Your choice of clutch disk can affect your vehicle’s performance by a lot, as different materials handle vastly different power levels. Single organic clutch disks work well up to 400-450 HP, while sintered metallic options can handle 700+ HP. High-performance twin disk setups with sintered materials push the limits even further, supporting up to 1400 HP.

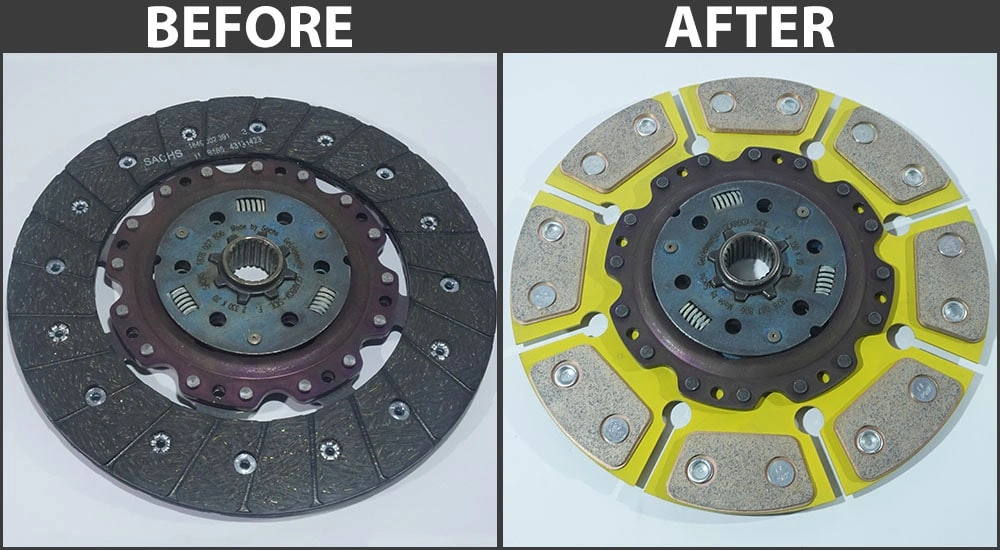

The right clutch choice depends on understanding how different materials work. Organic clutch disks give you smoother, more gradual engagement than other options, and sintered clutch disk material stands up exceptionally well under extreme conditions. Organic vs ceramic clutch or kevlar vs organic clutch comparisons go beyond just power handling – they affect your driving feel and how long the clutch lasts. Manufacturers create sintered plates by compressing and heating metal powders until they form a solid structure. This makes them much more durable than organic plates that blend fibers, resins, and other compounds. The trade-off is that sintered plates don’t engage as smoothly.

Understanding Clutch Disk Materials and Their Role

The clutch disk is a vital mechanical component in a vehicle’s power delivery system. This disk works as a middle component that controls power flow between major drivetrain parts.

How clutch disks transfer power from the engine to the transmission

Power transfer starts at the engine’s crankshaft, which links to the clutch basket. The assembly uses friction and drive plates that work together. Friction clutch plates connect to the outer basket, while drive plates attach to the inner basket (clutch boss). The pressure plate squeezes these components together when you engage the clutch. They bind and spin as one unit. This synchronized motion lets power flow from the crankshaft through the transmission input shaft and ended up at the wheels. The pressure plate lifts when you pull the clutch lever. This allows the plates to spin on their own and cuts off power transmission temporarily.

Why clutch material matters: heat, friction, and wear

Clutch disks turn a lot of rotational energy into heat at the time they’re working. The friction clutches create significant heat on their contact surfaces, especially when engaging. This heat leads to quick wear, breaks down materials, causes glazing, reduces torque, and can make the clutch fail early. The friction coefficient between parts determines how much torque can move through without slipping. The clutch material must handle the engine’s torque and RPM, plus the pressure plate’s clamping force and operational heat.

Overview of clutch types: organic, sintered, ceramic, hybrid

Each clutch disk material offers unique performance features:

- Organic clutch disks mix fibers (usually Kevlar, carbon), resins, and compounds to create smooth-engaging surfaces. These disks give you smooth engagement and work well in normal conditions. They can handle power up to 450 HP with single-disk setups.

