Sintered door lock components surpass the American National Standards Institute (ANSI) ‘Grade 1 Lockset’ requirement with an impressive 800,000 minimum cycle test . This outstanding durability explains why powder metallurgy leads the manufacturing process for premium lock systems worldwide. These components achieve relative density above 98% and deliver superior mechanical strength, wear resistance, and corrosion resistance .

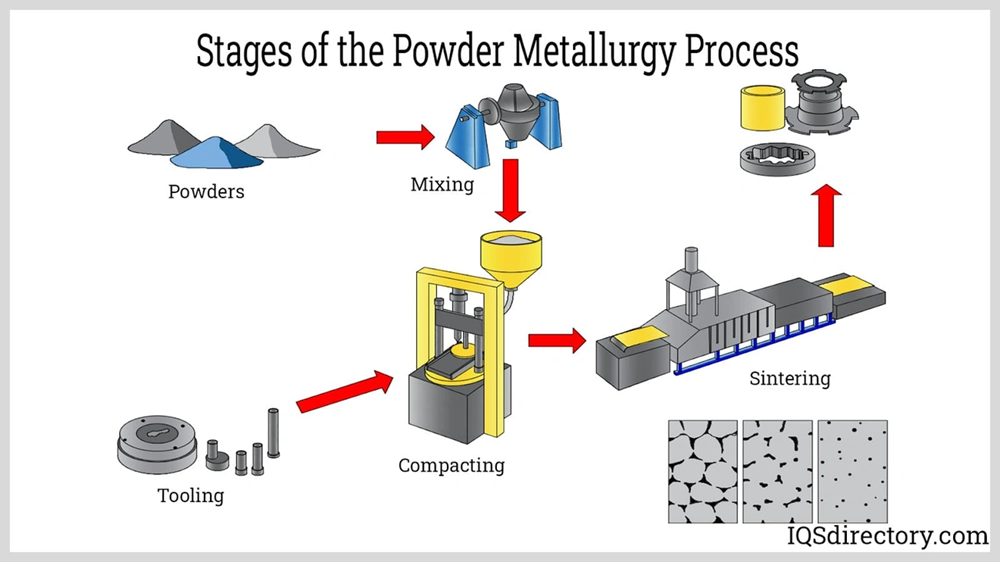

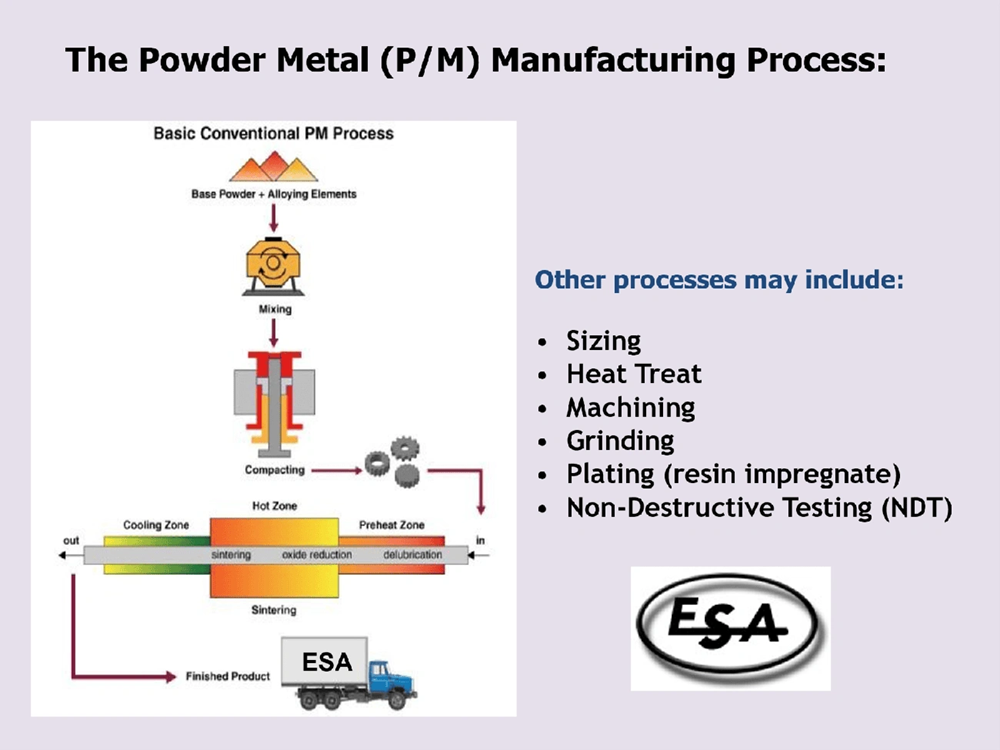

Powder metallurgy (PM) offers a budget-friendly manufacturing solution that excels at producing high-strength, tight-tolerance door lock components at scale . Manufacturers compact metal powder into a “green compact” and sinter it at high temperatures below the metal’s melting point . The process creates precision-engineered interior door lock parts with minimal waste, making it perfect for mass production.

Let’s explore how powder metallurgy converts raw materials into superior lock components and examine the performance benefits of sintered parts along with customization options for manufacturers. Companies like JH MIM have supplied these precision-engineered products to customers globally for almost 20 years. Their success shows how this technology has become a game-changer in the security hardware sector.

Powder Metallurgy Fundamentals for Lock Components

Powder metallurgy (PM) turns raw metal powders into finished lock components through specialized processes. The results are better than what you get from conventional manufacturing methods.

How Powder Metallurgy is Different from Traditional Machining

Traditional machining cuts away excess material. PM builds components from the ground up. This approach leads to remarkable material efficiency with only 3% scrap compared to machining’s 50% waste. PM uses nowhere near as much energy—usually 4-8 kWh per kilogram versus 15-30 kWh for machined parts.

Machined parts offer slightly better dimensional precision for single components. However, sintered parts give you better part-to-part consistency. This consistency makes PM valuable when you need to produce lock components in high volumes. On top of that, it lets manufacturers create complex shapes that would be tough or impossible with traditional machining, including internal passages and helical shapes up to 35° angles.

Sintering Process Overview for Door Lock Applications

