Metal injection molding started as a tiny US$9 million industry in 1986. Today it has exploded into a massive US$1.5 billion market in 2015 . This spectacular growth shows how companies just need this advanced manufacturing process that delivers both plastic injection molding’s versatility and powdered metallurgy’s strength .

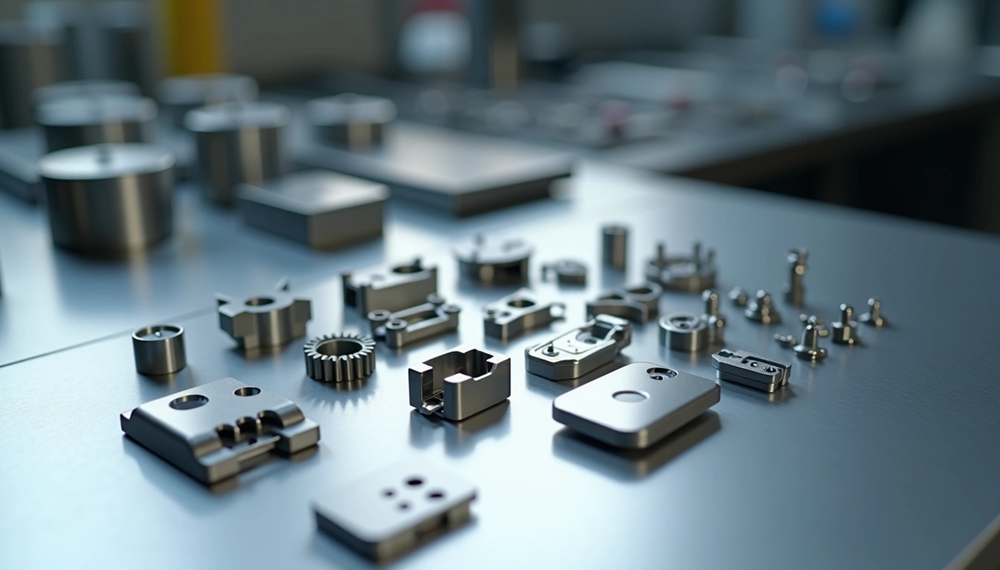

Metal injection molding creates small, complex metal parts that meet strict tolerance and density requirements . Manufacturers can produce intricate components that would be impossible to make any other way . The process is highly efficient – it turns 98% of raw materials into finished parts . The technology emerged in the 1970s and now serves in a variety of industries. Medical equipment, automotive parts, aerospace components, electronics, and consumer goods all benefit from this process.

This technology excels at making diverse products. Surgical tools, orthopedic implants, turbocharger parts, and smartphone components showcase its range. Manufacturers choose this game-changing process because it creates strong, hard, dense components with excellent mechanical properties . Traditional manufacturing methods often can’t match these capabilities.

Understanding the MIM Process and Its Product Capabilities

Metal injection molding blends the versatility of plastic injection molding with powder metallurgy’s material benefits. MIM creates complex parts through multiple steps that turn fine metal powders into solid, functional components with exceptional properties, unlike traditional manufacturing methods.

