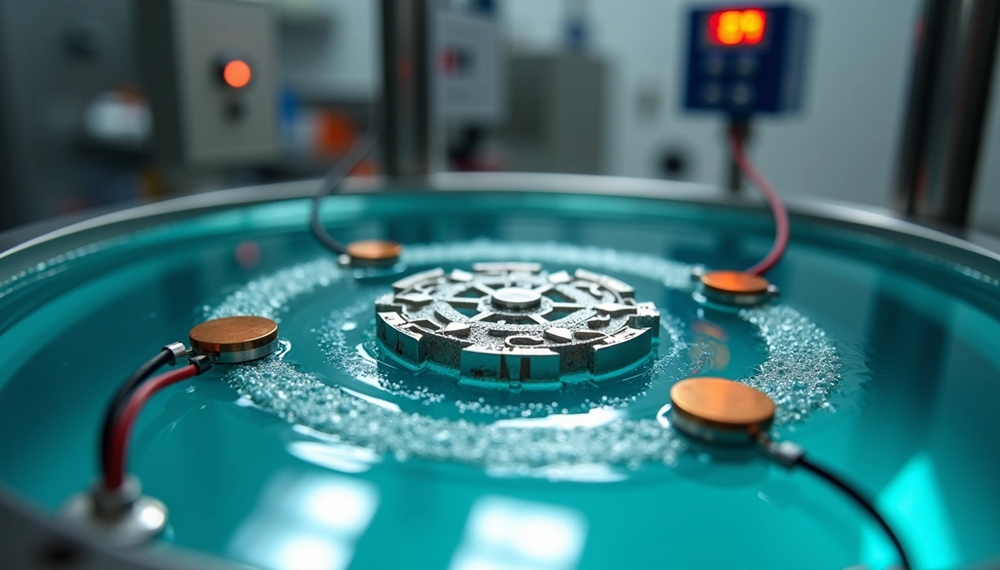

Electroplating complex geometries remains one of the toughest challenges manufacturers face today. The process improves surface properties by depositing metal on substrates and sees extensive use in electronics, automotive, and jewelry industries. Metal Injection Molded (MIM) components with their irregular surfaces, undercuts, and recessed areas make uniform coating particularly challenging.

Complex geometric designs create major hurdles in the electroplating process. Electric field distributions don’t behave predictably, and electrolyte flow patterns become erratic. Air pockets often form in parts with difficult geometries. These pockets block solution turnover, so affected areas don’t get plated at all. The industrial electroplating sector’s struggles with these issues can lead to serious problems. Poor metal plating on complex parts hurts product performance and lifespan. Companies end up spending more on fixes, scrapped parts, and longer processing times. Manufacturers working with detailed MIM components need to understand and tackle these challenges head-on.

This piece looks at the unique problems that come up when electroplating complex MIM geometries and offers practical solutions to these limitations.

Surface Preparation Challenges in MIM Electroplating

Surface preparation serves as the lifeblood of successful electroplating for Metal Injection Molded (MIM) components. The quality of adhesion and final plating uniformity depends directly on proper cleaning and activation. Industry reports indicate that inadequate surface preparation accounts for approximately 30% of plating defects [1]. This makes the preparation phase crucial to achieving optimal results.

Chemical Cleaning Limitations in Micro Cavities

MIM parts with intricate geometries create unique cleaning challenges. Traditional cleaning agents struggle to penetrate their small features and high aspect ratios effectively. These parts can trap contaminants in microscopic fissures and non-metallic inclusions, which leads to plating failures later.

Complex MIM parts have deep recesses that conventional cleaning methods cannot reach. Residual oils or oxides stay hidden in micro cavities even after thorough exterior cleaning. These hidden contaminants eventually show up as pitting, poor adhesion, or uneven deposition during the electroplating process.

Electrocleaning for High-Density MIM Parts

High-density MIM components benefit from electrocleaning, which combines electrical and chemical action to remove stubborn contaminants. The process uses alkaline solutions with sodium or potassium hydroxide as main ingredients, along with specialized additives like buffers, inhibitors, and wetting agents.

Different metal substrates need specific current densities and voltages to achieve the best results. Rack processing of steel and stainless steel needs anodic cleaning at 50-100 ASF, while sensitive metals like zinc work better at lower settings of 10-20 ASF. Complex geometries respond well to Periodic-reverse (PR) electrocleaning, which alternates between anodic and cathodic polarities to remove scale and oxide.

Surface Activation for Low-Conductivity Alloys

Low-conductivity MIM alloys need specialized surface activation to ensure proper electroplating adhesion. These activation techniques change the substrate’s surface topography and chemical composition to create ideal conditions for plating nucleation.

Alkaline pretreatments create a metal-OH layer on the substrate surface. Acidic treatments remove inclusions and form strong passive layers. Challenging alloys require careful attention to the distribution and number of active particles, as these substantially affect coating quality and corrosion resistance.

