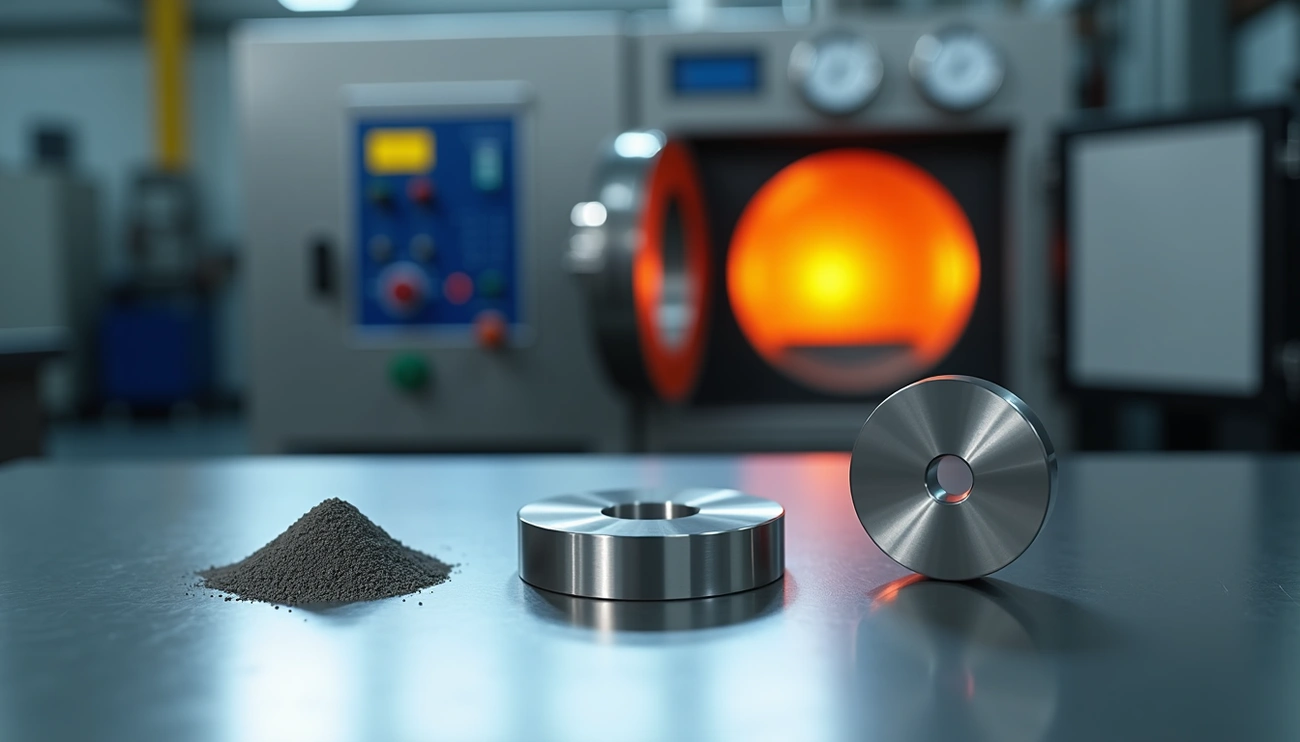

Molybdenum sintered parts start with high-purity metallic powder that contains at least 99.95% molybdenum. This gray-black powder is known for its exceptional properties. The powder has an impressive melting point of 2,623°C and shows remarkable resistance to most acids at room temperature. The specialized components undergo sintering at temperatures between 1800°C and 2200°C. The process holds these temperatures for 2-4 hours, which creates products with relative densities of 90-98% of theoretical values.

The manufacturing process requires careful compaction of molybdenum powder into desired shapes through pressure application. These components must meet strict quality standards. The standards specify a minimum tensile strength of 750 MPa and a density of at least 10.2 g/cm³. The specialized applications need precise dimensional control. Some examples include thin wafers that measure 29 mm in diameter with a thickness of just 0.5 mm. The finished parts must maintain high purity levels with ≥99.93% molybdenum by weight. The next sections get into each manufacturing stage thoroughly, from powder selection through final quality control testing.

