Sintering adds more than $23 billion to the U.S. economy each year and stands as one of the most valuable manufacturing processes in modern industry. This heat treatment process turns loose powdered materials into solid, cohesive masses under high temperature and pressure.

Sintering adds more than $23 billion to the U.S. economy each year and stands as one of the most valuable manufacturing processes in modern industry. This heat treatment process turns loose powdered materials into solid, cohesive masses under high temperature and pressure.

The sintering process works when atoms move across particle boundaries and fuse into one unified piece. The technique improves critical properties like strength, electrical conductivity, thermal conductivity, and translucency. Sintering’s applications span many sectors, and industries like automotive, aerospace, and medical heavily rely on sintered metal components. The process works well with materials that other technologies can’t handle, especially when you have metals with very high melting points. Growth rates vary between 10 to 40 percent yearly, depending on the industry. Sintering remains a vital manufacturing technique that produces everything from dental implants and ceramic turbochargers to rocket nozzles and golf clubs.

Understanding the Sintering Process

The sintering process is a thermal treatment method that turns loose powder or porous material into solid components with better properties. The process happens at temperatures below a material’s melting point. This allows manufacturers to make components from metals that have very high melting points, like tungsten and molybdenum.

Sintering definition and thermal principles

Sintering is a heat treatment that uses high temperature and pressure to turn loose materials into solid masses without melting them. Materials typically need temperatures between 60-70% of their melting point. The process works through basic thermodynamic principles. The main force behind it comes from reducing free energy by making the surface area smaller and replacing solid-vapor interfaces with lower-energy solid-solid interfaces.

The thermal principles of sintering happen in three stages. Particles first create point contacts and form necks. The middle stage brings major densification, rounds out pores, and makes grains bigger. The final stage moves and closes pores, which completes the densification process. Loose particles become a solid structure with better mechanical properties.

Atomic diffusion and neck formation

Atomic diffusion moves mass during sintering. Atoms become mobile with heat and move across particle boundaries until they join together. This tiny movement happens in different ways. Atoms can move along particle surfaces through surface diffusion or travel through lattice or grain boundaries via internal diffusion.

Neck formation starts when particles touch at contact points. Atoms gather at these spots through diffusion and create what metallurgists call “necks”. These connections between particles grow larger as sintering continues. Research shows that bigger necks between particles lead to smaller pores, which creates harder and stronger materials.

Live imaging shows that heat changes surface shapes and causes a lot of surface self-diffusion. Self-diffusing atoms get trapped in gaps between close particles. This leads to new atomic layers forming and growing to create necks.

Role of temperature and pressure in sintering

Temperature shapes the sintering process by controlling how atoms move and diffuse. Precise temperature control matters because diffusion depends heavily on it. Higher temperatures make diffusion faster, which speeds up neck growth and densification. Too much heat can cause problems like unusual grain growth or break down volatile components.

Pressure matters just as much for sintering results. The total sintering pressure combines capillary and external pressures. Studies show that higher pressures make microstructures better, stop grains from growing too much, and help with densification. A study of copper powder showed that more pressure led to 17% harder materials and 10.5% fewer pores.

Temperature and pressure work together to create different processing options. Pressure often affects densification more than temperature by itself. Manufacturers can adjust these settings based on what materials they use and what properties they need. Yttrium oxide pellets made with higher sintering pressures (40-80 MPa) and temperatures (1650-1750°C) ended up denser and had better optical properties.

Sintering of Metals, Ceramics, and Plastics

Materials go through sintering processes that match their chemical and physical properties. The process needs specific conditions to work best. Temperature, pressure, and time play crucial roles in getting the right results.

