, and ability to handle high torque. Their widespread use in automotive transmissions, industrial machinery, power tools, wind turbines, aerospace, and consumer electronics underscores their versatility and reliability. Understanding the advantages and applications of planetary gears can help businesses make informed decisions for their specific needs, ensuring optimal performance and efficiency.

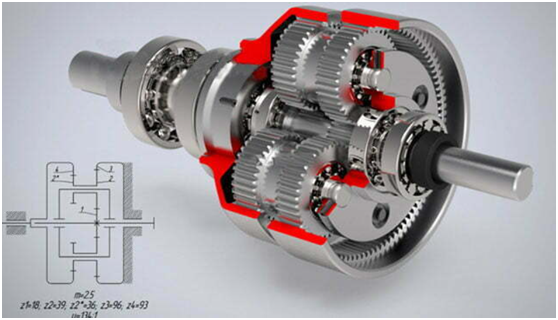

Application of Powder Metallurgy (PM) and Metal Injection Molding (MIM) Processes to Planetary Gears

MIM Process for Micro-Planetary Gears

Metal Injection Molding (MIM) is an effective method for producing micro-planetary gears. This process allows for the creation of small, complex gear components with high precision and detail, which is essential for applications requiring miniature gears. MIM is ideal for producing parts with intricate shapes and tight tolerances, making it suitable for micro-planetary gears used in various precision-driven industries.

PM in Planetary Gear Systems

Powder Metallurgy (PM) is extensively used to produce components for planetary gear systems, particularly in medical applications. The PM process enables the creation of intricate parts with excellent dimensional accuracy. This precision is crucial for the reliable operation of planetary gear systems in medical devices, where consistency and performance are paramount.

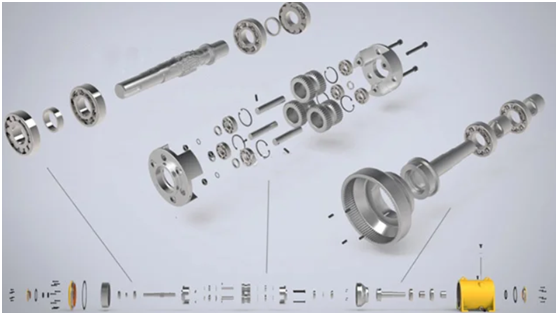

Miniature Planetary Gear Carrier Sets

Powder Metallurgy has demonstrated its capability by producing award-winning miniature planetary gear carrier sets. These sets highlight the effectiveness of PM in manufacturing small, complex gear components. The ability to produce these intricate parts showcases the versatility and precision of the PM process, making it suitable for high-performance applications.

Advantages of PM and MIM for Gears

- Net Shape Advantages: Both PM and MIM processes allow for the production of near-net-shape parts, significantly reducing the need for extensive machining and material wastage.

- Complex Geometries: These processes excel at creating intricate 3D shapes, beneficial for planetary gear components that require precise and complex designs.

- Material Versatility: PM and MIM can utilize a variety of materials, including alloy steels, stainless steels, and high-temperature alloys, offering flexibility in material selection to meet specific performance requirements.

Surface Densified PM

GKN, a major manufacturer, uses surface densified PM technology to produce gears that combine the net shape advantages of PM with the performance characteristics of wrought steel. This technology enhances the surface properties of PM gears, providing improved strength and durability while maintaining the benefits of near-net-shape manufacturing.

Design Freedom

PM and MIM offer excellent opportunities to create highly complex, 3-dimensional products. These processes allow for the inclusion of undercuts and other intricate design features in gear components, providing greater design flexibility and innovation.

Material Properties

PM parts, including gears, can be engineered to have specific material properties such as tensile strength, fatigue endurance, and notch sensitivity. These tailored properties are crucial for the performance and reliability of gear components in demanding applications.

Summary

PM and MIM processes offer significant advantages for the production of planetary gear components, including:

- High precision and dimensional accuracy

- Ability to produce complex geometries and intricate designs

- Material versatility for tailored performance properties

- Efficient production with reduced machining and material wastage

These benefits make PM and MIM ideal for manufacturing planetary gears used in automotive, medical, and industrial machinery applications, where high performance and reliability are essential.

Example Manufacturers of Planetary Gears Using PM and MIM

- GKN Sinter Metals Visit GKN Sinter Metals

- JHMIM Group Visit JHMIM Group

- Dynacast International Visit Dynacast International

- Indo-MIM Visit Indo-MIM

- Molex Visit Molex

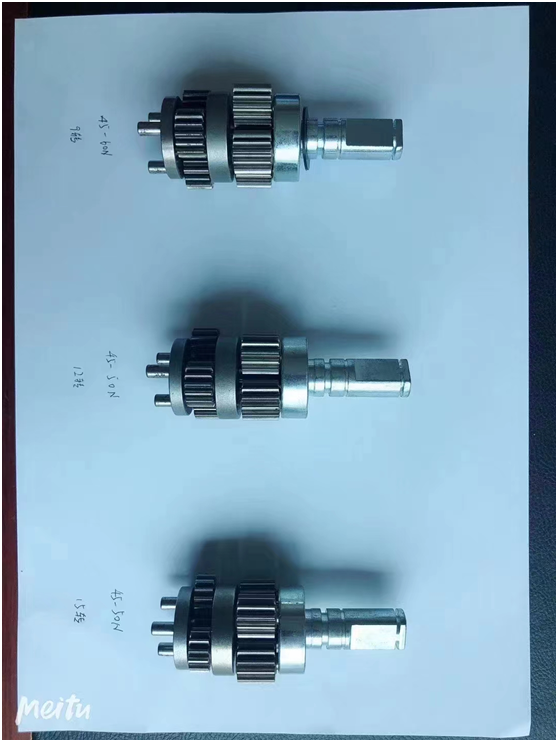

Metal injection molding VS Powder Metallurgy

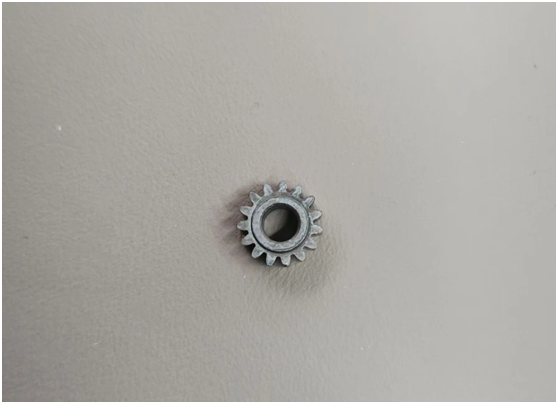

Planetary gear accessories produced by PM process

Planetary gear accessories produced by MIM process

We, JH MIM, have our own MIM and PM factories, and have mass-produced planetary gear accessories for both processes. With rich production experience, if you have any questions, please contact us directly.