Manufacturers can improve adhesion quality and electroplating uniformity across complex MIM geometries by choosing the right activation methods.

Electrolyte Flow and Composition Control for Intricate Shapes

Complex MIM geometries in electroplating don’t deal very well with electrolyte flow control. Traditional flow patterns create an uneven distribution of electrolyte products, particularly in intricate channel structures. Research shows that electrolyte moving slowly in perpendicular channels creates obvious flow marks at the channel bottom.

Manufacturing companies have created different flow configurations to solve these problems. The “two-in and two-out” design adds an extra electrolyte inlet to traditional flow fields. The “three-in and one-out” configuration works better by adding two extra inlets. Both simulations and experiments show that this is a big deal as it means that the three-in and one-out flow mode creates flatter bottom surfaces for cross-channel arrays.

Ion Depletion in Recessed Features

Ion depletion poses a critical challenge in electroplating recessed MIM features. The electric double layer (EDL) forms in complex microchannels when dielectric surfaces acquire charges through polar medium contact, chemical reaction, ionization, or ion absorption. The wall’s attention is drawn to positive ions while negative ions move away, which creates ion redistribution near the walls.

Deep recesses create problems because limited electrolyte flow prevents proper ion replenishment. The electrode recess relates directly to electrical properties – an increased electrode recess improves isolation between electrodes and reduces leakage current. External electric fields can control electroosmotic flow, which is a great way to get uniform deposition in microfluidic applications.

Additive Behavior in High-Aspect Ratio Cavities

Successful electroplating of complex MIM components needs significant additive behavior management within high-aspect ratio cavities. The final coating quality depends on how electroplating additives interact with intricate geometries. Traditional additive packages face major diffusion limitations in high-aspect ratio structures that create concentration gradients and affect deposition uniformity.

Scientists have found that void-free copper plating in vias 70 μm deep and 10 μm wide needs specific additives combined with pulse-reverse current and dissolved-oxygen enrichment. This method fills completely within 60 minutes and outperforms traditional approaches. Superfilling additives’ effectiveness relies on Cu(I) thiolate accelerant’s formation, destruction, and distribution, which changes based on reverse current patterns and oxygen concentration.

Temperature Uniformity in Dense MIM Batches

Electroplating densely packed MIM components creates special problems with temperature control. MIM parts need heating to about 85% of the material’s melting point during sintering to get the best properties. Complex geometries make this precise temperature management harder by creating thermal shadows and uneven heat distribution.

Industrial applications need specialized degreasing furnaces with temperature uniformity systems. These systems keep temperatures steady across components of different sizes and densities. Standard electroplating processes usually achieve thickness uniformity within 5.5%. This improves to 1.9% maximum deviation with integrated temperature control systems.

Current Distribution and Thickness Uniformity in MIM Geometries

Metal distribution uniformity remains a persistent challenge when electroplating MIM components with complex geometries. These parts often have intricate shapes that create uneven current distribution, which affects coating thickness and quality on all surfaces. The coating thickness typically increases by about 50% at sharp edges compared to flat areas in cathodic arc evaporation.

Edge Effect and Overplating in Sharp Corners

MIM components with sharp corners create major current distribution problems. The electric field lines concentrate naturally at these points and cause accelerated deposition rates and overplating. This “edge effect” makes coating thickness up to 1.5 times greater at edges than on flat surfaces. The effects multiply when two edges meet at a corner. This can create deposits up to 11 μm thick even though the target thickness might be only 3 μm. Manufacturers avoid designing parts with edge radii smaller than 0.005-0.006 inches to minimize these issues.

Pulse Plating for Uniform Deposition

Pulse electroplating technology brings major improvements to complex MIM geometries. The technique applies voltage in controlled bursts, unlike traditional direct current methods. This allows better management of deposition patterns and produces denser, pore-free, and corrosion-stable alloy layers even on complex workpiece shapes. The coating characteristics depend directly on pulse parameters like frequency, duty cycle, and amplitude. Higher frequencies help prevent metal ion diffusion problems and enable more uniform distribution across substrate surfaces.

Anode-Cathode Positioning for Internal Channels

The strategic placement of anodes and cathodes plays a crucial role in electroplating uniformity for MIM parts with internal channels. Shields placed between anodes and cathode areas help control electrodeposition rates across plating surfaces by modulating electric fields. These non-conductive barriers create high-resistance paths for material ions and effectively balance current density distribution. Complex geometries often need multiple anodes positioned to mirror the workpiece shape. This helps minimize current flow discrepancies and produces better results.

Defect Mitigation and Real-Time Monitoring Techniques

Live monitoring systems help identify and fix defects in complex MIM electroplating operations. Companies that use digital monitoring tech can cut down defects, use resources better, and keep quality consistent through production runs.