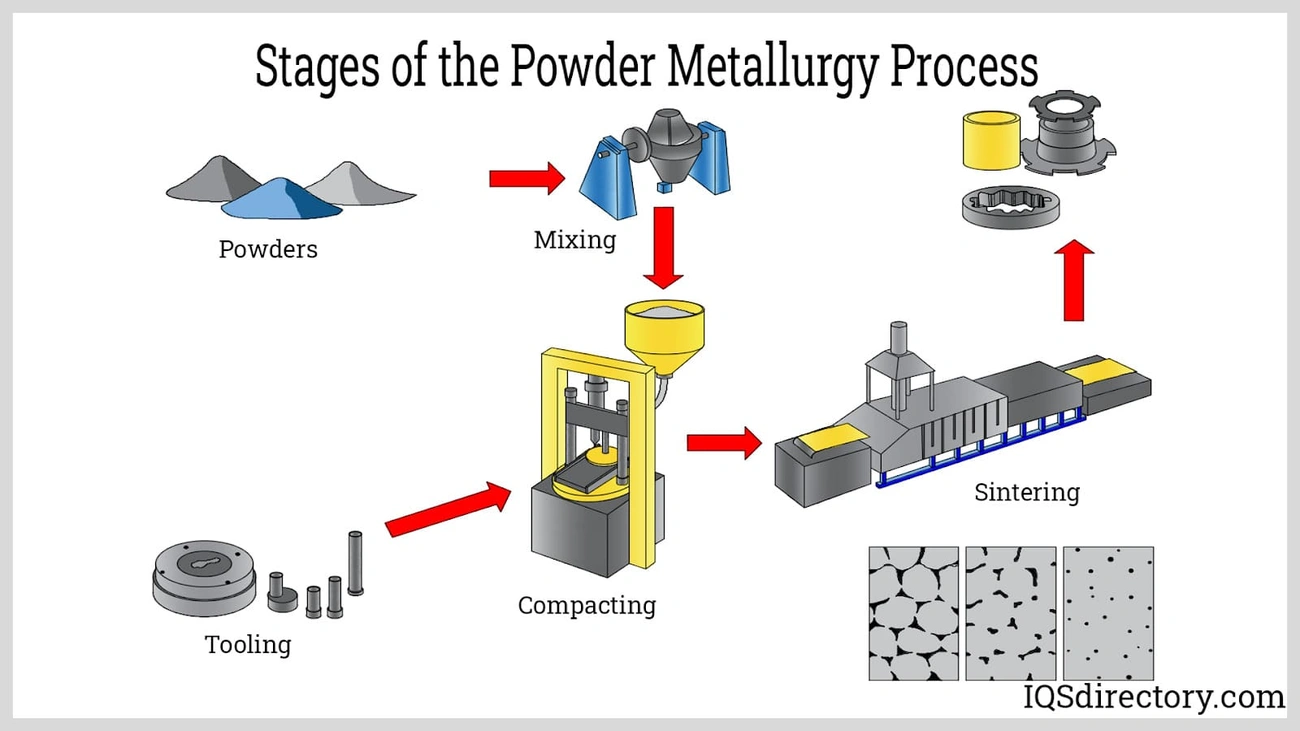

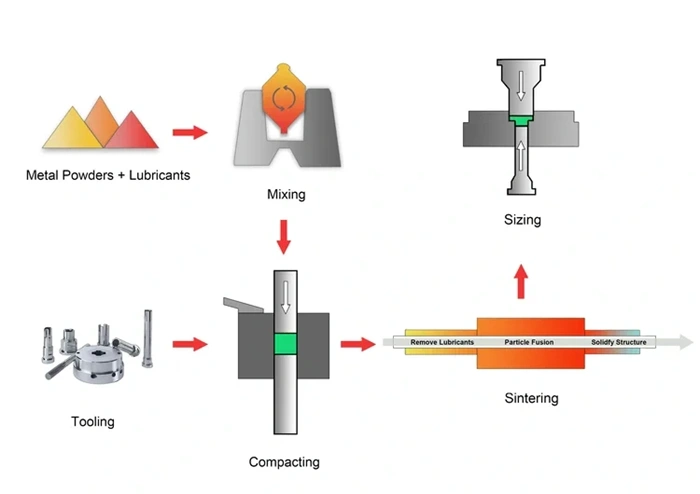

Sintering metal powders: iron, tungsten, and titanium

Metal sintering reshapes loose metal powder into solid objects using heat and pressure without reaching melting temperature. This method works great when you have metals with very high melting points like tungsten, tantalum, and molybdenum, where regular manufacturing just isn’t practical. Metal sintering happens at temperatures between 800°C and 1300°C, and most structural powder metal parts are sintered at about 1120°C.

