Inconel 718 Properties Explained: From Microstructure to Industrial Applications

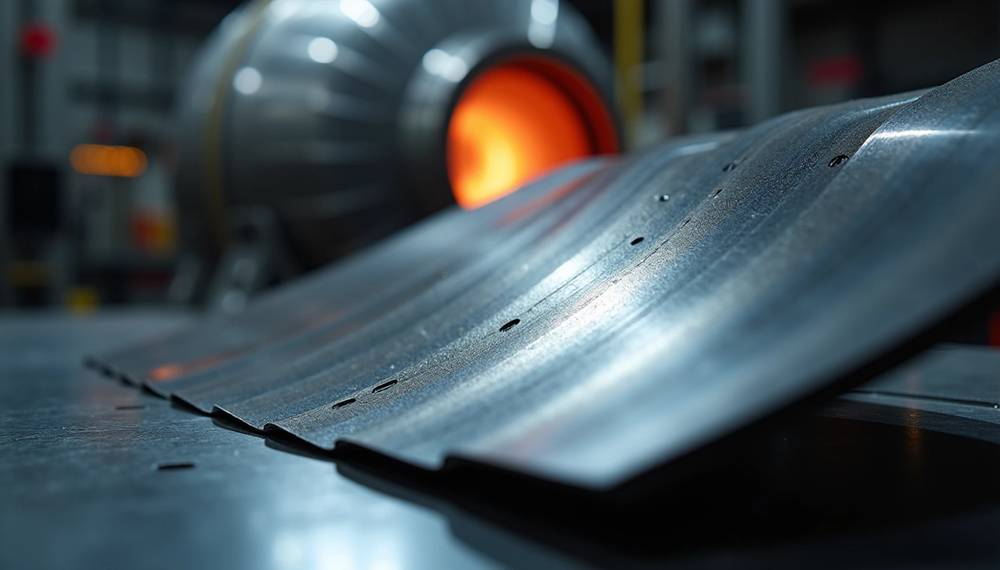

Inconel 718 is the most widely used nickel-based superalloy in aerospace, automotive, and energy industries because of its exceptional heat and mechanical properties . This remarkable material keeps its strength and mechanical properties at high temperatures. These qualities make it perfect for high thermal stress applications like gas turbines, jet engines, and rocket motors .

The alloy’s properties after heat treatment include outstanding tensile strength from 1034 MPa to 1380 MPa . Its ultimate tensile strength reaches up to 1,240 MPa. The material shows excellent corrosion resistance and maintains impressive phase stability at high temperatures . Inconel 718’s value comes from its ability to handle intense stress loads for extended periods at temperatures up to 650°C. This makes it ideal for advanced gas turbine engine technology.

The material’s exceptional properties stem from its microstructure. Heat treatment creates γ′ precipitates that block dislocation movement. This process effectively stops creep deformation even at high temperatures . The microscopic strengthening mechanism substantially contributes to the alloy’s performance characteristics that engineers depend on for demanding applications.

What is Inconel 718 and Why It Matters

Inconel 718 started as a material for supercritical steam power plants but has become the lifeblood of advanced engineering. This remarkable alloy belongs to the nickel-based superalloy family that withstands extreme environmental conditions while keeping its exceptional mechanical properties.

Nickel-Chromium Superalloy Classification

Inconel 718’s classification shows it as a precipitation-hardened nickel-chromium-iron superalloy with a complex composition. The alloy contains approximately 50-55% nickel, 17-21% chromium, 4.75-5.5% niobium plus tantalum, and 2.8-3.3% molybdenum, with smaller percentages of iron, aluminum, titanium, and carbon. This unique chemical makeup creates a material with remarkable properties through controlled metallurgical processes.

This superalloy stands out because of its microstructure, which consists primarily of a solid solution matrix reinforced by precipitate phases. The strengthening mechanism relies heavily on the precipitation of γ″ phase (Ni₃Nb) during aging heat treatment, which provides excellent creep and tensile strength at elevated temperatures. The γ′ phase (Ni₃(Al,Ti)) also acts as a secondary strengthening phase that contributes to the alloy’s exceptional heat resistance.

