Zirconia vs Ceramic: Breaking Down Material Strength Tests for Industry

Engineers face a crucial choice between zirconia and ceramic materials due to their vastly different strength values. Zirconia (ZrO₂), which scientists call zirconium dioxide, shows remarkable mechanical properties. Its flexural strength reaches 900-1200 MPa, and compression resistance hits approximately 2000 MPa. These numbers put it right up there with stainless steel, setting zirconia apart from other ceramic materials.

Yttria-stabilized zirconia (YSZ) stands out with its impressive fracture toughness of 9-10 MPa·m½ – one of the highest ratings among all ceramics. Zirconia’s exceptional hardness and wear resistance make it the perfect choice, especially when you have abrasive conditions. To name just one example, zirconia cutting tools have earned a reputation for durability and precision in industries of all sizes. The material’s strength adapts to different uses – from hip replacements with compressive strength of 2580 MPa to dental applications that need fracture toughness of 4-5 MPa m½.

We’ll get into the key differences between zirconia and other ceramic materials here. The discussion covers their performance in strength tests, specific application requirements, and provides an explanation about failure analysis to help with design choices.

Material Composition and Microstructure Differences

The basic differences between zirconia and traditional ceramics start at the microscopic level. Their composition and structure directly affect how they perform.

Zirconia Grain Size and Stabilizer Additives

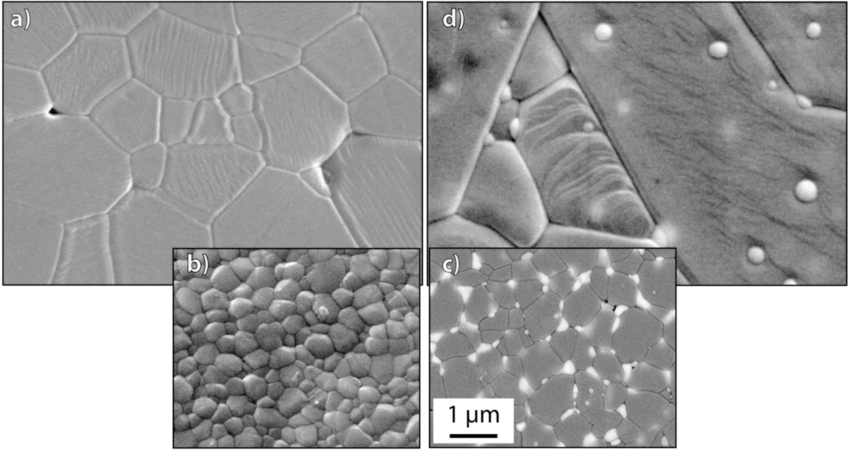

A close look at the microstructure shows that zirconia’s properties change by a lot based on stabilizer content and crystal phases. Yttria-stabilized zirconia (YSZ) shows different phase compositions that depend on yttrium content. Higher yttrium creates more cubic phase presence (5Y > 4Y > 3Y). Tetragonal zirconia polycrystals (TZP) have fine-grained structures (typically below 2 μm) and keep excellent mechanical properties through transformation toughening. The 3Y-TZP shows better grain uniformity than 4Y and 5Y variants that display surface pores.

Stabilizers such as yttria, magnesia, and ceria stop harmful phase transformations. Magnesia-stabilized zirconia (MSZ) resists low-temperature degradation well. Ceria-stabilized zirconia (Ce-TZP) reaches exceptional fracture toughness of 11-12 MPa·m1/2. Partially stabilized zirconia (PSZ) has coarser grains (25-75 μm) with metastable tetragonal precipitates inside cubic matrices.

Alumina and Silicate-Based Ceramic Structures

Alumina-based ceramics show high crystalline content with minimal porosity (0.1-0.2%). This results in better mechanical performance than silicate-based materials. Adding silica to alumina changes properties by a lot. The flexural strength rises from 13.3 MPa to 46.3 MPa when silica content increases from 0% to 30%. This happens because of mullite phase formation.

Silicate-based ceramics contain more amorphous phases. This limits their mechanical strength. To name just one example, porcelains have lower characteristic strength values (68-75 MPa) compared to zirconia. Porcelains’ critical flaw size (75-86 μm) is larger than high-crystalline framework materials (34-48 μm).

