ABS system components play a vital role in modern vehicle safety systems. Car manufacturers now put more emphasis on advanced brake systems as safety awareness grows. These safety features started in luxury vehicles but have evolved into standard equipment over the last several years.

The automotive industry widely accepts electronically controlled four-wheel antilock brake systems, thanks to cheaper and better microelectronics. The ABS sensor ring sits at the core of these systems, and its material makeup can make or break its performance. ABS components need exact engineering to work reliably in tough conditions, especially when you have sensor rings. Choosing between powder metallurgy and cast iron to make these crucial parts affects everything from how long they last to how well they signal.

This detailed comparison looks at how material choice shapes ABS sensor ring performance by matching traditional cast iron against newer powder metallurgy options.

Material Role in ABS Sensor Ring Performance

Material properties are the foundations of reliable performance in ABS sensor rings. These small but critical components act as the main feedback mechanism for anti-lock braking systems. They need specific physical and electromagnetic characteristics to work properly under tough conditions.

Everything in dimensional stability in ABS brake system components

The precision of dimensions directly affects how well ABS brake system components work. Powder metallurgy ABS rings keep tight tolerances of ±0.02mm after the sizing process. This precision gives consistent performance throughout the vehicle’s life.

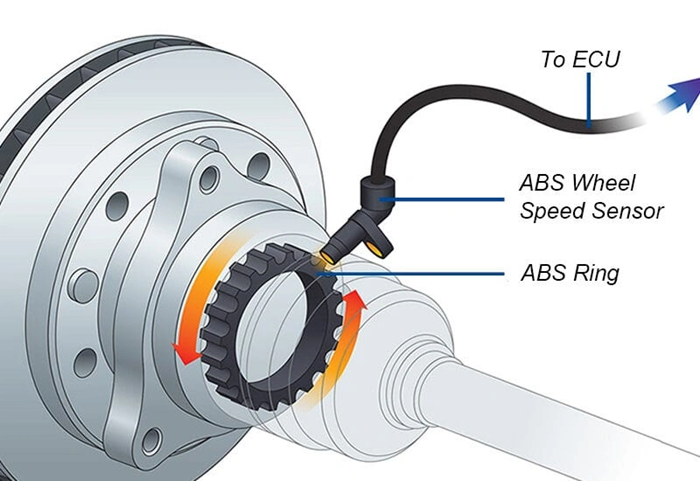

You can’t deny the connection between dimensional stability and signal quality. ABS sensors work with an air gap of 0.016 to 0.050 inches (0.40 to 1.3 mm) between the sensor and tone ring. This gap must stay consistent while running. Signals become weak or vanish if the gap is too wide. Physical damage might occur if it’s too narrow.

ABS rings have many teeth or notches that create recurring signals as the wheel turns. These signals help the system track wheel speed and spot potential lock-up situations. The system’s safety becomes compromised when dimensional stability fails. The ring’s ability to keep precise dimensions throughout its service life affects how well the ABS knows when to release and re-engage the brakes.

Thermal expansion behavior in high-speed wheel rotation

Thermal factors become crucial during high-speed wheel rotation. Bearing heat causes thermal expansion that changes fit tolerances and affects both load capacity and precision. Temperature-induced expansion can lead to several problems:

- Changes in lubricating components

- Component deformation

- Reduction of working clearances between components

- Increased localized stress and temperature

- Accelerated wear initiation and propagation

- Reduced overall service life

ABS system components need materials that account for these thermal dynamics. Good materials keep stable physical properties across temperatures from -40°C to 85°C. The thermal expansion coefficient must stay moderate – typically around (6-13×10^-5/°C) for certain plastic materials. This minimizes dimensional changes caused by temperature shifts.

Traditional manufacturing often creates thermal deformation problems. Powder metallurgy gives better control over thermal characteristics than conventional methods. This helps integral ABS components maintain dimensional stability even when temperatures change.