What is metal injection molding and how it works

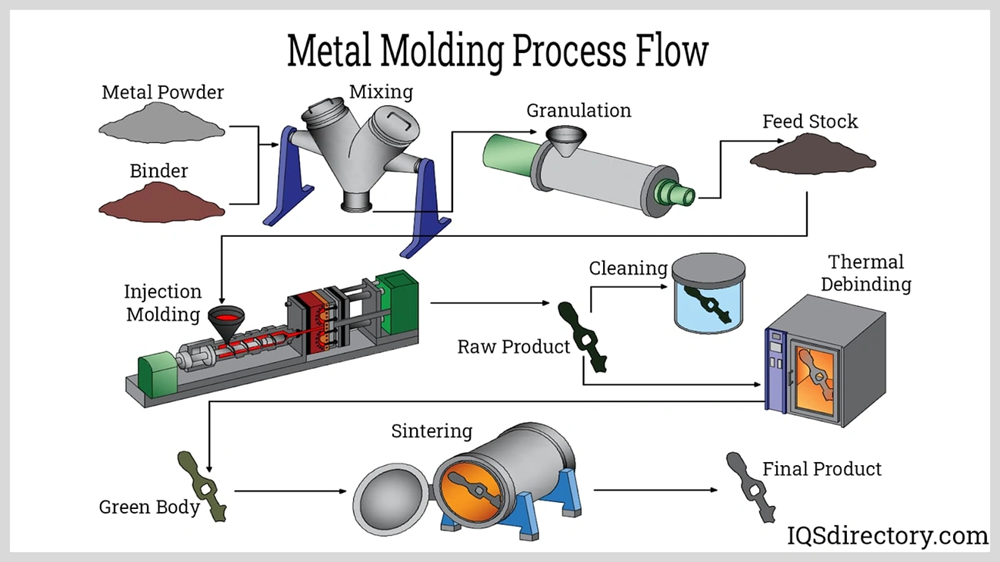

The process starts with feedstock preparation. A precise mix of fine metal powders (typically less than 20 micrometers) combines with a binder system of thermoplastics, waxes, and other materials. The metal-to-binder ratio is close to 60:40, which lets the material flow like plastic while keeping its metal properties. This mixture becomes pellets that work well in molding machines.

The MIM process has four key steps:

- Feedstock Preparation: Metal powders blend with thermoplastic and wax binders in exact amounts. The mixture cools and becomes free-flowing pellets.

- Injection Molding: Heat and high pressure push the feedstock into a mold cavity. The “green part” comes out after cooling.

- Debinding: Thermal, solvent, or catalytic processes remove most of the binder. This creates a “brown part” strong enough to handle.

- Sintering: A controlled-atmosphere furnace heats the brown part to about 85% of the metal’s melting point. The remaining binder evaporates while metal particles fuse into a dense solid part.

Why MIM is ideal for small, complex parts

MIM shines at making components that other methods struggle with or can’t produce. This comes from its unique mix of plastic molding flexibility and metal material qualities.

The best MIM parts weigh under 30 grams, with most between 5-15 grams. Good candidates should fit in your palm, ranging from 2mm to 150mm long, though most average around 25mm. Micro metal injection molding handles even tinier parts – those under a gram with intricate details.

MIM beats conventional manufacturing in several ways. The technique shapes complex and high-melting-point metals without melting them completely. Parts come out dense, which means they’re strong and hard.

Wall thickness plays a big role in MIM parts. Walls thinner than 0.010 inches (0.25mm) might not fill properly because of high shear forces or trapped air. The best results come from parts with even wall thickness, which prevents distortion during sintering.

Shrinkage and density considerations in MIM parts

Managing shrinkage during the sintering process is vital to MIM’s success. Metal particles bond as the part heats near its melting point. The part shrinks and gets denser, creating its final strength and shape.

Parts typically shrink 15-20% linearly during sintering. Manufacturers factor this in from the start. They make mold cavities about 20% larger than the final part size. Different materials shrink differently – 316L and 17-4PH stainless steel use a 1.165 shrink factor, while tungsten alloys need 1.259.

MIM creates parts with impressive densities – 95% to 99% of theoretical values. Density is vital since even small drops affect strength, hardness, and how well parts resist fatigue. Vacuum sintering works better than nitrogen atmospheres because it removes gas pressure from internal pores.

Success depends on many factors like even temperature, proper atmospheric pressure, and stable material flow [6]. When managed properly, MIM consistently produces parts with excellent mechanical properties and precise dimensions.

Medical and Consumer Electronics Applications

Metal injection molding (MIM) plays a key role in medical and consumer electronics. Companies need small, complex, high-precision components to drive product performance and new breakthroughs.

Surgical tools and orthodontic brackets

Medical device makers choose MIM to create detailed surgical instruments for minimally invasive procedures. This method produces strong tools, resist wear and fight corrosion – qualities that medical tools must have. Surgical scissors, forceps, endoscopic jaws, graspers, and dissectors work better thanks to MIM’s ability to shape complex parts with exact measurements. Most of these surgical tools are made from 17-4 PH stainless steel. This material combines high strength with corrosion resistance that matches 300-series stainless steel.

MIM has changed how orthodontic brackets and hooks are made. These tiny, precise parts were some of MIM’s first big successes and still lead the dental market. The process gives these parts the exact shape and smooth finish needed for successful orthodontic treatment without sacrificing patient comfort.

Implantable devices using titanium MIM

Titanium MIM (TiMIM) stands out as the best way to make implantable medical devices. Titanium works well with the human body because it naturally forms a smooth, sticky, thin oxide layer on its surface. This feature, along with its resistance to corrosion, makes titanium perfect for orthopedic and dental implants, artificial joints, pacemakers, bone plates, and screws that fix fractures.

Ti-6Al-4V first appeared in medical use in 1954 and remained the go-to titanium alloy in orthopedics and dentistry for many years. New β-type titanium alloys are becoming popular as they solve problems found in older alloys. TiMIM creates parts without pores that resist corrosion better than stainless steel alloys and work better with the body.

