Tungsten carbide coating achieves a remarkable 9.0-9.5 on the Mohs scale and shows a Vickers hardness of around 2600. These properties make it one of the most durable surface treatments accessible to more people for industrial components . The material’s stiffness exceeds steel by three times, demonstrating a Young’s modulus of 530-700 GPa . Companies dealing with extreme wear conditions can benefit from these properties through longer service life and lower maintenance costs.

Scientists have discovered that the tungsten carbide coating’s performance substantially depends on its microstructure. The coating’s hardness and tensile strength increase with smaller grain sizes, while larger grains improve fracture toughness. HVOF tungsten carbide coating process produces protective layers that last exceptionally long, especially when you have WC/Co/Cr compositions. These spray coatings resist temperatures up to 250°C (480°F) without major degradation . The coating’s composition serves as a vital factor in determining its mechanical properties, with the binder phase amount playing a key role . This piece shows how these coatings can double industrial components’ service life and explains their integration with manufacturing processes of all types.

Tungsten Carbide Coating Process and Composition

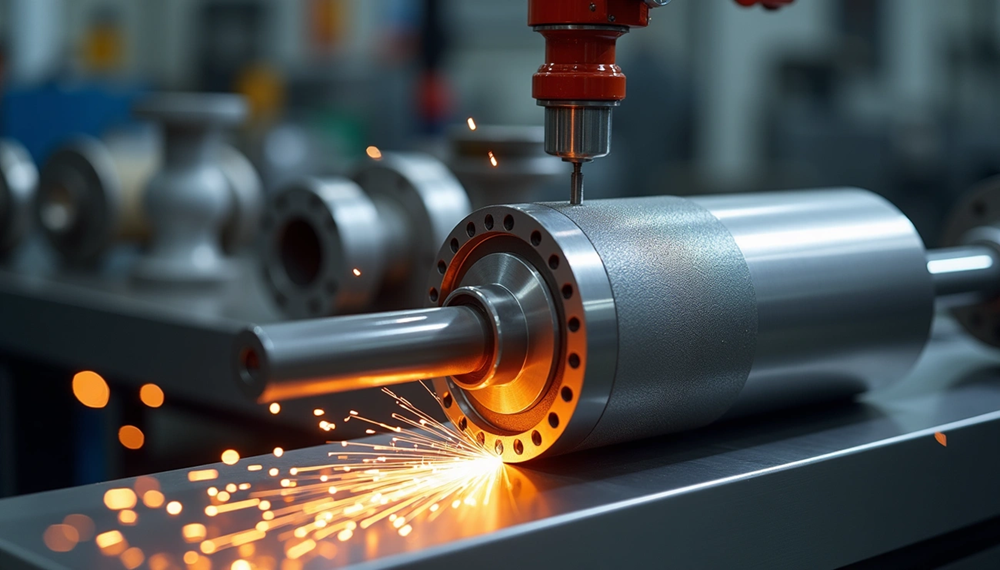

Thermal spray processes are the foundations of modern tungsten carbide coating applications. This procedure melts and accelerates powdered materials toward a substrate. The materials create protective layers that solidify quickly on impact.

