The power of sintering process optimization is remarkable. Material hardness can jump from 62.17 HV to 182.8 HV with the right parameters .

The power of sintering process optimization is remarkable. Material hardness can jump from 62.17 HV to 182.8 HV with the right parameters .

Sintering process optimization goes beyond standard procedures. The secret lies in finding the perfect mix of parameters that deliver outstanding results. A newer study, published by reveals how specific parameters make a difference. Titanium alloy samples can reach 934.3 MPa yield strength with plastic elongation above 10%. These numbers meet ASTM B348-02 standards needed for medical grade materials.

The sintering process needs careful control through multiple stages and mechanisms. Research shows that CNTs weight percentage affects relative density (83.58%) and micro-hardness (77.75%). Temperature plays a vital but secondary role in both these properties . The optimization of walnut shell composite powder parameters yields best results with specific settings. These include 12 W laser power, 2000 mm/s scanning speed, 0.15 mm layer thickness, and 80°C preheating temperature .

Maximum density and hardness in sintering applications need the right mix of parameters. Laser power, scan spacing, and bed temperature must work together perfectly. To name just one example, see the study that found ideal parameters: 24.05 mm laser power, 0.1 mm scan spacing, and 173.65°C bed temperature. These settings help achieve peak material density and hardness .

This detailed guide explores each step of sintering process optimization. You’ll learn everything from material selection to parameter adjustment that helps create superior density and mechanical properties in sintered products.