Powder Selection and Preparation for Molybdenum Sintering

The quality of molybdenum sintered parts depends heavily on the powder selection. The powder’s characteristics shape how it behaves during compaction and sintering, which determines the physical properties of finished components.

High-Purity Molybdenum Powder ≥99.95%

Powder purity stands as a key quality indicator for industrial-grade molybdenum sintered parts. Applications that need superior mechanical properties and electrical performance require high-purity molybdenum powder with ≥99.95% metals basis. Common metallurgical uses find 99.9% purity good enough, but electronic applications need the higher 99.95% standard.

Purity levels affect these aspects of the sintering process:

- Oxygen content – Sintering works best with oxygen levels below 0.05% (500 ppm), while commercial powders usually contain 1000-1400 ppm

- Carbon content – Changes the hardness and brittleness of the final parts

- Sulfur traces – Makes finished components less ductile

Production starts with ammonium paramolybdate (3(NH4)O·7MoO3·4H2O) or molybdenum trioxide (MoO3) as precursors. Manufacturers need to control reduction conditions carefully to keep impurities low, especially oxygen that hampers densification. Purer grades lead to better electrical conductivity, thermal performance, and corrosion resistance in sintered parts.

Particle Size Distribution Control (1–150 µm)

Particle size distribution shapes both compaction behavior and sintering characteristics. Commercial molybdenum powders range from ultra-fine (0.5-2 μm) to coarser grades (up to 150 μm). Getting the right distribution is key to achieving optimal results.

Smaller particles help sintering happen faster, but can be tricky to handle. Research shows that ultra-fine molybdenum powder (100-200 nm) can reach 96% relative density at sintering temperatures as low as 1200°C. Most industrial applications use slightly coarser powders because they’re easier to process.

Particle shape plays a vital role, too. Spherical particles flow better and pack more densely, while irregular shapes give better green strength. Commercial powders have a specific surface area between 0.5-5 m²/g, which directly affects how they sinter.

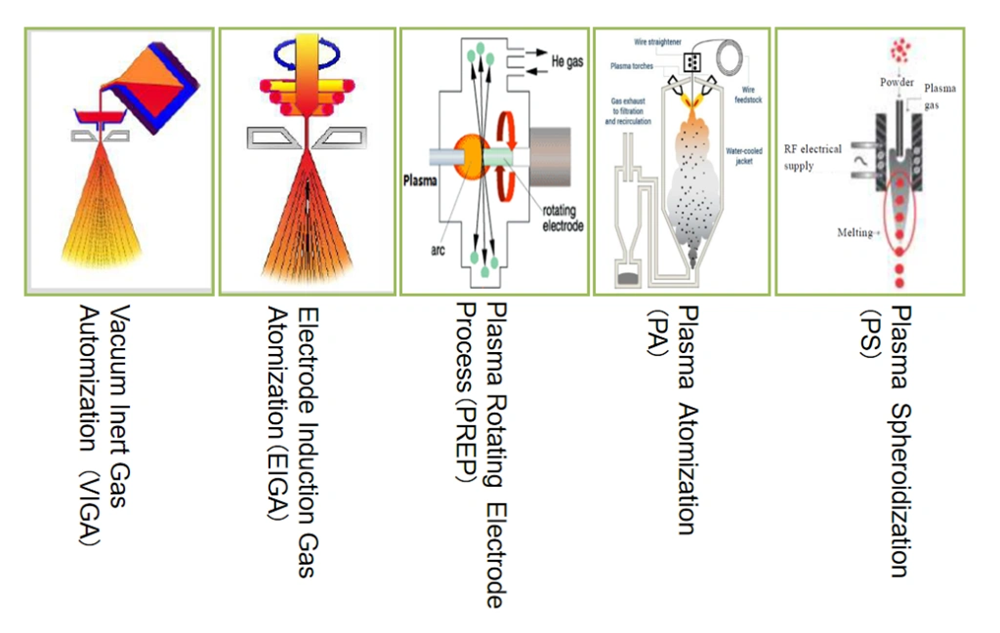

Spray-Dried vs Hydrogen-Reduced Powders

Molybdenum powder production mainly uses two methods: spray drying and hydrogen reduction.

