Sintered bearings last 3 times longer than plastic bearings and 10 times longer than milled metal alternatives, making them the perfect choice for tough applications. These impressive components start as carefully selected metal powders that consist of exactly 90% copper and 10% tin bronze. The manufacturing process heats these materials, allowing atomic diffusion to bond the metal particles while creating a network of microscopic pores that make up 15-30% of the material’s volume.

The self-lubricating capability makes sintered bearings truly unique. Lubricating oil fills the pores of these metal bearings and stays there at room temperature. The sintered bushing’s temperature rises from friction during operation, which releases the lubricant from the pores and spreads it throughout the bearing. This creates a very durable component that lubricates itself throughout its service life. Sintered bearings also resist heat effectively and handle high-impact loads well, which makes them perfect for industrial settings.

Let’s get into the engineering principles that drive sintered bearings, their production methods, and how they stack up against traditional bushings in different performance areas.

How Sintered Bearings Work at the Microstructural Level

Sintered bearings showcase a remarkable engineering achievement at the microscopic level. These components stand apart from conventional bearings because of their unique porous metallic matrix. The matrix creates a network of tiny interconnected pores that form during the sintering process. This special structure makes up 10-30% of the total volume, with variations based on material needs and applications.

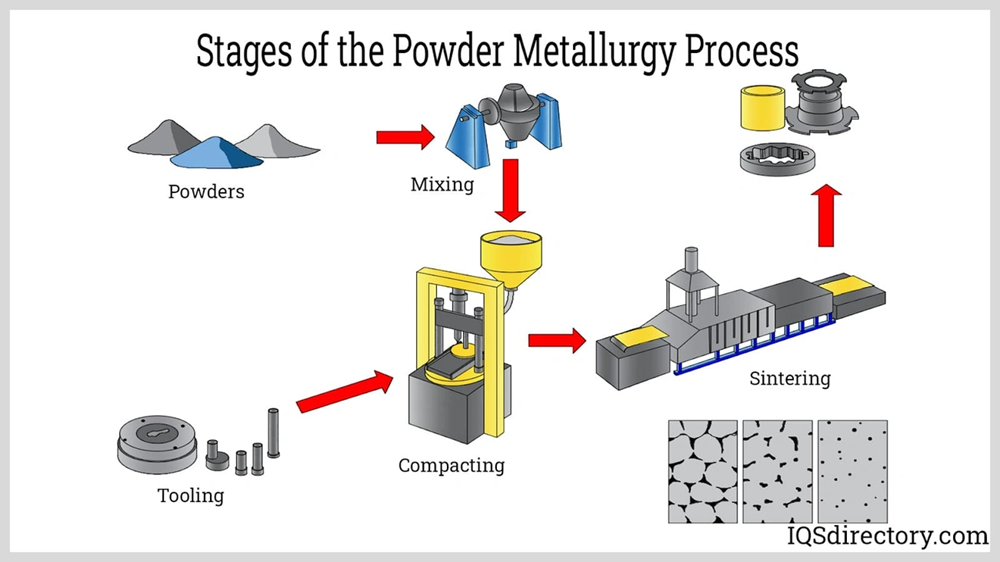

Powder Metallurgy and Porosity Formation

The journey of a sintered bearing starts with carefully chosen metal powders. Bronze compositions usually contain a precise mix of 90% copper and 10% tin. Manufacturers compress these powders in precision molds under high pressure to create initial bearing shapes. The real magic happens during sintering – when the compressed powder heats up just below the metal’s melting point. Bronze requires 750-850°C while iron needs 1100-1200°C. This heat triggers atomic diffusion that bonds particles together without complete melting. The process preserves the vital network of pores that gives the bearing its special properties.

Oil Impregnation and Capillary Lubrication

The next step removes all air from the porous structure. Manufacturers force lubricant into every microscopic cavity under pressure. This creates a built-in lubrication system that controls oil distribution throughout the bearing’s life. The oil fills the entire pore network and stays trapped inside until the bearing operates. Experts point out that these pores are not flaws but a thought-over design feature that makes the bearing self-lubricating.

Thermal Activation and Lubricant Release

The brilliance of sintered bearings shows in their thermal activation system. The bearing’s rotation creates heat that expands the oil. Capillary action then draws this oil to the surface to form a thin lubricating film between the bearing and shaft. This creates what engineers call a “pumping action” during operation. The oil wedge lifts the shaft away from the bearing surface and prevents direct metal contact. When the operation stops and the bearing cools, capillary forces pull excess oil from the sliding surface back into the pores. This continuous cycle maintains perfect lubrication without any maintenance needed.