The sintering process for door lock components heats compacted metal particles to 1120-1150°C in controlled nitrogen-hydrogen atmospheres. This crucial stage turns loose particles into solid, working components through five key phases:

- Delubing (400-1200°F): Removes lubricants used during compaction

- Finish Delube/Oxide Reduction: Eliminates remaining contaminants

- Sintering (>2000°F): Creates atomic bonds between particles

- Initial Cooling: Stabilizes the microstructure

- Final Cooling: Brings parts to room temperature

This controlled heating cycle will give a predictable dimensional stability by ensuring proper particle neck growth and densification in lock applications.

Material Blending and Compaction Techniques

Everything starts with careful blending of iron-based or stainless steel powders with 0.5-0.8% lubricant. Steel tooling compresses these mixtures at pressures between 500-800 MPa. The best compaction happens in four stages: die filling, pressing to form the “green compact,” careful demolding, and transfer to sintering.

Some manufacturers improve density by using warm compaction at 120-150°C. The powder must spread evenly throughout the die cavity to achieve consistent mechanical properties in the finished lock components.

Companies like JH MIM have become skilled at these techniques over the last 20 years. They create interior door lock parts that meet exact specifications for the global market.

Precision-Engineered Sintered Parts for Lock Systems

Manufacturing precision defines powder metallurgy’s role in door lock systems. The PM process delivers parts with remarkable dimensional accuracy of ±0.05mm. This precision ensures that lock mechanisms work perfectly for years.

Common Interior Door Lock Parts Made via PM

Modern locks depend on several sintered components that work together seamlessly. These parts include:

- Transmission components like pawls, forks, cams, and shafts that move the bolt when you turn the key

- Support elements such as sleeves, plates, levers, clips, and positioning blocks that keep everything stable and properly arranged

- Near-net-shape parts need minimal extra machining, which cuts production costs by 20-40%

JH MIM brings 20 years of powder metallurgy expertise to the table. The company delivers these precision-engineered interior door lock parts to customers worldwide, with consistent quality in high-volume production.