The high iron content in Inconel 718 makes it less expensive than other superalloys and improves its weldability. The iron’s low mobility in the matrix gives the main strengthening phase (γ″) a sluggish precipitation kinetics that reduces susceptibility to post-weld cracking.

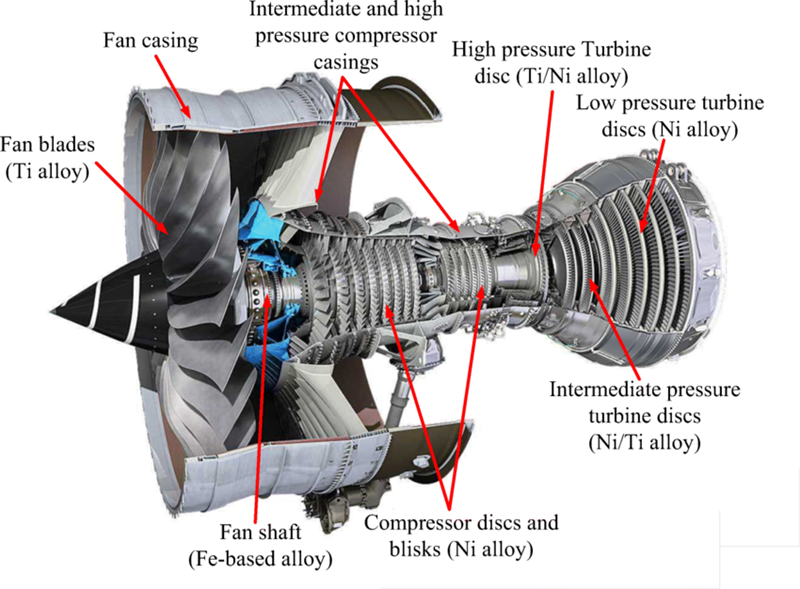

Common Use Cases in Aerospace and Energy

General Electric Aircraft Engines (GEAE) uses Inconel 718 for 34% of their finished component weight, split between forgings and investment castings. The aerospace industry relies heavily on this alloy for critical rotating parts, airfoils, supporting structures, and pressure vessels. Modern aircraft engines use Inconel 718 for more than 30% of their finished component mass.

Inconel 718 has found its way into several other industries:

- Oil and Gas Industry: Critical in downhole applications, including packers, hangers, sub-sea valves, and drill tools, thanks to its elevated strength and non-magnetic properties

- Power Generation: Essential in gas and steam turbines that produce electricity with higher efficiency

- Nuclear Power Plants: A key material in nuclear reactors due to its radiation resistance and high-temperature performance

- Rocket Engines: Used in tanks, containers, rings, and pressure vessels because they maintain temperature stability at both extreme high and cryogenic temperatures (down to -250°C)

Knowing how to retain strength at temperatures up to 650°C, combined with exceptional corrosion resistance, makes this alloy essential for these demanding applications.

