Tungsten alloy manufacturing comes with distinct challenges because of its exceptional properties. This material has the highest melting point among practical metals at approximately 3,400°C. Metal Injection Molding (MIM) technology now offers a groundbreaking solution to create precision tungsten components with complex geometries. The advanced process delivers up to 98% material conversion efficiency, which surpasses traditional manufacturing methods substantially.

Tungsten alloy’s dense and strong characteristics make it essential for applications where weight and durability matter most. MIM processing allows tungsten heavy alloy parts to achieve 95-99% of theoretical density. The process can create intricate three-dimensional shapes that conventional methods cannot produce effectively. The components also demonstrate superior corrosion resistance, fracture toughness, and fatigue resistance. MIM’s material optimization capabilities and its ability to create parts that shrink 15-20% during processing enable manufacturers to produce high-precision tungsten components for medical, aerospace, electronic, and industrial applications.

Tungsten Alloys in Precision Manufacturing

Precision engineers love tungsten alloys because they offer unique properties that you won’t find in regular materials. Industries just need these specialized materials more and more as they look for components that won’t fail in tough conditions.

What is Tungsten Alloy and Why It Matters

A tungsten alloy combines tungsten with other metals like nickel, iron, or copper. This smart blend retains tungsten’s best qualities while addressing its brittleness issue. Pure tungsten has amazing properties, but it’s tough to work with in manufacturing. We developed these alloys to make the material easier to machine while keeping tungsten’s best features.

These materials are vital in precision manufacturing because they combine density, mechanical strength, corrosion resistance, and good value. Tungsten alloys work better than old-school dense materials like lead or uranium – they’re safe, eco-friendly, and stay strong even in extreme conditions.

Common Compositions: W-Ni-Fe, W-Ni-Cu, W-Cu

Tungsten alloys contain 85-97% tungsten by weight. The rest consists of carefully picked binder metals that boost specific properties:

W-Ni-Fe (Tungsten-Nickel-Iron): This magnetic alloy has 90-97% tungsten mixed with nickel and iron binders. It boasts high density (17-18.5 g/cm³), great strength, easy machinability, and strong corrosion resistance. Its mix of density and ductility makes it perfect for radiation shields and aerospace parts.

W-Ni-Cu (Tungsten-Nickel-Copper): This non-magnetic alloy usually has 90-95% tungsten with nickel and copper. With densities of 16-18 g/cm³ and decent strength, these alloys shine in places where magnetic properties aren’t wanted, like medical imaging gear and sensitive electronics.

W-Cu (Tungsten-Copper): This blend improves heat and electrical flow, which makes it great for electrical contacts and heat sinks. Adding copper to tungsten creates materials that move heat and electricity really well.

Material Properties: Density, Hardness, Radiation Shielding

Tungsten alloys’ amazing properties make them crucial in precision manufacturing:

Density: These heavy alloys pack an impressive 15.8-18.7 g/cm³ density – almost twice as dense as lead. This high density lets engineers create compact, weight-efficient parts that fit in tight spaces.

Hardness: The hardness typically ranges from RC 24-28, and more tungsten means harder material. To cite an instance, see how a 97W-2.1Ni-0.9Fe alloy reaches RC 28 hardness, giving it excellent wear resistance for tough jobs.

Yield Strength: These alloys can handle 500-850 MPa of yield strength , so they stay intact under heavy mechanical stress. Some blends can take over 1000 MPa of ultimate tensile strength.

Radiation Shielding: The material’s high density blocks radiation really well, especially X-rays and gamma radiation. This makes it perfect for medical and nuclear applications where safety comes first.

Thermal Stability: These alloys keep their shape in extreme heat, with thermal expansion values between 4.4-5.4 × 10⁻⁶/°C (20-400°C). This means parts stay the same size even when temperatures change a lot.

Companies like JH MIM have spent nearly 20 years becoming skilled at making precision-engineered tungsten alloy products through metal injection molding and powder metallurgy. Their know-how will give a perfect match for the strict standards needed in aerospace, defense, medical, and industrial uses.