- Sintered clutch disks are made by compressing and heating metal powders (copper, bronze, steel) into solid pieces. These disks shine in high-heat conditions and are nowhere near as fragile as other types. They can handle more than 700 HP.

- Ceramic clutch disks blend copper, iron, tin, bronze, and other materials. They work in temperatures up to 1,000°F without losing grip. All the same, they tend to engage suddenly.

- Hybrid/Kevlar clutch disks strike a balance between smooth engagement and better durability. They’re great for performance driving but still work well for daily use.

Organic Clutch Disks: Composition, Pros, and Limitations

Organic clutch disks are the most common type in stock vehicles. These disks contained asbestos in their early days until health concerns led to its ban. Modern organic clutch disks now employ alternative materials that ensure safer operation.

Material breakdown: Kevlar, carbon, and resin matrix

Modern organic clutch disks are made mostly of cellulose fibers (like cardboard) with heat-resistant materials such as chopped fiberglass and mineral wool. These components sit in a thermosetting phenolic resin base. This mix creates the right balance between durability and engagement quality. Heavy-duty versions include chopped Kevlar strands that provide six times steel’s tensile strength while maintaining good heat resistance. Some manufacturers add metal strands like brass or copper to improve cooling properties.

Smooth engagement and low heat generation

Organic clutch disks stand out because of their smooth engagement characteristics. Their gentle, progressive clutch action makes them perfect for everyday driving where comfort matters most. These organic materials produce less heat than metallic ones under normal conditions. Quality organic disks also feature proper cushioning between linings that helps deliver smooth, progressive engagement without compromising simple performance.

Common issues: glazing, wear under high stress

Organic clutch disks have their limitations despite their benefits. The phenolic resins start to outgas, melt, and create a slippery glaze that causes clutch slip in extreme conditions. These resins and cellulose parts can burn in demanding situations. The materials’ limited mechanical strength often leads to failure under high RPM and heavy loads because of their structural weaknesses.

Best use cases: daily commuting and light street riding

Organic clutch disks shine in specific applications based on their strengths and limitations. They work best in daily commuter vehicles that value smooth operation and driving comfort over peak performance. Cars with stock or slightly modified engines benefit from these disks’ balanced features. These disks can handle moderate use without long break-in periods, making them ideal for everyday driving.

Sintered Clutch Disks: Performance, Durability, and Trade-offs

Sintered metal clutch disks are the gold standard in high-performance power transfer technology. These reliable components outperform their organic counterparts and last longer in extreme conditions.