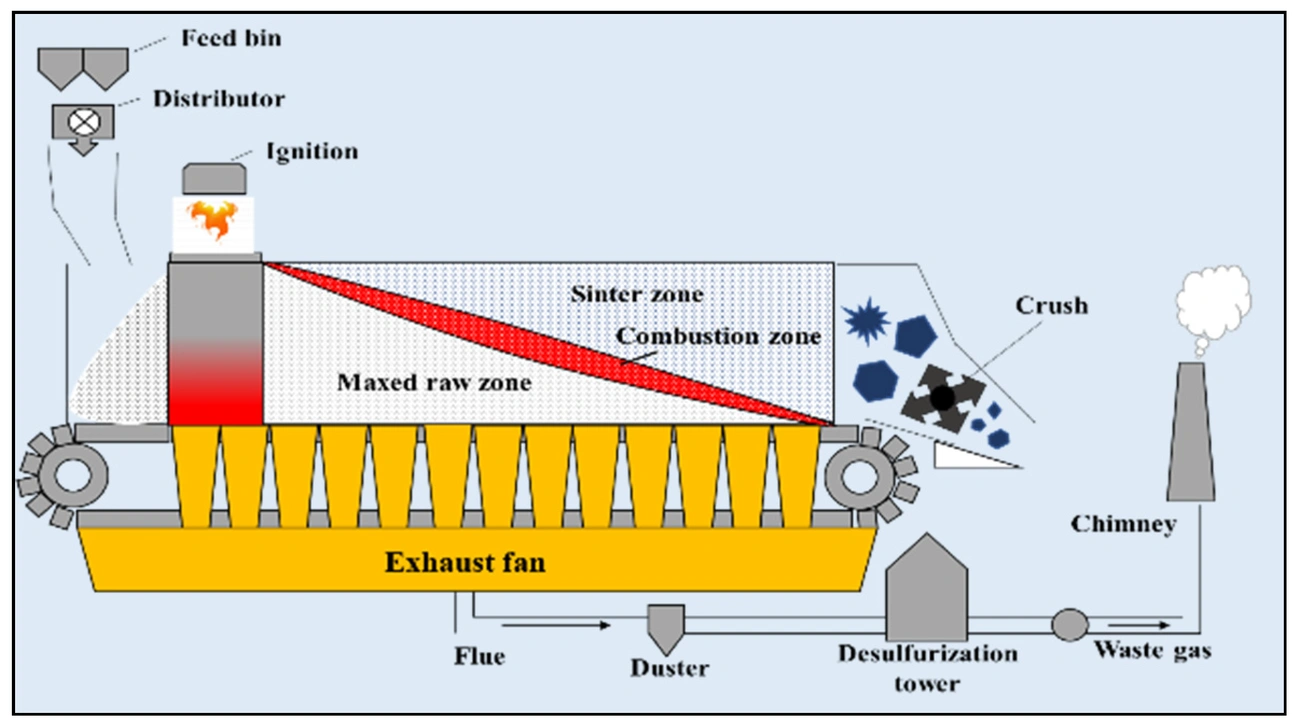

Basics of the Sintering Process

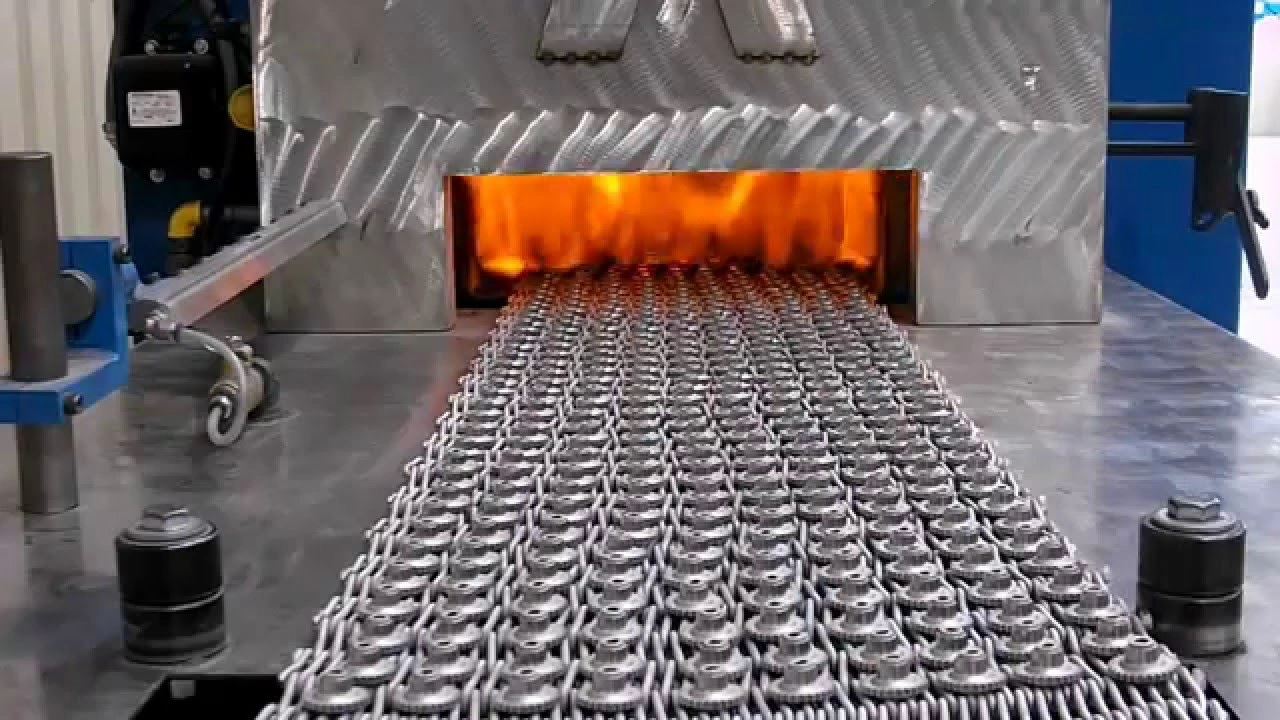

Sintering is a key thermal process that turns loose powder materials into solid components without melting them completely. This manufacturing technique bonds particles together at temperatures below their melting point. The process boosts material strength and cuts down porosity. Atomic diffusion creates strong bonds between particle boundaries and improves several material properties.

Definition and industrial relevance

Sintering is a vital thermal treatment that unites powdered materials into a solid structure through atomic-level mass transport. The process bonds loose particles at high temperatures – usually between one-half to two-thirds of the material’s melting point. The main force driving sintering is how surface energy drops when powder changes into a bulk component.

Sintering plays a crucial role in many industries. The process has major applications in:

- Ceramics industry: Creating everything from everyday tiles to advanced technical ceramics

- Metals manufacturing: Making components with better mechanical properties for automotive, aerospace, and healthcare industries

- Electronics: Producing capacitors, resistors, and other components that need specific electrical and thermal properties

- Refractory metals: Working with materials that have very high melting points like tungsten, molybdenum, and tantalum

- Jewelry making: Sintering precious metal powders like gold and silver

- Bearings production: Making sintered bronze bearings whose porosity lets lubricants flow through or stay trapped inside them

JH MIM has specialized in metal injection molding and powder metallurgy for almost 20 years. They use sintering processes to create precision-engineered products for customers worldwide.

Sintering process of ceramics vs metals

The basic principle stays the same, but ceramic and metal sintering are quite different from each other.

Ceramic sintering starts at temperatures as low as 1,100°F (593°C). The process changes temporary hydrogen bonds into permanent covalent bonds, which makes the ceramic shape resist water. The process combines both sintering and vitrification during firing. Most ceramics can handle heat well and are refractory, so their sintering temperatures usually go above 1,100°C. Adding glass can help with viscous-flow sintering at lower temperatures.