Iron-based powders are the foundation of the powder metallurgy industry. We used them to make automotive parts, agricultural equipment, and transportation components. These parts get their strength when particles bond together as the metal heats up below its melting point.

Tungsten’s incredibly high melting point means sintering is pretty much the only way to make things with it. You’ll find tungsten in electrical contacts, wiring, and cutting tools. Tungsten carbide needs liquid-state sintering to get its amazing hardness and resistance to wear.

Titanium alloys are tougher to sinter but give you fantastic strength-to-weight ratios for aerospace and medical implants. These materials work best with special techniques like hot isostatic pressing to become fully dense.

Ceramic sintering: alumina, zirconia, and silica

Ceramic sintering needs higher temperatures than metal sintering because ceramics have strong covalent bonds. Alumina (Al₂O₃) stands out as a ceramic that balances ballistic performance and economical solutions. It’s super hard, which makes it perfect for wear-resistant uses, though it does have some limits with density and fracture toughness.

Zirconia (ZrO₂) has a special phase transformation that makes composites tougher. The process turns tetragonal zirconia into monoclinic zirconia, which creates compressive stresses that stop cracks from spreading and make the material stronger. Zirconia-toughened alumina (ZTA) combines the best of both materials, giving you better strength than pure zirconia while keeping good fracture toughness.

Silica mixed with alumina and zirconia creates glass-ceramic composites that work well in dental applications. Two-step sintering is the quickest way to work with ceramic materials because it stops grains from growing too much while still making them dense. The technique starts hot to begin sintering, then cools down to a temperature that helps densification but keeps abnormal grain growth in check.

Plastic sintering: UHMWPE and porous polymers

Ultra-high-molecular-weight polyethylene (UHMWPE) ranks among the most sintered plastics because it resists wear so well and lubricates itself. Scientists are still learning about UHMWPE’s manufacturing process. The material sinters best at temperatures between 180°C and 190°C, usually taking about 10 minutes.

Porous UHMWPE materials made through rotary sintering show even internal structures with high porosity and great mechanical properties. These materials cut friction in half under oil lubrication, and you can reuse them 99% of the time. The sintered UHMWPE’s connected porous structure stores and moves oil around, which means it keeps lubricating itself without needing more lubricant.

Recent advances in UHMWPE sintering create special porous structures with unique properties. A new o-xylene solvent-based sintering method makes UHMWPE surfaces that reflect 93% of sunlight, perfect for keeping buildings cool. These materials can cool things down by about 4.7°C in direct sunlight.

UHMWPE isn’t the only plastic that gets sintered. You’ll find sintered plastics in filtration systems, fluid flow control, and sports equipment like ski and snowboard bases.

Advanced Sintering Techniques and Their Applications

Material science has made great strides with new specialized sintering techniques that go beyond traditional methods. Scientists can now control microstructure with precision, which leads to better properties and new applications.

Spark Plasma Sintering (SPS) for nanomaterials

Spark Plasma Sintering (SPS), also called pulsed electric current sintering, uses high-intensity, low-voltage pulsed current to unite powders faster. The technique heats materials at rates up to 1000°C per minute, which is much faster than regular sintering methods. SPS works at temperatures 200-500°C lower than traditional sintering and still achieves near-theoretical densities.

The process creates clean grain boundaries at the atomic level by applying uniaxial pressure and direct current at the same time, which helps grains bond better. A key benefit is that it keeps nanoscale features during densification. Higher pressures (100 MPa versus 30 MPa) help SPS stop crystallites from growing too much, which protects the material’s nanometric structure.