Pitting and Voiding in Undercuts

MIM components with undercut features often develop voids and pitting during electroplating. Pinholes in the gold layer of Ni/Au plating systems speed up corrosion in nickel layers below. This is a big deal as it means that the plating becomes less reliable. In nickel-only plating, voids grow downward and create pinholes and cracks. These ended up triggering corrosion in the copper layer. The electroless Ni/Pd/Au plating offers a better solution. Its protective Pd/Au layers stop void diffusion and block corrosion from spreading.

XRF-Based Thickness Validation

X-Ray Fluorescence (XRF) is the quickest way to prove coating thickness right on complex MIM geometries. This method measures thickness and composition at the same time in seconds. XRF measurements’ accuracy depends on statistical changes in X-ray intensity counts. The fundamental parameter method gets within ±10% accuracy for top layers, but deeper layers are harder to measure precisely. Manufacturers get the best results when they calibrate using standard substances with known thicknesses. They often use electroless Ni/Pd/Au multilayered plating on copper substrates.

Closed-Loop Control Systems in Industrial Electroplating

Closed-loop systems give precise control over the electroplating process. These systems prevent defects by watching bath temperature, chemical makeup, and voltage constantly. Operators use special software to plan their work, get alerts about problems right away, and keep chemical levels steady. The benefits go beyond quality improvements. These systems help the environment too. They cut water use from 3-5 gallons per minute to just a fraction. This eliminates wastewater discharge and makes regulatory compliance easier.

Conclusion

Electroplating complex MIM geometries requires careful attention to many interconnected factors. This piece explores the sophisticated process of achieving uniform, high-quality coatings on intricate surfaces. Surface preparation forms the foundation of successful electroplating. Specialized techniques like electrocleaning and targeted activation processes prove vital for complex components.

The “three-in and one-out” approach helps control electrolyte flow and substantially improves deposition uniformity in recessed features. Temperature control plays a key role, especially when you have densely packed MIM batches where thermal shadows can lead to inconsistent results.

Manufacturers now use pulse plating technology to overcome edge effect and overplating problems. This approach combined with strategic anode-cathode positioning gives unprecedented control over current distribution across complex geometries.

Live monitoring has reshaped quality control capabilities. XRF-based thickness validation and closed-loop control systems help manufacturers detect potential defects early. These advanced techniques boost product quality while reducing resource consumption and environmental effects.

The electroplating industry adapts continuously through flexible solutions for increasingly complex MIM geometries. Companies that become skilled at these techniques gain major advantages in product performance, longevity, and production efficiency. Understanding and applying appropriate strategies for specific geometrical challenges gives manufacturers a competitive edge in precision metal component production.

Key Takeaways

Electroplating complex MIM geometries requires specialized approaches to overcome unique challenges in surface preparation, current distribution, and defect prevention for optimal coating quality.

• Surface preparation is critical: 30% of plating defects stem from inadequate cleaning, requiring electrocleaning and specialized activation for complex MIM geometries.

• Strategic flow control improves uniformity: “Three-in and one-out” electrolyte configurations significantly reduce flow marks and ion depletion in recessed features.

• Pulse plating overcomes edge effects: This technique produces denser, more uniform coatings while preventing overplating at sharp corners and edges.

• Real-time monitoring prevents defects: XRF thickness validation and closed-loop control systems reduce defects while optimizing resource consumption and environmental impact.

• Temperature uniformity is essential: Precise thermal management across densely packed MIM batches improves coating consistency from 5.5% to 1.9% deviation.

Success in electroplating complex MIM components depends on integrating these advanced techniques with proper equipment positioning and continuous process monitoring to achieve consistent, high-quality results across intricate geometries.

FAQs

Q1. What are the main challenges in electroplating complex MIM geometries? The primary challenges include achieving uniform coating on irregular surfaces, managing electrolyte flow in recessed areas, controlling current distribution, and preventing defects like pitting and voiding in undercuts.

Q2. How does pulse plating improve electroplating results for complex MIM parts? Pulse plating applies voltage in controlled bursts, allowing for more precise management of deposition patterns. This technique produces denser, pore-free, and corrosion-stable alloy layers, even on complex workpiece shapes, resulting in more uniform coatings.

Q3. Why is surface preparation crucial for electroplating MIM components? Proper surface preparation directly impacts adhesion quality and final plating uniformity. Inadequate cleaning can lead to plating defects, especially in micro cavities and recessed areas of complex MIM geometries.

Q4. What role does temperature control play in electroplating MIM parts? Temperature uniformity is essential for achieving consistent coating quality, especially in densely packed MIM batches. Proper temperature management can improve coating thickness uniformity from 5.5% to 1.9% maximum deviation.

Q5. How do real-time monitoring systems benefit the electroplating process? Real-time monitoring systems, such as XRF-based thickness validation and closed-loop control systems, help identify and address defects early, optimize resource consumption, and maintain consistent quality standards throughout the production cycle.