Magnesium alloy casting stands out with its exceptional lightweight properties, making it a valuable material in modern manufacturing. Magnesium weighs about 35% less than aluminum and 75% less than iron, with a specific gravity of only 1.74 . This metal ranks as the lightest structural material commonly found in industrial applications.

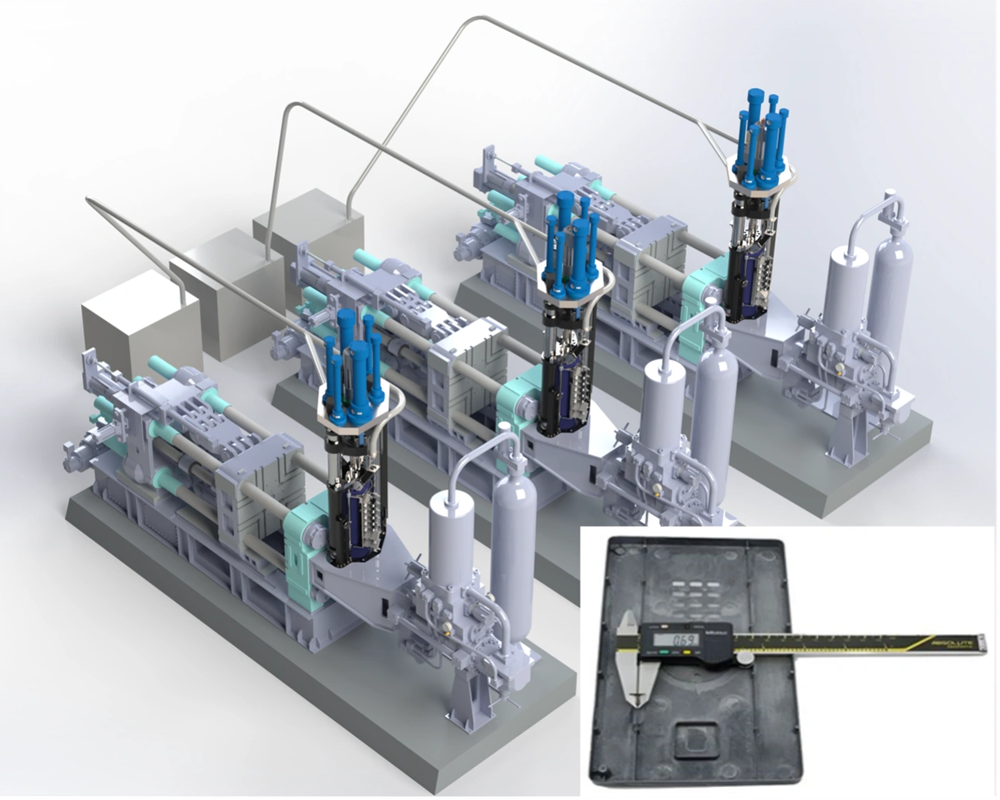

Magnesium die casting has come a long way since World War II and the post-war period . Modern manufacturers now use high-pressure die casting techniques to produce complex parts. These parts range from under a pound to over 30 pounds, reaching up to 60 inches in length . Magnesium’s superior thermal conductivity and low heat capacity make it perfect for heat dissipation applications .

Magnesium casting has proven its worth across industries, though it’s nowhere near as common as aluminum, which makes up nearly 319 pounds per vehicle in North American cars . The classic Volkswagen Beetle serves as a great example, containing about 90 pounds of magnesium alloy parts . Magnesium’s recyclability adds to its appeal, with some facilities remelting up to 4,000 tons each year .

Lightweight magnesium castings show great promise as global energy demands rise and environmental regulations become stricter. Modern manufacturing engineers just need to understand magnesium die casting basics, whether they work with automotive parts, electronic enclosures, or aerospace components.

Magnesium Die Casting Process: Step-by-Step Breakdown

The magnesium die casting process needs several key stages that you must execute precisely to create high-quality parts. Manufacturing engineers need to understand each step to make production better and fix problems quickly.

Die Preparation and Lubrication Techniques

You start die preparation by cleaning the die halves thoroughly to remove leftover residues from previous cycles. A protective barrier forms between molten magnesium and the mold surface when you apply lubricant. Today’s die casting operations struggle with temperature differences on large die surfaces. Temperatures can range from 200°C in cooler areas to 400°C in hot spots. The Leidenfrost effect creates problems at these temperatures because water-based lubricants can’t wet very hot surfaces properly.

