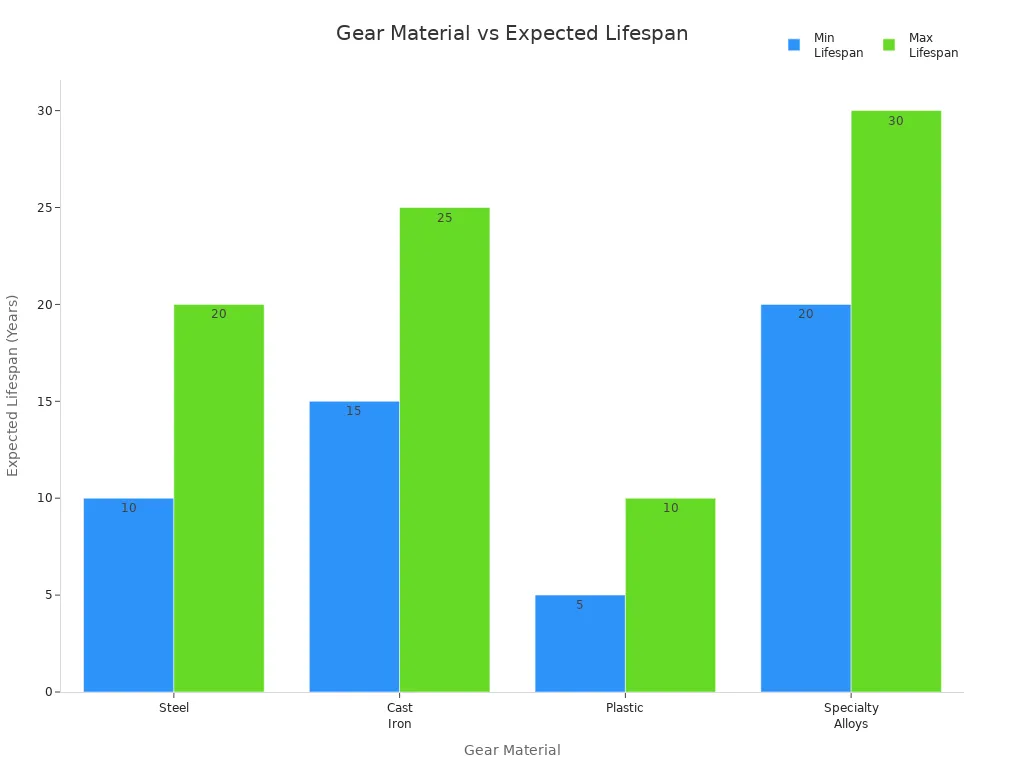

Choosing the right gear production process significantly influences the operational efficiency and lifespan of mechanical systems. Various factors, such as material properties and environmental conditions, affect gear performance. For instance, steel gears may last between 10 to 20 years, while those made from specialty alloys can endure for 20 to 30 years.

Key considerations when selecting a gear production process include:

- Material type

- Load and stress factors

- Maintenance practices

Understanding these elements is crucial when producing gears that meet specific application requirements.

Key Takeaways

- Choosing the right gear production process affects efficiency and lifespan.

- Material type, load factors, and maintenance practices are key considerations.

- Forging enhances strength and durability, while casting allows for complex shapes.

- High-quality gears reduce wear and improve performance, following AGMA standards.

- Production volume influences the choice of manufacturing methods.

- Precision requirements vary by industry, impacting material and process selection.

- Advanced techniques like CNC machining and additive manufacturing offer unique benefits.

- Understanding defects in gear production helps ensure reliability and longevity.

Overview of Gear Manufacturing Processes

Definition of Gear Manufacturing

Gear manufacturing encompasses a series of processes designed to create gears that meet specific performance requirements. These processes include design, production, and finishing stages. The primary methods used in the industry are:

- Casting: This involves pouring molten metal into molds to form gear shapes.