Spray drying creates round powder particles that flow excellently. This method turns feed material into a fine mist that meets heated air, which quickly dries into particles. The Climax PM grade shows what spray-dried molybdenum powder can do – it forms strong green bodies with 76% theoretical density when pressed into disks at 690 MPa.

Hydrogen reduction remains the most common traditional method. This process reduces molybdenum oxide in two temperature stages:

- First stage: 450-650°C

- Second stage: 900-950°C

These factors affect hydrogen-reduced powder quality:

- Loading density in reduction boats

- Hydrogen flow rate and humidity

- Time spent in the furnace

Manufacturers often treat the powder with more hydrogen at 1273-1373K to reduce oxygen content further. Hydrogen-reduced powders usually have irregular shapes with more surface area than spray-dried ones, which helps them sinter better at lower temperatures.

Application requirements determine which powder type works best. Spray-dried powders excel in automated pressing operations, while hydrogen-reduced versions are great for better sinterability.

Advanced Compaction Techniques for Uniform Green Density

Uniform compaction plays a key role in producing high-performance molybdenum sintered parts. The green density distribution affects the final dimensional stability, mechanical properties, and quality of sintered components.

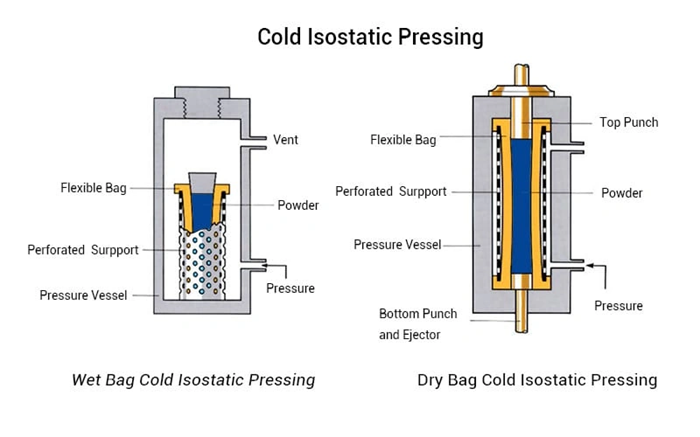

Cold Isostatic Pressing (CIP) at 150–200 MPa

Cold isostatic pressing is an advanced technique where molybdenum powder receives uniform pressure from all directions at once. This method creates better density distribution throughout the green body and builds a strong foundation for later sintering processes. Most manufacturers use isostatic pressures between 150-200 MPa to get the best results.

CIP works better than standard uniaxial pressing because it eliminates density gradients that often cause distortion during sintering. The powder particles sit inside flexible rubber molds that can handle complex shapes beyond what traditional die pressing can achieve. The green bodies turn out remarkably uniform, so we can predict how much they’ll shrink during sintering.

CIP pressure has a big impact on final densification. Tests with pressures from 50 MPa to 250 MPa show that higher CIP pressures create important dislocations in the powder structure. This prepares the material for better sintering kinetics. These dislocations decrease during early-stage sintering and encourage the formation of substructures and sub-grains within the particles.

Double-Acting Die Pressing for Flatness Control

Double-acting die pressing (also known as floating die technology) works much better than single-sided pressing techniques. The die body floats freely while pressure comes from both directions. This setup allows symmetric compaction of the molybdenum powder.

This technique solves a common problem with single-sided pressing – uneven density distribution that creates conical-shaped parts after sintering. Single-direction compaction leads to decreasing green densities along the compact’s height from where the moving punch makes contact. This density gradient causes uneven shrinkage during sintering.

Tests using double-acting pressing created molybdenum disks measuring 29.04 ± 0.005 mm in diameter with thickness variations of just ±0.005 mm across parts. Individual specimens showed thickness variations within +22 μm/-47 μm tolerances. However, significant cupping distortion happened during sintering, with surface deviations going beyond 400 μm.