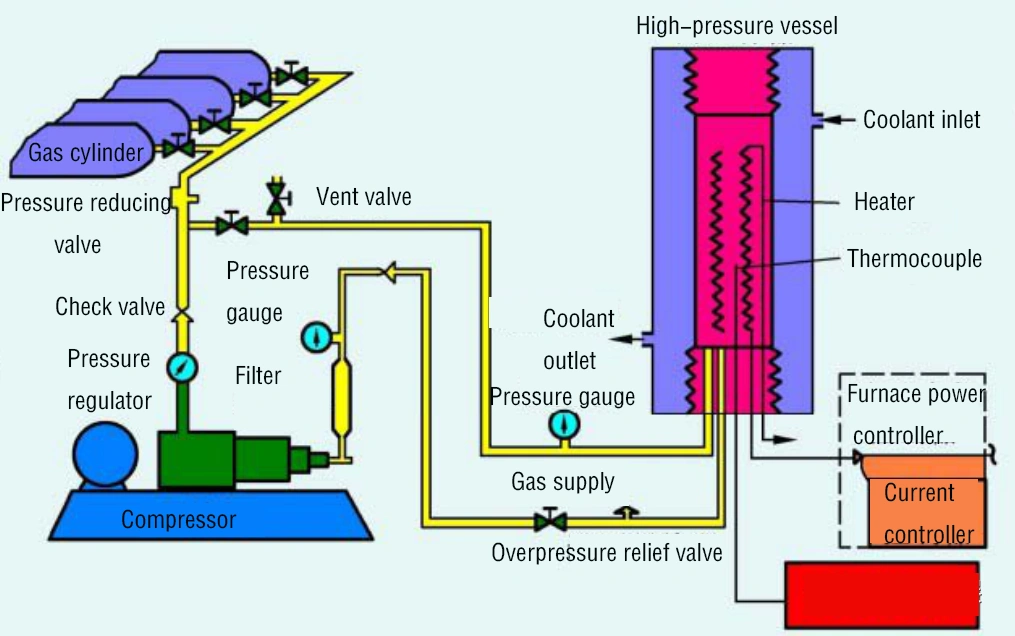

Hot Isostatic Pressing (HIP) for full densification

Hot Isostatic Pressing applies high pressure (100-200 MPa) and heat (800-1350°C) evenly from all sides to create fully dense parts. Regular powder metallurgy parts reach only 85-93% density, but HIP consistently produces parts that are almost 100% dense.

The process happens in three steps: quick initial densification, more consolidation as pressure rises, and finally, any remaining pores become spherical. These pores start with irregular shapes but surface tension makes them round, and they get smaller over time.

HIP is a near-net-shape manufacturing method that wastes less material and often removes the need for expensive welded joints, which cuts production costs. The even pressure also means the whole component has consistent density, which matters a lot for high-performance uses.

Microwave sintering for bioceramics

Microwave sintering uses electromagnetic waves to create heat inside materials, which leads to quick and even heating. This method works better than others because it heats selectively, needs lower temperatures, and keeps out environmental contaminants.

The technique works great with bioceramics. Silicon nitride bioceramics made this way are really strong—928 MPa bending strength and 9.61 MPa·m^(1/2) fracture toughness—while staying biocompatible. Two-step microwave sintering of hydroxyapatite bioceramics creates nanograined structures (78 nm) that are 50% tougher than those made the usual way.

Electro sinter forging for hard metals

Electro sinter forging (ESF) combines powder metallurgy, traditional forging, and field-assisted sintering. This state-of-the-art method uses quick high-current discharge with mechanical pulses to unite metal powders efficiently.

ESF works really well with hard metals and magnetic materials. Nd₂Fe₁₄B-based materials reach full consolidation with coercivities of 400-1400 kA/m. The process lets you make metal composites without long-range diffusion, so hard magnetic flakes can mix with metals like zinc, aluminum, and even high-melting-point metals like molybdenum.

ESF uses less than 6% of the energy needed by direct hot pressing. Quick processing, low energy use, and the ability to create unique material combinations make ESF valuable for industries that need high-performance parts.