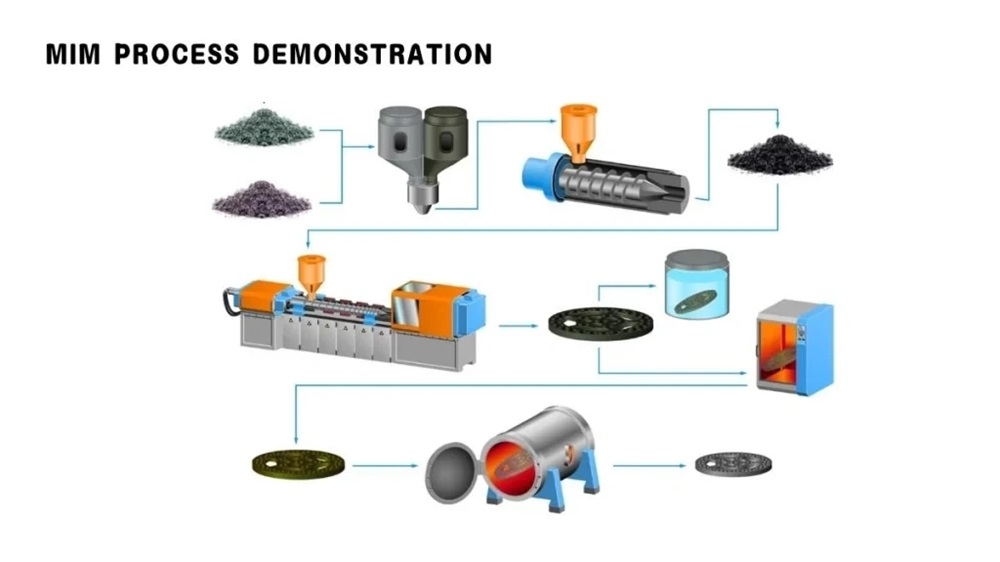

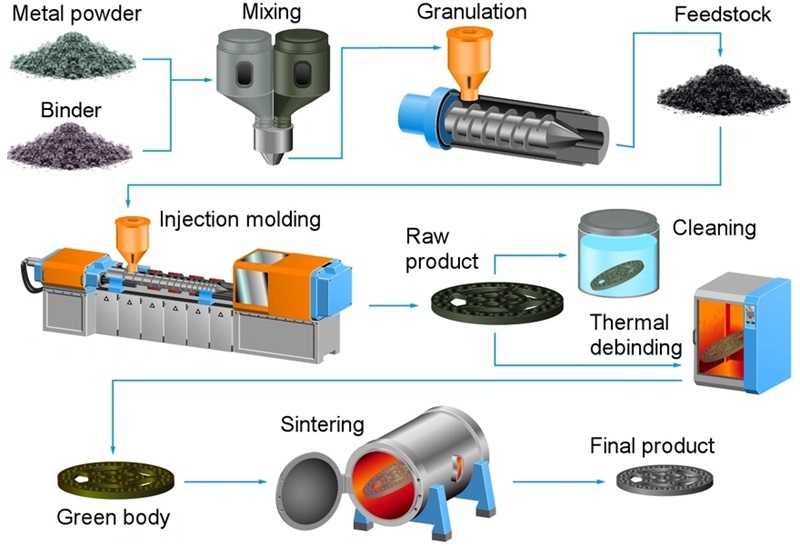

How MIM Works for Tungsten Alloys

Metal Injection Molding (MIM) is a breakthrough process that creates complex tungsten components through multiple manufacturing stages. This technique produces intricate, near-net-shape parts with minimal waste. It works perfectly for manufacturing high-value tungsten alloys.

Feedstock Preparation: 60% Metal, 40% Binder

The first step starts with feedstock preparation. This vital phase combines fine tungsten powder with specially developed binder materials. The feedstock mix contains about 60% metal powder and 40% binder by volume. These specific proportions give the right flow properties during injection and keep enough green strength for later processing.

The metal part uses carefully picked tungsten or tungsten alloy powders. These range from 10 to 25 microns in size. Using smaller particles helps with sintering, but can make the mix thicker. The binder system usually contains:

- Polyethylene or paraffin wax is the main ingredient

- Secondary polymers that add structural strength

- Lubricants that help with flow

Mixing everything under controlled conditions creates an even mixture. This consistency is key for quality parts in production runs. Research shows mixing ultrafine tungsten powders of different sizes helps solve flow problems.

