Alumina ceramic stands among the hardest materials we know. It scores 9 on the Mohs scale and serves as an exceptional material for tough engineering applications. The material contains over 99.99% alumina and shows remarkable durability. It resists wear, high temperatures, and mechanical stress effectively. Engineers value this ceramic especially when they have to deal with extreme thermal conditions. The material withstands temperatures up to 1650°C in a normal atmosphere and can handle up to 2000°C in a vacuum.

Alumina ceramic stands among the hardest materials we know. It scores 9 on the Mohs scale and serves as an exceptional material for tough engineering applications. The material contains over 99.99% alumina and shows remarkable durability. It resists wear, high temperatures, and mechanical stress effectively. Engineers value this ceramic especially when they have to deal with extreme thermal conditions. The material withstands temperatures up to 1650°C in a normal atmosphere and can handle up to 2000°C in a vacuum.

You’ll find alumina ceramic materials in many industries, from everyday products to advanced engineering solutions. Its unique properties make it useful way beyond standard applications. The material’s strength remains impressive even at high temperatures. At 1000°C, it keeps 50% of its tensile strength compared to room temperature readings. Alumina ceramic tubes are great insulators against extreme temperatures. They also resist erosion and corrosion remarkably well. These qualities make alumina ceramics essential in places that just need chemical inertness and corrosion resistance. Engineers get outstanding performance and great value for money with this material.

Material Science Behind Alumina Ceramic Properties

Alumina ceramic’s unique properties come directly from its atomic structure and bonding mechanisms. Learning about these basic elements shows why this material works so well in engineering environments that just need high performance.

Alumina Oxide Ceramic Structure and Bonding

Alpha-alumina (corundum), aluminum oxide’s most common form, has a hexagonal closed packing (HCP) structure. Each Al³⁺ ion sits surrounded by six O²⁻ ions. Larger O²⁻ ions take up octahedral voids while smaller Al³⁺ ions fill tetrahedral voids. Together, they occupy about 74% of the interstitial space. This crystal structure creates strong ionic bonds between aluminum atoms that lost 3 electrons and oxygen atoms that gained 2 electrons. Alumina exists in several metastable phases beyond its stable alpha phase. These include cubic γ- and η-phases, monoclinic λ, θ phases, and hexagonal χ-phase. These ionic bonds are so strong that alumina’s melting point reaches 2,072°C with a boiling point of 2,977°C.

Grain Size and Density Effects on Strength

Grain size shapes alumina’s mechanical properties substantially. Studies show that smaller grain sizes lead to higher fracture strength, particularly between 1.7 and 11 μm. Alumina samples with narrow grain size ranges show more consistent strength compared to wider distributions. The material’s fracture behavior changes from intergranular to transgranular as grain size grows. This affects the overall toughness. Density plays a crucial role too, with a theoretical maximum of 3.95 g/cm³. Denser alumina ceramics typically show better mechanical strength, wear resistance, and thermal conductivity. The atmosphere during sintering affects how well the material densifies. Research reveals different densification rates between oxygen and air sintering at various heating speeds.

Thermal Conductivity vs. Thermal Resistivity in Al2O3

Alumina stands out among ceramics with its exceptional thermal conductivity of 30-35 W/mK at room temperature. Both thermal diffusivity and conductivity drop as temperatures rise. The material maintains its shape under heat stress thanks to a steady thermal expansion coefficient of about 8.2 × 10⁻⁶/°C from 25-1000°C. These features create a rare combination – excellent heat conduction paired with superior electrical insulation (volume resistivity >10¹⁴ ohm·cm). This makes alumina perfect for thermal management systems that just need electrical isolation.

Mechanical and Thermal Advantages in Engineering Applications

Engineers choose alumina ceramic material because of its outstanding mechanical and thermal performance in tough industrial settings. This material combines properties that make it perfect for applications needing both durability and thermal stability.

Hardness on Mohs and Vickers Scales

Alumina ceramic shows incredible hardness at 9 on the Mohs scale, which puts it right below diamond (10) in scratch resistance. The material is about three times harder than stainless steel, making it perfect for parts under extreme mechanical stress. Tests on the Vickers hardness scale show alumina ceramics range from 1340 HV to over 1700 HV based on purity and manufacturing. The material’s hexagonal crystal structure creates strong atomic bonds that stop dislocations under external forces. This makes it excellent for applications that need structural strength under load, like cutting tools and precision parts.

Thermal Shock Resistance up to 1650°C

The material’s best features include knowing how to keep its structure intact at extreme temperatures. Alumina stays stable in both oxidizing and reducing atmospheres up to 1650°C. The material keeps 50% of its tensile strength at 1000°C compared to room temperature. Grain size, microcracks, porosity, and geometric dimensions affect its thermal shock resistance. Yes, it is possible to boost this property by adding specific compounds like Al2TiO5. This remarkable thermal stability lets alumina work in high-temperature applications where other materials fail.