Powder Metallurgy vs. HVOF Tungsten Carbide Coating

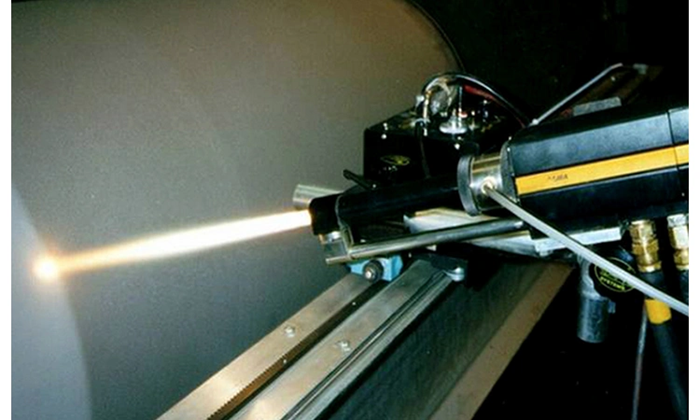

High Velocity Oxy-Fuel (HVOF) stands out as the most advanced way to apply tungsten carbide coatings. The technique employs a high-pressure combustion chamber that reaches temperatures around 5,600°F (3,093°C). Hot gasses push coating particles at speeds up to 3,000 feet per second. These high-energy particles bond instantly to the substrate when they hit, which creates very dense coatings. The porosity stays below 0.5%. Traditional powder metallurgy methods can’t match this combination of density and adhesion for surface treatments.

Cobalt and Chromium Additives in Coating Composition

The makeup of tungsten carbide coating plays a big role in how well it works. Common mixtures include:

- WC-17Co: Contains 17% cobalt, offers excellent wear resistance with a hardness range of 850-1300 Vickers

- WC-12Co: Features 12% cobalt, provides hardness between 850-1400 Vickers

- WC-10Co-4Cr: Incorporates 10% cobalt and 4% chromium, delivers superior corrosion protection compared to standard WC-Co coatings

- WC-10Ni: Uses nickel instead of cobalt, suitable for radioactive environments

Adding chromium to the matrix improves corrosion resistance significantly in many settings. These include humid atmospheres, seawater, and solutions with moderately alkaline or slightly acidic properties. The coatings work well at temperatures up to 500°C.

Role of Binder Phase in Coating Durability

The binder phase plays a crucial role in how well tungsten carbide coatings perform. Higher cobalt content leads to better fracture toughness and flexural strength, though hardness decreases slightly. The binder’s viscosity affects how quickly material gets removed during polishing and finishing.

Research shows that cooling rate and carbide dissolution in the binder phase determine the crystallinity of as-sprayed coatings. Engineers can adjust these factors to match coating properties with specific needs. Ultra-fine powder formulations create smooth, thin, dense coatings that serve as budget-friendly alternatives to galvanic hard chrome plating.

How Coating Enhances Component Life in Industrial Settings

Industrial components typically fail because of three main types of damage: abrasion, corrosion, and thermal fatigue. Tungsten carbide coatings protect against these failures and give components a much longer service life in many industries.

Abrasion Resistance in High-Load Machinery

Tungsten carbide coating gives outstanding abrasion resistance because it’s extremely hard – over 1200 HV. This impressive hardness helps coated parts handle constant friction and wear, which reduces material loss when carrying heavy loads. Tests in the field show that HVOF tungsten carbide coatings can add 20,000 to 40,000 more cycles to critical structural wing components’ life. These coatings have also tripled the life of positive displacement pumps that handle abrasive viscous fluids at pressures up to 2800 psi.

Corrosion Resistance in Chemical Processing Equipment

Tungsten carbide coatings do more than just protect against mechanical wear – they also shield against chemical damage. Different compositions offer unique benefits:

- WC-Co works well in acidic environments

- WC-Ni resists alkaline solutions better

- WC-10Ni3Al protects well against acidic, alkaline, and neutral salt solutions

Latest tests confirm these coatings boost corrosion resistance by 53-64% compared to uncoated samples. Protection improves even more when coating layers merge – corrosion current densities drop from 0.5 to 0.08 (µA/cm²).

Thermal Stability in High-Temperature Environments

These coatings keep their structure and performance even at high temperatures, which makes them perfect for hot environments. Most formulations stay stable up to 500°C, and some can handle even higher temperatures. The coatings combine exceptional hardness with a low coefficient of thermal expansion, so they barely change size when heated.

Heat affects all materials eventually, but tungsten carbide’s wear rate at 800°C can be as low as 1.3 × 10⁻⁵ mm³/N·m – much better than bare steels. This excellent thermal stability makes these coatings valuable for metal injection molding parts that need to stay precise under heat stress.