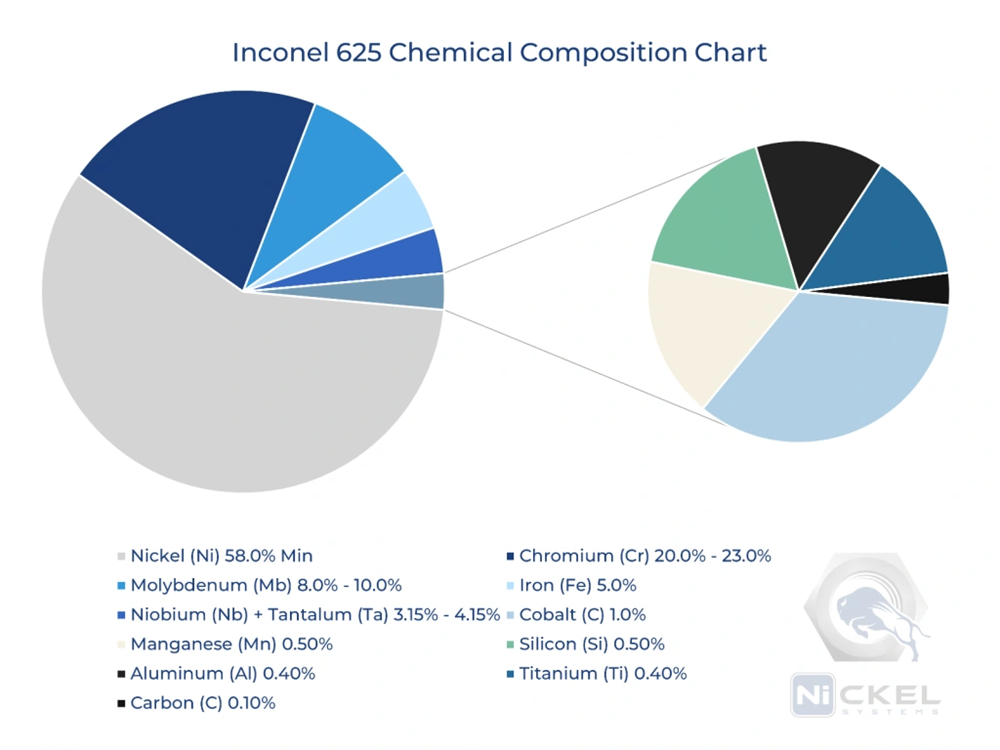

Comparison with Other Inconel Grades

Each Inconel grade has its unique advantages for specific applications, though they share certain characteristics:

Inconel 718’s superior strength properties set it apart from other grades. It delivers extreme high strength with a minimum of 185 ksi UTS and 150 ksi yield strength per ASTM B637, while Inconel 625 excels in corrosion resistance and suits chemical processing environments better.

Inconel 601 shows excellent oxidation and carburization resistance with improved high strength and mechanical toughness compared to grade 600. Its performance in high-temperature applications doesn’t match 718’s capabilities. The 107 ksi tensile strength (compared to 93 ksi of grade 600) provides good creep and rupture strength, but falls short of Inconel 718’s performance.

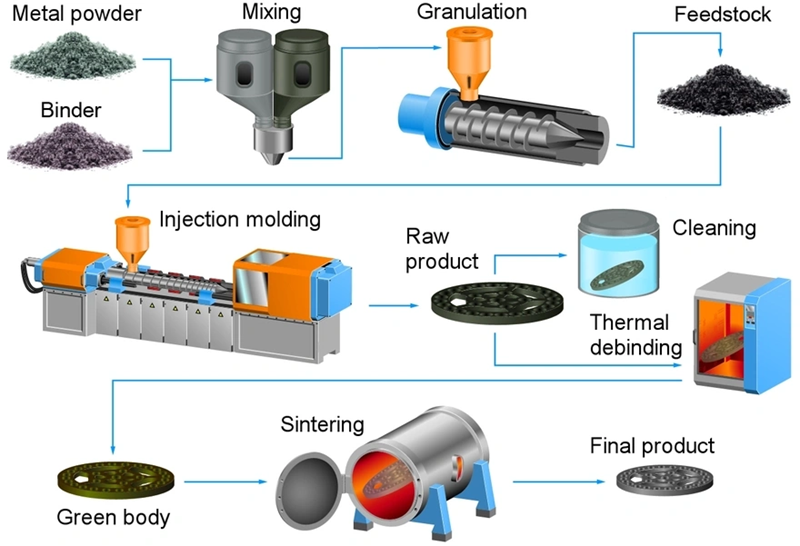

Manufacturing techniques have evolved to overcome Inconel 718’s challenging machining properties, which stem from its work-hardening tendency and toughness. Engineers can now tap into its full potential for intricate geometries through metal injection molding and additive manufacturing processes that would be difficult to achieve through conventional machining.

Inconel 718 Chemical Composition Breakdown

Inconel 718’s exceptional performance comes from its precise chemical makeup. This superalloy has a carefully developed mix of elements that work together to create remarkable properties under extreme conditions.