- Forging: This method shapes metal using compressive forces, enhancing strength.

- Extrusion: This versatile technique pushes material through a die to create long shapes.

- Powder Metallurgy: This process involves compacting metal powders and sintering them to form gears.

- Gear Machining: Techniques such as hobbing, shaping, and milling refine the gear’s final shape and dimensions.

The gear manufacturing process is comprehensive, ensuring that gears meet the necessary specifications for various industrial applications. As the global market for gears is projected to reach around $250 billion by 2026, understanding these processes becomes increasingly important for manufacturers.

Importance of Gear Quality

The quality of gears plays a crucial role in the performance and reliability of both automotive and industrial equipment. High-quality gears ensure optimal functioning, reduce wear and tear, and enhance longevity. Conversely, poor-quality gears can lead to mechanical failures and safety hazards.

To maintain high standards, manufacturers often adhere to AGMA (American Gear Manufacturers Association) standards. These guidelines help ensure consistent quality across production runs, contributing to increased gear longevity and reduced maintenance needs. Following these standards also improves overall efficiency in gear production.

Forming Processes for Producing Gears

Forming processes play a vital role in producing gears, as they directly influence the mechanical properties and overall performance of the final product. Two primary forming methods are forging and casting.

Forging

Forging involves shaping metal through compressive forces, enhancing its strength and durability. This process can be categorized into two main types: hot forging and cold forging.

Hot Forging

In hot forging, manufacturers heat the metal above its recrystallization temperature. This method allows for easier shaping and improved ductility. Hot forging produces gears with superior mechanical properties, including:

- Increased load-carrying capacity compared to cut gears.

- Enhanced fatigue strength due to the alignment of grain flow with the tooth contour.

- Reduced material loss, leading to cost savings in both material and machining.

Most forged gears achieve near-net shape configurations, minimizing the need for extensive machining.

Cold Forging

Cold forging occurs at or near room temperature. This method results in a denser and stronger final product. Cold forging is ideal for producing gears with tight tolerances and excellent surface finishes. However, it may require more energy and can lead to increased tool wear.

Casting

Casting is another prevalent method for producing gears. This process involves pouring molten metal into molds to create the desired shape. Several casting techniques exist, including sand casting, investment casting, shell casting, and die casting.

Sand Casting

Sand casting is one of the oldest and most widely used methods. It involves creating a mold from sand and pouring molten metal into it. While this method is cost-effective, it may produce gears with rough surfaces and lower dimensional accuracy.

Investment Casting

Investment casting, also known as lost-wax casting, offers higher precision and better surface finishes. This method involves creating a wax pattern, coating it with a ceramic shell, and then melting away the wax. Investment casting is suitable for complex gear shapes but can be more expensive.

Shell Casting

Shell casting combines elements of sand and investment casting. It uses a thin shell of sand and resin to create molds. This method provides better dimensional accuracy and surface finish than traditional sand casting.

Die Casting

Die casting involves forcing molten metal into a mold under high pressure. This technique produces gears with excellent surface finishes and dimensional accuracy. However, it is typically limited to non-ferrous metals.

The casting process can introduce defects that impact gear performance. Common defects include tooth-bending fatigue, which leads to cracking under stress, and abrasive tooth wear, which increases wear due to hard particles. Understanding these defects is crucial for ensuring the longevity and reliability of cast gears.

| Defect Type | Impact on Performance |

|---|---|

| Tooth-Bending Fatigue | Leads to cracking under repeated stresses, reducing durability. |

| Tooth-Bending Impact | Results from shock-loading, causing potential yield failure. |

| Abrasive Tooth Wear | Material removal due to hard particles, increasing wear. |

| Macropitting | Initiates cracks at the surface, leading to material loss. |

By selecting the appropriate forming process, manufacturers can optimize the performance and lifespan of gears, ensuring they meet specific application requirements.