Injection Molding Parameters: Temperature, Pressure, Hold Time

The feedstock goes into precision molds under specific conditions. These settings directly shape the final part quality:

| Parameter | Typical Range | Impact on Process |

|---|---|---|

| Temperature | 171-177°C (340-350°F) | Controls viscosity and flow |

| Injection Pressure | 500 psi (3.445 MPa) | Ensures complete mold filling |

| Hold Pressure | 500 psi (3.445 MPa) | Prevents shrinkage and voids |

| Injection Time | 6 seconds | Determines filling rate |

| Hold Time | 2 seconds | Maintains pressure during cooling |

| Cooling Time | 18 seconds | Allows part solidification |

Even wall thickness is key in part design. It stops sink marks and warping. Draft angles help parts come out of the mold easily, while corner radii cut down stress points. The molded part comes out about 20% bigger than its final size and stays strong enough to handle.

Debinding Techniques: Solvent vs Thermal

Debinding removes binder parts from the “green” piece. This creates a porous structure ready for sintering. Two main methods exist:

Solvent Debinding dips parts in chemicals like acetone, heptane, or nitric acid solutions. This method dissolves lower molecular weight binder parts and creates connected pores throughout. Research found the best results come from using 5M nitric acid solution at 60°C. The process gives good “brown part” strength and reliable results through closed-loop systems.

Thermal Debinding uses controlled heat to remove remaining binder parts. It takes longer than solvent methods but removes higher molecular weight components well. Some modern processes combine thermal debinding with sintering to speed up production.

Most manufacturers use both methods. They start with solvent debinding and follow up with thermal processing. This stops cracking, warping, and carbon leftovers.

Sintering Conditions: 1525°C for WHA, 1350–1500°C for WC

Sintering is the final step that turns the porous “brown” part into a dense, strong tungsten component. Tungsten heavy alloys (WHAs) work best at 1525°C with a 30-minute hold time. This exact temperature and time combination creates:

- Ultimate tensile strength exceeding 1000 MPa

- Plasticity greater than 20%

- Even microstructure with minimal gaps

Lower temperatures don’t mix materials well enough and leave gaps. You can get similar results at 1500°C by sintering longer. This also reduces gravity settling issues that sometimes happen at higher temperatures.

The right atmosphere prevents oxidation. Hydrogen environments remove oxygen from powder particles. Some manufacturers get exceptional results using liquid phase sintering in wet hydrogen. They follow this with vacuum treatment to remove hydrogen brittleness.

JH MIM uses 20 years of metal injection molding expertise through these four key stages. They create precision-engineered tungsten products that meet strict industry standards.

Designing for Precision in Small Tungsten Parts

Precision in tungsten alloy parts demands careful design that balances material properties with manufacturing constraints. Metal Injection Molding (MIM) delivers remarkable accuracy for small tungsten components that other machining methods can’t match. Manufacturers who pay attention to design parameters can discover the full potential of MIM to create complex tungsten parts with exceptional dimensional control.

Tolerances Achievable: ±0.1% Dimensional Accuracy

Tungsten MIM’s dimensional precision outperforms traditional manufacturing methods for complex geometries. Standard MIM processes yield tolerances of ±0.3% to ±0.5%. Better quality management and specialized processing help manufacturers achieve tighter tolerances of ±0.1% for critical applications. This precision becomes more vital as components get smaller.

Achievable tolerances follow a clear pattern for specific feature sizes:

- ±0.03 mm for features below 3 mm

- ±0.05 mm for features between 3 and 6 mm

- ±0.08 mm for features between 6 and 15 mm

These tolerances depend on several key factors:

- Tooling precision sets the baseline capabilities

- Feedstock quality affects flow behavior and dimensional consistency

- Process parameters include temperature and pressure control

- Sintering conditions determine final shrinkage

Sintering creates about 15-20% volumetric shrinkage. Manufacturers must calculate and adjust for this in mold design. Automated processes from material handling to sintering ensure consistent part-to-part dimensional stability.

Design Rules: Uniform Walls, Draft Angles, Corner Radii

Quality tungsten MIM parts follow specific design principles that optimize manufacturability and performance. Uniform wall thickness stands out as one of the most important considerations, usually ranging from 0.5 mm to 6 mm. Parts with thinner sections move faster through molding, debinding, and sintering cycles, which cuts production time.

Tungsten MIM shows more flexibility with draft angles than many manufacturing processes. MIM needs only 2° draft angles for recessed features or blind holes, while conventional molding demands more. The wax in binders helps release parts from molds, allowing for these minimal draft requirements.