Nickel, Chromium, and Iron Base Elements

Nickel makes up the largest part of Inconel 718, between 50-55% of the total composition. This base element creates the foundation for excellent corrosion resistance and stability at high temperatures. The microstructure’s nickel manages to keep atoms from moving randomly, which helps maintain stability even when temperatures go above 650°C.

The alloy has 17-21% chromium that creates a thick Cr₂O₃ chromium oxide film on the surface. This layer acts like protective armor against corrosive substances. The oxide shield protects the material from oxygen, water, sulfide, and acid attacks, which lets Inconel 718 survive in harsh environments.

Iron fills in the remaining balance, making up about 17% of the alloy. While often overlooked, iron helps overall stability without hurting other important properties. Iron also makes the alloy easier to weld and cheaper to produce compared to other nickel-based superalloys.

Role of Niobium, Molybdenum, and Titanium

Niobium (also called columbium) sets Inconel 718 apart, with 4.75-5.5% content. This element strengthens the alloy by creating γ” phases through precipitation hardening. Most analyses show niobium at around 4.79%, carefully balanced to maximize strength while keeping toughness.

The alloy contains 2.8-3.3% molybdenum, which dissolves into the nickel-based solid solution and makes atomic bonds stronger. This substantially improves high-temperature strength, creep resistance, and hardness. Molybdenum also helps resist pitting and crevice corrosion, especially in environments containing chlorides.

Titanium amounts to 0.65-1.15% of the mix and works with niobium during precipitation hardening. This partnership helps Inconel 718 resist stress corrosion cracking and oxidation under extreme pressures and temperatures. Standard formulations usually have about 1.00% titanium.

Trace Elements and Their Effects

Aluminum (0.20-0.80%) helps form γ’ precipitate phases that add to the alloy’s strength. Standard formulations typically contain about 0.70% aluminum.

Small amounts of carbon (0.08% max), manganese (0.35% max), silicon (0.35% max), and sulfur (0.015% max) shape Inconel 718’s microstructure. Research shows that phosphorus, sulfur, boron, and silicon can affect how the alloy solidifies.

Some modified versions include tiny amounts of calcium, magnesium, zirconium, and hafnium. These additions can create more carbides and improve mechanical performance. Adding calcium and magnesium can increase carbide density, which reduces anisotropy and makes the alloy more ductile.

Boron (0.006% max) and phosphorus (0.001% recommended) need careful control. Research suggests keeping phosphorus below 0.001%, silicon below 0.05%, and boron between 0.002-0.004% for best results.

Each element in Inconel 718 serves a specific purpose. Together, they create a superalloy that performs exceptionally well under extreme conditions. This careful balance of elements makes it perfect for applications needing extraordinary strength and corrosion resistance at high temperatures.

Thermal and Mechanical Properties of Inconel 718

Inconel 718’s outstanding performance in extreme environments comes from its thermal and mechanical properties. These characteristics make it the top choice for applications that need both strength and thermal stability.

Yield Strength and Ultimate Tensile Strength

Heat treatment conditions determine Inconel 718’s strength values. Standard precipitation hardening helps the alloy reach a yield strength (0.2% offset) of about 1036 MPa (150 ksi) and an ultimate tensile strength of 1240 MPa (180 ksi) at room temperature. The material keeps a minimum elongation of 12% after solution treatment plus precipitation heat treatment.

Inconel 718’s strength stays stable across a wide range of temperatures. The yield strength drops only slightly to 980 MPa (142,000 psi) at 650°C (1200°F), and the ultimate tensile strength stays at 1100 MPa (160,000 psi). This is a big deal as it means that most engineering materials lose strength quickly at high temperatures.

The mechanical properties depend heavily on heat treatment. A standard heat treatment uses solution treatment at 980-1065°C and a two-step aging process: 8 hours at 718°C, cooling at 55°C/hour to 621°C, and holding for 8 more hours. This careful process optimizes precipitation strengthening while keeping good ductility.

Creep Resistance up to 700°C

Inconel 718’s high creep-rupture strength makes it valuable up to 700°C (1300°F). Components can handle constant loads without deforming at temperatures that would make regular alloys fail.