High-Strength Lock Bolts and Pawls

Lock systems need exceptional durability as their first line of defense. Sintered latchbolts deliver impressive results:

- They last through more than 1,000,000 cycles, which goes beyond ANSI A156.2 Grade 1 standards

- Their load capacity ranges from 800-1200N lateral force, making them resistant to forced entry

- Secure locking comes from standard engagement depths of 12.7-25.4mm

- Complex internal shapes take shape through multi-level tool design that prevents density distribution problems

These parts stay dimensionally stable while handling repeated stress cycles – crucial for long-term security performance.

Cylinder Cores and Cam Locks for Security Systems

Security systems rely heavily on precisely manufactured cylinder components:

- Pin chambers work smoothly with keys thanks to ±0.025mm tolerance

- You’ll find 5-7 pin positions standard, with options for up to 10 positions

- Security increases with support for up to 100,000 unique key combinations

- Vending machines, cash dispensers, and gaming machines benefit from specially designed cam locks where security matters most

Careful material selection combined with controlled sintering helps these components achieve perfect dimensional precision. They resist wear effectively, which makes them reliable for security applications long-term.

Performance Advantages of Sintered Door Lock Components

Sintered door lock components stand out with their exceptional performance metrics in security applications. These specially engineered parts show clear advantages that are vital for reliable lock function.

Dimensional Accuracy and Repeatability in Mass Production

The precision of sintered components is remarkable. They typically achieve tolerances between IT-7 and IT-9 for most dimensions. Critical diameters can reach tolerances as precise as IT-6 (±0.013mm) after sizing operations. Production consistency is excellent, with size variations staying under 0.08% (20μm) for 25mm dimensions. JH MIM uses its 20 years of powder metallurgy expertise to deliver these precise standards consistently.

Wear Resistance and Surface Hardness in High-Use Locks

Door lock parts made through sintering reach impressive hardness levels of 45-70 HRC (Rockwell Hardness Scale). These components resist wear exceptionally well during repeated use. Steam treatment can improve surface hardness even further, which helps the locks last longer in busy locations.

Corrosion Resistance in Stainless Steel Lock Parts

Austenitic stainless steel grades (304L, 316L) provide outstanding protection against corrosion for outdoor use. The controlled sintering environment preserves chromium content and prevents oxide formation that could reduce corrosion resistance. This protection works well against moisture, chemicals, and weather exposure.

Impact Resistance in Latchbolts and Hammer Mechanisms

Powder metallurgy-made latchbolts surpass ANSI Grade 1 requirements by lasting through 800,000 cycles without failing. High-density (6.8-7.0 g/cm³) diffusion-alloyed materials give excellent impact resistance to hammer mechanisms and lock parts that face constant mechanical stress. These components handle strong forces while keeping their shape and reliability intact.

In-House Manufacturing and Customization Capabilities

Secondary operations significantly improve the performance of sintered door lock components beyond simple manufacturing. These processes turn simple parts into high-performance security elements.

CNC Machining and Surface Densification

Our in-house CNC capabilities include turning, milling, drilling, tapping, and grinding operations to refine critical dimensions of sintered parts. Surface densification via radial rolling compresses the flank and root regions of components. This process achieves density levels comparable to solid steel and improves dimensional scatter and surface roughness.

Heat Treatment and Resin Impregnation

Customized processing meets specific product requirements through complete in-house heat-treating services. Steam treatment creates a protective Fe₃O₄ layer that prevents rusting and increases surface hardness to HRB 60-90. Oil or resin impregnation seals porous structures and reduces friction in bearing applications.

Custom Tolerances for OEM Interior Door Lock Parts

Sintered components achieve IT-8/9 radial tolerances directly from sintering. Tolerances improve to IT-7 after sizing operations, with certain dimensions reaching IT-6 (±0.013mm). JH MIM utilizes nearly 20 years of experience to maintain these exacting standards.