Microstructure Evolution During Sintering

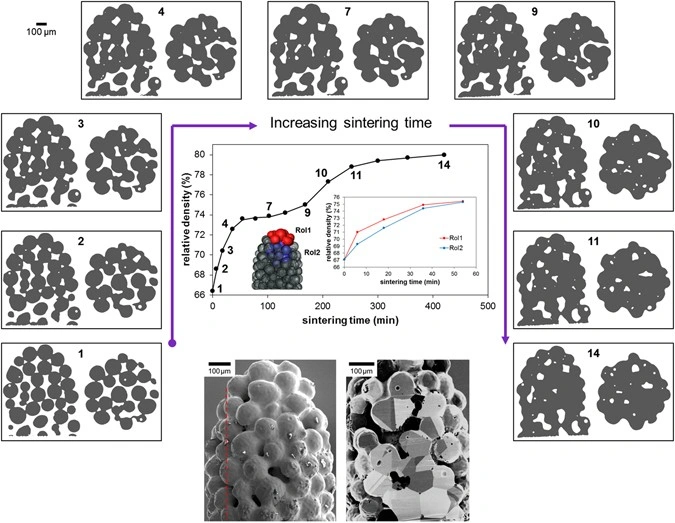

The sintering process creates major changes in microstructure as loose powder combines into a dense solid. Temperature is a vital factor that reshapes the scene, and higher temperatures make atomic diffusion happen faster.

Grain boundary diffusion and grain growth

Grain boundaries work as diffusion pathways and vacancy sinks during sintering. Higher temperatures cause grain boundaries to migrate, which makes smaller grains shrink while larger ones grow. Research proves that higher sintering temperatures reduce both pore numbers and sizes by a lot—from 1,521 pores per field of view to just 17, and from 19.5 μm to 4.8 μm. Materials show exponential grain growth over time, with growth exponents ranging from 2.8 for crystallite growth to 4 for grain growth.

Densification vs. porosity retention

The relationship between pore elimination and density follows a clear pattern during densification. Pores exist in three forms at the start: they can slow down grain growth, move along with grain boundaries, or break away from them completely. Pore size determines how hard they are to eliminate—fine micropores smaller than half the average particle size disappear completely, while coarse micropores tend to join together instead of vanishing.

Reducing abnormal grain growth with solute ions

Solute atoms create pinning effects by gathering at grain boundaries, which restricts their movement. This solute drag effect prevents abnormal grain growth (AGG), stopping certain grains from becoming too large. Adding elements like Ti and Cr to tungsten removes metastable phases and helps maintain the desired α-phase, which keeps it stable up to 1000°C.

Choosing the Right Sintering Method for Your Material

You need to think about material properties, application needs, and mechanical characteristics when choosing a sintering technique. This choice will affect the quality and performance of your final product.

Material compatibility with sintering techniques

Different materials react to sintering conditions based on their makeup, particle size, and melting points. Regular sintering alone can’t fully densify compounds with strong covalent bonding, such as nitrides, carbides, and borides. Refractory metals need high temperatures in reducing atmospheres or vacuum environments to stop oxidation. Zirconia ceramics with different additives react differently to sintering parameters. Yttria-stabilized zirconia’s sensitivity to temperature changes stands out among these materials.

Sintering process selection for automotive vs. aerospace

The automotive sector leads the market for sintered components. A typical vehicle has about 10-15 kg of sintered parts, which adds up to 600 components per vehicle. These parts work in engine components, transmission systems, and braking mechanisms. The aerospace industry takes a different approach. It prefers pressure-assisted sintering techniques like hot isostatic pressing. This method creates components with near-theoretical density that can handle extreme conditions.

Impact of sintering method on mechanical properties

The choice of sintering parameters shapes the final mechanical properties a lot. To name just one example, TiB2-TiN-NiTi cermet material reaches a flexural strength of 762.7 MPa when sintered at 1650°C for 5 minutes. A modified process with a holding stage at 900°C pushes this strength to 931.3 MPa—22.1% higher. Another case shows cerium oxide-containing zirconia ceramics processed through modified spark plasma sintering. These ceramics expressed 33% higher bending strength (609 MPa) compared to yttria-stabilized variants (410 MPa).