What material choice mean for signal accuracy

The material makeup affects the electromagnetic properties needed for signal generation. High-quality ABS system components use specific material formulations:

| Material Property | Powder Metallurgy ABS Rings | Alternative (Plastic-Ferrite) |

|---|---|---|

| Base Material | MPIF 35 F-0000 iron-based powder | Polyamide with ferrite powder |

| Density | 6.6-7.0 g/cm³ | Varies with ferrite content |

| Tensile Strength | 300-450 MPa | Lower than metal alternatives |

| Magnetic Properties | Excellent for signal generation | 300-3000 gauss residual magnetism |

| Weight | Higher | Lower (lightweight advantage) |

Powder metallurgy ABS rings with sintered density (typically 7.0g/cm³) provide ideal electromagnetic properties. These components achieve optimal magnetic properties with F-0000 iron-based powder (96-98%) and copper additions (1.5-2.0%).

Powder metallurgy’s controlled porosity (5-8%) boosts magnetic field characteristics. This controlled microstructure helps the ABS system components diagram stay accurate as the vehicle ages.

Lightweight applications can use alternative compositions with plastic resin containing 30-80% ferrite powder. These alternatives maintain good magnetic properties. They don’t need high-temperature sintering, which reduces thermal deformation risks during manufacturing.

Cast Iron ABS Rings: Strengths and Limitations

Cast iron has been the go-to material for industrial applications that need strength and vibration dampening. All the same, modern technology shows us that this traditional material falls short in precision applications like ABS sensor rings.

Corrosion susceptibility in humid environments

Cast iron shows weakness against moisture despite its strength. The risk of corrosion shoots up when relative humidity crosses 60%. ABS rings made of cast iron face tough challenges in automotive uses as they deal with weather conditions of all types.

Cast iron drain pipes share the same metal properties as ABS rings. These pipes develop rust that weakens their structure over time. This weakness creates serious reliability concerns for abs brake system parts.

The problem gets worse when cold metal meets warm, humid air. Condensation forms right on the metal and speeds up corrosion. ABS rings face this issue often during normal use as temperatures change between driving and parking.

Graphitic corrosion happens in wet environments where water works as an electrolyte. This creates a weak electrical current between iron and graphite in the material. The process removes iron and leaves behind the more cathodic graphite. This decay hurts both the structure and precision of ABS system parts.

Chipping under mechanical stress

Gray cast iron breaks easily and has low tensile strength because of its unique structure. You can envision this structure as an iron-carbon alloy with graphite pores that make the material less tough and flexible.

The flake graphite cavity structure creates sharp-edged cracks that spread fast under stress. These microcracks grow along the easiest paths when exposed to high-speed wheel rotation, which leads to chips and breaks.

Chipping in abs system parts happens because of:

- Mechanical stress combined with microstructural weaknesses

- Surface conditions that promote microcrack formation

- Material processing parameters, including cooling rates and heat treatment

Brittle phases break or grain boundaries split under stress in these microstructural interactions. Tensile stresses mix with uneven microstructures to start cracks that grow into chips. These chips hurt how well high quality abs system parts work.

Machining and weight drawbacks in cast iron

Cast iron brings its own set of manufacturing challenges. These parts have a hard “skin” that needs machining before reaching the main material. This creates inefficient manufacturing for precision ABS brake system parts.

Cast iron’s heavy weight causes several problems:

- Installation takes more work than with other materials

- Moving and handling during manufacturing is harder

- Support structures might crack under too much weight

- Cars use more fuel because of the extra weight

Cast iron creates chips that wear down cutting tools fast. These tiny, dust-like chips speed up tool wear and make manufacturing areas harder to keep clean. Makers of abs system parts that follow diagram specs pay more because of these machining challenges.

Machining cast iron needs slow cutting speeds – about 130 to 160 SFM for harder types – which takes longer. The material also needs coolant while machining. This creates thermal shock that cuts tool life by a lot.