Corner radii play a vital role in design. Sharp corners create stress points that can cause sintering defects. Adding filets and radii between 0.1-0.15 mm improves structural integrity. Well-designed radii also help material flow during molding and prevent early component failure.

MIM excels at producing complex geometries that combine multiple functions into single components, offering more design freedom than conventional methods. Specifications for flatness (0.1-0.2%), perpendicularity (0.1-0.3°), and roundness (0.3%) still need careful attention.

Microstructure Control via Ultrafine Powder

Powder characteristics determine the quality and precision of tungsten MIM parts. Research shows that ultrafine powder (particle size between 100 nm and 1 μm) creates tungsten components with better sharpness and performance. These finer powders allow more precise microfeatures and boost mass efficiency in applications like electron emitters.

Ultrafine powder comes with its challenges:

- Powder tends to clump, reducing solid loading capacity

- Flow properties can be inconsistent during mold filling

- Final products might have uneven pore distribution

Jet milling techniques solve these issues by enhancing powder characteristics. This method boosts maximum solid loading from 45% to 51% and improves flow properties, leading to better dimensional control.

Powder shape directly affects the feedstock’s critical powder loading. Studies reveal optimized tungsten powders increase loading from 45 vol.% to 56 vol.% and improve dimensional precision from ±0.61% to ±0.33%. These better powder characteristics also raise relative density from 97.8% to 98.6%.

JH MIM brings nearly 20 years of expertise to controlling tungsten powder characteristics. This knowledge helps achieve optimal dimensional stability and mechanical properties in precision-engineered products for customers worldwide.

Performance Metrics of MIM Tungsten Components

Performance metrics are the key indicators of success in tungsten alloy manufacturing. These metrics determine if components will work reliably in high-demand applications. Metal Injection Molding (MIM) technology makes shared material properties that are a big deal as it means that they surpass conventional manufacturing methods.

Density Range: 95–99% of Theoretical

The density of MIM tungsten components plays a crucial role in their mechanical properties and performance. Modern MIM processes can create components with densities from 95% to 99% of theoretical values. This exceptional densification happens through precise sintering parameters at temperatures between 1900°C and 2300°C. Higher temperatures lead to better densification. In fact, sintering at 1900°C reaches 98.4% density, while processing at 2300°C achieves 99.2% density.

Each tungsten alloy composition shows unique density characteristics:

- W-5Ni-2Fe alloys reach 100% of theoretical density

- W-4Ni-1Fe alloys achieve 99% density

- W-5Ni-2Cu alloys attain 98% density

The relationship between density and mechanical properties follows an exponential curve rather than a linear one. The final 6-8 percentage points of densification remove the exact defects that cause early failure during service.

Ultimate Tensile Strength > 1000 MPa

MIM tungsten components show exceptional tensile strength properties that exceed traditional manufacturing methods. W-5Ni-2Cu alloys show ultimate tensile strength values of 1050 MPa with 10% elongation. Heat-treated W-4Ni-1Fe alloys reach 1000 MPa with 20% elongation.

These strength values match specific alloy compositions:

- MT-17C (90% W, 6% Ni, 4% Cu): ≥94,000 PSI (≈648 MPa)

- MT-17F (90% W, 7% Ni, 3% Fe): ≥110,000 PSI (≈758 MPa)

- MT-18C (95% W, 3.5% Ni, 1.5% Cu): ≥94,000 PSI (≈648 MPa)

- MT-18F (95% W, 3.5% Ni, 1.5% Fe): ≥105,000 PSI (≈724 MPa)

JH MIM has refined processes over the last several years to maximize these strength properties. The company uses precise control of sintering conditions and microstructure development.

Wear Resistance and Thermal Stability Standards

MIM tungsten components deliver exceptional wear resistance – a vital feature for parts exposed to friction and abrasion. The density-wear relationship shows that as density increases from 92% to 98%, wear rate drops from 0.15 mm³/m to 0.037 mm³/m. This represents a 300% improvement in wear resistance at peak density levels.

Tungsten alloys maintain their structural integrity at high temperatures because of tungsten’s high melting point of 3,422°C (6,192°F). This feature makes MIM tungsten components perfect for aerospace and high-temperature industrial settings where dimensional stability matters most.