Secondary Finishing: Plating, Polishing, and Coating

Post-sintering finishing options include:

- Electroplating (nickel, chrome, zinc) for corrosion resistance

- Dacromet coating provides superior protection without internal corrosion problems

- Tumble finishing removes burrs and improves surface smoothness

- Polishing processes reduce cycle time by 50% compared to conventional methods

Conclusion

Powder metallurgy is the best manufacturing solution for high-quality door lock components. It offers clear advantages over traditional methods. The production process creates parts with exceptional accuracy of ±0.05mm and achieves density levels of over 98%. Lock mechanisms made this way work flawlessly for longer periods. These locks go beyond ANSI Grade 1 standards and complete 800,000 cycles without failing.

The budget-friendly aspects of powder metallurgy are impressive too. The manufacturing process wastes very little material – only 3% scrap compared to machining’s 50%. Energy use drops to 4-8 kWh per kilogram, while traditional machining needs 15-30 kWh. This gives companies a competitive edge through lower production costs without compromising quality.

The material properties of sintered door lock components are a big deal. These parts reach hardness levels between 45-70 HRC and deliver excellent wear resistance during repeated use. Steam treatment boosts surface protection even more, which means longer life in high-traffic areas. Stainless steel versions resist corrosion exceptionally well, making them perfect for outdoor use in harsh weather.

Powder metallurgy’s customization options open up new design possibilities for manufacturers. Complex shapes including internal passages and helical forms up to 35° angles are now possible, while traditional machining struggles with these features. Extra processes like CNC machining, surface densification, heat treatment, and various finishes can boost performance to meet specific needs.

JH MIM shows excellence in this field with almost 20 years of experience. Their knowledge of powder metallurgy and metal injection molding helps deliver precision-engineered door lock components to customers worldwide. As security needs keep changing, powder metallurgy remains without doubt the best manufacturing method to create durable, precise, and budget-friendly lock systems that last.

Key Takeaways

Powder metallurgy revolutionizes door lock manufacturing by delivering superior performance, cost efficiency, and design flexibility that traditional machining simply cannot match.

• Exceptional Durability: Sintered lock components exceed ANSI Grade 1 standards, completing 800,000+ cycles while achieving 98% density and 45-70 HRC hardness for long-lasting performance.

• Cost-Effective Production: PM reduces material waste to just 3% (vs. 50% in machining) and cuts energy consumption by 50-75%, making it ideal for high-volume manufacturing.

• Superior Precision: Achieves dimensional accuracy of ±0.05mm with excellent part-to-part consistency, enabling complex geometries impossible with traditional machining methods.

• Enhanced Performance: Stainless steel variants provide exceptional corrosion resistance while secondary treatments like steam processing and surface densification further improve wear resistance and durability.

• Customization Flexibility: In-house capabilities including CNC machining, heat treatment, and various finishing processes allow manufacturers to create tailored solutions for specific security applications.

The combination of material efficiency, dimensional precision, and performance advantages makes powder metallurgy the definitive choice for modern lock component manufacturing, delivering both economic benefits and superior security hardware.

FAQs

Q1. What is the sintering process in powder metallurgy for lock components? Sintering is a heat treatment process where compacted metal powder is heated to just below its melting point in a controlled atmosphere. This causes the metal particles to bond together, forming a solid, cohesive component without fully melting the material.

Q2. How are sintered door lock parts manufactured? Sintered door lock parts are made by compressing metal powder into a desired shape, then heating it to a specific temperature for a set time. The heating process allows the particles to bond, creating a solid piece. The exact temperature and duration depend on the type of metal powder and the desired properties of the final product.

Q3. What materials are commonly used for sintered door lock components? Door lock components made through powder metallurgy often use stainless steel or iron-based alloys. Stainless steel is particularly favored for its excellent corrosion resistance, strength, and longevity, making it ideal for high-performance and long-lasting security solutions.

Q4. What are the advantages of using powder metallurgy for door lock parts? Powder metallurgy offers several advantages for door lock manufacturing, including exceptional durability, cost-effective production with minimal waste, superior precision, and the ability to create complex geometries. It also allows for customization through various secondary processes to enhance performance characteristics.

Q5. How does the hardness of sintered door lock components compare to traditional methods? Sintered door lock components typically achieve hardness levels between 45-70 HRC (Rockwell Hardness Scale). This high hardness, combined with excellent wear resistance, allows these components to withstand repetitive use and exceed industry standards like the ANSI Grade 1 requirement of 800,000 cycles without failure.