Metal sintering works without complete melting. Metal particles join at contact points as temperatures rise. Higher temperatures speed up bonding because of increased chemical activity at particle surfaces. The process works better with finer particles, well-planned particle size distribution, and higher temperatures.

The perfect metal sintering temperature should be half the melting temperature (in °C), but this would take too long. So metal sintering usually happens at about two-thirds of the melting temperature to balance sintering speed and grain growth control.

Metal sintering gives great control over porosity. Manufacturers can make parts that are either dense or have specific porosity levels based on what’s needed. The sintering environment is different too – most metals need protective gasses or vacuum conditions to avoid oxidation, especially for refractory and reactive metals.

Both processes go through similar stages: they start with neck formation between particles, move to changes in pore structure and densification, and end with pore closure and grain growth.

Stages of sintering: initial to final

Sintering happens in distinct stages. Each stage changes the microstructure in unique ways that shape the final properties of sintered components. Engineers need to understand these stages to optimize the sintering process.

The initial stage kicks off the transformation as contacts form and grow between neighboring particles. The relative density goes up from 0.5 to 0.6 during this time. Particles touch and create small “necks” between them through diffusion and other mass transport mechanisms. This neck formation leads to minimal size changes—only 2-3% densification occurs. These early changes set up everything that follows.

Surface diffusion drives most mass transport in this first stage. The Euler characteristic stays negative and drops slightly with relative density until it hits 74%. Closed pores start to form at this point, though not many.

The intermediate stage begins when adjacent necks start to meet. This vital phase brings big changes to the microstructure:

- Pores turn into connected cylindrical channels that mostly run along three grain edges

- Pores get smaller and smoother as densification speeds up

- Bulk transport mechanisms like grain boundary diffusion take over

- The Euler characteristic rises with relative density until it peaks at 96% density

Most densification happens during the intermediate stage. Parts reach about 92% of theoretical density by the time this stage ends. Pore cross-sections keep getting smaller, and the microstructure looks like a network of connected cylindrical pores.

The final stage starts when the connected pore channels pinch off to form closed pores at 0.9 relative density [2]. This stage has several unique features:

- Round, isolated pores sit at four-grain corners

- Grains grow and coarsen by a lot

- The Euler characteristic drops as closed pores disappear

- Grains grow much faster

This final stage moves much more slowly than the earlier ones. Gas trapped in closed pores can block further densification because atmospheric pressure matters more. Yes, pore shrinkage can stop completely when trapped gas pressure matches the capillary pressure.

Temperature control plays a vital role in all sintering stages because grain-boundary and volume diffusion depend heavily on it. Sintering typically starts at 50–80% of the material’s melting point. Higher temperatures make diffusion faster, but engineers must balance this against potential grain growth problems.

Knowledge of these stages helps manufacturers optimize sintering for specific uses. Engineers can achieve their target density and mechanical properties by controlling temperature profiles, holding times, and atmospheric conditions at each stage. These fundamentals are the building blocks for advanced process optimization techniques covered in later sections.

Choosing the Right Materials and Binders

The success of sintering largely depends on choosing the right materials and binders before processing starts. Your choice of materials directly shapes the final density, mechanical properties, and how well sintered components perform.

