Powdered metal gears cut component costs by up to 70% and deliver high performance, operational efficiency, and design versatility. These crucial components are accessible to more people in cars, trucks, motorcycles, robotics, and many industrial applications because they’re exceptionally strong and can form complex geometries. On top of that, manufacturers produce powdered metal gears through a green process that uses minimal energy and creates less scrap, making them more budget-friendly than standard machining or other metal-forming technologies.

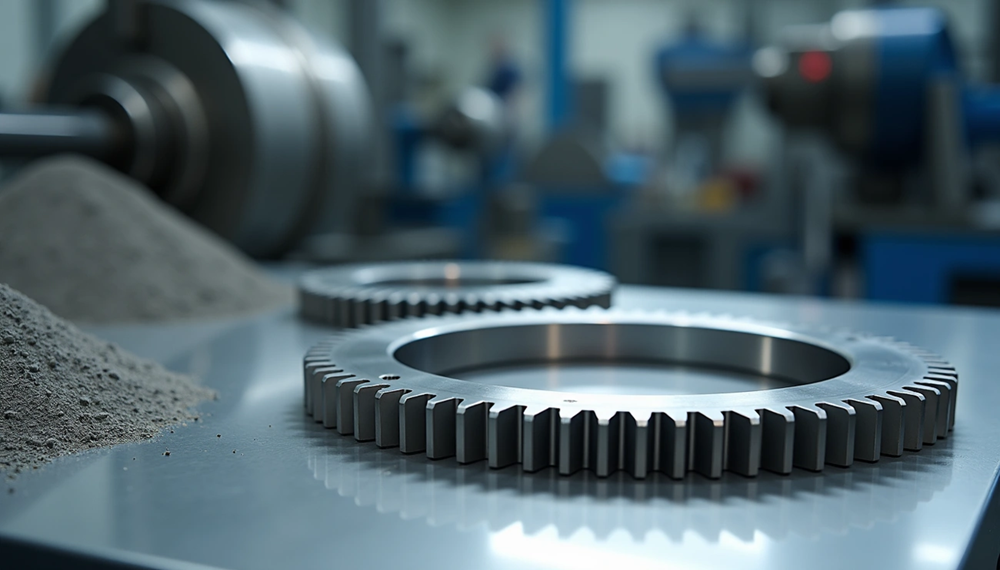

Powdered metal is a manufacturing method that produces gears to near-net or net shape, and they need little to no secondary machining. Powder metallurgy gears come with unique advantages – they transfer power, motion, speed, and directional speed between axes. The creation process of powdered metal gears adds to their porosity, which makes them lighter and helps dampen sound in different applications. Powdered metal gears are the quickest way to manufacture compared to machined options, and they save substantial costs at higher volumes. These gears work great in agriculture, power transmission, fluid handling, marine, and recreational applications.

This piece explores the engineering principles of powdered metal gears, material selection, performance optimization, and application-specific designs that help engineers build more efficient and budget-friendly gear systems.