Cast iron works well in some uses, but these big drawbacks explain why makers of precision parts, including abs system components, now look for better materials with fewer problems.

Powder Metallurgy ABS Rings: A Modern Alternative

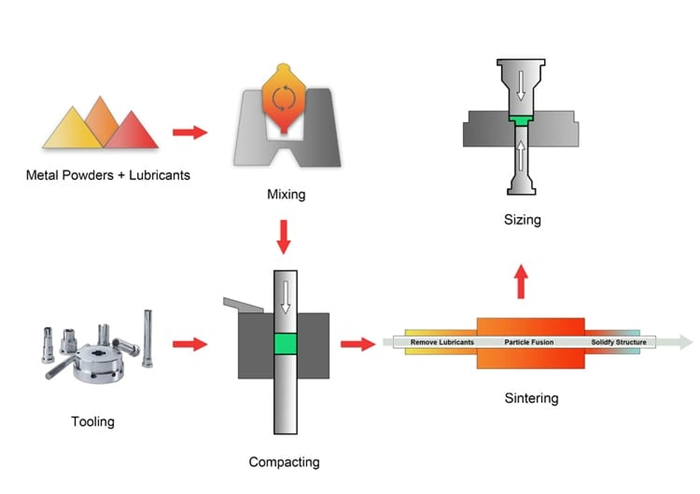

Powder metallurgy has revolutionized how we manufacture critical vehicle safety components. This precision process maintains accuracy up to 0.01mm. Quality components need strict control at each production stage. Powder metallurgy serves as a modern alternative to traditional materials and brings several benefits that make it perfect for producing high-performance ABS sensor rings.

Microstructure control for improved wear resistance

Powder metallurgy gives manufacturers unprecedented control over material composition and microstructure through carefully controlled sintering processes. The sintering process heats material to a temperature below its melting point in a controlled atmosphere. This helps achieve specific mechanical properties. Manufacturers can now add hard, wear-resistant materials directly into the component structure.

Powder metallurgy ABS rings have radial tensile strength above 300 MPa. This makes them tough enough to handle high-speed wheel rotation. The microstructure can be customized to optimize wear resistance. This is vital for ABS system components that must perform well throughout a vehicle’s life.

Parts made through carburized powder metallurgy show excellent wear resistance under optimized conditions. Creating composite materials with specific properties at the microstructural level leads to better durability. Traditional casting methods cannot achieve these results.

ABS brake system components face constant mechanical stress. Their microstructure uniformity plays a key role in consistent performance. Powder metallurgy parts have remarkable uniformity throughout their structure. This reduces weak points where failures usually start, unlike cast components that often show structural irregularities.

Reduced porosity and better surface finish

Manufacturers can control porosity in powder metallurgy components for optimal performance. Modern powder metallurgy ABS rings reach a sintered density of 7.0g/cm³. This substantially reduces porosity issues. A tight tolerance of ±0.02mm after sizing ensures the dimensional stability needed for proper sensor operation.

Surface finishing through tumbling removes burrs and flash from component surfaces. Parts vibrate with abrasive media like stone or ceramic. This creates smoother finishes that boost both performance and longevity of ABS system components.

Most people think porosity hurts mechanical properties. However, controlled closed porosity in powder metallurgy offers benefits in tribological applications:

- Works as oil reservoirs under boundary lubrication conditions

- Captures debris that could speed up wear

- Adds extra load-carrying capacity through “micro bearing effect”

Recent studies show that powder metallurgy materials with well-controlled porosity can reduce friction and wear better than non-porous alternatives. Getting this balance right needs expertise. JH MIM uses its 20 years of experience in powder metallurgy to produce precision-engineered ABS components that meet strict standards.

Weight reduction benefits in fuel efficiency

Lighter powder metallurgy components directly improve vehicle efficiency. These lightweight, high-strength parts can cut vehicle weight by about 10%. This leads to 6–8% better fuel economy and lower CO₂ emissions.