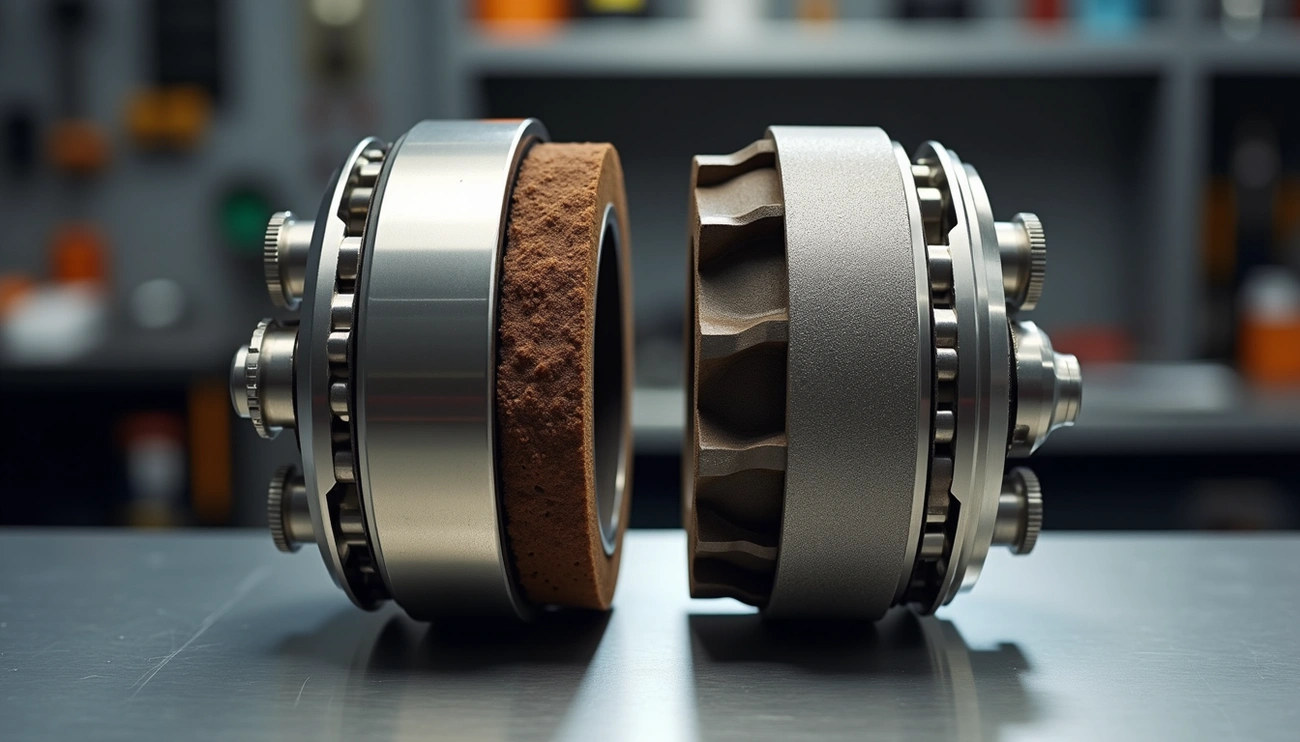

Sintering process: metal powder compression and heating

Making sintered clutch disks starts with filling molds with powdered metals like copper, bronze, steel, or iron. Manufacturers then compress these materials under high pressure. The compressed powder heats up to temperatures just below melting point (around 2050-2150°F). This heat fuses the metal particles into a solid structure with great thermal properties. The whole process needs careful control of time, temperature, and atmospheric conditions to get the best mechanical properties.

High heat resistance and aggressive engagement

These sintered materials shine in extreme operating environments. They can handle temperatures up to 1000°F for brief periods without any damage. This impressive heat handling helps them deliver consistent performance across different temperatures. The metallic makeup also gives them more aggressive friction characteristics, which makes quick, responsive gear changes possible – something that’s crucial for performance uses.

Drawbacks: abrupt feel, higher cost, more heat

Sintered clutch disks do have their downsides. The way they engage feels quite sudden – almost like flipping a switch – which makes them tricky to use in traffic. They create more heat while running, though the sintered materials actually work better in hot conditions. The specialized way they’re made also pushes up their price compared to organic options.

Ideal for: racing, track days, and high-performance bikes

These characteristics make sintered clutch disks perfect for high-demand situations. They work great in racing, track days, aggressive riding, and vehicles with major horsepower upgrades. These disks are a great choice for machines that face frequent high-stress situations where reliability matters more than comfort.

Choosing Between Sintered and Organic: Use Case Scenarios

Your riding needs and priorities should guide your choice of clutch disk material. The right clutch matched to your vehicle and driving style can substantially change both performance and driving experience.

Street riders vs track riders: what to prioritize

Street riders get better results with organic clutch disks that give smooth engagement and excellent drivability for daily commuting. These disks work quietly and comfortably—qualities you need for regular street use. Track enthusiasts should go for sintered metallic materials that handle extreme heat and stress during aggressive riding. Weekend racers who do both often find a Kevlar/organic combination hits the sweet spot.

Kevlar vs organic clutch: when to upgrade

You might want to switch from standard organic to Kevlar clutch disks if you need better durability without losing that smooth engagement. Kevlar clutches last 2-3 times longer than regular organic ones. The trade-off comes with a longer break-in period—about 1,000 miles. Riders who push their bikes harder than casual driving but still want decent comfort end up finding Kevlar the perfect middle ground between pure organic and aggressive metallic options.

Longevity vs comfort: which matters more?

Your priorities make this call. Organic materials give you smooth, comfortable engagement but wear down faster under stress. Sintered metallic clutches last much longer but engage more abruptly. Some riders love the smooth, progressive feel of organic materials for daily rides. Others prefer the consistency and durability of sintered options—especially for high-stress riding.