Understanding Powder Metallurgy in Gear Design

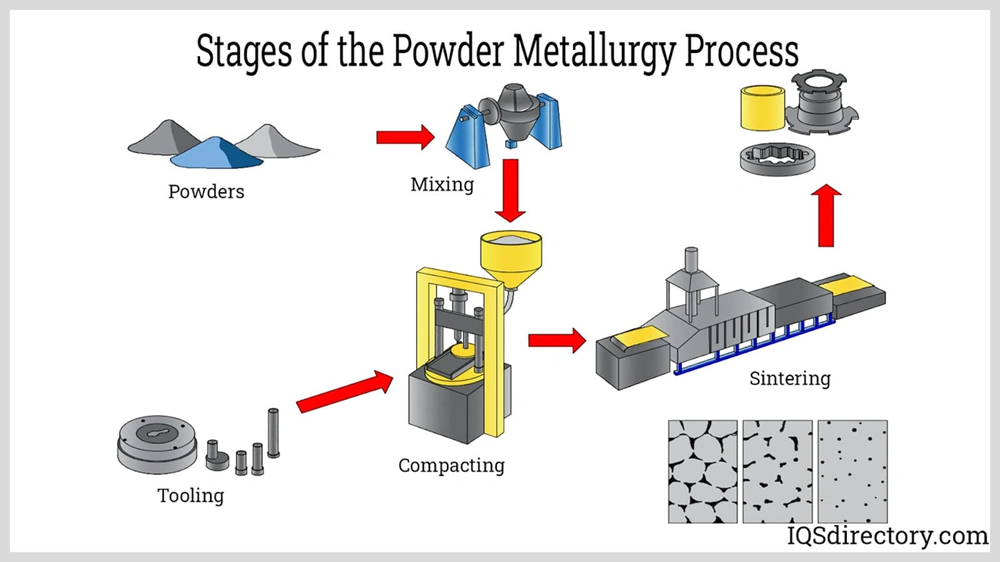

Powder metallurgy stands out as the quickest way to produce precision gears. The process consists of three basic steps: mixing metal powders, compacting them into the desired shape with precision tooling, and sintering them at high temperatures to fuse the particles.

What is powdered metal, and how is it used in gears?

The powder metallurgy process creates components to near-net or net shape, which reduces or eliminates the need for secondary machining. Metal powders become solid, durable parts through controlled pressure and heat. Iron-nickel, nickel steel, prealloyed steel, and sinter-hardened steel varieties are common materials.

These materials deliver the perfect mix of strength, wear resistance, and impact properties. Powdered metal gears maintain tight tolerances, dimensional accuracy, and consistency at any production volume. The gears’ natural porosity serves two purposes – it makes operation quieter by dampening sound and creates self-lubricating components through oil impregnation.

Powdered metal gears vs machined gears: Key differences

Powder metallurgy has several advantages over traditional manufacturing methods:

- Material Utilization: Powdered metal achieves nearly 100% material utilization with minimal waste

- Manufacturing Efficiency: Complex gear geometries requiring multiple machining operations can be formed in a single step

- Cost Effectiveness: The process reduces both labor and processing costs in mass production

Powdered metal gears have about 50% lower impact resistance and 33% lower contact fatigue strength than wrought steel gears. Double pressing, double sintering, high-temperature sintering, or case hardening can partially make up for these limitations.

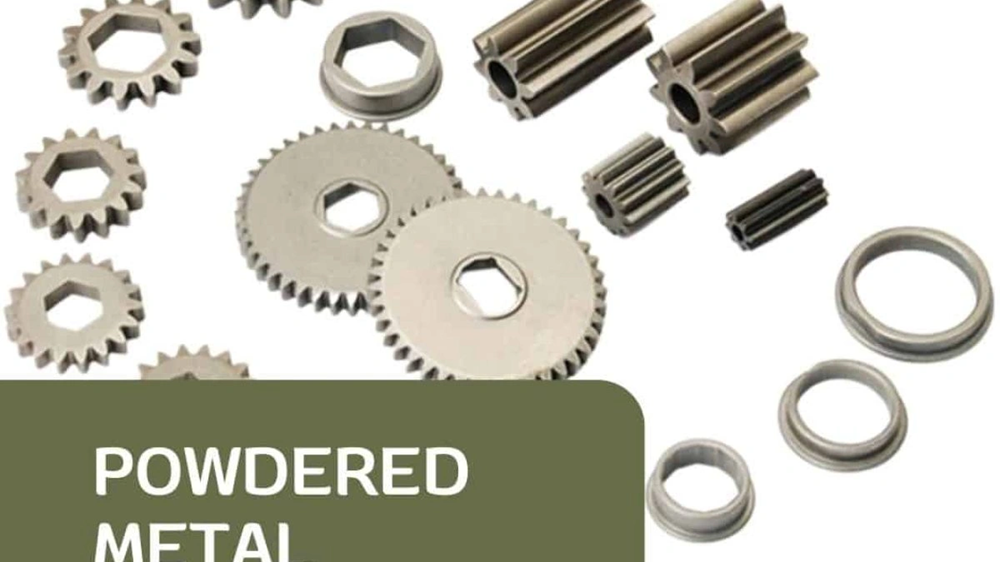

Common gear types: Spur, Helical, Bevel, and Planetary

The powder metallurgy process excels at manufacturing different gear configurations. Spur gears achieve relatively dense teeth through vertical compaction, with their straight teeth running parallel to the gear centerline. These gears work great in applications that need mechanical motion transfer and torque control.

Helical gears come with teeth at an angle to the axis and provide better noise reduction and vibration control. Their angled teeth make them challenging to produce through powder metallurgy, but they can achieve helical angles up to 35°.