Use of EBS Lubricant for Density Uniformity

Adding lubricant to molybdenum powder makes compaction work better by reducing friction between particles and die walls. EBS (ethylene bis-stearamide) works exceptionally well with spray-dried molybdenum powders.

Using less than 0.2% EBS improves several aspects: density increases, flow gets better, compact weight becomes more consistent, and parts come out of the mold more easily. These improvements lead to longer tool life, faster press output, and better dimensional stability in finished components.

Real-world tests show that mixing 0.25 weight percent EBS with Climax PM molybdenum powder creates green bodies with 77% theoretical density when pressed at 690 MPa. After 4 hours of sintering at 1600°C, these parts reach 90% density with only 5% open porosity. Parts made with EBS shrink more evenly and show less cupping distortion than those made with stearic acid or polyvinyl butyral.

The first sintering stage needs careful attention to remove lubricant properly. Most manufacturers heat parts to 500-600°C at controlled rates to remove the lubricant before reaching higher sintering temperatures. Poor lubricant removal can cause several problems, such as micro-cracks, carbon buildup at grain boundaries, and surface defects.

Sintering Process Optimization in Controlled Atmospheres

Controlled atmospheres are crucial to successful molybdenum component sintering. They directly affect the final properties and dimensional stability of finished parts.

Vacuum and Hydrogen Atmosphere Sintering (1800–2200°C)

High-temperature sintering is a critical phase that turns molybdenum powder into dense, structurally sound components. The process takes place in hydrogen furnaces at temperatures between 1800-2200°C. Both mechanical strength and density reach levels needed for processing into semifinished products.

Manufacturers need to choose between hydrogen and vacuum environments, each with its own benefits. Vacuum sintering yields slightly higher densities (9.80-9.90 g/cm³) compared to hydrogen sintering (9.75-9.85 g/cm³). Vacuum processing takes longer (12-15 hours) than hydrogen (8-10 hours) and costs 50% more.

The sintering atmosphere needs a consistent composition. Small changes can affect how molybdenum particles oxidize or reduce. Commercial operations show that atmosphere flow rates of 0.2-2 standard liters per minute work well. Research confirms that steady atmosphere composition is key to achieving desired properties, as steady-state conditions form at metal-gas interfaces.

Pre-Sintering at 1373–1573K for Strength Enhancement

Many manufacturers use a pre-sintering stage before high-temperature sintering. This step happens at 1373-1573K (1100-1300°C) and lasts 20-40 minutes. It improves two key properties of molybdenum billets: mechanical strength and electrical conductivity.

Pre-sintering creates necks between adjacent particles, which builds structural integrity before the main sintering cycle. This early consolidation stops deformation during transfer to high-temperature furnaces and creates even shrinkage patterns. Components keep enough porosity to fully densify during final sintering.

Shrinkage Management and Cupping Reduction

Controlling dimensional changes in molybdenum disks is challenging, especially preventing “cupping” distortion. Sintering shrinkage reaches about 5% in all directions, yet complex geometries often shrink unevenly.

These techniques help reduce distortion during sintering:

- Narrowing particle size distribution through milling or sieving

- Repressing green disks between flat plates at higher pressures

- Sintering disks horizontally on beds of fine milling media

- Restraining disks between metal plates during the sintering cycle

Cupping happens because of density gradients in the green body. Higher compaction densities occur near one flat surface’s perimeter and at the opposite surface’s center. These density variations cause different shrinkage rates, which lead to cupping. Advanced compaction techniques that create a uniform green density distribution work best to prevent distortion.