Smartphone hinges and connectors

Consumer electronics make up about 30.8% of MIM market revenue in 2023. Phone makers rely heavily on MIM to produce camera brackets, buttons, frames, hinges, and SIM card slots. These parts are usually small, need high precision, and have complex designs – perfect for MIM production.

Hinges in foldable smartphones show what MIM can do with complex mechanisms. A single two-screen foldable phone might need more than 100 parts, and over thirty are made through MIM. Three-screen devices need two hinge modules with up to sixty MIM parts. These hinges support folding screens while reducing creases and staying strong through thousands of folds.

Wearable device components with tight tolerances

Wearable technology needs very precise parts to work properly in small designs. MIM makers can hit tolerances within ±0.3% of target sizes – about ±0.03 mm on a 10 mm stainless steel part. For detailed parts like Bluetooth headset pieces, they can achieve tolerances as small as ±0.002 inches (±0.05 mm).

Picking the right materials is vital for wearable devices. MIM works with corrosion-resistant stainless steels, medical-grade metals that are safe for the body, light titanium alloys, and metals without nickel for skin contact. MIM can also make parts with walls as thin as 0.010 inches (0.25 mm), sometimes even down to 0.008 inches (0.2 mm). These features make MIM perfect for smartwatch parts, earphone frames, and fitness trackers that need to be both tough and precise.

Automotive, Aerospace, and Defense Components

Critical components in automotive, aerospace, and defense sectors now depend heavily on metal injection molding capabilities. This technology has transformed manufacturing across these industries.

Turbocharger vanes and fuel system parts

MIM produces variable nozzle turbocharger vanes that boost engine efficiency and performance. These components need to withstand extreme temperatures of 800–850°C, especially when made with heat-resistant materials like HK30 austenitic stainless steel. The wing profiles of MIM turbocharger vanes maintain tight dimensional tolerances of ±0.015 mm. This precision ensures optimal air compression that improves power and fuel efficiency.

MIM’s precision makes it perfect for fuel system components like injectors, nozzles and housings. These parts help meet strict emissions standards such as the International Euro 6 policy. The result is better vehicle fuel efficiency through complex, compact designs that stand up to corrosive environments. Companies can cut costs by 65% when they use combined MIM assemblies instead of traditional manufacturing methods.

Sensor housings and fasteners in aerospace

Aerospace companies use MIM to create lightweight components that meet strict industry standards. The sensor housings shield sensitive instruments from harsh conditions like G-forces, vibrations, and temperature changes. These MIM parts achieve dimensional accuracy within ±0.3–0.5%, surface finishes under 1 μm Ra, and thread accuracy of ±0.02 mm.

MIM also produces engine and turbine components such as seals, impellers, and vanes. Aircraft fasteners made from MP35N-sintered MIM provide exceptional strength, durability, and superior corrosion resistance. These properties are crucial for parts exposed to different weather conditions and extreme altitudes.

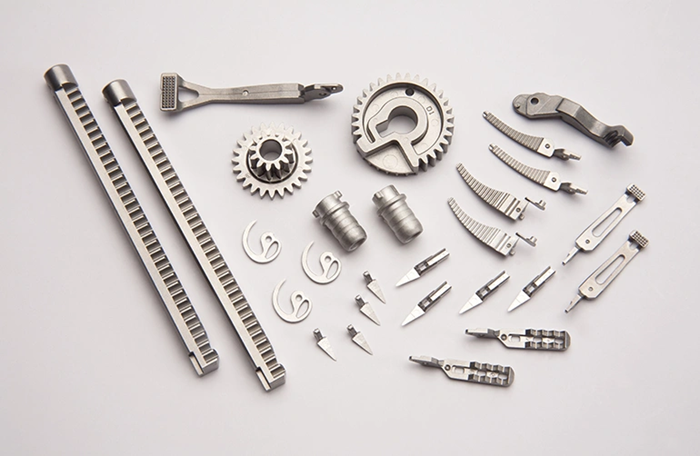

Firearm triggers and military-grade components

The defense sector represents another key market for MIM technology. Firearm parts like triggers, hammers, slides, and safety mechanisms are made better through MIM’s precision in creating complex metal components. MIM titanium triggers weigh less and have exceptional fatigue properties . This improves both handling and performance.