Effect of Microstructure on Mechanical Behavior

Transformation toughening explains why zirconia performs better. Tetragonal crystals transform to a monoclinic structure under stress and expand by about 4%. This volume increase creates compressive stresses that block crack growth, which makes fracture resistance much better.

Grain size plays a crucial role in all ceramics’ mechanical properties. Research shows that larger grain sizes improve fracture toughness in 3Y-TZP ceramics from 0.1 μm to 1.4 μm. However, there’s a critical point where spontaneous transformation occurs. This is a big deal as it means that ultrafine-grained Ce-TZP ceramics with average grain sizes below 500 nm can reach three-point bending strengths over 800 MPa.

Performance in Industrial Strength Tests

Industrial testing gives us vital data to determine if materials suit demanding applications. Zirconia performs better than traditional ceramics in standard tests.

3-Point Bending Test Results: Zirconia vs Ceramic

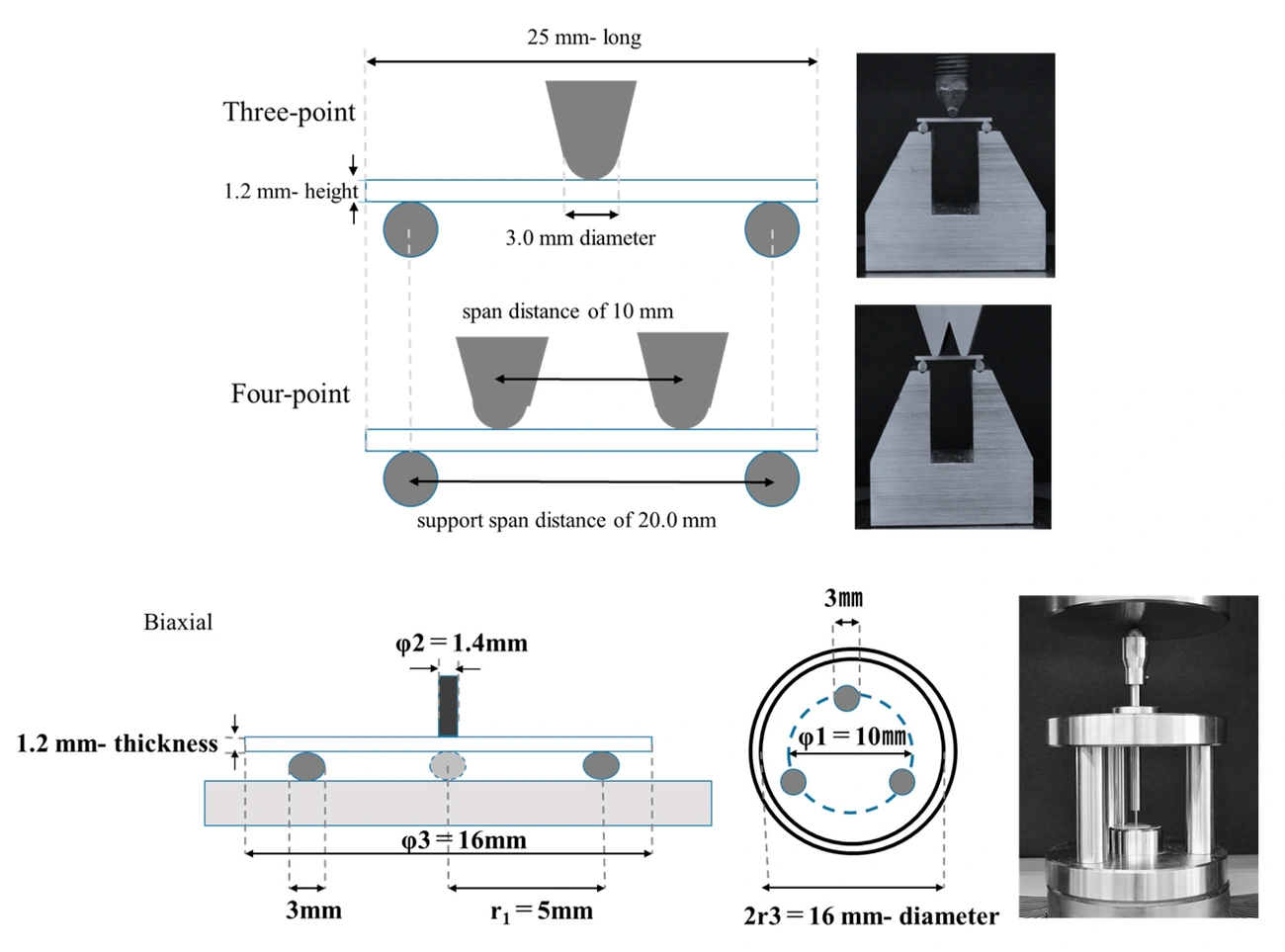

Three-point bending tests are the standard way to measure ceramic flexural strength per ISO 6872 specs. Lab tests show zirconia has remarkable flexural strength between 900-1200 MPa, this is a big deal as it means that it outperforms traditional ceramics. Tests on polished zirconia samples (25mm length, 5mm width, 2mm thickness) reached about 1000 MPa flexural strength.

Test methods affect results by a lot. Biaxial testing gives higher values than three-point bending. Span length settings also change the outcomes—shorter spans show higher flexural strength. This explains why manufacturers often report different strength values for similar materials.

Compressive Strength: 2000 MPa in ZrO2

Zirconia shows impressive compressive strength at 2000 MPa in materials of all types. This exceptional resistance to compression makes it perfect for load-bearing uses where materials face strong forces. Zirconia’s compressive strength beats alumina-based ceramics by a mile.

Ultra Tough zirconia types keep this 2000 MPa measure even after HIP (Hot Isostatic Pressing) treatments. This proves the material stays consistent across different processing methods.

Fatigue Resistance Under Cyclic Loading

Zirconia loses some strength during long-term cyclic loading. Research with 3 million cycles at low stress shows that polished zirconia samples lose about 38% flexural strength. But this beats surface-damaged samples, which lose 67% strength after similar testing.

Looking at it under a microscope shows that fatigue failure happens because grain boundaries thicken and micro-cracks form on tensile surfaces. Notwithstanding that, all tested samples survived cyclic loading—showing zirconia’s unique crack resistance.