Manufacturing Process of Sintered Bearings

Sintered bearings come to life through a precise three-step manufacturing sequence. This process combines metallurgical science with engineering precision to create components with exceptional performance characteristics.

Metal Powder Blending and Compaction

The process starts with careful selection of metal powders—typically copper, bronze, or iron-based compositions. Base materials mix with additives and lubricants to improve wear resistance, machinability, and lubricity. A homogeneous mixture emerges that shapes the bearing’s final properties. The powder mixture then moves to compaction, where precision dies apply immense pressure—200-400 MPa for softer metals and 400-800 MPa for harder materials. This compression turns loose powder into a cohesive “green compact” strong enough to handle. These green compacts stay relatively fragile until the next phase.

Sintering at Sub-Melting Temperatures

The green compacts then undergo sintering—a controlled thermal process at temperatures below the metal’s melting point. Copper-based alloys typically sinter between 750-850°C, about two-thirds of their melting temperature. Parts move through specialized furnaces with protective atmospheres that prevent oxidation. Atomic diffusion bonds the metal particles without completely melting and creates a strong yet intentionally porous structure. The process maintains about 25% porosity throughout the material, which becomes crucial for the final stage.

Vacuum Oil Impregnation for Self-Lubrication

The final stage fills the porous sintered structure with lubricant. Bearings sit in a sealed chamber where vacuum pressure (approximately 29″ Hg) removes air from interconnected pores. Heated lubricant enters the chamber once a vacuum is established. The oil penetrates the entire porous network through capillary action. Application requirements, environmental conditions, and component compatibility determine the lubricant type. This vacuum impregnation ensures lubricant fills every microscopic void, creating self-lubricating capabilities that set sintered bearings apart from traditional options.

Sintered Bearings vs Traditional Bushings: Engineering Comparison

A comparison of engineering performance metrics shows that sintered bearings work better than traditional bushings in critical applications. Let’s look at why these components perform better than regular alternatives in tough environments.

Friction Coefficient: Sliding vs Rolling Contact

Sintered bearings have friction coefficients between 0.03-0.12, which is much lower than traditional bronze bushings’ 0.08-0.15 in lubricated conditions. Steel bushings show even higher dry friction values of 0.4-0.6. Ball bearings have very low coefficients (0.001-0.0015), but they can’t match sintered bearings’ versatility in dirty or intermittently used systems. Sintered bearings also keep steady lubrication, no matter how the speed or load changes.

Heat Resistance in High-Load Environments

Sintered bearings shine in high-temperature applications. Advanced materials can handle short-term temperatures up to 572°F and long-term temperatures up to 482°F. Traditional bearings’ lubricants break down in high heat and stop working well. Heat-resistant bearings use materials like ceramic to work in higher temperatures, especially in places where normal lubrication fails.

Maintenance Requirements and Service Life

The best thing about sintered bearings is how little maintenance they need. These bearings typically last between 5,000-20,000 operating hours in good conditions. Tests show they last 3 times longer than plastic and 10 times longer than milled metal options. You need to check and add lubricant often with traditional bushings, but self-lubricating sintered bearings keep providing lubricant from their porous structure.

Noise and Vibration Dampening Capabilities

Sintered bearings run much quieter than regular options. Their constant lubrication film naturally dampens vibrations, making them very quiet. Surface roughness, lubrication, load/speed, and material properties affect noise levels. The porous structure and oil inside absorb vibrations and reduce noise throughout connected systems.

Cost Efficiency Over Lifecycle

Sintered bearings might cost more upfront, but they save money over time because they last longer and need less maintenance. Users can save up to 40% on maintenance costs compared to traditional bushings. These savings matter most when maintenance downtime is expensive or parts are hard to reach.

Applications Where Sintered Bearings Excel

Sintered bearings are used in many industries because of their self-lubricating properties and durability. These specialized components work best in places where maintenance is difficult and reliability matters most.

Automotive: Alternators, Starters, Suspension Joints

Car systems use sintered bearings in alternators and starters because they work continuously without needing maintenance. The suspension joints use special “gusher” bearings that let grease flow through them. This helps lubricate parts and clean out dirt. These bearings help sockets last longer and prevent steering issues like shimmying and loose wheels. Tests show that sintered bearings last 3 times longer than plastic ones and 10 times longer than milled metal versions.