MIM-produced military electronic components meet strict military standards (MIL-STD) for performance, durability, and reliability. The defense industry also uses MIM for “safe and arm” rotors in explosive devices and barrel blocks. These parts need narrow tolerances, superior strength, and exceptional wear resistance.

Industrial, Mechanical, and Home Tooling Products

Metal injection molding has revolutionized how manufacturers create complex mechanical components with great precision. MIM technology makes it possible to produce intricate parts that would cost too much to machine or assemble.

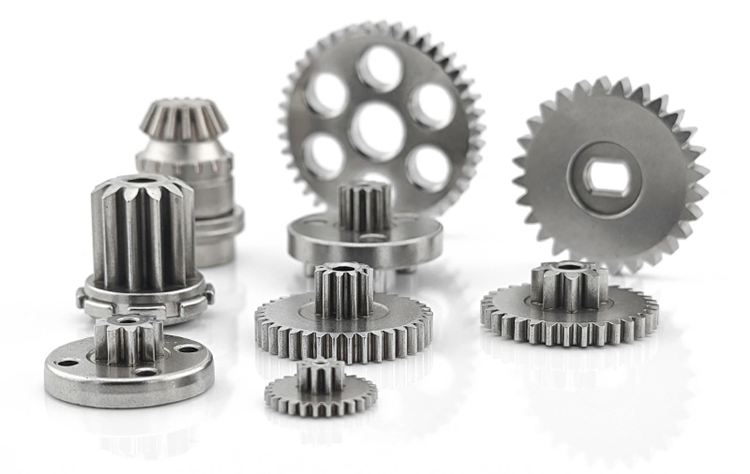

Gears, cams, and structural parts

MIM creates many types of gears that power mechanical systems everywhere. These gears include straight-toothed spur gears for power transmission between parallel shafts, angled-tooth helical gears that run more smoothly, and bevel gears that move power between non-parallel shafts. Manufacturers often boost gear performance through specialized surface treatments. The treatments involve polishing to cut friction, passivation to fight corrosion, and various coatings to reduce wear.

MIM-made cam mechanisms convert rotary motion into back-and-forth or oscillating motion with amazing precision. These parts need very tight tolerances—usually between 0.0001 and 0.002 inches—to work properly in systems like automotive valve trains. MIM also shines at making structural components. Brackets, bushings, and support elements made this way are the foundations of many mechanical assemblies.

Precision tools and cutting inserts

The tooling industry now relies heavily on MIM to make cutting inserts and precision tool components. MIM-made cutting inserts work great against wear thanks to special coatings like TiN, TiCN, and TiAlN. These coatings, first used on twist drills in 1980, improved tool performance in metalworking by a lot.

MIM produces tools that resist wear well with walls as thin as 0.5 mm (20 mil). Notwithstanding that, some high-tolerance components need post-MIM machining to reach their final size, with tolerances as precise as ±15 μm (0.6 mil).

Appliance components like latches and locks

Home and commercial appliances use many MIM parts, especially in locks and latching mechanisms. MIM offers big advantages for lock housings, cylinders, carriers, pins, and other security components. In fact, a typical lock system has MIM-produced lock cylinders, bolts, latches, retaining plates, and even keys.

Appliance makers use MIM to create valves, connectors, handles, hinges, and supports. The process lets manufacturers combine multiple parts into single components. This eliminates the need for screws, adhesives, or welding—which cuts both weight and cost. MIM’s surface finish options range from matte to highly polished, giving appliance designers plenty of cosmetic choices.

Luxury, Fashion, and Miscellaneous MIM Products

Metal injection molding has become the life-blood of luxury goods manufacturing. This technology brings together precision, esthetics, and durability in remarkable ways.

Watch cases and eyeglass hinges

Citizen Watch Co. led the way in watchmaking with MIM technology. They built their first MIM facility in Tokyo back in 1987 to make stainless steel watch cases and tungsten alloy balance weights. Swatch took the next big step. They launched their first MIM-produced nickel-free 316L stainless steel Irony watch cases in October 1994. This manufacturing method has become the life-blood of luxury timepieces and opens up design possibilities that weren’t achievable before.

MIM capabilities have transformed eyewear manufacturing too. The technology shines in creating revolutionary rotating spring hinges. These innovative parts weigh just 2.6g and use polished, nickel-coated 316L stainless steel. They feature two rotating disks at a 27° angle that give the spectacle temple a spring effect. Spectacle frames now represent a major sector for MIM applications.

Jewelry and decorative metal parts

The jewelry industry has embraced MIM techniques, especially for complex geometric designs. The process stands strong against traditional investment casting operations. It works with various stainless steel grades including 316L, 304, and 17-4PH. These parts then go through polishing, wire-drawing, sandblasting, or plating treatments to create stunning finishes.