Powder metallurgy manufacturing delivers impressive efficiency improvements beyond fuel savings:

| Aspect | Powder Metallurgy | Conventional Processes |

|---|---|---|

| Raw Material Utilization | Over 95% | Nowhere near as high |

| Energy Consumption | About 43% of forging/machining | 100% (baseline) |

| Manufacturing Steps | Fewer | More extensive |

These gains come from powder metallurgy’s near-net-shape production capabilities. This means less material waste, fewer secondary machining needs, and lower overall energy use.

Manufacturing advantages for ABS system components include:

- Less material waste in production

- Fewer processing steps than traditional methods

- Lower energy consumption during manufacturing

Industry experts say these benefits make powder metallurgy ideal for high-volume production of precision components like ABS sensor rings. Stricter efficiency standards and sustainability requirements are becoming common. The ability to produce lightweight, high-performance components with minimal waste makes powder metallurgy perfect for manufacturing ABS system components that meet diagram specifications.

Corrosion Resistance and Durability Comparison

ABS sensor rings’ long-term reliability depends largely on how well they resist corrosion in automotive uses. Cast iron and powder metallurgy rings show notable differences in their ability to handle environmental challenges.

Salt spray test results for cast iron vs PM rings

ASTM B117 standards guide salt spray testing and give us standardized data to compare how materials hold up under accelerated corrosion conditions. This method helps us review surface coating effectiveness and shows key differences between old-school cast iron and powder metallurgy options.

Commercial H2-sintered 410L stainless steel powder metallurgy ABS rings show remarkable corrosion resistance even after long testing periods. These parts barely rust after 100-hour salt spray testing, which matches their ground performance well. Quality powder metallurgy components go through tough validation tests, including 120 hours of salt spray exposure to make sure they work in harsh conditions.

Cast iron ABS rings don’t deal very well with corrosion. Salt causes these rings to split apart, which stops the ABS from working properly. This becomes a real headache in northern regions where road salt is common, and rings often need replacement pretty quickly.

The materials and manufacturing process create this difference in corrosion performance:

| Material | Salt Spray Performance | Relative Corrosion Resistance |

|---|---|---|

| Cast Iron | Poor, visible corrosion after brief exposure | 2+ orders of magnitude worse than wrought counterparts |

| PM 410L Stainless | Minimal rusting after 100-hour test | Adequate for automotive applications |

| PM 434L/434L-Modified | Even less rusting/pitting than 410L | Superior for demanding environments |

The industry agrees that 100-hour testing better matches ground conditions, as 1000-hour salt spray testing proves too harsh.

Surface treatment compatibility with ABS system components

Both materials can be treated to boost corrosion protection, but results vary. Anti-corrosion coatings protect vital ABS system components from environmental damage.

Dacromet coating on powder metallurgy rings provides excellent protection, letting parts last 12-15 years even in tough environments. This coating works especially well with powder metallurgy substrates, making it valuable to critical ABS brake system parts.

Cast iron parts usually get paint, coating, or plating for protection. But these treatments don’t protect as well as specialized coatings on powder metallurgy alternatives. Advanced coating technologies now make use of what was once seen as a drawback – sintered materials’ porosity – by fully protecting even porous structures.

JH MIM brings nearly 20 years of powder metallurgy expertise to the table. Their high-quality ABS components show better coating adhesion than cast alternatives.

Long-term exposure performance in ground conditions

Ground performance data tells the most compelling story about durability differences. Commercial H2-sintered 410L powder metallurgy ABS sensor rings were reviewed after 10+ years and 100,000+ miles of North American service. They showed less rust than what happens in a 100-hour salt spray test. These parts managed to keep their mechanical strength and flexibility throughout this time.

Cast iron ABS rings often need replacement after just a few years in tough environments. The problem gets so bad that some vehicle makers suggest replacing entire axle assemblies instead of just the rusty ring—costing about $500 per side.