Good lubricants do many jobs at once. They stop metal from sticking to the die, help metal flow better, protect die surfaces, and control how the metal solidifies. The newest formulas use materials that quickly create films at high temperatures and stay stable in tough conditions.

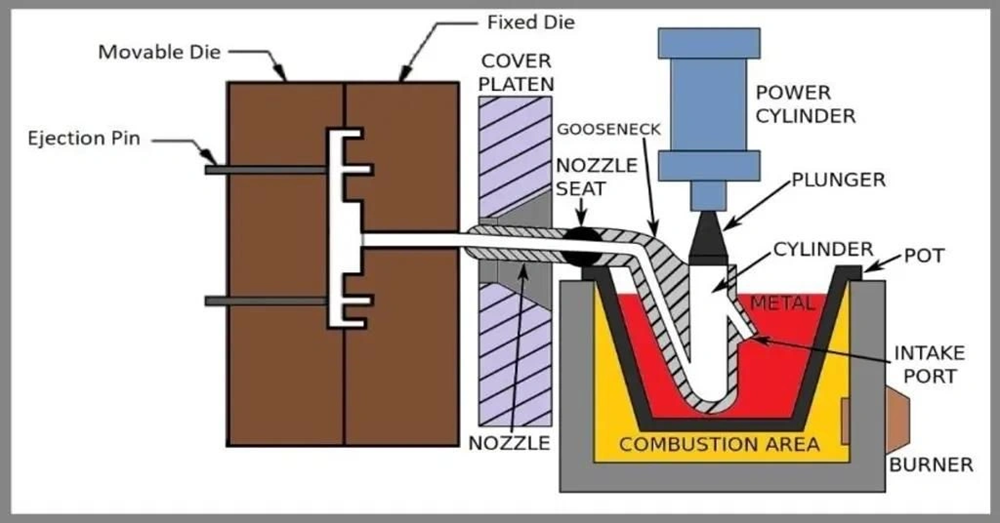

Hot-Chamber Injection Mechanism for Magnesium

The hot-chamber die casting system keeps its injection mechanism in a molten metal bath inside a holding furnace. A gooseneck-shaped feed system connects this to the machine. The plunger moves up to open a port that fills the injection cylinder with molten magnesium. The metal flows through the gooseneck and nozzle into the die cavity as the plunger moves down and seals the port.

Sulfur hexafluoride serves as a cover gas to keep oxide bits out of the molten material. You can work faster with hot-chamber methods than cold-chamber ones because the furnace and casting parts work together as one unit.

Solidification and Cooling Time Considerations

The magnesium needs to solidify while the pressure stays constant after injection. Part shape, wall thickness, and material properties determine cooling time. Thin-walled parts (6mm) show temperature differences of about 15°C per millimeter. Thicker sections (20mm) might see differences of 20°C per millimeter.

Smart placement of cooling lines makes solidification patterns better. Cooling lines can only drop casting temperature by about 5°C in thick-walled sections, even when they sit just 15mm from the cavity wall.

Ejection and Trimming of Cast Parts

Parts shrink onto the mold as they solidify, which creates strong holding forces. Ejection pins push against these forces to get the part out of the die. Many things affect the ejection force needed. You can cut this force from 95kN to 47kN by lowering the friction coefficient from 0.2 to 0.1.

The next step involves removing gates and overflows either by hand or with trim dies. The final steps usually include smoothing out ejector marks and polishing extra material off edge surfaces.

Mechanical and Thermal Properties of Magnesium Alloys

Understanding the properties of magnesium alloy die casting materials helps you select the best options for specific applications. Each alloy has unique performance characteristics that engineers need for making decisions.

AZ91D vs AM60B: Strength and Corrosion Resistance

AZ91D shows excellent strength properties with tensile strength reaching 200-220 MPa and yield strength around 100 MPa. AM60B has a lower tensile strength of about 180 MPa with a yield strength of 85 MPa. Tests show that AZ91D has a lower friction coefficient and wear quantity than AM60B. It also resists crack propagation better.

The corrosion resistance ranking of these alloys goes from ZK60>AM60>AZ31>AZ91. AM60B has better corrosion resistance because manganese creates AlMnFe compounds that reduce iron content in the alloy matrix. The elongation of AM60B is also three times higher (8-10%) than AZ91D.