Key performance metrics include:

- Hardness: W-5Ni-2Cu alloys reach 345 VHN

- Modulus of Elasticity: Ranges from 40 × 10⁶ PSI for W-Ni-Cu alloys to 53 × 10⁶ PSI for high-tungsten content alloys

- Thermal conductivity: W-10Cu alloys achieve 195 W/mK

MIM tungsten components offer superior performance for applications that need high density, excellent wear resistance, and thermal stability. These properties make them the perfect choice for medical devices, aerospace components, and industrial tools.

Applications of Precision Tungsten Alloy MIM

Metal Injection Molding (MIM) creates precision tungsten alloy components that shine in a variety of industries. These parts give exceptional density, strength, and dimensional accuracy when you need them most. This manufacturing process opens up amazing possibilities for high-performance materials.

Medical Devices: Radiation Shields, Implants

The medical industry uses tungsten alloy MIM heavily, where biocompatibility and radiation protection are vital. Companies make complex parts for radiation shielding devices such as collimators, syringe shields, and specialized imaging equipment parts. These components block radiation while keeping the precise shapes needed for medical imaging systems. Medical tools made this way can handle high-temperature sterilization without losing their edge.

Tungsten’s compatibility with the human body makes it perfect for implants that need both density and precision. Some tungsten alloys even help reduce infection risks in medical settings thanks to their antibacterial properties. JH MIM’s 20 years of experience help ensure these medical components meet strict regulatory standards.

Aerospace and Defense: Counterweights, Armor

Aerospace companies rely on tungsten MIM to produce counterweights, inertial system parts, and vibration-dampening components. These parts keep aircraft balanced while taking up minimal space. The defense sector uses tungsten heavy alloys to make kinetic energy penetrators and armor components that need both density and precision.

Missile components benefit from tungsten’s ability to handle extreme heat. MIM technology lets manufacturers create complex shapes that would be impossible with traditional machining – this works great for aerospace fluid control systems. These parts reach 95% to 98% of theoretical density, which matters a lot for critical aerospace and defense components.

Consumer Electronics: Vibration Motors, Camera Stabilizers

Modern electronics manufacturers pick tungsten MIM for tiny parts where weight and precision count. Smartphone vibration motors use tungsten counterweights to give good feedback despite their small size. Camera stabilizers work better with tungsten parts because they pack more density into less space.

Hinges are becoming a hot item, especially in foldable devices where precise tungsten MIM parts help create smooth, reliable movement. A single hinge might use between thirty and fifty tiny MIM pieces, with many weighing under 1 gram. Tungsten heavy alloys also protect sensitive electronic circuits.

Industrial Tools: Cutting Inserts, Nozzles, Valve Seats

Industrial settings put tungsten MIM to work in tools that face extreme wear. Cutting tools, boring bars, and grinding quills last longer thanks to tungsten’s hardness and wear resistance. Tungsten carbide nozzles excel in petrochemical, mining, and electronics jobs because they resist wear and handle high temperatures well.

Valve cores and seats made with tungsten MIM stand up to erosion in chemical manufacturing and oil refining. They resist corrosion so well that maintenance costs drop significantly. These parts also prevent leaks, which you need for precision fluid control systems.

Comparing MIM with Other Tungsten Alloy Manufacturing Methods

Understanding the comparative advantages of manufacturing methods for tungsten alloy parts is vital to achieving optimal results.

MIM vs Traditional Machining: 90% Less Material Waste

Traditional machining creates parts by removing material from larger blocks, which produces substantial waste. Metal Injection Molding (MIM) offers better material efficiency with up to 98% material conversion. This results in 90% less waste—a huge benefit considering tungsten’s high cost. MIM also excels at creating complex geometries with intricate details that conventional machining cannot achieve. JH MIM uses these streamlined processes they have perfected through nearly 20 years of industry experience.

MIM vs Powder Metallurgy: Higher Density and Strength

These processes show a substantial difference in density—MIM components reach 95-99% theoretical density while powder metallurgy maxes out at 85-92%. This difference creates real performance benefits: MIM tungsten parts are 67% stronger in tensile strength and show 300% better wear resistance. The relationship between density and mechanical properties follows an exponential pattern, so those final density percentage points substantially affect performance. Tungsten MIM components at 98% density achieve 1,090 MPa tensile strength compared to 650 MPa at 92% density.

MIM vs Investment Casting: Better Surface Finish and Detail

Investment casting works well for larger components, but MIM shows better precision for smaller, intricate parts. Surface finish quality stands out as a clear difference—MIM achieves surface roughness of 0.8-1.6 μm while investment casting reaches 1.6-3.2 μm. On top of that, MIM’s dimensional accuracy and precise detail creation make it the better choice for applications that need both aesthetic quality and exact functionality.