Selecting matrix and reinforcement powders

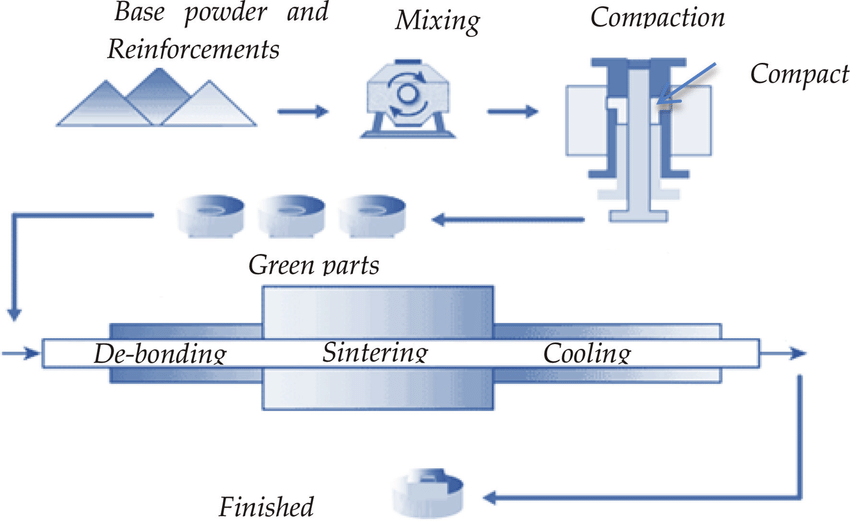

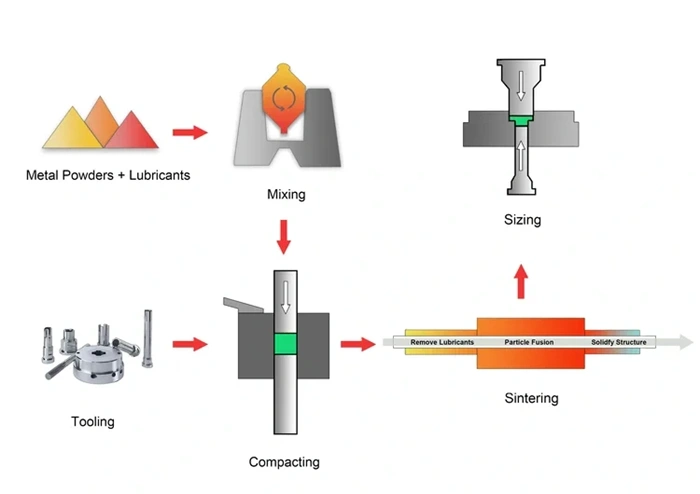

The right matrix choice lays the groundwork for optimizing any sintering process. Powder metallurgy (PM) lets manufacturers create high-strength alloys from elemental powders that are compacted, sintered, and adjusted to final dimensions. This method works exceptionally well with aluminum and its alloys – materials you can adapt through proper alloying.

Picking the right reinforcement is vital for particle-reinforced metal matrix composites (PMMCs). These composites are popular in aviation, transportation, microelectronics, and nuclear industries. They stand out because of their specific strength, thermal conductivity, and how well they resist high temperatures and abrasion. You can choose from:

- Ceramic particles (oxides, carbides, nitrides)

- Metal whiskers or sliced fibers

- Small particles with unique metallurgical properties

Engineers need to look at both practical and cost factors when picking reinforcement materials. Titanium nitride makes an excellent choice with its 2927°C melting point, high hardness, corrosion resistance, and thermal stability. Recent tests with combined AlN reinforcement (made by low-temperature direct nitridation of Al powder) showed big improvements. The ultimate tensile strength went up by 11.5%, while ductility improved five times compared to regular ceramic AlN reinforcement.

Role of binders in powder compaction

Binders play a key role in powder metallurgy. They prevent separation and dust problems while keeping powder mixes stable. These compounds hold powder bases together in semi-rigid states, so mixtures stay well-blended even when granules tend to separate naturally.

The amount of binder you use makes a big difference in product quality. Research shows that binder content effects can be unpredictable – using more doesn’t always mean better density or hardness. This happens because of clumping issues and uneven mixing between grains and binders. Tests show that less binder often works better, with 0.6 wt% typically giving the best density and hardness.

You need to remove binders through solvent evaporation or pre-processing heat before sintering starts. Any leftover binder can get in the way of the sintering process. That’s why knowing how binders burn out is vital for successful sintering.

Material compatibility and thermal behavior

Combining different materials often hits roadblocks because of compatibility issues. Regular sintering processes make it hard to mix metals, plastics, and ceramics because they melt at such different temperatures and react differently to heat.

Cold sintering process (CSP) offers a clever fix for this problem. Materials can be sintered between 100-300°C under 100-350 MPa pressure. The process uses water or acid solution to wet ceramic powder, which partly dissolves solid surfaces where particles meet. This lets you combine materials that wouldn’t work together before, while using less energy and time.

Heat management during sintering needs careful attention. Ceramic materials, being heat-stable and refractory, need temperatures above 1100°C for sintering. Metal sintering works best at about two-thirds of the melting temperature – this sweet spot balances sintering speed against too much grain growth.

Companies like JH MIM have spent nearly 20 years mastering metal injection molding and powder metallurgy. They know exactly how to pick materials and optimize processes to create precision-engineered products for customers worldwide.

Setting Up the Sintering Parameters

The right calibration of sintering parameters makes all the difference between average results and parts with the best density and mechanical integrity. Manufacturers can improve material performance in many applications by adjusting parameters carefully.

Temperature, time, and pressure explained

Temperature drives the sintering process. It works best at 0.7 to 0.85 of the material’s absolute melting point. This range starts diffusion processes without complete melting. The control of temperature affects densification rates directly. Higher temperatures make diffusion faster but might cause too much grain growth.