Generating Processes for Producing Gears

Generating processes are essential for producing gears with precise shapes and dimensions. These methods include gear hobbing, gear shaping, and various cutting techniques. Each process has unique advantages and applications.

Gear Hobbing

Process Overview

Gear hobbing involves using a specialized cutting tool called a hob to create gear teeth. The hob rotates while the gear blank moves, allowing for efficient material removal. This method is particularly effective for producing spur gears and helical gears.

Applications

Hobbing is widely used in industries requiring high production rates. It excels in creating gears for automotive, aerospace, and machinery applications. The advantages of gear hobbing include:

| Advantage | Description |

|---|---|

| Speed | Gear hobbing is relatively fast, requiring less operational attention and allowing for multiple units to be processed simultaneously. |

| Precision | Hobbing can achieve high precision with the right expertise, resulting in high-quality gears. |

| Output | The quicker manufacturing process increases output, enabling fulfillment of more orders in less time. |

Gear Shaping

Process Overview

Gear shaping utilizes a reciprocating cutter to remove material from the gear blank. This method allows for the production of gears with complex profiles. The cutter and gear blank do not roll together, which enables precise cutting.

Applications

Gear shaping is preferred for producing various types of gears, including:

| Gear Type | Reason for Preference in Gear Shaping |

|---|---|

| Spur Gears | High accuracy and exceptional surface finish |

| Helical Gears | Capable of producing gears with near tolerances |

| Bevel Gears | Effective for creating complex shapes with precision |

| Worm Gears | Suitable for specific applications requiring detailed shaping |

This process is commonly used for cutting spur gears, herringbone gears, and ratchet gears due to its ability to achieve high accuracy and fine surface finishes.

Other Cutting Techniques

Skiving

Skiving is a cutting technique that engages multiple teeth at once, allowing for high-speed production. This method is flexible and can produce gears with complex shapes. It is often faster than shaping and can achieve high precision.

Broaching

Broaching involves using a toothed tool to remove material in a single pass. This technique offers high precision but requires expensive machines and setup time. It is suitable for specific applications where accuracy is paramount.

Milling

Milling is a versatile cutting technique that can produce gears of various shapes. It is less efficient for gear teeth compared to hobbing and shaping but remains a valuable option for custom gear production.

Power skiving matches the efficiency of broaching and gear shaping while being cost-effective. This makes it a competitive option for series production, balancing quality and productivity.

Finishing Processes for Producing Gears

Finishing processes are crucial in enhancing the performance and longevity of gears. These processes refine the surface and dimensions of gears, ensuring they meet stringent operational standards. Key finishing techniques include grinding, honing, and tooth profile finishing.

Grinding

Gear Grinding Techniques

Gear grinding employs various techniques to achieve high precision and surface quality. This process significantly improves the geometry of gear teeth. It reduces radial runout by more than sevenfold compared to unground gears. Additionally, grinding enhances surface roughness, which improves tribological properties such as friction and wear. The grinding process also decreases surface stress concentrations, leading to increased fatigue life of components. Notably, grinding reduces hole roundness significantly, achieving reductions of over five times at one measurement level and almost seven times at others.

Benefits of Grinding

The benefits of gear grinding extend beyond mere dimensional accuracy. This process ensures that gears operate smoothly and efficiently. Improved surface finishes lead to reduced friction, which enhances overall gear performance. Consequently, gears exhibit longer service lives and lower maintenance needs.

Honing

Process Overview

Honing is a finishing process that utilizes abrasive stones to refine the surface of gears. This technique enhances the dimensional accuracy and surface finish of gears, making it an essential step in gear manufacturing. Honing can correct minor imperfections and improve the overall quality of the gear.

Applications

Honing finds applications in various aspects of gear manufacturing. The following table outlines its typical applications and benefits:

| Application | Benefit |

|---|---|

| Hard finishing of gears | Improves surface finish |

| Reduces friction | Enhances overall gear longevity |

| Corrects tooth geometry | Results in quieter, stronger, and longer-lasting gears |

Honing also facilitates smoother performance in transmissions and contributes to reduced noise in powertrains. This process allows for both roughing and finishing operations in one setup, increasing efficiency.

