Tungsten powder is one of the most extraordinary metals in manufacturing. Its melting point reaches approximately 6,192°F (3,422°C). This remarkable heat resistance makes tungsten especially valuable when you have aerospace applications where high-strength materials must perform under extreme temperatures. We produced it through the hydrogen reduction of tungsten oxide. This versatile material forms the foundation for many industrial applications, and more than 70% of tungsten powder goes into cemented carbide production.

Creating tungsten alloys through powder metallurgy substantially improves precision, stability, and energy efficiency. Manufacturers apply pressures up to 30,000 lb./sq. inch to shape the material before sintering. The sintering process shrinks pressed components by 15%-18%, based on the original pressure applied. Production speeds vary based on manufacturing methods. Operator-run presses create 1-20 pieces per hour, while automatic presses can deliver between 20-2,000 pieces hourly.

U.S. reserves contain approximately 70,000 to 80,000 tons of tungsten metal. The quickest way to process this valuable metal deserves our attention. This piece gets into the essential steps in tungsten powder metallurgy. You’ll learn about powder production techniques, consolidation methods, sintering processes, and what makes finished tungsten alloy products superior.

Powder Production Techniques for High-Purity Tungsten

High-purity tungsten powder production is the foundation of successful tungsten metallurgy. The finished products’ performance depends on the quality and characteristics.

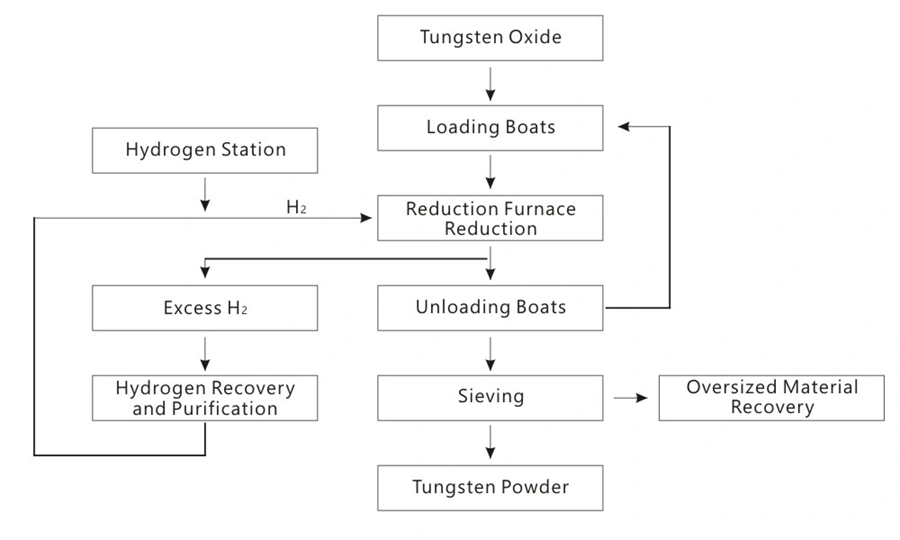

Hydrogen Reduction of WO₃ to Pure Tungsten Powder

Manufacturers primarily produce tungsten powder through hydrogen reduction. This process employs H₂ as a reducing agent to convert tungsten oxide into metallic powder through the reaction: WO₃ + 3H₂ = W + 3H₂O. The reduction moves through a specific sequence: WO₃→WO₂.9→W₁₈O₄₉→WO₂→W. The WO₂→W transition determines the final grain size. Yellow tungsten oxide (WO₃), blue tungsten oxide (WO₂.₉), or purple tungsten oxide (WO₂.₇₂) serve as raw materials.

Effect of Reduction Temperature on Particle Size

The desired particle characteristics depend on temperature control. The reduction happens in two stages:

- First stage (500-700°C): WO₃ reduces to WO₂

- Second stage (700-900°C): WO₂ converts to tungsten powder

Higher reduction temperatures lead to coarser tungsten powder. Manufacturers can get well-developed coarse grain tungsten powder with particle sizes above 15 μm at 950°C by controlling the partial pressure ratio (pH₂O/pH₂) within the powder layer.