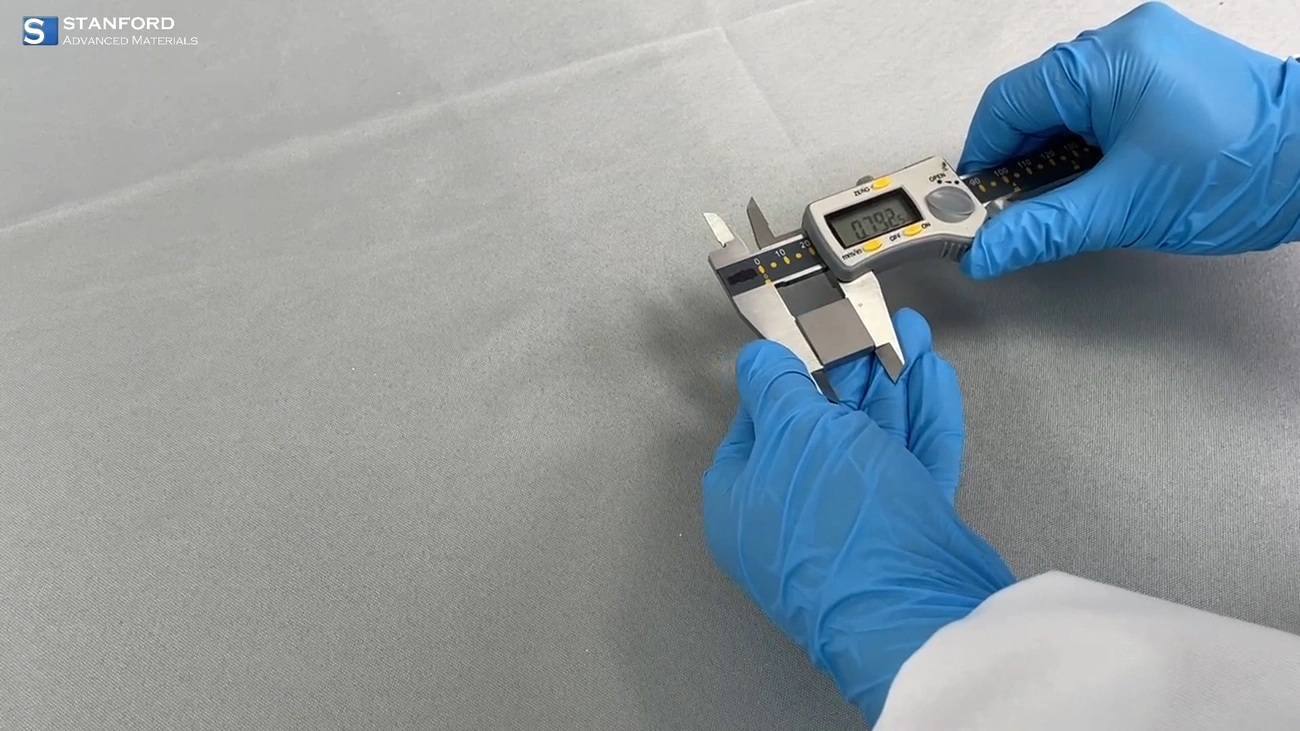

Dimensional Accuracy and Quality Control Standards

Quality inspection plays a vital role in manufacturing molybdenum sintered parts. Strict standards will give a consistent performance in critical applications for aerospace, electronics, and chemical processing industries.

ASTM B386 and B387 Compliance

ASTM B386 and B387 standards are the foundations of molybdenum product requirements. ASTM B386 defines chemical composition, mechanical properties, dimensions, density, and surface finish parameters. Materials that meet these standards show excellent thermal conductivity, structural stability at high temperatures, and remarkable resistance to oxidation in controlled atmospheres. TZM variants improve creep resistance for heavily loaded applications. ASTM B387 focuses on powder metallurgy applications and requires detailed records to track production processes.

Archimedes Method for Density Verification

The Archimedes method is the lifeblood of quality control for density verification. This technique measures volume accurately for irregularly shaped components with open pores. Manufacturers should ensure the measuring liquid (typically water) reaches all open pores to get accurate readings. Low-surface-tension liquids like isopropyl alcohol work better for narrow-opening pores. The density measurement should be 10.2 g/cm³ or higher to meet industry requirements.