You can sometimes clean ABS rings with minor surface rust rather than replace them. But once rust affects the tooth profile or magnetic properties, you’ll need new parts. This damage causes random ABS activation and warning lights, making vehicles less safe.

Powder metallurgy rings offer substantial advantages to meet ABS system component requirements and long-term reliability through:

- Natural resistance to environmental damage

- Working well with advanced protective coatings

- Keeping signal generation strong over long service periods

Better material properties combined with precise manufacturing make powder metallurgy the clear winner when corrosion resistance affects safety system performance.

Manufacturing and Cost Efficiency Factors

The cost structure and production efficiency of ABS sensor rings depend heavily on their manufacturing processes. The differences between traditional casting and powder metallurgy approaches play a big role in this.

Tooling and cycle time differences

Powder metallurgy equipment needs a bigger original investment but helps streamline processes better. PM components require fewer secondary operations, while cast pieces need extensive post-processing. The quick compaction and sintering process makes PM much faster when producing high volumes of components. Cast processes can take several weeks for complex parts—sometimes up to a month.

Material utilization and scrap rates

The economics of manufacturing depends a lot on material efficiency. Powder metallurgy shows impressive results with material utilization rates that exceed 95%, while machined alternatives only reach 60-70%. This is a big deal as it means that both production costs and environmental impact are lower.

Quality control uses scrap rate as a key metric, and industry standards call it acceptable when it stays below 5%. JH MIM, a 20-year old powder metallurgy company, manages to keep strict quality control throughout production. This ensures minimal waste even for high-precision integral ABS components.

Scalability for high-volume production

Each manufacturing method shows distinct economic benefits at scale:

| Production Factor | Powder Metallurgy | Traditional Casting |

|---|---|---|

| Volume Capacity | Several thousand parts per hour | Limited by cooling time |

| Energy Consumption | About 43% of forging/machining | 100% (baseline) |

| Secondary Processing | Minimal | Extensive |

PM works best for high quality abs system components in moderate to high-volume production. The process delivers consistent output with minimal variation between runs once the tooling is set up. This makes powder metallurgy the best choice for ABS brake system components where dimensional precision affects signal reliability across many production batches.

Integration with ABS System Components

The smooth interaction between an ABS ring and its sensor is the lifeblood of anti-lock braking systems that work well. A proper combination creates consistent performance in all operating conditions.

Sensor alignment precision in integral ABS components

ABS systems need precise sensor-to-ring alignment to work reliably. The optimal air gap between the sensor and ring should measure 0.5-1.5mm. Sensors often touch the ring directly when corrosion builds up around mounting points. This direct contact triggers ABS warning lights immediately and might damage the ring. The ABS system will not function properly if the integrated magnetic encoder rings have wrong orientation.

Magnetic property consistency for signal generation

Two main technologies power ABS sensors: passive inductive sensors that create analog signals and active Hall-effect sensors that produce digital signals. The ring material’s magnetic properties affect signal quality directly. Hall sensors commonly use injection molded ferrite magnetic rings that deliver magnetic field strength from 1200-1300Gs. High-end applications can reach 1700Gs.

Compatibility with ABS system components diagram standards

The modern ABS architecture combines wheel speed sensors, electronic control units, and actuators. The sensor’s output must work with the vehicle’s ABS controller. JH MIM’s 20 years of powder metallurgy expertise help create products that match standardized ABS system architectures. The new automotive microcontrollers must meet IEC61508 and ISO26262 safety standards.

Conclusion

Powder metallurgy proves to be the best choice for making ABS sensor rings when compared to traditional cast iron options. Modern automotive manufacturers are choosing powder metallurgy more often for these safety-critical components, and there are several good reasons why.

Powder metallurgy ABS rings offer remarkable dimensional stability with tolerances of ±0.02mm. This is a big deal as it means that they work much better than cast iron versions. The precision helps create consistent signals, which are the foundations of reliable ABS operation. These components also have a controlled microstructure that resists wear better while keeping the ideal magnetic properties needed for accurate readings.