Controlling Impurities: Fe, Si, Mo, and C Levels

Tungsten alloy performance hinges on impurity management. Residual elements like Ca, Mg, P, As, Si, S, Fe, Ni, Cu, Al, and Mo weaken tungsten alloys significantly. Manufacturers start high-purity tungsten powder production by purifying ammonium paratungstate (APT) through:

- Chemical precipitation separation

- Solvent extraction

- Ion exchange techniques

Modern purification methods show impressive results—ion exchange with 201×7 type strongly basic resin eliminates 99.999% of Fe impurities.

Ultrafine vs Coarse Powders: Use Cases and Trade-offs

The particle size spectrum of tungsten powder ranges from submicron to over 100 microns. Most applications use 1-50 μm powders. Each size category brings unique benefits:

- Ultrafine powders (<0.5 μm): Perfect for high-density and high-strength hard alloys, but need careful particle distribution control

- Standard powders (1-50 μm): Popular in hard alloy tools, molds, and electronic components

- Coarse powders (>50 μm): Best for high-temperature protective coatings and specialized tungsten products, despite processing challenges

Fine-grained alloys show better mechanical properties than similar coarse-grained versions.

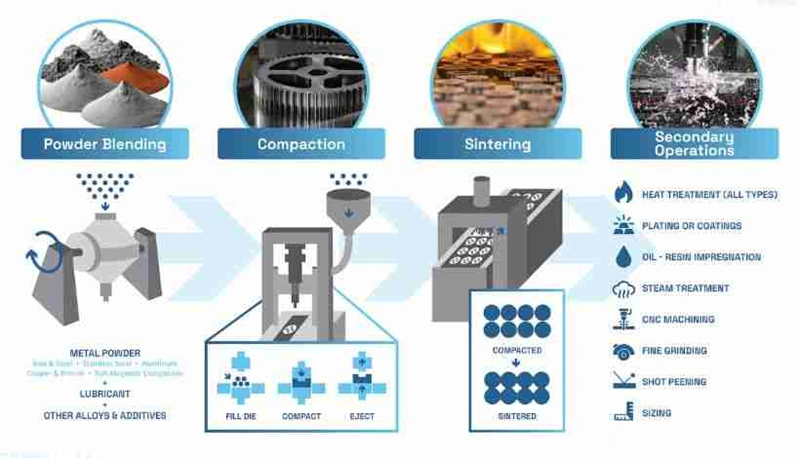

Consolidation Methods for Tungsten Alloy Preforms

The production of high-quality tungsten powder leads to a vital next step – consolidating the material into preforms. This consolidation process shapes the final product’s structural integrity and performance.

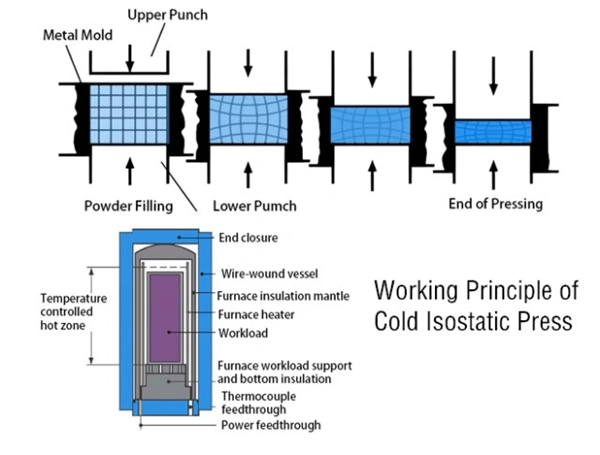

Cold Isostatic Pressing for Uniform Density

Cold isostatic pressing (CIP) works by applying uniform pressure from all directions to tungsten powder held in a flexible mold at room temperature. The process uses pressures between 5,000 psi and 100,000 psi (34.5 to 690 MPa). The process starts when operators fill a rubber mold with tungsten powder and seal it with a cover. They then immerse it in hydraulic fluid where pressure transforms the powder into a near-net-shape product.

CIP stands out because it creates components with uniform density throughout the material. The process ensures consistent strength distribution and uniform shrinkage during later sintering stages. It also helps process high melting point metals that don’t respond well to conventional casting methods.

Tungsten heavy alloys need CIP at compaction pressures around 140 MPa. These pressures are the foundations for the next processing stages.

Hot Pressing at 1500–1800°C for High Strength

Hot pressing combines heat and pressure to work with tungsten powder. This combination leads to better densification than cold pressing alone. The process runs at temperatures between 1500°C and 1800°C, which improves the material’s mechanical properties.