Surface Treatments’ Effect on Strength

Surface treatments change zirconia’s long-term performance drastically. Mechanical polishing boosts flexural strength from about 700 MPa to 1000 MPa. But sandblasting with coarse alumina particles (110 μm) drops the original flexural strength to 720 MPa and reduces fatigue resistance further.

Commercial coloring liquids don’t change mechanical strength much. Surface roughness where the core meets the veneer plays a vital role in how things fail. Dental applications show that air-particle abrasion and hot hydrofluoric acid etching give the best shear bond strength (about 18 MPa). This ensures reliable prosthetic performance.

Application-Specific Strength Requirements

Selecting materials for specialized applications requires a deep grasp of strength requirements beyond standard testing. Each industry presents unique challenges that help determine if zirconia or traditional ceramics will work best.

Dental Implants: Load-Bearing and Biocompatibility

Zirconia dental implants have become popular because they integrate well with bone and are highly biocompatible. Yttria tetragonal zirconia polycrystal (Y-TZP) shows impressive flexural strength of 1200 MPa and performs better than traditional porcelain-fused metal crowns. Y-TZP’s high fracture toughness pairs well with excellent corrosion resistance. Bacteria grow less on zirconia compared to titanium, which reduces plaque buildup. Solid zirconia restorations can handle extreme forces without breaking, making them perfect for patients who grind their teeth. Layered zirconia crowns stay biocompatible in the mouth but need standard cementation with resin ionomers.

Cutting Tools: Edge Retention and Wear Resistance

Zirconia ceramic beats conventional materials in precision cutting through better hardness and wear resistance. Surgical blades crafted from zirconia stay sharp much longer than standard options. This durability comes from strong mechanical properties and resistance to wear, corrosion, and abrasion. Manufacturing remains tricky because zirconia’s hardness requires special diamond tools and advanced machining methods.

Thermal Barrier Coatings: Aerospace Use Cases

Aerospace parts depend on thermal barrier coatings made from yttria-stabilized zirconia (YSZ) ceramic layers over oxidation-resistant metallic bond coats. These protective systems cut down heat transfer to base materials and extend part life. TBCs shield critical components like transition ducts, combustors, heat shields, and turbine blades. These coatings handle extreme temperatures up to 1482°C while providing excellent heat insulation.