Bevel gears transfer shaft power between intersecting shafts, while planetary gear sets benefit from specialized powder metallurgy processes. Techniques like Densgrad® and Denscal® boost surface density to improve strength.

Material Selection for Powdered Metal Gears

Material selection plays a crucial role in powdered metal gear manufacturing. Different materials bring unique properties that affect performance and determine cost in various applications.

Iron-copper vs stainless steel: Strength and cost trade-offs

Most powdered metal gear applications are built on iron-based alloys. Iron-copper alloys reach strength ranges of 40-50 ksi (276-344 MPa) when pressed at pressures between 90-112 ksi. Adding graphite boosts strength levels to 75 ksi (517 MPa). These materials work well for automotive components like camshaft drive sprockets. Iron-copper combinations deliver simple strength and remain economical, especially for moderate load applications.

Stainless steel, on the other hand, resists corrosion better and looks more appealing. The higher cost comes with benefits – stainless steel from the 300 and 400 series resists impact and abrasion exceptionally well. This makes it the right choice for parts exposed to harsh environments or visible to customers.

Sinter-hardened steel for high wear resistance

Sinter-hardened steels stand out as excellent materials when components need high strength, wear resistance, and tight tolerances. These materials harden during the sintering process instead of requiring additional operations.

The sintering process speeds up cooling to transform the austenitic phase into a martensite-bainite structure. This results in apparent hardness up to 45HRC and particle hardness of 57HRC. The process eliminates separate austenitizing steps, which leads to faster processing times, better dimensional control, and less environmental impact by avoiding quench oil entrapment.

Porosity and its impact on NVH and lubrication

What was once seen as a drawback, controlled porosity now offers special benefits for gear applications. Powdered metal gears can maintain porosity levels up to 10%, which helps dampen sound. This feature becomes valuable in electric vehicles where gear noise stands out without the masking effect of combustion engines.

The porous structure also acts as a storage space for lubricants, enabling self-lubrication. This reduces friction between touching surfaces and keeps wear minimal. Research shows that regular steel sliding against powdered metal materials experiences less friction and wear as the pore size grows. This proves how porosity can be used to improve performance rather than being seen just as a structural limitation.

Design Considerations for Performance Optimization

Creating high-performance powdered metal gears just needs precision in several critical design elements. These factors work together and affect the gear’s durability and how well it works.

Tooth geometry and load distribution

The tooth profile design affects load capacity a lot. A 25° pressure angle improves load capacity by 12% compared to the standard 20°. The tooth strength improves by 15-20% when the root radius increases to a minimum of 0.25× module. Powder metallurgy gears with optimized tooth root designs show less stress than traditionally machined roots. The right tooth count makes a big difference – more teeth mean smoother operation but might reduce load capacity per tooth.

Surface densification using Densgrad® and Denscal®

Surface densification technologies improve gear performance. Selective densification helps tooth flanks handle high contact stresses better and resist pitting, scuffing, and surface fatigue. This creates a densified layer about 0.5mm deep on the flank and a bit less in the root area. The process also reduces noise, vibration, and harshness (NVH).

Dimensional tolerances and AGMA class targets

Sintered parts expand by 1-3% after sintering, and their radial dimensional accuracy ranges from IT8 to IT9. Accuracy gets better to IT6-IT7 after sizing processes. Fine-pitch gears can meet AGMA quality levels Q7-Q8, and some products can reach Q9.

Self-lubricating features through oil impregnation

Oil impregnation creates parts that lubricate themselves during operation. This gives three main benefits: longer product life through less friction and wear, protection from corrosion with a protective oil layer, and less maintenance.

Application-Specific Engineering and Use Cases

Powdered metal gears show excellence in a variety of industries and meet unique application requirements with tailored performance characteristics.

Automotive and eMobility gear applications

We used PM gears in transmission components, achieving success in 6-speed manual transmissions at torques up to 230 Nm. These gears are vital in electric powertrains since combustion engines no longer mask the noise. PM gear variants with 7.15 g/cm³ density showed 3dB lower structure-borne noise compared to conventional gears. This makes them perfect for EVs. They also work well in steering systems, oil pumps, and synchronizers.