The relationship between temperature and density becomes clear when hot pressing tungsten powder at 5000 psi – higher temperatures create increased density. This is a big deal as it means that applications need exceptional strength characteristics. Hot pressed tungsten alloys reach relative densities above 98%. Careful temperature control can achieve grain sizes as fine as 0.9 μm.

Powder Rolling and Extrusion for Sheet Production

Powder rolling offers the quickest way to produce tungsten sheets compared to traditional methods. Metal powder moves through roll gaps where high pressure compacts it into green strips. These strips then undergo sintering in specific atmospheres to boost their density and strength.

Roll speed plays a key role in the final product quality. Lower speeds create higher green strip densities. To cite an instance, see how a roll speed of 0.366 rpm achieves 90% of cast aluminum density, while 0.73 rpm only reaches 79.6%.

Extrusion provides another solid approach, especially to produce tungsten tubing. The process uses binders like methylcellulose with careful debinding steps to avoid microcracking. Well-executed extrusion can create tungsten components reaching 97% of theoretical density.

Sintering Process and Dimensional Control

The sintering process turns compacted tungsten powder into strong, dense components through carefully controlled heat treatment. The process requires precise temperature management to achieve the best results.

Debinding at 900°C to Remove Paraffin Binders

Dry hydrogen atmospheres with dew points near -55°C remove the paraffin wax that holds pressed parts together. The process needs temperature increases of 0.5-1.0°C per minute with 30-90 minute holds at vital transition points.

Preheating at 1100°C to Minimize Distortion

Parts shrink gradually during preheating to prevent distortion. Nano-tungsten powders show remarkable activity at this temperature and reach near-full density without pressure. Preliminary particle bonding occurs with minimal dimensional changes.

Final Sintering at 1380–1420°C for Full Densification

Brief 2-minute dwell times achieve complete densification. Components reach approximately 96% theoretical density in this temperature range. The process yields hardness values around 1700 kg/mm² when done correctly.

Shrinkage Control: 15–18% Dimensional Reduction

Sintering shrinks pressed parts by 15-18%, which directly relates to the original compaction pressure. A 1.0″ height component ends up at 0.82-0.85″. Manufacturers design larger components to account for this predictable reduction.

Hydrogen Atmosphere in Pusher Furnaces

Pusher furnaces deliver exact temperature and atmosphere control for extended sintering operations. These systems work safely with hydrogen or reducing gasses to create ideal sintering conditions. Tungsten rod elements make extreme processing temperatures up to 2200°C possible.

Achieving Superior Alloy Properties in Final Products

The microstructural characteristics that develop during powder processing and sintering directly determine final tungsten alloy properties. Success depends on careful control throughout manufacturing because processing parameters and material performance are closely linked.

Sintered Tungsten Microstructure and Grain Size

Grain size plays a crucial role in how well tungsten alloys perform. After liquid phase sintering, most sintered tungsten components show grain sizes between 20-50 μm. The tungsten content and sintering conditions determine these dimensions. Research shows that smaller tungsten powder particles lead to slightly higher ultimate strength. The grain growth activation energy of tungsten particles in NiTi binder reaches 330 kJ/mol. This is a big deal as it means that it’s higher than traditional W-NiFe and W-NiCo tungsten heavy alloys. Higher activation energy helps keep grain boundary migration in check during liquid phase sintering.

Impact of Powder Purity on Mechanical Strength

Material purity levels make a huge difference in mechanical properties. Small amounts of metallic glass powder help alloy densification at lower sintering temperatures. Studies show that adding elements like Si, B, Fe, and Al strengthens both tungsten and binder phases through solid solution strengthening. On top of that, disordered interfaces about 60 nm wide make it harder for cracks to start along boundaries and reduce the forces driving tungsten grain growth.

Tungsten Carbide Powder Integration in Hard Alloys

Tungsten carbide powder comes close to diamond’s hardness and resists wear exceptionally well. Manufacturers usually mix this powder with cobalt or nickel binders to create hard metal components through pressing and sintering. Pure tungsten carbide breaks too easily for many uses, but cemented carbide strikes the right balance between hardness and toughness. Different types of carbide powder offer unique properties—fused tungsten carbide gives maximum hardness but less toughness.