Wear Resistance in High-Friction Environments

Alumina oxide ceramic shows exceptional wear resistance when friction is high, with wear rates as low as 0.00052‰. This relates directly to its hardness, while its stable crystal structure, high density, chemical stability, and low friction coefficient also help. The ceramic works great in bearings, seal rings, valves, and wear-resistant parts where metals or plastics would wear out faster.

Electrical and Chemical Stability in Harsh Conditions

Alumina ceramic stands out for more than just its mechanical strength. Its remarkable electrical and chemical stability makes it perfect for harsh operating conditions. These qualities are a great way to get reliable performance where electrical insulation and corrosion resistance matter most.

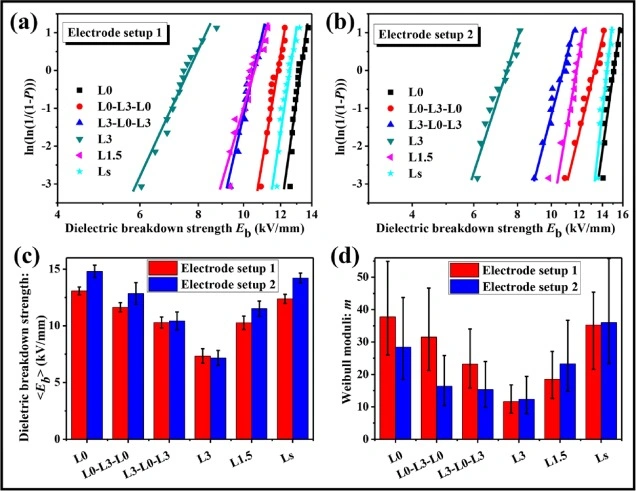

Dielectric Strength at 635 µm Thickness

Alumina ceramic shows impressive dielectric breakdown strength of 21 kV/mm at room temperature when tested at the standard 635 µm thickness. The material’s purity plays a key role – higher alumina content leads to better dielectric performance. Tests show that thinner samples have higher dielectric strength than thicker ones. The material’s performance depends on several factors. Mechanical stress can make a big difference – applying mechanical prestress at 50% of the mechanical breakdown value drops the dielectric strength by about 12%. The firing conditions also matter. Wet hydrogen firing helps improve dielectric breakdown strength, while dry hydrogen does the opposite.

Volume Resistivity and Insulation Performance

The insulating properties of alumina ceramics are outstanding, with volume resistivity values that are a big deal, as it means that they exceed 10¹⁴ ohm-meters at room temperature. Temperature changes affect these values significantly. The resistivity drops from >10¹⁴ ohm-cm at 25°C to 2.0 × 10¹¹ ohm-cm at 300°C, and reaches 1.8 × 10⁹ ohm-cm at 500°C. High-purity alumina (≥94%) leads the pack with the highest resistivity among ceramics. This makes it the perfect choice when you need reliable electrical isolation across different temperatures.

Chemical Inertness in Acidic and Alkaline Environments

The chemical resistance of alumina ceramic material truly shines. It easily handles sulfuric, hydrochloric, nitric, and phosphoric acids. While hydrofluoric acid and hot concentrated phosphoric acid can cause some damage, alumina still performs better than most other materials. The material works great with alkaline substances, too. It resists sodium hydroxide, potassium hydroxide, ammonium hydroxide, and calcium hydroxide. The material keeps 90% of its strength even at scorching temperatures of 1100°C. Three key factors determine its chemical stability: alumina content, sintering density, and the temperature/concentration during exposure.

Use Cases of Alumina Ceramics in Engineering Systems

Alumina ceramics are vital components across engineering sectors due to their exceptional material properties.

Alumina Ceramic Bearings and Seals in Aerospace

Aerospace companies utilize alumina ceramic bearings because of their superior hardness and wear resistance in high-stress environments. These components weigh nearly half as much as steel, with a density of just 3.9 g/cm³. This weight reduction leads to 40% lower centrifugal forces during high-speed rotation. The exceptional smoothness (Ra < 0.01 μm) of these bearings creates friction levels that are 10× lower than steel versions. This results in wear rates of just 1% compared to metal components. Traditional steel bearings stop working at -100°C in Mars-bound mechanisms. However, alumina bearing systems continue to function in temperatures from -180°C to 1200°C.

Sensor Housings for High-Temperature Monitoring

Alumina ceramic makes an excellent choice for sensor housings where heat resistance and precise monitoring are crucial. High-temperature wireless sensors built with alumina substrates work effectively between 500-1000°C. These sensors show an average sensitivity of 0.56 MHz/°C. Alumina ceramic-based pressure sensors remain stable at 850°C for over 20 minutes. Their performance at 600°C shows a linear characteristic response with an 8.3% repeatability error, 5.05% hysteresis error, and minimal zero-point drift of just 1%.

