Modern vehicles use more than 1,000 powder metallurgy parts made through sintering in automotive applications. These parts range from engine components to transmission gears, and sintering technology has become a crucial manufacturing process for automakers.

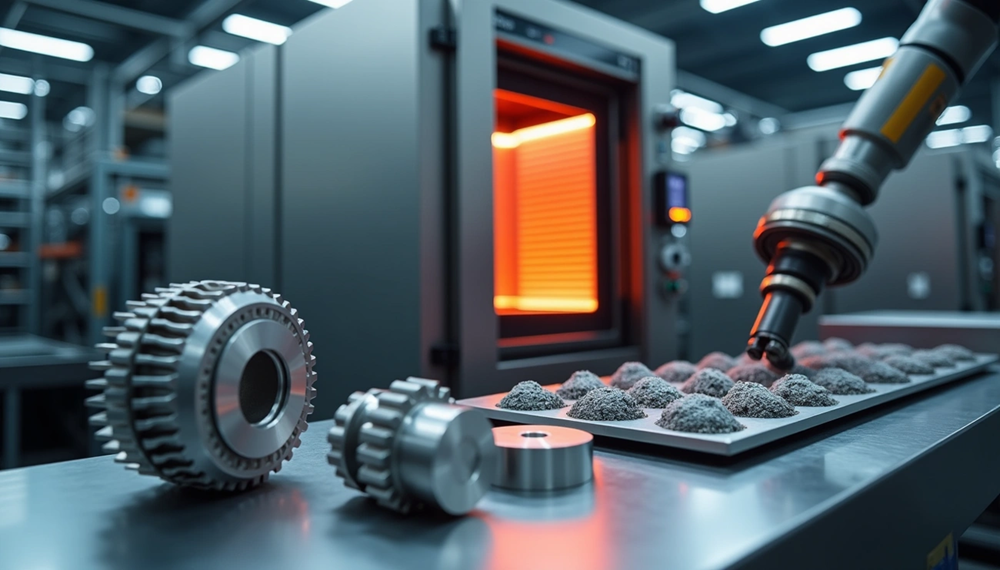

Manufacturers use sintering to compact and heat powdered materials into solid masses without complete melting. This technique has changed how complex, high-precision automotive components are produced. U.S. vehicles typically contain 13 to 45 kg of sintered parts, which shows their importance in vehicle construction. On top of that, almost every classic car contains sintered parts, which proves this manufacturing technique’s long history in the automotive world.

Sintering has become popular in automotive manufacturing because of its key benefits. The process improves metal components’ mechanical properties, which creates parts that handle extreme conditions. The technique also reduces porosity by removing gaps between particles. This results in denser materials perfect for critical applications. Strong and durable sintered components like pistons, gears, and bearings can withstand high temperatures and pressures, making them ideal choices.

This piece covers sintering’s role in automotive manufacturing, from engine parts to brake systems. We’ll learn about the materials used, the benefits gained, and the future trends that shape this vital manufacturing technology.

Key Automotive Components Made Using Sintering

Modern vehicles contain about 600 powder metal parts that weigh between 10-15 kg per car. Sintering technology plays a vital role in manufacturing these automotive components.

Engine parts: oil pump rotors, valve seat inserts, crankshaft sprockets

Powder metallurgy creates oil pump rotors that ensure steady oil flow in engines and provide lubrication and heat removal. These rotors need tight radial clearances (typically 0.08-0.13 mm) to perform optimally and reduce leakage. Sintered valve seat inserts move combustion heat from valves to cylinder heads. Modern engine generations use sintered valve seats because traditional cast materials can’t handle the thermal strains in today’s combustion chambers. Crankshaft sprockets connect timing chains or belts and synchronize rotation between crankshafts and camshafts.

Transmission parts: synchronizer rings, clutch hubs, planetary gears

Synchronizer rings make gear shifts smoother by matching gear speeds. Steel synchronizer rings now replace brass components in many applications and last longer. Tests show brass rings have a B10 life of just 11,700 km. Sintered clutch hubs help create smooth clutch engagement and disengagement for better power transmission. Automatic transmissions use planetary gears that enable smooth acceleration through complex gear systems. These gears benefit from sintering’s precision in creating intricate shapes.

Brake and safety systems: ABS sensor rings, brake pads

ABS sensor rings track wheel speed and provide vital data to prevent wheel lockups. The global automotive sintered brake pads market will reach USD 1.07 billion in 2024. Experts project a 6.8% CAGR through 2034. Performance applications prefer sintered brake pads because they conduct heat better and reduce brake fade during long braking periods. Disk brakes represent 68.4% of the sintered brake pad market.

Thermal and fluid systems: water pump pulleys, timing pulleys

Water pump pulleys move rotational energy from the crankshaft to power water pumps and maintain proper engine temperatures. These parts need sintering’s precise tolerances (±0.015 mm). Timing pulleys ensure exact synchronization between engine components and improve overall engine efficiency and reliability.