Tooth Profile Finishing

Tooth profile finishing is vital for extending the service life of gears. This process improves surface integrity and reduces contact fatigue damage. Research indicates that techniques like vibration honing and stream barrel finishing modify the micro-profile of gear teeth. This modification helps reduce peak stress at critical points, such as the tooth tip and root. Consequently, it leads to a notable decrease in contact fatigue damage, extending the operational lifespan of the gears. Studies show that barrel-finishing can increase the service life of gears by 5 to 7 times compared to conventional grinding methods under similar loading conditions.

Gear Shaving

Gear shaving is a method that refines the tooth profile of gears. This process enhances the surface finish and improves the overall performance of the gear. It is particularly effective for achieving tight tolerances and smooth operation.

Gear Lapping

Gear lapping involves using an abrasive slurry to polish the gear teeth. This technique further enhances the surface finish and ensures precise tooth geometry. Lapping is especially beneficial for high-performance gears that require exceptional accuracy and durability.

Advanced Manufacturing Techniques for Producing Gears

Additive Manufacturing

Additive manufacturing, commonly known as 3D printing, has gained traction in gear production. This innovative technique allows manufacturers to create complex geometries that traditional methods cannot achieve.

Benefits and Limitations

The benefits of additive manufacturing are numerous:

- Quick Iteration: Designers can rapidly prototype and test new gear designs.

- Design Freedom: This method enables the creation of intricate shapes and structures.

- Cost and Time Savings: Lower start-up costs arise from reduced needs for custom tooling.

- Custom Products: Manufacturers can produce unique parts tailored to specific applications.

- End-Use Parts: Additive manufacturing can create functional components that traditional methods struggle to replicate.

However, limitations exist. The materials available for 3D printing may not always match the mechanical properties of traditionally manufactured gears. Additionally, the surface finish may require further processing to meet industry standards.

The global 3D printing market was valued at USD 13.78 billion in 2020 and is expected to expand at a compound annual growth rate (CAGR) of 21.0% from 2021 to 2028. This growth reflects the increasing adoption of additive manufacturing among gear manufacturers for both prototyping and production.

Applications in Gear Production

Additive manufacturing finds applications in various sectors, including aerospace, automotive, and medical industries. It allows for the production of lightweight gears that maintain strength and performance. As industries continue to explore this technology, the potential for innovative gear designs expands.

CNC Machining

CNC (Computer Numerical Control) machining represents a significant advancement in gear production. This method utilizes computer-controlled machines to automate the manufacturing process.

Process Overview

CNC machining involves programming a computer to control the movement of cutting tools and workpieces. This precision allows for the creation of gears with tight tolerances and complex shapes. The process begins with a digital design, which the CNC machine follows to produce the final product.

Advantages of CNC Machining

CNC machining offers several advantages over manual machining:

- Precision Control: CNC machines provide precise control over cutting tools, ensuring consistent accuracy.

- Repeatability: They excel in reproducing the same operations across multiple workpieces with high precision.

- Reduced Human Error: Digital control systems minimize mistakes during operation.

- Convenient Modifications: Adjustments can be made easily based on design needs.

Higher accuracy leads to a lower scrap rate, reducing overall part costs. Additionally, increased precision decreases the likelihood of customer rejections due to defects. CNC machining can achieve micron-level processing accuracy, making it essential in industries with stringent requirements.

Factors to Consider When Choosing a Process for Producing Gears

Selecting the appropriate process for producing gears involves careful consideration of several factors. Each factor can significantly impact the performance, cost, and efficiency of the final product.