Alumina Tubes in Electrical Insulation Systems

Alumina ceramic tubes serve as excellent electrical insulators while handling extreme temperatures. These tubes maintain their structure even above 1600°C and provide superior electrical isolation. They work great as thermocouple protection sheaths and high-voltage insulators because they resist corrosive substances at high temperatures. Circuit boards and pressure vessels are just some of the critical systems that utilize these tubes. They act as structural supports and isolation barriers in environments that need long-term reliability without maintenance.

Heat Shields and Exhaust Nozzles in Jet Engines

Aerospace propulsion systems utilize alumina ceramic components to protect against extreme thermal-structural and thermal-chemical conditions. High-purity alumina heat shields protect aircraft and sensitive parts from excessive heat during high-speed flight. Alumina’s hardness and abrasion resistance make it perfect for exhaust nozzles. These properties help prevent erosion from high-velocity gases while insulating internal components. Engineers utilize alumina’s unique mix of wear resistance, thermal stability, and dimensional consistency for these demanding applications.

Conclusion

Our deep dive into alumina ceramics shows how versatile they are in engineering applications. This amazing material ranks 9 on the Mohs scale, which makes it almost three times harder than stainless steel. It keeps its structural integrity at temperatures up to 1650°C and holds onto 50% of its tensile strength at 1000°C compared to room temperature.

Alumina ceramic’s capabilities go beyond just strength. Its volume resistivity is more than 10¹⁴ ohm-meters at room temperature, which makes it perfect for electrical isolation. The material stays stable against most acids and bases, so it lasts much longer in corrosive environments where other materials would break down faster.

These features make alumina ceramic essential for critical engineering systems. The material shines in aerospace bearings that cut centrifugal forces by 40% during high-speed rotation. It works great in sensor housings at extreme temperatures, too. Engineers rely on it for electrical insulation systems and heat shields where steady performance under harsh conditions matters most.

Alumina ceramics offer the perfect answer for engineers tackling issues with mechanical stress, thermal stability, electrical insulation, and chemical resistance. Its excellent value for money makes it the life-blood of modern engineering. Engineers can pick alumina with confidence when they build systems that need to handle the toughest operating conditions.

Key Takeaways

Alumina ceramics offer engineers a unique combination of exceptional hardness, thermal stability, and chemical resistance that makes them indispensable for demanding applications across aerospace, electronics, and high-temperature systems.

• Exceptional hardness and durability: Alumina rates 9 on the Mohs scale—nearly three times harder than stainless steel—with wear rates as low as 0.00052‰ in high-friction environments.

• Superior thermal performance: Maintains structural integrity up to 1650°C and retains 50% of tensile strength at 1000°C, making it ideal for extreme temperature applications.

• Outstanding electrical insulation: Volume resistivity exceeds 10¹⁴ ohm-meters at room temperature with dielectric breakdown strength of 21 kV/mm at standard thickness.

• Chemical stability in harsh conditions: Resists most acids and bases while maintaining up to 90% strength at 1100°C, ensuring longevity in corrosive environments.

• Proven aerospace applications: Reduces centrifugal forces by 40% in high-speed bearings and enables sensor functionality from -180°C to 1200°C in space missions.

These properties position alumina ceramics as a cost-effective solution for engineers designing systems that must withstand mechanical stress, thermal extremes, and chemical exposure while maintaining precise performance standards.

FAQs

Q1. What are the primary advantages of alumina ceramics in engineering applications? Alumina ceramics offer exceptional hardness, thermal stability up to 1650°C, excellent electrical insulation, and high chemical resistance. These properties make them ideal for use in aerospace, electronics, and high-temperature systems where durability and performance under extreme conditions are crucial.

Q2. How does alumina ceramic compare to other materials in terms of hardness? Alumina ceramic ranks 9 on the Mohs scale, making it nearly three times harder than stainless steel. This exceptional hardness contributes to its superior wear resistance and durability in high-stress environments.

Q3. What makes alumina ceramics suitable for high-temperature applications? Alumina ceramics maintain structural integrity at temperatures up to 1650°C and retain 50% of their tensile strength at 1000°C compared to room temperature. This thermal stability makes them ideal for components in jet engines, heat shields, and high-temperature sensors.

Q4. How do alumina ceramics perform in terms of electrical insulation? Alumina ceramics exhibit excellent electrical insulation properties with a volume resistivity exceeding 10¹⁴ ohm-meters at room temperature. They also have a high dielectric breakdown strength, making them suitable for various electrical and electronic applications.

Q5. In which industries are alumina ceramics commonly used? Alumina ceramics find widespread use in aerospace (for bearings, seals, and heat shields), electronics (for sensor housings and electrical insulation), and various high-temperature industrial applications. They are also utilized in chemical processing equipment due to their resistance to corrosive environments.