Conclusion

Sintering is a key manufacturing process that works well in many industries. This thermal treatment turns loose powder materials into solid components without melting them completely. The process lets manufacturers work with materials that have very high melting points. Atomic diffusion creates neck structures between particles that lead to fully dense materials with better properties.

Different materials react uniquely to sintering conditions. Metal sintering helps create iron parts for cars, tungsten for electrical contacts, and titanium alloys for medical implants. Ceramic materials need higher temperatures because of their strong covalent bonds. Plastic sintering produces specialized materials like self-lubricating UHMWPE components.

New techniques have boosted sintering capabilities well beyond basic methods. Spark Plasma Sintering keeps nanomaterial structures intact through quick processing. Hot Isostatic Pressing reaches near-100% theoretical density by applying uniform pressure. Microwave sintering creates superior bioceramics, while Electro Sinter Forging processes hard metals quickly with less energy.

Microstructural evolution plays a vital role in sintering science. The way grain boundary diffusion, pore elimination, and densification work together shapes the material’s final properties. Manufacturers can control grain growth and get the right microstructural features by managing temperature and adding solute ions.

The right sintering method depends on what works with the material, what it’s needed for, and what properties you want. Car parts can use standard sintering, but aerospace components need pressure-assisted methods to get the best density and performance.

The technology keeps growing with new uses across industries. Scientists now focus on creating green processes, saving energy, and combining materials in ways that weren’t possible before. These advances will expand what sintered materials can do, helping solve tomorrow’s engineering challenges.

The industry’s $23 billion economic impact shows how important it is. But its value goes beyond money – sintering helps make materials with unique properties that drive innovation in many fields. This versatile process will stay crucial for creating next-generation materials that meet tough performance standards.

Key Takeaways

Understanding sintering fundamentals and advanced techniques enables manufacturers to select optimal processes for creating high-performance materials across diverse industrial applications.

• Sintering transforms loose powders into solid components through atomic diffusion at 60-70% of melting temperature, enabling processing of ultra-high melting point materials like tungsten and molybdenum.

• Advanced techniques like Spark Plasma Sintering achieve 1000°C/min heating rates while Hot Isostatic Pressing delivers near-100% theoretical density for critical aerospace applications.

• Material selection drives sintering method choice: metals require reducing atmospheres, ceramics need higher temperatures due to covalent bonds, and plastics like UHMWPE create self-lubricating components.

• Temperature and pressure control directly impact final properties—proper parameter optimization can increase material strength by over 20% while preventing abnormal grain growth.

• The $23 billion sintering industry continues expanding with 10-40% annual growth rates, driven by automotive, aerospace, and medical applications requiring specialized material properties.

Sintering technology represents a cornerstone manufacturing process that bridges the gap between material science and practical engineering applications, enabling the creation of components with previously impossible property combinations.

FAQs

Q1. What is sintering and how does it work? Sintering is a heat treatment process that transforms loose powdered materials into solid, cohesive masses without complete melting. It works by applying high temperature and pressure, causing atoms to diffuse across particle boundaries and fuse together.

Q2. What are the main advantages of sintering? Sintering enhances critical material properties such as strength, electrical and thermal conductivity, and translucency. It also allows for the processing of materials with extremely high melting points that cannot be manufactured using other techniques.

Q3. Which industries commonly use sintered components? The automotive, aerospace, and medical industries extensively utilize sintered components. For example, a typical vehicle contains approximately 10-15 kg of sintered parts, totaling around 600 components.

Q4. How does temperature affect the sintering process? Temperature plays a crucial role in sintering by dictating atomic mobility and diffusion rates. Higher temperatures accelerate diffusion, leading to faster neck growth and densification. However, excessive temperatures may cause undesirable effects like abnormal grain growth.

Q5. What are some advanced sintering techniques? Advanced sintering techniques include Spark Plasma Sintering (SPS) for nanomaterials, Hot Isostatic Pressing (HIP) for full densification, microwave sintering for bioceramics, and electro-sinter forging for hard metals. These methods offer improved control over microstructure and enhanced material properties compared to conventional sintering.