Performance Metrics from Recent Research Studies

Lab tests show impressive performance results for tungsten carbide coatings in industrial applications of all types. These findings confirm what field engineers have seen for decades about extended component life.

Tungsten Carbide Coating Hardness: 2600+ Vickers

Tests prove that tungsten carbide coatings reach exceptional hardness levels from 1,500 to 2,600 HV based on grain size and cobalt content. The highest hardness comes from finer-grained formulas with lower cobalt percentages (3-6%). These coatings measure 88-94 HRA on the Rockwell scale. Some specialized formulas like C1000Cr hit 1,044-1,076 HV while keeping good corrosion resistance.

Wear Rate Reduction in Rotating Shafts and Valves

Field data proves tungsten carbide coatings cut down wear rates in critical components. Electrochemical tests show WC-coated samples have corrosion rates of 1.122 mmpy versus 2.599 mmpy for uncoated specimens—a 53% reduction. HVAF thermal spray systems can deposit tungsten carbide coatings harder than 1,600 HV300 for valve applications. These create gas-tight seals that withstand pressures up to 30,000 psi (2,070 bar).

Double Service Life in Oil & Gas Drilling Tools

Drilling operations benefit from tungsten carbide coatings that contain 60% tungsten carbide and 0.3% graphene. This mix offers the best protection against erosion when fluid flows at high speeds. The combination helps spread hardness evenly throughout the coating. These coatings help save money by cutting maintenance costs and making components last longer.

Impact of Coating Thickness on Fatigue Resistance

Coating thickness affects fatigue performance a lot. Even thin layers (100 microns/0.004″) can create gas-tight seals that protect valve and seat base metals from corrosive agents. But too much thickness might reduce fatigue resistance. Research on aircraft landing gear parts shows HVOF tungsten carbide coatings affect fatigue strength less than hard chrome electroplating, especially when you have high-cycle applications.

Integration with Metal Injection Molding (MIM) Products

Metal Injection Molding (MIM) stands out as a sophisticated manufacturing process. Fine metal powders combine with binders to create complex shapes. These shapes undergo sintering to produce high-strength components. MIM technology’s combination with tungsten carbide coatings creates new possibilities and challenges across industrial applications.

MIM-Compatible Coating Techniques for Complex Geometries

Chemical Vapor Deposition (CVD) tungsten carbide coatings provide better coverage than traditional thermal spray methods for MIM parts with intricate shapes. The technique reaches internal and external surfaces that HVOF can’t access. Most MIM components feature complex geometries that form in a single step, which makes conventional coating methods fall short. CVD tungsten carbide coatings maintain consistent thickness (50-100 microns) and uniform hardness (800-1200 Hv). This preservation ensures dimensional precision of MIM parts remains intact.

Post-Molding Coating Adhesion Challenges

MIM components’ porous microstructure after debinding creates the biggest problem with coating adhesion. Thermal spray coatings depend on mechanical adhesion rather than chemical or metallurgical bonds. This dependence leads to weak points at material interfaces. Manufacturers have brought down defect rates from 50% to less than 1% through careful process control. The difference in thermal expansion between coating and substrate presents another reason for concern, as it can cause stress during sintering.

Case Study: MIM Gears with Tungsten Carbide Spray Coating

A European manufacturer achieved success by replacing HVOF with CVD tungsten carbide coating on MIM gearbox components. Thin steel plate parts would buckle at the time of HVOF application due to cooling stresses. The smooth CVD coating (0.5-0.6 microns Ra) showed less abrasion against seals, which reduced oil leakage and maintenance needs. Tungsten carbide encapsulation cut monthly costs by nearly 50% for plastic injection molding feedscrews.

Conclusion

Tungsten carbide coatings are a 50-year-old trailblazing solution that extends industrial component life in a variety of applications. These coatings have exceptional hardness ratings up to 2600 Vickers. They’re three times stiffer than steel and show substantially better wear resistance. Companies that use these protective layers report their critical components last twice as long.