The rings resist corrosion much better too. Salt spray tests show that powder metallurgy rings keep working even after exposure that would make cast iron parts useless. So vehicles with these rings maintain their safety systems even after years in harsh conditions.

The manufacturing process makes powder metallurgy an even more attractive choice. Near-net-shape production wastes less than 5% of materials, while traditional methods waste 30-40%. These parts also need fewer extra steps, which makes high-volume production budget-friendly and good for the environment.

The weight savings are worth noting. Lighter ABS parts help make the whole vehicle more efficient, and a complete light-weighting approach could improve fuel economy by 6-8%. These weight benefits come without any loss in strength or durability.

JH MIM leads this manufacturing progress. With almost 20 years of powder metallurgy experience, they create precision-engineered ABS parts that match or exceed industry standards. Their expertise will give a perfect fit between sensor rings and other ABS system parts.

The facts clearly show why powder metallurgy is the right choice for manufacturers who want high-performance, lasting ABS sensor rings. While cast iron worked well enough before, today’s safety systems just need the precision, consistency, and reliability that powder metallurgy provides. Without doubt, as automotive technology moves forward, powder metallurgy will stay crucial for making parts that balance performance, durability, and cost.

Key Takeaways

Understanding the material differences between powder metallurgy and cast iron for ABS sensor rings reveals critical insights for automotive safety and manufacturing efficiency.

• Powder metallurgy delivers superior precision with ±0.02mm tolerances versus cast iron’s dimensional instability, ensuring consistent ABS signal generation throughout vehicle life.

• Corrosion resistance dramatically favors powder metallurgy, with minimal rusting after 100-hour salt spray tests while cast iron fails quickly in harsh environments.

• Manufacturing efficiency improves significantly with powder metallurgy achieving 95%+ material utilization and 43% less energy consumption compared to traditional casting methods.

• Weight reduction benefits fuel economy as powder metallurgy ABS rings contribute to 6-8% efficiency improvements through comprehensive vehicle lightweighting strategies.

• Long-term durability proves superior with powder metallurgy rings maintaining performance after 10+ years and 100,000+ miles versus frequent cast iron replacement requirements.

The transition from cast iron to powder metallurgy represents more than just material substitution—it’s a fundamental shift toward precision manufacturing that enhances vehicle safety while reducing environmental impact and production costs.

FAQs

Q1. What are the key advantages of powder metallurgy over cast iron for ABS sensor rings? Powder metallurgy offers superior dimensional stability, better corrosion resistance, and improved manufacturing efficiency. It allows for tighter tolerances, maintains functionality in harsh environments, and reduces material waste compared to cast iron.

Q2. How does powder metallurgy impact the durability of ABS sensor rings? Powder metallurgy ABS rings demonstrate excellent long-term durability, maintaining performance after 10+ years and 100,000+ miles of use. They show minimal rusting even after extensive salt spray testing, significantly outperforming cast iron alternatives in corrosion resistance.

Q3. What precision can be achieved with powder metallurgy for ABS components? Powder metallurgy can achieve tolerances of ±0.02mm for ABS sensor rings. This high level of precision ensures consistent signal generation throughout the vehicle’s operational life, which is crucial for reliable ABS performance.

Q4. How does the manufacturing process of powder metallurgy contribute to cost efficiency? Powder metallurgy achieves over 95% material utilization and consumes about 43% less energy compared to traditional casting methods. It requires fewer secondary operations and is more suitable for high-volume production, leading to improved cost efficiency.

Q5. What impact does using powder metallurgy have on vehicle fuel efficiency? The use of powder metallurgy for ABS rings contributes to overall vehicle weight reduction. As part of comprehensive lightweighting strategies, this can lead to fuel economy improvements of 6-8%, enhancing the vehicle’s overall efficiency and environmental performance.