Time parameters affect how the microstructure develops. Studies show that shorter holding times help achieve refined grains, especially in processes like spark plasma sintering. All the same, long sintering times can cause unwanted grain growth when smaller grains combine into larger ones.

Adding pressure makes densification better. Research shows that high-pressure sintering offers many advantages. It achieves near-full densification while keeping grain growth in check. A test study found that sintering with pressures from 50 to 110 MPa showed better microstructural features. The highest pressure created the smallest crystallite size and highest microstrain.

How scan spacing and layer thickness affect results

Scan spacing changes how energy spreads across the sintering area. Studies indicate that scan spacing of 0.12 mm, combined with the right scan speed (1.8 m/s) and laser power (16 W), creates better mechanical properties in polymer sintering applications.

Layer thickness changes final material properties by a lot. Research showed that thinner layers led to better material strength (432 MPa) and density (94.35% of theoretical density). The best conditions for highest mechanical strength used layer thickness of 100 µm with a binder removal temperature rate of 0.2 °C/min.

Layer thickness affects mechanical properties in different materials. Tests with 316L austenitic stainless steel showed that thin layers (100 µm) produced stronger results than thick layers (300 µm). Small changes in layer thickness can transform the microstructure. This affects fatigue resistance and tensile strength properties.

Preheating and cooling considerations

Preheating plays several key roles in making the sintering process better. Powder bed systems become stronger and conduct heat and electricity better with preheating. Better beam-matter interaction happens as a result. This allows lower beam currents in later melt tracks.

The best results come from preheating in stages. Powder metallurgy applications start with heating components to 500-900°C. This removes lubricants and binders while reducing surface oxides on metal powders. Poor preheating leads to structural defects and weak bonding between particles.

Choosing the right cooling rate matters just as much for final part quality. Research shows that cooling rates change phase composition, microstructure, optical, and mechanical properties. Tests comparing different cooling rates in zirconia revealed interesting results. Steady cooling reduced flexural strength and mechanical reliability in 5Y-PSZ materials but had little effect on 3Y-TZP zirconia grades.

Companies like JH MIM know from 20 years of powder metallurgy experience that exact sintering parameters need both technical knowledge and hands-on experience. They balance theoretical ideals with manufacturing realities while keeping quality consistent across production runs.

Optimizing with Taguchi and DOE Methods

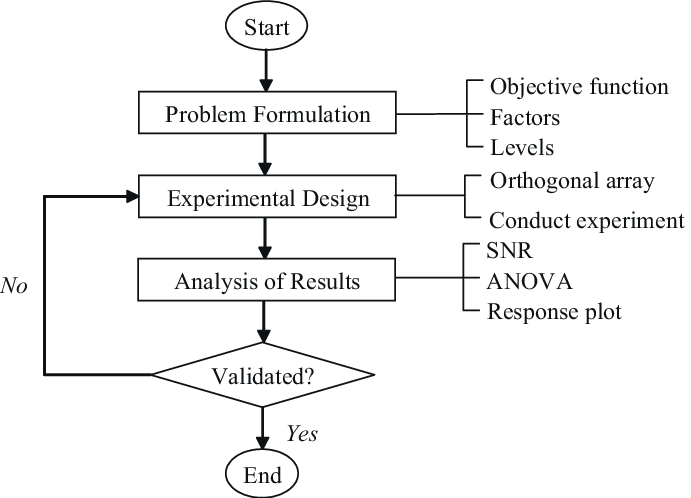

You need systematic experimentation, not just trial and error, to get the best sintering results. Design of Experiments (DOE) methods give you a well-laid-out path to process optimization. The Taguchi method stands out as a great technique to use with sintering.

Why Taguchi is ideal for sintering

The Taguchi method works great at optimizing complex technological processes with multiple parameters. This makes it perfect for sintering operations that need to handle many variables. Traditional approaches change one parameter at a time. Taguchi’s technique needs fewer experiments while keeping statistical validity. This becomes really valuable in sintering research where you often have limited time and materials for testing.

This method works best with a moderate number of variables (3 to 50) and when just a few variables make a big difference in the outcome. A titanium alloy study found that only two factors—sintering temperature and composition—were responsible for over 61% of density changes, even though researchers tested four different parameters.

Creating orthogonal arrays for testing

Orthogonal arrays are the foundations of Taguchi’s approach. They organize parameters and their levels in a way that shows important relationships without endless testing. These arrays test specific parameter combinations instead of trying every possible combination.