Material Type

The choice of material directly influences the gear’s performance and the manufacturing process selected. Different materials offer unique properties that can affect strength, wear resistance, and machinability. Here are some common materials used in gear manufacturing:

| Material | Advantages | Disadvantages |

|---|---|---|

| Alloy Steel | High strength, excellent wear resistance, suitable for high loads. | More expensive, requires higher machining standards. |

| Carbon Steel | Cost-effective, good mechanical properties, easy to machine. | Inferior wear and corrosion resistance, suitable for lighter loads. |

| Stainless Steel | Excellent corrosion resistance, stable in wet or chemical environments. | Generally more costly, average strength and toughness. |

| Cast Iron | Exceptional wear resistance, handles heavy loads, good machinability. | Lower toughness, poor impact resistance, susceptible to cracking. |

| Engineering Plastics | Lightweight, corrosion-resistant, good friction performance. | Poor high-temperature performance, lower strength and rigidity. |

When selecting a material, manufacturers should consider factors such as strength, hardness, wear resistance, and cost-effectiveness. For instance, materials with high wear resistance are crucial for gears subjected to heavy loads. Additionally, machinability plays a vital role in determining production efficiency. Poor machinability can lead to increased tool wear and higher operational costs.

Production Volume

Production volume significantly impacts the choice of manufacturing process. Different processes excel at varying scales of production. For example, processes like forging and die casting are more cost-effective for high-volume production due to their ability to produce large quantities efficiently. Conversely, methods such as investment casting may be better suited for lower volumes where precision is paramount.

Manufacturers must also consider the relationship between batch size and automation levels. Smaller batch sizes can reduce lead times and improve cash flow. Higher automation levels can enhance throughput and minimize downtime, leading to increased efficiency. The following table illustrates the impact of batch size and automation on production:

| Factor | Batch Production | Continuous Production |

|---|---|---|

| Automation Impact | 20-35% throughput increase with smart sensors | 40-60% throughput gains through full-line integration |

As production volumes increase, companies should design their processes holistically. This approach ensures that all aspects of the manufacturing sequence align for maximum efficiency, ultimately optimizing cost-effectiveness.

Cost Considerations

Cost is a critical factor in selecting a gear manufacturing process. Various costs, including tooling, labor, and material expenses, can vary significantly among different methods. The following table outlines typical cost breakdowns for various processes in medium-scale production:

| Process | Tooling cost (relative) | 100 units | 1,000 units | 10,000 units | Notes |

|---|---|---|---|---|---|

| Sand casting | Low | 1.00 | 0.80 | 0.70 | Best for low volume, large parts |

| Investment casting | Medium | 1.30 | 0.85 | 0.75 | Tighter tolerances, complex shapes |

| Closed-die forging | Medium-high | 1.50 | 0.90 | 0.65 | Strong lifecycle economics |

| Die casting (Al/Zn) | High | 2.00 | 1.00 | 0.50 | Requires high volumes to amortize dies |

Manufacturers should also consider variable costs, such as supplies and wages, which fluctuate with production volume. Understanding these costs helps companies make informed decisions about which processes to adopt based on their specific production needs.

Precision Requirements

Precision plays a crucial role in gear manufacturing, particularly in applications where performance and reliability are paramount. Different industries impose varying precision requirements based on their operational demands. For instance, aerospace applications necessitate tighter tolerances compared to automotive applications.

The following table outlines the standard precision requirements for gears in both sectors:

| Aspect | Aerospace Requirements | Automotive Requirements |

|---|---|---|

| Material Selection | Exceptional strength-to-weight ratios, high fatigue resistance, aerospace-grade alloys | Durability and reliability for continuous usage, cost-effective materials |

| Precision Engineering | Tight tolerances, accurate gear tooth profiles | Precise gear tooth profiles for efficient power transfer |

| Performance Conditions | Operate under extreme temperatures, high speeds, and dynamic loads | Endure various loads and operating conditions |

| Weight Considerations | Lightweighting for fuel efficiency and payload capacity | N/A |

| Compliance | Adherence to stringent regulations (FAA, EASA) | N/A |

In aerospace applications, gears must withstand extreme conditions, including high speeds and fluctuating temperatures. The materials used must offer exceptional strength-to-weight ratios to enhance fuel efficiency. Conversely, automotive gears prioritize durability and reliability, ensuring they can handle continuous usage without failure.