ROTF Sizing for Precision Machining

Precision machining of tungsten presents unique challenges because the material becomes brittle at room temperature. Parts often need special processing techniques. Pure tungsten’s layered structure and grain directions make standard machining more difficult. The best results come from slow cutting speeds between 100-150 feet per minute with light feed rates. Many manufacturers turn to alternatives like grinding, electrical discharge machining, or laser cutting instead of traditional cutting methods.

Conclusion

Tungsten powder metallurgy is a sophisticated manufacturing process that creates material properties you can’t get through regular methods. Each step in the production cycle affects the final performance of tungsten alloys by a lot. Powder production techniques, especially hydrogen reduction, are the foundations for superior alloys through exact particle size distribution and impurity control. Cold isostatic pressing and hot pressing create uniform preforms with carefully engineered density profiles.

The sintering process changes these components through careful temperature control. Final sintering at 1380–1420°C reaches impressive densification levels close to 96% theoretical density. This step-by-step approach helps manufacturers predict and adjust for the 15-18% dimensional shrinkage during processing. The microstructural development during sintering determines mechanical strength, and grain size plays a vital role in getting the best performance.

Powder purity is the most important factor in tungsten alloy quality. Even tiny amounts of impurities can reduce strength properties drastically, while adding tungsten carbide powder helps boost hardness and wear resistance. Manufacturers must keep tight control over each processing parameter to get consistent, high-quality results. These tungsten components show extraordinary heat resistance, strength, and density—properties that make them essential in aerospace, defense, radiation shielding, and other demanding applications.

Companies with decades of experience in powder metallurgy know these subtle connections between processing techniques and material performance well. Their expertise helps them create precision-engineered tungsten components that meet strict specifications in a variety of industries. As material science moves forward, tungsten powder metallurgy will without doubt keep evolving and offer new ways to create components with better properties.

Key Takeaways

Master these critical steps to achieve superior tungsten alloy properties through powder metallurgy:

• Temperature control is paramount: Hydrogen reduction at 700-900°C determines particle size, while final sintering at 1380-1420°C achieves 96% theoretical density for optimal strength.

• Powder purity directly impacts performance: Even trace impurities like Fe, Si, and Mo can dramatically reduce alloy strength, making rigorous purification essential for high-quality results.

• Plan for 15-18% shrinkage: Tungsten components predictably shrink during sintering, requiring oversized initial designs to achieve precise final dimensions.

• Consolidation method selection matters: Cold isostatic pressing creates uniform density, while hot pressing at 1500-1800°C delivers superior mechanical properties for demanding applications.

• Grain size optimization enhances strength: Controlling tungsten powder particle size and sintering conditions produces 20-50 μm grain structures that maximize mechanical performance.

The success of tungsten powder metallurgy lies in understanding how each processing step—from powder production through final sintering—influences the microstructure and ultimately determines the exceptional properties that make tungsten alloys indispensable in aerospace, defense, and high-temperature applications.

FAQs

Q1. What are the main applications of tungsten powder? Tungsten powder is primarily used in cemented carbide production, which accounts for over 70% of its use. It’s also crucial in aerospace applications, high-strength materials for extreme temperatures, and various industrial components requiring exceptional heat resistance and strength.

Q2. How does the tungsten powder metallurgy process work? Tungsten powder metallurgy involves several key steps: powder production (usually through hydrogen reduction of tungsten oxide), consolidation (using methods like cold isostatic pressing or hot pressing), sintering (typically at 1380-1420°C for full densification), and final shaping. This process allows for precise control over the material’s properties and structure.

Q3. What are the advantages of using tungsten in manufacturing? Tungsten offers several benefits, including an extremely high melting point (around 3,422°C), excellent strength at high temperatures, good electrical conductivity, and strong wear resistance. These properties make it invaluable in applications ranging from aerospace components to electronic parts and high-temperature industrial tools.

Q4. How does powder purity affect tungsten alloy performance? Powder purity is critical in determining the final alloy’s strength and performance. Even small amounts of impurities like iron, silicon, or molybdenum can significantly reduce the alloy’s strength. High-purity tungsten powder, achieved through advanced purification techniques, is essential for producing superior quality alloys with optimal mechanical properties.

Q5. What dimensional changes occur during tungsten powder sintering? During the sintering process, tungsten components typically experience a 15-18% reduction in size. This shrinkage is directly related to the initial compaction pressure used in forming the part. Manufacturers must account for this predictable reduction by designing oversized components to achieve the desired final dimensions after sintering.