Thermal Conductivity and Melting Range of AE42

Engineers developed AE42 alloy for high-temperature applications. It has a thermal conductivity of 68 W/m-K. The melting range goes from 565°C to 620°C. During solidification, the Al2RE phase forms at 616°C and the AlRE3 phase at 604°C. These properties give AE42 great creep resistance at high temperatures.

Impact Strength and Elongation in AM20 and AS41B

AM20 has remarkable ductility with elongation between 12-20%, while AS41B ranges from 6-15%. AM20’s thermal conductivity is higher at 94 W/mK compared to AS41B’s 68 W/mK. The combination of moderate strength (190-210 MPa tensile) and excellent elongation makes AM20 perfect for applications that need energy absorption.

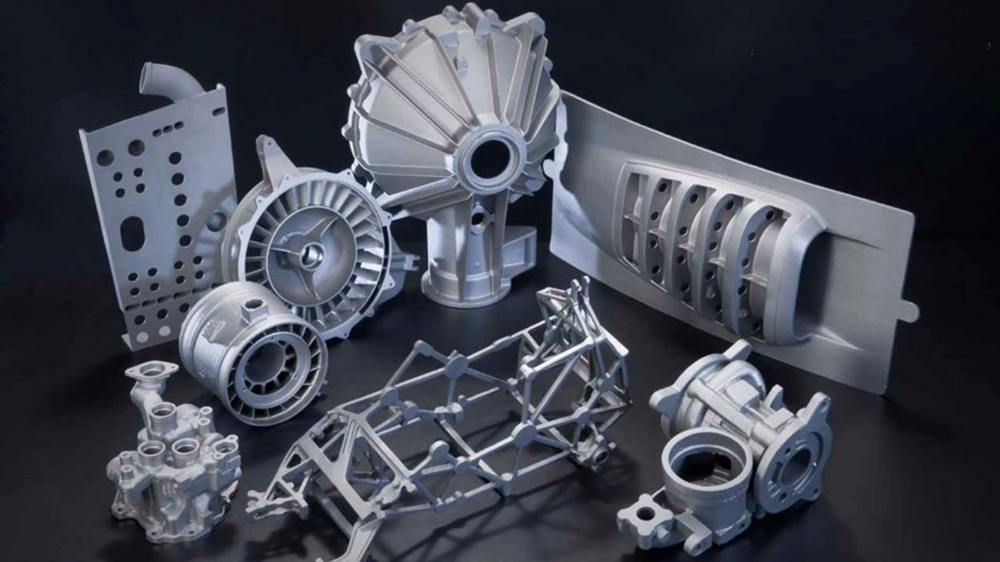

Applications of Magnesium Alloy Die Casting in Industry

Magnesium alloys have become the most important material in many industries because of their exceptional strength-to-weight ratio and versatile properties.

Automotive Use: Steering Wheels and Transmission Housings

Car manufacturers use magnesium die casting extensively for steering wheels. These components reduce road vibration by 25 times compared to aluminum. Transmission housings, gearbox cases, and instrument panel structures work best with magnesium alloys like AZ91D and AM60B. Seat frames made with AM60B deliver both strength and excellent energy-absorbing properties. The result shows weight reductions of up to 24.6% compared to steel components.

Electronics: EMI/RFI Shielding Enclosures

Electronic manufacturers choose magnesium alloys because they shield against electromagnetic interference (EMI) and radio frequency interference (RFI) effectively. Medical and telecommunication devices need these protective enclosures to safeguard sensitive equipment. Magnesium’s high thermal conductivity helps electronic components stay cool, which makes laptop and mobile device batteries last longer.

Aerospace and Defense: Lightweight Structural Components

The aerospace industry benefits greatly from magnesium’s lightweight properties. Each kilogram of weight removed from an aircraft saves about 106 kilograms of jet fuel every year. This makes magnesium components perfect for seat frames, brackets, and structural elements throughout aircraft. Defense contractors also use magnesium die casting to protect sensitive avionics from electromagnetic interference.

Power Tools and Consumer Products

Power tools made with magnesium die casting help reduce user fatigue while staying strong and durable. Sports equipment like bicycle frames, golf clubs, and snowboard bindings becomes lighter and stronger with magnesium. The Volkswagen Beetle led the way in consumer applications by using about 20kg of magnesium components.

Challenges in Magnesium Casting and Lubrication Control

Engineers must overcome several technical challenges when they work with magnesium alloy casting processes. These challenges need specialized knowledge to solve.