EMI shielding and magnetic components

Electronic devices need electromagnetic interference (EMI) protection because almost every electrical signal creates some EMI/RFI interference. MIM components play a crucial role in specialized shielding, particularly with ASTM A753 Type 4 specialty alloys.

Custom fasteners and identity-marked parts

MIM excels at making customized fasteners with identity markings and maintains dimensional tolerances of ±0.3%. The beauty of MIM lies in its flexibility – adding identity marks to components doesn’t typically increase production costs, unlike traditional manufacturing methods.

Conclusion

Metal Injection Molding has reshaped the manufacturing landscape and revolutionized production capabilities in countless industries. This piece explores how MIM blends the versatility of plastic injection molding with powder metallurgy. The result? Small, complex metal parts with exceptional precision and quality. On top of that, it converts up to 98% of raw materials into usable components while maintaining tight tolerances and high densities.

MIM applications cover an impressive range of sectors. Medical professionals count on MIM-produced surgical instruments, orthodontic brackets, and titanium implants for life-saving procedures. Consumer electronics manufacturers need MIM to create smartphone hinges, connectors, and wearable device components that combine miniaturization with durability. The automotive and aerospace industries benefit from MIM’s capacity to produce turbocharger vanes, fuel system parts, and sensor housings that handle extreme conditions.

MIM technology shines at creating precision gears, cams, cutting tools, and structural components for industrial machinery. Without doubt, luxury markets have embraced MIM to produce watch cases, eyeglass hinges, and decorative metal parts with exquisite finishes.

The widespread adoption of MIM in a variety of sectors showcases its remarkable versatility. Manufacturers value MIM because it produces previously impossible geometries. The process delivers exceptional material properties, including strength, hardness, and corrosion resistance. MIM provides cost advantages for medium to high-volume production runs compared to traditional manufacturing methods.

Materials science advances and production techniques continue to improve. MIM will expand into new applications that need both complex designs and superior mechanical properties. This manufacturing process remains vital for industries that need precise, durable components in increasingly miniaturized and sophisticated products.

Key Takeaways

Metal Injection Molding (MIM) has revolutionized manufacturing by enabling the production of small, complex metal parts with exceptional precision across diverse industries.

• MIM excels at creating small, complex parts – Ideal for components under 30 grams with intricate geometries that traditional manufacturing cannot efficiently produce

• Medical and electronics drive major adoption – From titanium implants and surgical tools to smartphone hinges and wearable components requiring tight tolerances

• Process combines plastic molding flexibility with metal strength – Achieves 95-99% density with minimal waste, converting 98% of materials into usable parts

• Critical for high-performance applications – Automotive turbocharger vanes, aerospace sensors, and defense components rely on MIM’s precision and durability

• Enables luxury and precision manufacturing – Watch cases, cutting tools, and custom fasteners benefit from MIM’s ability to create previously impossible designs

The technology’s 15-20% shrinkage during sintering requires careful design consideration, but delivers unmatched capabilities for producing strong, precise components that would be difficult or impossible to manufacture through conventional methods.

FAQs

Q1. What is Metal Injection Molding (MIM) and how does it work? Metal Injection Molding is a manufacturing process that combines powdered metals with a binder to create complex metal parts. The mixture is injected into a mold, the binder is removed, and the part is sintered to achieve its final properties.

Q2. What types of products are commonly made using MIM? MIM is used to produce a wide range of small, complex parts including medical devices, automotive components, consumer electronics, aerospace parts, and precision tools. Examples include surgical instruments, smartphone hinges, turbocharger vanes, and watch cases.

Q3. What are the advantages of using MIM over traditional manufacturing methods? MIM offers several advantages including the ability to create complex geometries, high material utilization (up to 98%), excellent mechanical properties, and cost-effectiveness for medium to high-volume production runs. It also allows for the production of parts that would be difficult or impossible to make using conventional methods.

Q4. What materials can be used in the MIM process? MIM can work with a variety of metals and alloys including stainless steel, titanium, tungsten, and nickel-based alloys. The choice of material depends on the specific application and desired properties of the final product.

Q5. What are the size limitations for parts produced by MIM? MIM is best suited for small, complex parts. Typically, MIM parts weigh under 30 grams, with most averaging between 5-15 grams. The ideal size range is from 2mm to 150mm in length, with most parts averaging around 25mm. Micro-MIM can produce even smaller parts weighing less than a gram.