Researchers pick the right orthogonal array setup based on what they need to test. Common choices include:

- L8 arrays for three factors at two levels each, cutting required experiments from 12 to 8

- L9 arrays to test three factors with three levels each

- L18 arrays for more complex cases that could represent hundreds of test conditions

Researchers working with hydroxyapatite samples used the Taguchi method and found the best cold sintering parameters (250°C, 500 MPa, 60 minutes, and 10% liquid content) to reach 99% density.

Signal-to-noise ratio explained

The signal-to-noise (S/N) ratio is the key metric in Taguchi analysis. It measures how strong a response signal is compared to unwanted variation or “noise.” Better processing conditions show up as higher S/N ratios.

S/N calculations change based on what you want to achieve:

- “Larger-is-better” works for properties like density or strength

- “Smaller-is-better” helps minimize defects or variation

- “Nominal-is-best” helps hit specific target values

Density in sintering usually follows the “larger-is-better” S/N calculation because researchers want to maximize material density. After getting S/N ratios for each test condition, the response tables and graphs show how each parameter affects the final result.

ANOVA (Analysis of Variance) usually comes after S/N ratio analysis to measure how much each parameter contributes to the results. A study of CNT-reinforced aluminum composites showed through ANOVA that CNT concentration affected relative density variation by 83.58%, while temperature only contributed 14.58%.

Analyzing Results with ANOVA

ANOVA is a powerful statistical tool that helps learn about sintering experiments. Manufacturers need to interpret their experimental data to identify the parameters that matter most.

Breaking down variance contributions

ANOVA measures how much each parameter affects outcome variation. To name just one example, a study on CNT-reinforced composites showed CNT concentration was responsible for 83.58% of relative density variation. Temperature accounted for 14.58%, which proved that material composition mattered more than processing conditions. As with research on sintered Fe-Mn-Cr-Mo-C steels, chemical composition, sintering temperature, and heat treatment had the strongest effect on mechanical properties. The sintering atmosphere barely affected the outcome.

The coefficient of determination (R²) helps verify ANOVA models. Values closer to 1 show a strong correlation between independent and dependent variables. Regression models for hardness and relative density achieved high R² values of 98.7% and 99.79%. These results give manufacturers confidence in ANOVA findings when they optimize their processes.

Identifying dominant parameters

Different sintering applications show varying parameter dominance. The production of (Zr₀.₄Ti₀.₆)₀.₃₃Ni₀.₃₃(Sn₀.₉₈Sb₀.₀₂)₀.₃₃ using FAST processes revealed temperature as the key factor. It contributed 61.928% to density variation, with pressure at 16.980%, holding time at 12.580%, and heating rate at 6.753%. This ranking helps manufacturers focus on the most crucial parameters.

ANOVA calculates p-values for each factor and their interactions to determine statistical significance. Parameters with p-values under 0.05 substantially affect outcomes. Higher values suggest minimal influence. Manufacturers can avoid wasting resources on parameters that don’t improve final quality.

Using ANOVA to refine experiments

ANOVA enables post-hoc tests that determine the best parameter levels. A study on pressing density and sintering modes used post-hoc tests with Bonferroni correction. Results showed hardness values at pressing density A4 (44.967 ± 3.319) exceeded other densities. Sintering mode B2 (44.025 ± 4.045) performed better than alternatives. These findings let manufacturers choose exact parameter values instead of ranges.

The tool also reveals hidden interactions between parameters. Factorial analysis can show how sintering temperature and pressure influence each other’s effect on final density. Some studies found no interaction between variables, like pressing density and sintering mode. This allows manufacturers to optimize these parameters on their own.

Companies like JH MIM tap into their 20 years of powder metallurgy experience through statistical analyses. Manufacturers who use ANOVA systematically can improve their sintering outcomes through analytical insights rather than gut feeling.

Simulating the Sintering Process

Digital tools have transformed how manufacturers optimize their sintering processes. These tools let companies test virtually before actual production starts. Manufacturers can now spot and fix problems early while cutting down development time and costs substantially.

Introduction to sintering simulation tools

Several specialized software solutions now tackle the complex challenges of sintering simulation. Live Sinter runs on a GPU-accelerated multi-physics engine that models interactions between hundreds of thousands of particle masses and rigid bodies. The software simulates a typical sintering cycle in five minutes and creates compensated geometries in about fifteen minutes. Simufact Additive uses multiphysics finite element approaches to determine part warpage from gravity and friction with the sinter plate. These tools were first built for binder jetting but proved useful for sintering technologies of all types.

Modeling thermal diffusion and densification

The core of sintering simulation lies in modeling how materials react to many factors: gravity, shrinkage, density variations, elastic bending, plastic deformation, and friction drag. The models must factor in thermodynamic and mechanical changes that happen under intense heat.