Solid Oxide Fuel Cells: Ionic Conductivity at High Temperature

Solid oxide fuel cells employ zirconia-based electrolytes, mainly yttria-stabilized zirconia (YSZ), that work best at temperatures between 600-900°C. Thin electrolytes ranging from 75-360 µm show biaxial strength of 520-940 MPa. The ionic conductivity reaches beyond 0.1 S/cm at 1000°C. Tape-casting methods create YSZ with 98% relative density and 2-3 µm grain size for optimal electrolyte performance. Scandium-doped zirconia proves even more conductive at 0.003 S/cm at 500°C, making it valuable for lower-temperature uses.

Failure Analysis and Design Considerations

Understanding how zirconia and ceramics fail reveals key factors that affect their performance in tough applications.

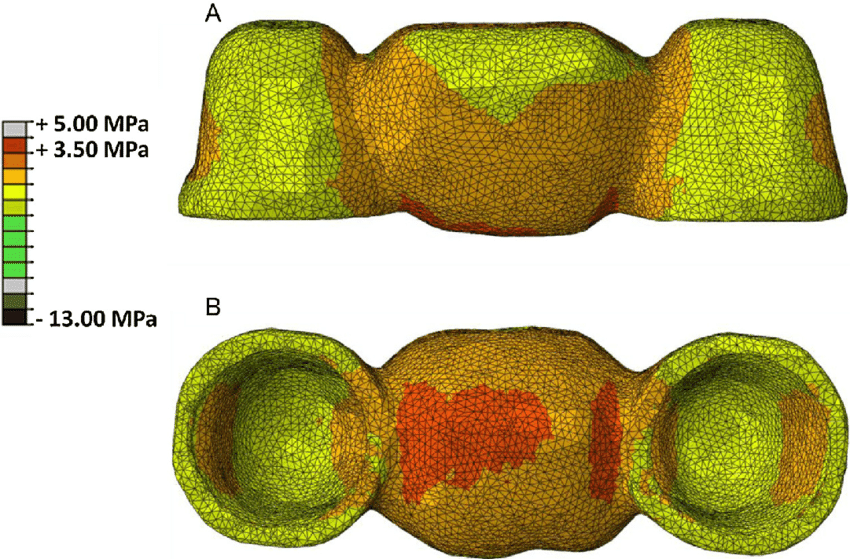

Connector Geometry and Stress Distribution

The strength of zirconia substantially depends on stress concentration, and connector geometry creates stress magnification factors of 2-3. All-ceramic bridges typically break from the connector regions. The connector’s minimum dimensions should handle both functional loads and geometric stress factors. Multi-unit bridges experience higher stress in connector areas when loads hit pontic elements. The tension values go up as oblique load angles become larger (35°).

Chipping in Veneered Zirconia Crowns

Chipping remains the most common way these materials fail. About 53-59% of failures happen through porcelain chipping instead of complete framework breakage. Catastrophic failures often start with radial cracks on the inner surfaces of 3Y-TZP frameworks. Graded zirconia proves four times stronger than porcelain-veneered zirconia. Clinical data show veneered zirconia restorations have 54% more veneer fractures than metal-ceramics.

Thermal Expansion Mismatch and Bond Failures

The difference in the Coefficient of thermal expansion (CTE) between zirconia and veneering materials plays a crucial role in bond strength. The best results come from a CTE difference of 0.77-0.87×10-6/°C below zirconia’s CTE, which creates helpful compressive stress. CTE mismatches above 1.0×10-6/°C lead to high failure rates. Cooling things down slowly helps reduce leftover thermal stresses that cause veneer fractures.

Coloring Pigments Impact on Surface Integrity

Different coloring methods create varying surface characteristics. Pre-colored zirconia shows the highest Vickers hardness (1302.95±31.60 HN). White zirconia has the roughest surfaces (Ra=0.44±0.22µm). The smoothest finish comes from external staining through coloring liquid immersion (Ra=0.19±0.03µm). Ferric oxide coloring pigments gather at grain boundaries and reduce bond strength.

Pressed vs Layered Veneering Techniques

Pressing techniques work better mechanically than traditional layering. Pressed zirconia prostheses break and chip less often than layered ones. CAD/CAM-made lithium disilicate ceramics attached to zirconia frameworks resist fracture better (1565±137N) than manually veneered crowns (1166±189N). All the same, pressing techniques with precolored ingots might limit esthetic results.

Conclusion

Zirconia performs better than traditional ceramics in multiple strength parameters. This makes it the best choice to use in demanding industrial applications. The mechanical properties are impressive – flexural strength reaches 1200 MPa and compression resistance is about 2000 MPa. These numbers show that zirconia rivals stainless steel. On top of that, it has a unique transformation toughening mechanism. Tetragonal crystals transform to monoclinic structure under stress. This explains zirconia’s remarkable fracture resistance that other ceramics cannot match.