Medical and power tool gear requirements

The healthcare sector uses powder metallurgy to produce intricate components for arthroscopic and laparoscopic surgical instruments. The precision manufacturing process creates detailed parts with exceptionally tight tolerances. This enhances biocompatibility for medical dispensers and laboratory equipment. PM gears in power tools can handle high torque, shock loads, and millions of duty cycles. Materials like MIM-4140 or MIM-9310 give excellent hardenability and dimensional stability. These properties are vital for compact gear sets that need durability.

Custom decoupled gears for vibration control

Miba’s PAD Decoupled Gear brings an innovative solution with its outer gear ring and inner hub ring separated by elastomer elements. Engineers can optimize specific damping characteristics with this configuration and control NVH throughout the gear system effectively. PM gears’ porosity creates natural vibration absorption properties. This feature enhances their performance in noise-sensitive applications even further.

Conclusion

Powdered metal gears showcase modern manufacturing ingenuity. They deliver exceptional value through affordable pricing and stellar performance. This piece explores how these components cut costs by up to 70%. They maintain strength, operational efficiency, and design versatility at the same time. A simple three-step process turns metal powders into durable, precise components. Mixing, compacting, and sintering create parts that serve countless industrial uses.

Material choice plays a vital role in gear performance. Iron-copper alloys provide affordable options for moderate load applications. Stainless steel excels at fighting corrosion. Sinter-hardened steels resist wear without extra processing steps. This cuts production time and reduces environmental effects.

What engineers once saw as a weakness – porosity – now offers major benefits. The porous structure helps dampen sound. This makes powdered metal gears perfect for quiet applications like electric vehicles. The structure also allows self-lubrication. Parts last longer and need less maintenance.

Design improvements boost performance through specialized tooth geometry and surface densification. Technologies like Densgrad® and Denscal® help maintain precise dimensional tolerances. These engineering choices ensure powdered metal gears meet specific needs in automotive, medical, and power tool industries.

JH MIM brings 20 years of powder metallurgy expertise to the table. They deliver precision-engineered products to customers worldwide. Their knowledge shows how powdered metal technology creates affordable, high-performance gear solutions.

Engineers who grasp these concepts can design powdered metal gears with confidence. They balance cost limits against performance needs. This creates more efficient and reliable mechanical systems that meet today’s demanding applications.

Key Takeaways

Powdered metal gears offer engineers a powerful combination of cost reduction, performance optimization, and design flexibility that’s transforming modern manufacturing across industries.

• Cost and efficiency advantage: Powdered metal gears deliver up to 70% cost reduction with near-net shape manufacturing and 100% material utilization • Strategic material selection: Choose iron-copper for cost-effective moderate loads, stainless steel for corrosion resistance, or sinter-hardened steel for high wear applications • Leverage porosity benefits: Controlled porosity reduces noise by 3dB and enables self-lubrication, making these gears ideal for electric vehicles and noise-sensitive applications • Optimize through surface densification: Use Densgrad® and Denscal® technologies to enhance tooth flank strength and achieve AGMA quality levels Q7-Q9 • Design for specific applications: Tailor tooth geometry with 25° pressure angles and optimized root radius to increase load capacity by 12-20%

When properly engineered, powdered metal gears transform manufacturing economics while delivering superior performance in automotive, medical, and industrial applications where traditional machining falls short.

FAQs

Q1. What are the main advantages of powdered metal gears? Powdered metal gears offer up to 70% cost reduction, near-net shape manufacturing, and 100% material utilization. They also provide excellent performance, operational efficiency, and design versatility for various applications.

Q2. How does the porosity of powdered metal gears affect their performance? The controlled porosity in powdered metal gears offers two key benefits: it dampens sound, reducing noise by up to 3dB, and enables self-lubrication. These properties make them ideal for noise-sensitive applications like electric vehicles and reduce maintenance requirements.

Q3. What materials are commonly used in powdered metal gear production? Common materials include iron-copper alloys for cost-effective moderate load applications, stainless steel for superior corrosion resistance, and sinter-hardened steel for high wear resistance without requiring secondary operations.

Q4. How can the performance of powdered metal gears be optimized? Performance can be optimized through strategic tooth geometry design, surface densification technologies like Densgrad® and Denscal®, and achieving precise dimensional tolerances. For example, using a 25° pressure angle can increase load capacity by 12%.

Q5. In which industries are powdered metal gears commonly used? Powdered metal gears are widely used in automotive and eMobility applications, medical devices, power tools, and various industrial equipment. They’re particularly valuable in electric vehicles, surgical instruments, and applications requiring high precision and durability.