The physics behind sintering simulation typically has:

- Coupled thermal, electrical, chemical and mechanical fields

- Surface and grain boundary diffusion mechanisms

- Ludwig-Soret thermal diffusion effects that create concentration gradients

- Macroscopic temperature gradients reaching 103 K/min

Advanced simulations combine multiple physics-based approaches. Some models merge elastic, thermal, and viscous creep deformation. Others exploit the discrete element method to show microstructural changes accurately.

Validating models with experimental data

Good simulation needs thorough testing against experimental results. A copper powder study compared actual neck radius values after sintering for 300, 600, and 1200 seconds with simulated predictions. The researchers found “very good agreement,” which proved their modeling approach worked well. For titanium alloy parts, the simulation predicted density changes with just 2% mean error.

JH MIM draws from nearly 20 years of industry expertise and knows how simulation tools help set the right sintering parameters before production begins. This approach eliminates costly trial-and-error methods. Their skilled workers can deliver precision-engineered products with better density and mechanical properties to customers worldwide.

Improving Density and Mechanical Properties

The sintering process aims to create components with maximum density and superior mechanical properties. Materials with substantially improved performance characteristics emerge when you master specific density-enhancing techniques for applications of all types.

How to reduce porosity

We improved diffusion mechanisms to optimize density in sintering and eliminate voids. Temperature provides the most powerful tool since diffusion rates grow exponentially as temperature rises. You can combine these essential approaches to get maximum results:

- Extend sintering time at peak temperature so slow diffusion processes can close isolated pores. This becomes vital during final sintering stages

- Use finer starting powders to boost the surface-area-to-volume ratio. This speeds up densification and reduces required diffusion distances

- Control furnace atmosphere to stop oxide formation on particle surfaces that block densification

Liquid phase sintering works remarkably well to enhance density. This technique generates capillary pressures between 1,210-12,100 kPa for silicate liquids and 6,720-67,200 kPa for metals like cobalt. These pressures actively pull particles together. A bio-sourced feedstock study showed 97% final density with optimized liquid phase sintering.

Grain refinement techniques

Two-step sintering gives you better control over microstructural development without sacrificing density. A magnesium aluminate spinel implementation reached 99.2% relative density with 429nm grain size at 1280°C for 20 hours after original heating to 1350°C. Applications needing closed porosity saw the same material achieve 95.2% density with finer 184nm grain size at a lower second-step temperature of 1235°C.

Starting powder size directly shapes the final grain structure. Research shows that bulk specimens from finer starting powders (≈20μm) achieved 3.78μm average grain size and yield strength around 265 MPa. This strength triples that of conventional coarse-grained counterparts while maintaining good ductility (approximately 15% elongation).

Post-sintering processes like forging or extrusion

Hot isostatic pressing (HIP) excels at eliminating final closed pores. This technique uses uniform gas pressure at high temperature to overcome internal gas pressure within trapped pores. HIP becomes especially valuable when conventional sintering hits its density limit.

Post-sintering forging reduces residual porosity dramatically. A study revealed forging at 950°C cut porosity from 8% to about 4%. Forging at 1250°C (above β transus) created a highly refined lamellar microstructure with even lower residual porosity. Hot forging improved mechanical properties substantially while pushing out residual liquid phase.

JH MIM’s 20 years of powder metallurgy expertise helps them apply these advanced techniques. They create near-full density components that meet their global customers’ most demanding mechanical requirements.

Common Pitfalls and How to Avoid Them

Quality issues can plague even the best-designed sintering processes. Manufacturers need to spot these problems early and take preventive action before fixes get pricey.

Over-sintering and grain growth

Materials become too dense and lose their desired properties when exposed to high temperatures or long sintering times. This over-sintering happens more often than you might think. The process triggers abnormal grain growth – a serious issue where some grains grow much larger than the grains around them.

These big grains trap pores that can’t escape to grain boundaries or leave the material. The trapped pores make it impossible to achieve higher density and weaken the material’s mechanical properties. Several factors cause this:

- Too much heat and time during sintering

- Powder particles that vary too much in size

- Uneven density in the green body during molding

The solution lies in finding the right sintering settings and using precise control systems to watch the conditions.

Binder burnout issues

The binder burnout phase removes organic compounds like pore formers, binders, and lubricants. This critical step often causes problems. When binders don’t burn out completely, pressure builds up inside and creates defects and cracks.