Ultrasonic Testing (ASTM B594) for Internal Defects

ASTM B594 ultrasonic inspection procedures were first developed for aluminum alloys, but now work well to find internal flaws in molybdenum sintered components. This non-destructive technique spots voids, inclusions, cracks, and disbonds through pulse-echo evaluation. Modern systems use phased array technology with 64-128 sensors that can spot defects as small as 50μm. This cuts inspection time from 45 minutes to about 5 minutes.

Surface Flatness Tolerance ≤2%

High-performance applications need surface flatness tolerances of ≤2%. This tolerance ensures proper function when precise surface contact is needed. You can calculate flatness deviation using: H/L × 100 = % Flatness Deviation. H represents the maximum vertical distance between flat surface and lower sheet surface.

Profilometry for Thickness Variation Analysis

Contact profilometry measures thickness and provides key data for quality checks. This technique creates detailed surface maps that show thickness variations throughout the component. The analysis looks at mean thickness, minimum/maximum thickness, standard deviation, and areas that fall outside tolerance limits.

Tooling and Process Improvements for Industrial Scalability

Industrial scalability in molybdenum sintering just needs specialized tooling and consistent process controls. Recent advancements encourage better dimensional accuracy among reduced batch-to-batch variations.

New Tooling for 29 mm Disk Fabrication

Precision molybdenum disk production requires specialized tooling design. Modern dies made from D2-Tool steel with Rockwell C hardness of 60 surpass the ASTM standard’s minimum hardness requirement of 55. Engineers have created new tooling with expanded die cavity dimensions that specifically fit the typical 5% sintering shrinkage for 29 mm target disks. These improvements let manufacturers produce components with predictable final dimensions without much post-processing.

Floating Die Design for Symmetric Compaction

The floating die concept represents a major step forward from conventional single-acting pressing techniques. The die body stays suspended, which allows pressure application from both directions. This setup creates uniform green bodies consistently, even when using commercial spray-dried molybdenum powder that contains 0.25 wt% EBS lubricant.

Side-by-side testing shows:

- Both techniques reach 77% theoretical density before sintering

- After sintering at 1600°C for 4 hours, both methods achieve 89% density with 6% open porosity

- Double-acting technique creates disks averaging 29.04 ± 0.005 mm in diameter with minimal variation

Batch-to-Batch Consistency in Sintered Molybdenum Parts

Consistent production batches depend on precise control of multiple variables. Manufacturers have tested several lubricant types, including Teflon, stearic acid, and EBS. The right lubricant choice makes a big difference in consistency. Pressing pressure plays a crucial role in the final part characteristics and reliability. Latest research shows that milled powders boost mechanical reliability compared to commercial spherical powder.

Conclusion

This piece explores every aspect of manufacturing molybdenum sintered parts – from selecting the right powder to final quality checks. The foundation of successful production lies in powder purity, where industry standards require ≥99.95% purity to get optimal performance. The particle size must stay between 1-150 μm because it affects compaction behavior and sintering characteristics by a lot. This means manufacturers need precise control throughout the process.

Cold isostatic pressing at 150-200 MPa and double-acting die pressing have become the quickest way to achieve uniform green density distribution. These methods help minimize distortion during later sintering stages, especially when manufacturers use proper lubricants like EBS.

The sintering process must be optimized with temperatures typically ranging from 1800°C to 2200°C in vacuum or hydrogen atmospheres. Pre-sintering at 1373-1573K helps build strength and creates uniform shrinkage patterns before final densification. Manufacturers can reach relative densities of 90-98% of theoretical values through careful atmosphere and temperature control.

Quality standards remain strict. ASTM B386 and B387 compliance, density checks using the Archimedes method, and ultrasonic testing for internal defects ensure consistent performance. Surface flatness tolerances ≤2% and profilometry analysis guarantee dimensional accuracy for critical components.

Tooling breakthroughs, especially floating die designs for symmetric compaction, have improved batch-to-batch consistency while reducing variations in manufacturing. These advances let manufacturers create precision components like 29 mm disks with minimal dimensional deviation.