Leidenfrost Effect and Die Surface Temperature Variations

The die casting process faces a basic challenge when water-based lubricants touch very hot die surfaces. Water droplets float on a vapor cushion instead of wetting the metal surface when temperatures rise above the Leidenfrost point. This prevents lubricants from working properly. The problem gets worse because die surface temperatures can change dramatically—from 200°C in cooler sections to 400°C in hot zones. These temperature changes create hot spots that make soldering problems worse.

Hot Die Adhesion Index and Film Formation Efficiency

The Hot Die Adhesion Index shows how consistently films form across different temperature zones. This index compares film formation at 350°C to 250°C. A perfect score of 100% means films form evenly at all temperatures, but this rarely happens. New lubricant technologies work 2-3 times better than older formulas.

Creep Resistance in High-Temperature Applications

Metal’s gradual deformation under constant stress at high temperatures, known as creep, creates a major challenge. A newer die-cast Mg3.5RE(La,Ce,Nd)1.5GdMnAl alloy shows promise with a very low steady-state creep rate of 1.35 × 10^-10s^-1 at 300°C/50 MPa. This alloy performs 71% better than versions without aluminum.

Case Study: Steering Wheel Casting with Thin Ribs

A North American die caster struggled to make magnesium steering wheels with thin ribs. Their team used thermal imaging and found die temperatures ranging from 218°C to 338°C across the tool surface. Regular lubricants failed even after adjusting their concentration. The team solved the problem by using advanced technology that protected hot zones better without causing cooling or buildup issues.

Conclusion

Magnesium die casting is revolutionizing manufacturing by reducing weight in many industries. This piece explores everything in this technology – from process details to material properties and industrial uses. Magnesium alloys have an impressive strength-to-weight ratio and excellent thermal conductivity. These qualities make them valuable for manufacturers who want to cut weight and optimize efficiency.

Engineers must grasp both the advantages and challenges of magnesium die casting. Hot spots, the Leidenfrost effect, and creep resistance create technical challenges. However, advanced lubricants and specialized alloys provide solutions quickly. Case studies show how proper engineering controls and material choices overcome these obstacles effectively.

Without doubt, magnesium die casting has a bright future as environmental rules get stricter and energy efficiency becomes crucial. Car manufacturers keep adding more magnesium to vehicles. Electronics and aerospace sectors also benefit from its unique properties. The process creates complex, lightweight parts with excellent dimensional stability that will drive adoption across manufacturing sectors.

Ningbo Jiehuang Chiyang delivers complete metal parts solutions and die casting services. These services help engineers add magnesium components to their designs. The company’s expertise in powder metal manufacturing, metal injection molding, and die casting is a great way to get insights for new magnesium alloy products.

Different magnesium alloys have specific strengths. AZ91D offers superior strength, AM60B resists corrosion better, and AE42 has excellent thermal properties. Engineers can pick the best material for each use case. Becoming skilled at magnesium die casting techniques helps manufacturing engineers create lighter, more efficient products that meet today’s performance needs.

FAQs

Q1. What are the main advantages of magnesium die casting? Magnesium die casting offers exceptional lightweight properties, being 35% lighter than aluminum and 75% lighter than iron. It also provides excellent thermal conductivity, high strength-to-weight ratio, and the ability to create complex parts efficiently.

Q2. How does the hot-chamber injection mechanism work in magnesium die casting? In hot-chamber die casting, the injection mechanism is submerged in a molten metal bath. When the plunger rises, it allows molten magnesium to fill the injection cylinder. As it descends, it forces the metal through a gooseneck-shaped feed system into the die cavity.

Q3. What are some common applications of magnesium die cast parts? Magnesium die cast parts are widely used in automotive components (steering wheels, transmission housings), electronics (EMI/RFI shielding enclosures), aerospace (lightweight structural components), and consumer products (power tools, sports equipment).

Q4. How do AZ91D and AM60B magnesium alloys compare in terms of properties? AZ91D offers higher strength with tensile strength of 200-220 MPa, while AM60B provides better corrosion resistance and nearly triple the elongation (8-10%) compared to AZ91D. AM60B is often preferred for applications requiring energy absorption.

Q5. What is the Leidenfrost effect, and how does it impact magnesium die casting? The Leidenfrost effect occurs when water-based lubricants contact extremely hot die surfaces, causing water droplets to float on a vapor cushion instead of wetting the surface. This phenomenon can prevent proper lubricant application, especially problematic due to varying die surface temperatures in magnesium casting.