Material composition and microstructure substantially influence how well it performs. Engineers just need to think about stabilizer additives like yttria, magnesia, and ceria when they choose zirconia variants. The testing method is a vital part too. Similar materials show different strength values based on the testing approach. Biaxial testing usually shows higher values than three-point bending tests.

Surface treatments have a dramatic effect on long-term performance. Mechanical polishing boosts flexural strength from about 700 MPa to 1000 MPa. However, sandblasting with coarse alumina particles reduces the original flexural strength and lowers fatigue resistance. So manufacturers must balance their processing techniques with the mechanical outcomes they want.

Application requirements help distinguish which material to select. Dental implants work well with zirconia because of its biocompatibility and osseointegration capabilities. Aerospace parts use thermal barrier coatings made of yttria stabilized zirconia to protect against extreme temperatures. Cutting tools made from zirconia stay sharp longer than traditional options because they’re harder and resist wear better.

Failure analysis shows significant design factors, especially when you have connector geometry and stress distribution. In veneered zirconia crowns, chipping happens more often than complete framework fracture. The difference in thermal expansion coefficients between zirconia and veneering materials affects bond strength and how long it lasts.

Material scientists and engineers choose zirconia more often than traditional ceramics to use in critical applications that need exceptional strength. Designers can make use of zirconia’s superior mechanical characteristics and minimize its limitations by carefully examining microstructure, application requirements, and what might cause it to fail.

Key Takeaways

Understanding the fundamental differences between zirconia and traditional ceramics is crucial for engineers making material selection decisions in high-performance applications.

• Zirconia delivers exceptional strength with 1200 MPa flexural and 2000 MPa compressive strength, rivaling stainless steel performance • Transformation toughening mechanism gives zirconia superior fracture resistance through tetragonal-to-monoclinic crystal transformation under stress • Surface treatments dramatically impact performance—polishing increases flexural strength 43% while sandblasting reduces it significantly • Application-specific requirements determine optimal material choice: dental implants benefit from biocompatibility, aerospace needs thermal barriers • Failure analysis reveals connector geometry and thermal expansion mismatches as critical design factors in preventing catastrophic failures

When selecting between zirconia and traditional ceramics, engineers must balance exceptional mechanical properties against processing complexity and application-specific requirements. The superior strength characteristics make zirconia the preferred choice for demanding industrial applications where reliability and performance are paramount.

FAQs

Q1. How does zirconia compare to traditional ceramics in terms of strength? Zirconia significantly outperforms traditional ceramics in strength tests. It exhibits exceptional flexural strength of 900-1200 MPa and compressive strength of around 2000 MPa, rivaling the performance of stainless steel. This superior strength makes zirconia an ideal choice for demanding industrial applications.

Q2. What makes zirconia more fracture-resistant than other ceramics? Zirconia’s unique transformation toughening mechanism gives it superior fracture resistance. Under stress, tetragonal crystals in zirconia transform to a monoclinic structure, expanding and creating compressive stresses that oppose crack propagation. This mechanism significantly enhances its overall fracture resistance compared to conventional ceramics.

Q3. How do surface treatments affect zirconia’s performance? Surface treatments dramatically impact zirconia’s strength. Mechanical polishing can increase flexural strength from about 700 MPa to 1000 MPa. Conversely, sandblasting with coarse alumina particles can reduce initial flexural strength and decrease fatigue resistance. The choice of surface treatment is crucial for optimizing zirconia’s long-term performance.

Q4. In which applications does zirconia excel over traditional ceramics? Zirconia excels in various applications due to its superior properties. Dental implants offer excellent biocompatibility and osseointegration. For aerospace components, yttria-stabilized zirconia provides effective thermal barrier coatings. In cutting tools, zirconia maintains sharpness longer due to its exceptional hardness and wear resistance.

Q5. What are the key considerations in designing with zirconia to prevent failures? When designing with zirconia, key considerations include connector geometry and stress distribution, especially in multi-unit structures. Thermal expansion mismatches between zirconia and veneering materials can affect bond strength. For veneered zirconia crowns, chipping is a common failure mode. Understanding these factors is crucial for preventing catastrophic failures and ensuring long-term reliability.