Material Types Used in Automotive Sintering

The automotive industry uses various materials in the sintering process. Each material brings specific performance features that boost vehicle functionality.

Iron and alloy steels for structural strength

Iron-based powders lead the automotive sintering world because of their exceptional structural properties. Pure iron serves as the foundation material for manufacturers who want budget-friendly components with moderate mechanical demands. Sintered alloy steels become crucial for highly stressed components in engines and transmissions. These materials create strong interparticle bonds without complete liquefaction as they process at temperatures below their melting points. Prealloyed steels keep a consistent microstructure, whatever the sintering temperature. Mixed or diffusion-bonded grades show substantially different properties based on processing conditions.

Aluminum and MMCs for lightweight applications

The race toward better fuel efficiency has sped up the use of aluminum-based sintered components. Aluminum metal matrix composites (MMCs) strike a perfect balance between high strength, lightweight properties, and superior fatigue resistance. Many aluminum-based MMCs use silicon carbide (SiC) reinforcement to boost mechanical characteristics compared to traditional materials. These parts weigh 6-11% less than conventional steel components, making them perfect for vehicles that must shed extra weight.

Copper and bronze for electrical and lubrication systems

Copper’s outstanding electrical conductivity (59.6 million Siemens per meter) makes it vital for EV components. Electric vehicles concentrate 70-80% of their copper in battery anode collectors, module interconnects, high-voltage cables, and motor windings. Sintered copper and bronze components also excel in oil-impregnated bushings, filters, brake bands, and clutches. Their controlled porosity helps optimize lubrication performance.

Ceramics and soft magnetic composites for sensors and electronics

Advanced ceramic materials perform remarkably well in automotive sensor applications, especially where high temperatures and corrosion resistance matter. You’ll find ceramics like alumina and zirconia in oxygen sensors, thermal insulation, and fuel system parts. Soft magnetic composites (SMCs) consist of iron particles with insulating film coatings. They cut core losses at frequencies above 350 hertz better than traditional laminations. These materials allow three-dimensional flux paths and complex geometries that work perfectly in next-generation motor designs.

Benefits of Sintering in Automotive Manufacturing

Manufacturing efficiency is the lifeblood of automotive production. Sintering processes provide several key advantages that make them increasingly valuable in vehicle manufacturing.

Reduced material waste and energy consumption

Sintering excels with its exceptional material utilization rate—typically exceeding 95%—which is nowhere near what traditional subtractive manufacturing techniques can achieve. Traditional machining methods waste over 50% of raw materials, while sintered components generate scrap rates as low as 3%. Any unsintered powder can be collected and reused, and modern recovery systems reclaim 80-90% of loose metal powder. The thermal efficiency numbers tell a compelling story, too. Continuous sintering furnaces achieve 45%-65% efficiency, which is a big deal as it means that they outperform batch furnaces’ 30%-50% efficiency.

High-dimensional accuracy and batch consistency

Sintered parts deliver remarkable precision with ISO tolerances as tight as IT-6 for certain dimensions. Advanced sensors monitor critical parameters like temperature and pressure with up-to-the-minute data analysis. This ensures uniform shrinkage and final dimensions across production runs. Since all powder metallurgy components come from similar molds, the same product’s performance stays highly consistent.

Lower production costs compared to forging and casting

Sintering needs lower temperatures than forging and casting processes, which reduces energy costs. The near-net-shape capability cuts down expensive secondary operations. Powder forging achieves over 80% material utilization, while traditional forging typically reaches only 50%. Powder metallurgy’s tooling lasts remarkably long, which decreases long-term expenses.

Improved fuel efficiency through lightweight parts

Powder metallurgy creates lighter components—a vital factor in enhancing vehicle efficiency. To cite an instance, aluminum sprockets in automotive cam phasers weigh just 450 grams, compared to 900 grams for sintered iron alternatives. This weight reduction leads to lower fuel consumption and environmental benefits.

Sintering Technology Trends and Future Outlook

State-of-the-art technologies and market needs continue to revolutionize sintering in automotive manufacturing.

Adoption of selective laser sintering (SLS) for prototyping

Automotive manufacturers have embraced SLS technology because it creates tough, durable prototypes in just one day. The process doesn’t require support structures and allows multiple parts to nest in a single build. This makes it perfect for jigs, fixtures, housings, and snap-fit components. Well-designed parts can achieve tolerances of ±0.010 in. (0.25mm) plus 0.1% of nominal length consistently.

Integration with additive manufacturing for custom parts

Sintering and additive manufacturing have combined to create remarkable results. A manufacturer used TPM3D systems to produce large structural parts and cut production time in half from 4 days to 2. The weight dropped from 27 kg to just 4 kg—an 82% reduction. A prominent auto parts supplier implemented this technology to make jigs and fixtures. Their production time decreased by 55% and costs fell by 73%.