Aerospace: Flight Control and Landing Gear

Aircraft engineers choose sintered bearings for flight controls and landing gear parts that must perform well in extreme temperatures. The landing gear struts use sintered bronze-backed metal-polymer bearings that prevent ladder cracking and heat damage on the strut rod surface. On top of that, these bearings can handle heavy loads and last longer in harsh conditions.

Consumer Appliances: Washing Machines and Compressors

Manufacturers use sintered bearings in washing machine drums and refrigerator compressors that need to run quietly for years without service. These bearings work great in home appliances because their variable density (6.0-6.6 gm/cc) allows oil to soak in. The oil-filled pores create a thin film between the shaft and bearing that reduces friction.

Industrial Machinery: Conveyor Systems and Pumps

Sintered bearings prove their worth in industrial settings like conveyor systems and hydraulic pumps that work in dirty environments. They handle heavy loads and changing speeds well, making them perfect for equipment that needs reliable performance with minimal downtime. The sort of thing I love about these bearings is that in food plants, their self-lubricating feature means no messy external lubrication is needed.

Conclusion

Modern metallurgical engineering has given us sintered bearings that are far better than traditional bushings. These components work exceptionally well because they can lubricate themselves. Their porous structure holds lubricating oil and creates a self-maintaining system that adapts to operating conditions automatically.

The numbers tell a clear story. Sintered bearings last three times longer than plastic ones and ten times longer than milled metal versions. They also run with less friction and can handle higher temperatures than regular bushings. You’ll get less noise and vibration, too, which makes them useful in many different settings.

These bearings combine powder metallurgy with advanced oil filling methods to create parts that need very little maintenance but give maximum reliability. This becomes crucial especially when you have high downtime costs or hard-to-reach installation spots.

From cars to aircraft, home appliances to industrial machines, sintered bearings tackle key engineering challenges with their unique features. Companies that know powder metallurgy inside out, like JH MIM with its 20-year track record, keep improving these precision-made products for customers worldwide.

The science of sintered bearings shows a perfect mix of material choice, precise manufacturing, and practical design. Their ongoing improvements will keep them vital in demanding jobs where performance matters and reliability is a must.

Key Takeaways

Understanding the engineering advantages of sintered bearings reveals why they’re becoming the preferred choice for demanding applications across multiple industries.

• Self-lubricating design eliminates maintenance: Porous structure holds oil that automatically releases during operation, creating continuous lubrication without external servicing requirements.

• Superior durability extends component life: Sintered bearings outlast plastic alternatives by 3x and milled metal bearings by 10x through their robust microstructural design.

• Lower friction coefficients improve efficiency: Achieve 0.03-0.12 friction coefficients compared to traditional bronze bushings’ 0.08-0.15, reducing energy consumption and wear.

• High-temperature resistance handles extreme conditions: Withstand operational temperatures up to 572°F short-term and 482°F long-term, outperforming conventional lubricated bearings.

• Cost-effective lifecycle performance: Despite higher initial costs, sintered bearings deliver up to 40% savings in maintenance expenses through extended service life and reduced downtime.

The combination of powder metallurgy manufacturing and vacuum oil impregnation creates components that automatically adapt to operating conditions, making them ideal for automotive, aerospace, and industrial applications where reliability cannot be compromised.

FAQs

Q1. What are the main advantages of sintered bearings over traditional bushings? Sintered bearings offer self-lubrication, longer service life, lower friction coefficients, and better heat resistance. They typically last 3 times longer than plastic bearings and 10 times longer than milled metal alternatives, while requiring minimal maintenance.

Q2. How do sintered bearings achieve self-lubrication? Sintered bearings have a porous structure impregnated with oil during manufacturing. As the bearing heats up during operation, the oil expands and is released, creating a thin lubricating film. When the bearing cools, excess oil is reabsorbed, creating a continuous lubrication cycle.

Q3. In which industries are sintered bearings commonly used? Sintered bearings are widely used in automotive (alternators, starters, suspension joints), aerospace (flight control systems, landing gear), consumer appliances (washing machines, refrigerator compressors), and industrial machinery (conveyor systems, hydraulic pumps).

Q4. How do sintered bearings compare to ball bearings in terms of performance? While ball bearings have lower friction coefficients, sintered bearings offer greater design flexibility, compactness, and better performance in contaminated or intermittently operated systems. Sintered bearings also provide lower vibration and noise levels.

Q5. Are sintered bearings cost-effective in the long run? Yes, sintered bearings are cost-effective over their lifecycle. Despite a potentially higher initial cost, they can save up to 40% on maintenance costs compared to traditional bushings due to their extended service life and minimal maintenance requirements.