Processing conditions change the creep behavior. Hot isostatically pressed (HIP) specimens show better creep resistance than standard solution-annealed samples. Stress exponent values range from 2.245 to 3.55, showing that dislocation creep causes the main deformation.

The material can withstand 110 MPa (758 ksi) for 100 hours or 85 MPa (586 ksi) for 1000 hours at 649°C (1200°F) according to stress rupture data. γ″ precipitate phases create these excellent creep properties by blocking dislocation movement even at high temperatures.

Fatigue Strength and Impact Toughness

Components under cyclic loading need good fatigue performance. Surface treatments help conventionally manufactured Inconel 718 reach a fatigue limit of about 500 MPa. Surface quality affects fatigue resistance in additively manufactured parts – electropolishing can boost the fatigue limit by over 90%, from 220 MPa to 420 MPa.

Fatigue behavior depends on microstructural features. HIP-aged conditions with δ phase along grain boundaries usually have worse fatigue properties than solution-treated states. Crack analysis shows that cracks start at the surface and move through cleavage before switching to transgranular propagation.

The material has enough impact toughness for most uses, but additively manufactured specimens tend to be less ductile than wrought ones. Sulfur segregation in additive manufacturing causes this issue, but proper processing techniques can fix it.

Thermal Conductivity and Expansion Coefficient

Thermal properties make Inconel 718 perfect for high-temperature uses. Room temperature thermal conductivity measures about 11.4 W/m-K (79.1 BTU-in/hr-ft²-°F). Between 298K and 800K, thermal conductivity follows λ(T) = 5.291 + 0.0152T + 1.382×10⁻⁶T², rising slightly with temperature.

The thermal expansion coefficient is 13.0 μm/m-°C (7.22 μin/in-°F) between 20-100°C. This low expansion rate reduces thermal stresses during temperature changes, making it ideal for parts that heat and cool quickly.

Metal injection molding processes work differently with these thermal properties. The material’s low thermal conductivity needs careful cooling rate control but allows complex shapes with consistent properties throughout the part.

Microstructure and Strengthening Mechanisms

The remarkable strength of Inconel 718 at high temperatures comes from its complex microstructure and multiple strengthening mechanisms. Engineers have carefully designed this microstructural architecture through precise processing techniques to create a material that withstands extreme operating conditions.

γ′ and γ″ Precipitate Phases

Inconel 718’s exceptional properties come from two critical precipitate phases at the microscopic level. The γ′ phase (Ni3(Al, Ti)) shows an L12 face-centered cubic structure with spherical morphology that appears as small dots within the matrix. The γ″ phase (Ni3Nb) has a body-centered tetragonal D022 structure and forms ellipsoidal disk-shaped particles.

The γ″ phase acts as the dominant strengthening mechanism, though both precipitates contribute to the material’s strength. Two main factors explain this dominance: its substantial coherency strain with a tetragonal distortion ratio (c/a=2.04) and its higher volume fraction. The volume fraction typically reaches four times that of γ′, varying with the (Ti+Al)/Nb ratio [14].

The strengthening effect happens through:

- Coherent strain strengthening—interaction between dislocations and stress fields around γ″ precipitates

- Ordered particle strengthening—disruption of dislocation movement through the ordered structure

These nanometer-scale precipitates block dislocation movement at a fundamental level, which requires more stress to deform the material. Standard heat treatments result in γ″ particles measuring about 26.49 ± 1.82 nm in mean size.

Laves Phase and δ Phase Formation

The Laves phase ([Ni,Cr,Fe]2[Nb,Mo,Ti]) reduces mechanical properties, unlike the beneficial γ′ and γ″ phases. This hexagonal close-packed phase emerges during solidification at interdendritic regions as Nb separates. Its continuous and semicontinuous networks harm tensile properties, high-cycle fatigue life, and hot cracking resistance.

The δ phase (Ni3Nb) features an orthorhombic D0a structure that looks like needle-like formations. This phase can develop directly from the metastable γ″ phase or near the Laves phase at temperatures around 900°C. Scientists have found that the δ phase forms more readily around Laves phases, where higher Nb concentrations meet nucleation conditions.