Use of sintering ovens with controlled atmospheres

Modern automotive applications rely on controlled atmosphere ovens that contain precise mixtures of nitrogen, argon, hydrogen, and helium with minimal oxygen. These specialized environments help maintain quality consistently across batches by preventing contamination during heat treatment.

Sintering companies investing in electric vehicle components

Electric vehicle sales have grown by approximately 43% year-on-year. Major sintering companies see this opportunity. GKN Powder Metallurgy launched high-strength materials engineered specifically for EV powertrains in 2024. Samvardhana Motherson Group formed a mutually beneficial alliance with Jiangsu Sifang in 2025 to develop precision automotive sintered parts for EV platforms together.

Conclusion

Sintering technology has become the lifeblood of modern automotive manufacturing over the last few decades. This remarkable process transforms metal powders into critical components that power today’s vehicles. The technology’s widespread adoption touches virtually every automotive system. You’ll find it in essential engine parts like oil pump rotors and valve seat inserts, as well as transmission components such as synchronizer rings and planetary gears.

Material versatility stands as sintering’s greatest strength. Iron and alloy steels provide structural integrity when high-stress applications demand it. Aluminum and metal matrix composites deliver lightweight solutions that are vital for fuel efficiency. Copper and bronze components excel in electrical and lubrication systems. Advanced ceramics show exceptional performance in harsh operating environments.

Sintering’s advantages go way beyond the reach and influence of component diversity. Material utilization rates show this is a big deal as it means that 95% reduction in waste compared to traditional manufacturing methods. The technology’s exceptional dimensional accuracy will give a consistent performance across production batches. These benefits, combined with lower production costs and energy requirements, make sintering especially when you have automotive manufacturers facing intense cost pressures.

The technology continues to evolve with automotive industry needs. Selective laser sintering has emerged as a revolutionary force in prototyping. Integration with additive manufacturing creates complex custom parts that were impossible to produce before. Controlled atmosphere ovens improve quality control. Major sintering companies are developing specialized components for the electric vehicle market that grows faster than ever.

The automotive industry’s drive toward more efficient, sustainable transportation solutions makes sintering a vital manufacturing technology. Its unique combination of precision, efficiency, and adaptability positions it perfectly to tackle both current automotive needs and future challenges in vehicle production.

Key Takeaways

Sintering technology has become indispensable in automotive manufacturing, with modern vehicles containing over 1,000 powder metallurgy parts weighing 10-45 kg per car across critical systems.

• Sintering produces essential automotive components including engine parts, transmission gears, brake systems, and thermal components with exceptional precision and durability.

• The process achieves 95%+ material utilization rates and reduces production costs compared to forging and casting while maintaining tight dimensional tolerances.

• Multiple materials enable specialized applications: iron/steel for strength, aluminum for lightweight parts, copper for electrical systems, and ceramics for sensors.

• Advanced sintering technologies like SLS prototyping and controlled atmosphere ovens are driving innovation in electric vehicle component manufacturing.

• Weight reduction through sintered aluminum components (6-11% lighter than steel) directly improves fuel efficiency and environmental performance.

The automotive industry’s shift toward electric vehicles and sustainability makes sintering technology even more valuable, as manufacturers leverage its precision, efficiency, and material versatility to meet evolving transportation demands while reducing waste and energy consumption.

FAQs

Q1. What is sintering and how is it used in the automotive industry? Sintering is a manufacturing process that involves compacting and heating powdered materials to form solid components without full melting. In the automotive industry, it’s used to produce complex, high-precision parts for engines, transmissions, brakes, and other systems, offering benefits like reduced waste and improved efficiency.

Q2. What are some common automotive components made through sintering? Sintered automotive components include engine parts like oil pump rotors and valve seat inserts, transmission parts such as synchronizer rings and planetary gears, brake system components like ABS sensor rings and brake pads, and thermal system parts like water pump pulleys.

Q3. What materials are commonly used in automotive sintering? The most common materials used in automotive sintering include iron and alloy steels for structural strength, aluminum and metal matrix composites for lightweight applications, copper and bronze for electrical and lubrication systems, and ceramics for sensors and electronics.

Q4. How does sintering benefit automotive manufacturing? Sintering offers several benefits including reduced material waste (over 95% utilization rate), high dimensional accuracy, lower production costs compared to forging and casting, and the ability to produce lightweight parts that improve fuel efficiency.

Q5. What are some emerging trends in automotive sintering technology? Emerging trends include the adoption of selective laser sintering (SLS) for rapid prototyping, integration with additive manufacturing for custom parts, use of controlled atmosphere sintering ovens for improved quality control, and increased investment in developing components for electric vehicles.