Conclusion

Metal Injection Molding technology has reshaped tungsten alloy manufacturing through precision engineering and material efficiency. This piece shows how MIM delivers remarkable results with this challenging material. The process achieves components with 95-99% theoretical density and tensile strength above 1000 MPa. These impressive results come from a carefully controlled multi-stage process that starts with precise feedstock preparation and ends with fine-tuned sintering.

MIM produces complex tungsten components with minimal waste, unlike traditional manufacturing methods. The process converts 98% of materials efficiently and maintains dimensional accuracies of ±0.1% for critical applications. This level of precision makes it perfect for creating intricate medical devices, aerospace components, electronic parts, and industrial tools.

Engineers can optimize tungsten components for specific operational requirements through ultrafine powder selection that improves performance characteristics. MIM shows clear advantages when matched against traditional machining, conventional powder metallurgy, and investment casting. Each comparison highlights MIM’s better material efficiency, density, strength, and detail reproduction.

JH MIM leads this advanced manufacturing approach with nearly 20 years of experience in metal injection molding and powder metallurgy. Their expertise will give precision-engineered tungsten products that meet exact standards in a variety of industries. Companies that want high-performance tungsten components benefit from both MIM’s technological advantages and the specialized knowledge to maximize them.

Without doubt, MIM technology will remain essential as demanding applications expand material limits. It continues to create the next generation of precision tungsten alloy components that combine complex geometries with exceptional mechanical properties.

Key Takeaways

Metal Injection Molding (MIM) revolutionizes tungsten alloy manufacturing by delivering exceptional precision and material efficiency for complex small parts across critical industries.

• MIM achieves 98% material conversion efficiency with 90% less waste compared to traditional machining, making it cost-effective for expensive tungsten alloys.

• Precision reaches ±0.1% dimensional accuracy with 95-99% theoretical density, enabling complex geometries impossible through conventional manufacturing methods.

• Tensile strength exceeds 1000 MPa while maintaining excellent wear resistance, making MIM tungsten parts ideal for demanding aerospace, medical, and industrial applications.

• Four-stage process (feedstock preparation, injection molding, debinding, sintering at 1525°C) ensures consistent quality and microstructural control through ultrafine powder technology.

• Superior performance metrics include hardness up to RC 28 and exceptional radiation shielding, positioning MIM tungsten components as the preferred choice for precision applications requiring both strength and dimensional stability.

MIM technology represents the future of tungsten alloy manufacturing, combining advanced materials science with precision engineering to create components that meet the most demanding performance requirements while maximizing material utilization.

FAQs

Q1. What are the key advantages of using MIM for tungsten alloy manufacturing? MIM offers several advantages for tungsten alloy manufacturing, including high material efficiency with up to 98% conversion, the ability to create complex geometries, and achieving 95-99% theoretical density. It also allows for superior precision with dimensional accuracies of ±0.1% for critical applications.

Q2. How does the density of MIM tungsten components compare to other manufacturing methods? MIM tungsten components typically achieve 95-99% of theoretical density, which is significantly higher than conventional powder metallurgy (85-92%). This higher density translates to superior mechanical properties, including 67% higher tensile strength and 300% better wear resistance.

Q3. What industries benefit most from precision tungsten alloy parts made through MIM? Precision tungsten alloy parts made through MIM are particularly valuable in medical devices (for radiation shielding and implants), aerospace and defense (for counterweights and armor), consumer electronics (for vibration motors and camera stabilizers), and industrial tools (for cutting inserts and valve seats).

Q4. What are the typical sintering conditions for tungsten heavy alloys in MIM? For tungsten heavy alloys (WHAs), optimal sintering results are typically achieved at 1525°C with a 30-minute hold time. This precise temperature-time combination yields excellent structural characteristics and mechanical properties, including ultimate tensile strength exceeding 1000 MPa and plasticity greater than 20%.

Q5. How does MIM technology impact the design of small tungsten parts? MIM technology allows for greater design freedom in small tungsten parts. It enables the creation of uniform wall thicknesses (typically 0.5-6 mm), requires only 2° draft angles for recessed features, and allows for the integration of multiple functions into single components. This process also excels at producing complex geometries with high-dimensional accuracy.