The process naturally limits production speed because it needs slower heating cycles. Rushing through this phase will hurt product quality. Here’s what works best:

- Hold temperature at lower levels (450°C for 1-2 hours)

- Slow down heating to 1-2°C/min between 300-600°C

- Make sure the furnace has good airflow

Inconsistent powder mixing

Parts with unpredictable properties come from poorly mixed powders. Powder can separate at any point – during mixing, moving, or storage. This happens through fluidization, sifting, and dusting.

When powders clump together, spaces between these clumps often stay too large. These spaces leave unwanted pores in the final components. Here’s how to fix these issues:

- Pick the right mixer for your powder type

- Create and follow detailed mixing procedures

- Use proper ball, hammer, jet, or attritor milling to break up powder clumps

Companies like JH MIM, with their 20 years in powder metallurgy, know that dealing with these common problems helps create high-quality sintered parts consistently.

Conclusion

Becoming skilled at sintering process optimization demands scientific knowledge and hands-on practice. This piece shows how carefully chosen parameters affect final material properties by a lot. Temperature, pressure, scan spacing, and layer thickness combine to turn loose powders into components with exceptional density and mechanical strength.

Without doubt, choosing parameters methodically produces better results. Statistical methods like Taguchi design and ANOVA offer clear paths to identify key variables instead of guesswork. Evidence proves that CNT concentration, sintering temperature, and pressure contribute most to density variation. These optimal parameters change based on materials and applications.

Software solutions have changed how sintering works today. Manufacturers can now model complex thermal diffusion and densification processes before actual production. This virtual testing helps predict problems early and optimizes parameters for maximum density while cutting development time and costs.

Material selection plays a crucial role in achieving the best results. Matrix powders, reinforcement materials, and binders must work together smoothly during sintering. Companies can avoid getting pricey mistakes by preventing over-sintering, incomplete binder burnout, and uneven powder mixing that hurt product quality.

JH MIM shows these principles at work in real-life success stories. Their 150 skilled workers use world-class equipment and optimized sintering processes across 18,000 square meters of manufacturing space. The company’s 20 years of powder metallurgy expertise helps them deliver precision-engineered products to customers worldwide.

Technologies keep evolving but the basic principles stay the same. Working with ceramics, metals, or composites requires proper parameter selection and strict process control. This approach consistently creates components with superior density, mechanical properties, and performance characteristics.

Key Takeaways

Master these essential sintering optimization strategies to achieve superior material density and mechanical properties in your manufacturing processes.

• Optimize the parameter trinity: Temperature (0.7-0.85 of melting point), pressure (50-110 MPa), and time work together—higher temperatures accelerate diffusion but require careful balance to prevent grain growth.

• Use statistical methods for precision: Taguchi design and ANOVA identify which parameters truly matter—CNT concentration can contribute 83% to density variation while temperature accounts for just 15%.

• Leverage simulation before production: Modern tools predict sintering outcomes in 5 minutes, reducing costly trial-and-error while enabling virtual testing of parameter combinations.

• Control material selection carefully: Matrix powders, reinforcement materials, and binders must work harmoniously—optimal binder content is often lower (0.6 wt%) than expected.

• Avoid common pitfalls systematically: Over-sintering, incomplete binder burnout, and inconsistent powder mixing destroy quality—implement precise process controls and slower thermal cycles through critical temperature ranges.

The path to sintering mastery combines scientific methodology with practical experience. By applying these evidence-based strategies, manufacturers can consistently achieve components with exceptional density and mechanical performance across diverse applications.

FAQs

Q1. How does sintering affect material density? Sintering generally increases material density. As sintering temperature and time increase, density tends to improve. Studies show that sintering for 10-30 minutes at higher temperatures can achieve over 98% of theoretical density in many materials.

Q2. What are the key factors that influence the sintering process? The main factors affecting sintering include temperature, time, pressure, and atmospheric composition. These parameters work together to determine the final properties of the sintered product.

Q3. What is one of the biggest challenges in sintering? Managing porosity is a critical challenge in sintering. Achieving uniform density and consistent pore size distribution is difficult, but crucial, as uncontrolled porosity can significantly weaken the mechanical strength and performance of the final part.

Q4. How does shrinkage occur during sintering? Shrinkage during sintering is influenced by several factors, including the metal powder composition, sintering temperature and duration, presence of binders, and the initial density of the compacted part. These elements combine to determine the overall dimensional changes in the material.

Q5. What role does temperature play in the sintering process? Temperature is a primary driver in sintering, typically applied at 0.7 to 0.85 of the material’s absolute melting point. Higher temperatures accelerate diffusion processes, promoting densification, but must be carefully controlled to prevent excessive grain growth that can negatively impact material properties.