JH MIM’s unique experience of nearly 20 years in metal injection molding and powder metallurgy shows how precision-engineered molybdenum products meet global industrial needs. Their expertise emphasizes how these advanced manufacturing techniques create consistently high-quality sintered parts for applications that need exceptional thermal stability, electrical conductivity, and corrosion resistance. The future looks bright as manufacturing technologies advance, and molybdenum sintered parts will find new uses in aerospace, electronics, and chemical processing industries.

Key Takeaways

Master these critical manufacturing principles to produce high-quality molybdenum sintered parts that meet stringent industry standards and performance requirements.

• High-purity powder (≥99.95%) with controlled particle size (1-150 μm) forms the foundation for successful molybdenum sintering and optimal final part properties.

• Cold isostatic pressing at 150-200 MPa and double-acting die techniques eliminate density gradients, ensuring uniform compaction and minimal distortion during sintering.

• Sintering at 1800-2200°C in vacuum or hydrogen atmospheres achieves 90-98% theoretical density, with pre-sintering at 1373-1573K enhancing strength.

• ASTM B386/B387 compliance and Archimedes density testing ensure parts meet industry standards with surface flatness tolerances ≤2% for critical applications.

• Floating die designs and EBS lubricant addition dramatically improve batch-to-batch consistency while reducing manufacturing variations in precision components.

These advanced techniques enable manufacturers to consistently produce molybdenum sintered parts with exceptional thermal stability, electrical conductivity, and dimensional accuracy for demanding aerospace, electronics, and chemical processing applications.

FAQs

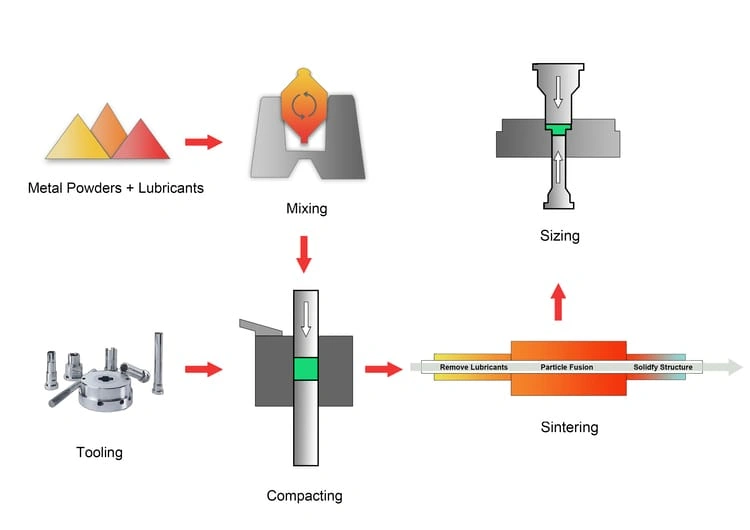

Q1. What are the key steps in manufacturing sintered molybdenum parts? The main steps include selecting high-purity molybdenum powder, compacting the powder using techniques like cold isostatic pressing, sintering at high temperatures (1800-2200°C) in controlled atmospheres, and performing quality control tests to ensure parts meet industry standards.

Q2. Why is molybdenum sintering important for industrial applications? Sintered molybdenum parts offer exceptional properties like high temperature resistance, excellent electrical conductivity, and corrosion resistance. These characteristics make them crucial for applications in aerospace, electronics, and chemical processing industries.

Q3. What are the typical sintering temperatures for molybdenum parts? Molybdenum parts are typically sintered at temperatures ranging from 1800°C to 2200°C. A pre-sintering stage at 1373-1573K is often used to enhance strength and establish uniform shrinkage patterns before final densification.

Q4. How is the quality of sintered molybdenum parts ensured? Quality control measures include compliance with ASTM B386 and B387 standards, density verification using the Archimedes method, ultrasonic testing for internal defects, and surface flatness tolerance checks (typically ≤2%). Profilometry is also used for thickness variation analysis.

Q5. What recent advancements have improved molybdenum sintering processes? Recent improvements include the development of floating die designs for symmetric compaction, use of EBS lubricant for better density uniformity, and specialized tooling for precise fabrication of components like 29 mm disks. These advancements have significantly enhanced batch-to-batch consistency and reduced manufacturing variations.