Recent research shows tungsten carbide coatings cut wear rates by 53% compared to uncoated specimens. The coating’s high performance comes from carefully controlled compositions. Different WC-Co-Cr formulations provide specialized protection for specific operating environments. Chromium makes them more corrosion-resistant, while adjusted cobalt percentages help balance hardness against fracture toughness.

The coating’s effectiveness depends on how you apply it. HVOF processes create dense protective layers with minimal porosity for external surfaces. CVD methods work better for MIM components that have complex geometries and need uniform internal coverage. This flexibility lets manufacturers protect almost any critical part, no matter how complex its shape.

These coatings do more than just double component lifespans. They stay stable at temperatures up to 500°C and work reliably in demanding environments. They also need less maintenance, which saves on operational costs and reduces equipment downtime.

Metal Injection Molding technology gets great benefits from tungsten carbide protection. Post-molding adhesion can be challenging, but manufacturers have cut defect rates through better processes. This successful tech integration shows how advanced manufacturing can solve tough wear problems.

Tungsten carbide coating applications have a bright future ahead. Researchers keep improving composition formulas and application techniques, which points to even better performance. Industrial operators will benefit from components that last twice as long and maintain top performance throughout their service life.

Key Takeaways

Recent research reveals how tungsten carbide coatings are revolutionizing industrial component durability through advanced material science and application techniques.

• Tungsten carbide coatings achieve 2600+ Vickers hardness, making them 3x stiffer than steel and capable of doubling component service life across industrial applications.

• HVOF application process creates ultra-dense coatings with <0.5% porosity, while WC-Co-Cr compositions provide optimal balance of wear resistance and corrosion protection.

• Field testing confirms 53% reduction in wear rates and extended service life of 20,000-40,000 additional cycles in high-load machinery applications.

• CVD coating techniques enable uniform coverage on complex MIM geometries where traditional thermal spray methods cannot reach internal surfaces effectively.

• Thermal stability up to 500°C combined with reduced maintenance requirements translates to 50% lower operational costs in demanding industrial environments.

The integration of tungsten carbide coatings with modern manufacturing processes like Metal Injection Molding represents a significant advancement in industrial component protection, offering manufacturers a proven path to dramatically extend equipment life while reducing total cost of ownership.

FAQs

Q1. What makes tungsten carbide coatings so effective for industrial components? Tungsten carbide coatings are highly effective due to their exceptional hardness (up to 2600 Vickers), which makes them about three times stiffer than steel. This results in superior wear resistance and can double the service life of industrial components in various applications.

Q2. How does the HVOF process contribute to the coating’s performance? The High Velocity Oxy-Fuel (HVOF) process creates extremely dense coatings with less than 0.5% porosity. This high-energy application method allows coating particles to bond instantly to the substrate, resulting in superior adhesion and performance.

Q3. Can tungsten carbide coatings be applied to complex-shaped components? Yes, while HVOF is effective for external surfaces, Chemical Vapor Deposition (CVD) techniques can be used to apply tungsten carbide coatings to complex-shaped components, including those produced by Metal Injection Molding (MIM). CVD provides uniform coverage on both internal and external surfaces.

Q4. What are the benefits of adding chromium to tungsten carbide coatings? Adding chromium to tungsten carbide coatings, such as in WC-10Co-4Cr formulations, significantly enhances corrosion resistance. This makes the coatings more effective in various environments, including humid atmospheres, seawater, and moderately alkaline or slightly acidic solutions.

Q5. How do tungsten carbide coatings perform in high-temperature environments? Tungsten carbide coatings exhibit excellent thermal stability, maintaining their structural integrity and performance characteristics at temperatures up to 500°C. This makes them ideal for use in thermally demanding industrial applications, where they can significantly extend component life.