Meeting precision requirements involves adhering to industry standards, such as those set by the American Gear Manufacturers Association (AGMA). Manufacturers must implement rigorous quality control measures to ensure that their products meet these standards.

Meeting AGMA classifications requires both technical expertise and manufacturing discipline. The sampling method used for quality control must align with the production processes to ensure consistent quality.

To achieve the necessary precision, manufacturers often follow these key practices:

- Selection of gear materials based on AGMA guidelines for specific applications.

- Implementation of special considerations for industrial gear oils in extreme temperatures.

- Collaboration with lubricant manufacturers to ensure appropriate oil grades.

For example, companies like Systrand utilize advanced gear manufacturing techniques that combine experienced personnel, state-of-the-art equipment, and structured processes. This integration allows them to meet stringent design requirements without compromising quality or timing. Their approach includes continuous data analysis and monitoring to ensure precision and repeatability in manufacturing, which is crucial for meeting industry standards.

Additionally, manufacturers often invest in cutting-edge technology to enhance precision. They may establish partnerships with leading global machine tool manufacturers and implement advanced CAD/CAM software and CNC-based machines. The use of Zeiss coordinate-measuring machines (CMMs) for performance assessment further ensures that gears meet the required specifications.

In summary, gear manufacturing processes encompass various methods, including forging, casting, hobbing, shaping, and advanced techniques like additive manufacturing and CNC machining. Each method offers unique advantages tailored to specific applications.

When selecting a gear production process, manufacturers should consider several factors:

- Application Requirements: Understand power transmission needs and speed requirements.

- Material Selection: Evaluate material options based on durability and performance.

- Production Volume: Determine the scale of production to optimize costs.

Key Takeaways:

- Demand for high-performance systems is rising across industries.

- Advancements in manufacturing processes enable customized gear solutions.

- The Asia-Pacific region leads in market growth due to rapid industrialization.

By carefully assessing these factors, manufacturers can choose the most suitable gear production process, ensuring optimal performance and longevity in their applications.

FAQ

What materials are commonly used for gear manufacturing?

Manufacturers often use materials such as alloy steel, carbon steel, stainless steel, cast iron, and engineering plastics. Each material offers unique properties that affect strength, wear resistance, and machinability.

How does the production volume affect gear manufacturing?

Production volume influences the choice of manufacturing processes. High-volume production benefits from methods like forging and die casting, while low-volume production may favor investment casting for precision.

What is the role of precision in gear manufacturing?

Precision ensures gears meet stringent operational standards. Industries like aerospace require tighter tolerances than automotive applications, impacting material selection and manufacturing processes.

What are the advantages of CNC machining in gear production?

CNC machining provides precise control, repeatability, and reduced human error. This method allows manufacturers to produce gears with tight tolerances and complex shapes efficiently.

How does gear quality impact performance?

High-quality gears enhance performance, reduce wear, and improve longevity. Poor-quality gears can lead to mechanical failures and safety hazards, making adherence to standards essential.

What are the common defects in gear casting?

Common defects include tooth-bending fatigue, abrasive tooth wear, and macropitting. These issues can significantly impact gear performance and longevity, necessitating careful monitoring during production.

Can additive manufacturing be used for producing gears?

Yes, additive manufacturing allows for creating complex geometries that traditional methods cannot achieve. It offers quick prototyping and customization but may require further processing for surface finish.

Why is it important to follow AGMA standards in gear manufacturing?

Following AGMA standards ensures consistent quality across production runs. Adhering to these guidelines enhances gear longevity, reduces maintenance needs, and improves overall efficiency in manufacturing.