Clutch disk material and its effect on maintenance cycles

The material you choose affects how often you’ll need maintenance. Heat can make organic clutches wear out faster than their design limits. Sintered materials handle heat better and need less frequent service, even under tough conditions. Your vehicle’s power output should match your clutch choice—properly matched clutches always outlast those working beyond their limits.

Conclusion

Your specific driving needs and performance expectations will determine the best clutch disk material for your vehicle. Organic clutch disks work great for everyday driving and give you smooth engagement with comfortable operation. These disks are perfect for street vehicles with stock or slightly modified engines. On the other hand, sintered clutch disks are better suited for high-performance applications where durability and heat resistance matter more than comfort.

The power handling capabilities between these materials vary by a lot. Single organic clutch setups can handle 400-450 HP, while sintered metallic options can take more than 700 HP. This becomes crucial if you plan to upgrade or modify your vehicle for better performance.

Temperature tolerance is another reason to consider your choice carefully. Sintered materials can handle extreme heat conditions that would make organic materials glaze, slip, or fail. Track enthusiasts and racers get better results from sintered options, even though these clutches engage more abruptly.

Your choice of material affects maintenance schedules too. The right clutch materials will last longer and cost less to maintain. Kevlar-enhanced organic clutches give you a middle ground – better durability without losing too much of that smooth engagement feel.

The manufacturing process shapes how well your clutch performs. Companies like JH MIM have spent almost 20 years working with metal injection molding and powder metallurgy. Their knowledge of sintering processes helps them make clutch components that can handle extreme conditions.

These differences between clutch materials help drivers make smart choices based on their needs. The right clutch disk material will improve your driving experience and make your components last longer, whether you need smooth daily driving or high-performance track capability.

Key Takeaways

Understanding the fundamental differences between sintered and organic clutch disks helps you make the right choice for your specific driving needs and performance requirements.

• Power handling varies dramatically: Organic clutch disks handle 400-450 HP while sintered options manage 700+ HP for high-performance applications.

• Choose organic for daily driving: Smooth engagement and comfortable operation make organic clutches ideal for street commuting and stock vehicles.

• Select sintered for extreme conditions: Superior heat resistance and durability make sintered clutches perfect for racing, track days, and aggressive riding.

• Material affects maintenance cycles: Properly matched clutch materials extend service intervals and reduce long-term maintenance costs significantly.

• Kevlar offers middle ground: Kevlar-enhanced organic clutches provide 2-3 times longer lifespan while maintaining reasonable engagement quality for performance-minded street riders.

The key is matching your clutch material to your actual driving style—comfort-focused daily drivers benefit from organic materials, while performance enthusiasts require the durability and heat resistance that only sintered metallic options can provide.

FAQs

Q1. What are the main differences between sintered and organic clutch disks? Sintered clutch disks are made from compressed metal powders and offer high heat resistance and durability, ideal for high-performance applications. Organic clutch disks, made from fibers and resins, provide smoother engagement and are better suited for daily driving and street use.

Q2. How do I choose between sintered and organic clutch disks for my vehicle? Consider your driving needs. Choose organic clutch disks for smooth, comfortable daily commuting and street use. Opt for sintered clutch disks if you’re into racing, track days, or have a high-performance vehicle that requires superior heat resistance and durability.

Q3. What power handling capabilities do sintered and organic clutch disks offer? Single organic clutch disks typically handle 400-450 HP, while sintered metallic options can manage 700+ HP. For extreme high-performance applications, twin disk setups with sintered materials can support up to 1400 HP.

Q4. Are there any drawbacks to using sintered clutch disks? Yes, sintered clutch disks tend to have a more abrupt engagement feel, which can be challenging in traffic conditions. They also generate more heat during operation and are generally more expensive than organic alternatives due to their specialized manufacturing process.

Q5. How do clutch disk materials affect maintenance cycles? Clutch disk material directly impacts maintenance frequency. Organic clutches may require more frequent replacement when subjected to high heat, while sintered materials can extend service intervals even under demanding conditions. Properly matched clutches always outlast those operating beyond their designed capacity.