Controlling these phases requires proper heat treatment. Heat treatments below the δ-solvus temperature can eliminate long Laves phase chains without causing excessive grain growth that happens at higher temperatures.

Solid Solution Strengthening with Mo and Nb

Solid solution strengthening adds another layer of enhancement to Inconel 718. Mo and Nb elements dissolve into the γ matrix (FCC structure) and increase interatomic bonding forces while stabilizing the matrix [19]. This mechanism creates a lattice distortion that slows dislocation movement.

Mo enhances high-temperature strength and creep resistance while improving resistance to pitting and crevice corrosion. Nb plays dual roles by participating in solid solution strengthening and forming strengthening precipitates during aging treatments.

Metal injection molding processes require a deep understanding of these strengthening mechanisms. The final microstructure and mechanical properties depend on precise control of cooling rates and subsequent heat treatments. Poor processing can lead to too much formation of harmful phases or insufficient strengthening precipitates.

The typical heat treatment involves homogenization above the eutectic temperature to dissolve secondary phases. This step precedes aging treatments that control strengthening precipitate formation. The lattice misfit between matrix and precipitates measures 0.6320% for γ/γ″, creating strain fields that strengthen the alloy [16].

Corrosion and Oxidation Resistance in Harsh Environments

Inconel 718’s most valuable feature is its outstanding resistance to corrosion and oxidation in harsh environments. This alloy keeps its structural integrity and performance in conditions where regular materials break down faster.

Oxide Layer Formation at High Temperatures

Inconel 718 creates protective oxide scales that shield the base material from breaking down at high temperatures. The alloy’s nickel and chromium actively oxidize between 800°C and 1000°C to form NiO and Cr₂O₃ protective oxide layers. X-ray diffraction studies show NiCr₂O₄ spinel elements and Cr₂Ni₃ form as temperatures reach 1000°C.

The oxidation process follows three main steps:

- Adsorption of oxidation gasses from the surrounding environment

- Ion penetration through the oxidation layer

- Elemental reactions at the interface

The oxide scales show distinct features based on temperature exposure. Scanning electron microscopy reveals tetragonal biaxial pyramids, flakes, and polygonal plates on samples heated at different temperatures. Studies of cross-sections show oxide layer thickness grows substantially from 800°C to 1200°C, and resistance values multiply between these points.

Parts made through metal injection molding need careful attention to these oxidation properties during post-processing heat treatments to get the best surface protection.

Resistance to Seawater and Acidic Media

Inconel 718 shows exceptional resistance in marine environments, making it ideal for offshore and naval uses. Natural seawater immersion tests prove that wrought Inconel 718 has substantially lower corrosion rates (1.21 μm y⁻¹) than wrought Incoloy 825 (4.1 μm y⁻¹) and selective laser melted (SLM) Inconel 718 (35.1 μm y⁻¹) after 5000 hours.

The alloy’s corrosion resistance comes from a continuous, compact passive film on its surface. This protective layer mainly contains nickel, chromium, and molybdenum compounds. Electrochemical impedance spectroscopy shows wrought alloy surfaces create a thick, chemically stable film that gives lasting protection.

Manufacturing methods greatly affect corrosion behavior. Surface analysis using scanning electron microscopy and energy-dispersive spectroscopy shows wrought Inconel 718 creates a continuous, compact film with just a few salt deposits. SLM-processed Inconel 718, however, develops a more porous, uneven film that protects less effectively.

The alloy resists pitting, crevice corrosion, and stress-corrosion cracking in oxidizing environments. Its chromium content fights off oxidizing media and sulfur compounds, while molybdenum helps prevent pitting corrosion.

Performance in Jet Engines and Reactors

Jet engines rely on Inconel 718’s corrosion and oxidation resistance. The alloy handles intense heat in crucial components like turbine blades, exhaust systems, and combustion chambers.

Nuclear facilities benefit from Inconel 718’s high resistance to radiation damage. The alloy works well in reactor cores and steam generators under high stress rates. Its protective oxide scales at high temperatures make it last longer in these critical uses.

Oil and gas extraction operations use Inconel 718 for downhole applications where it must resist hydrogen sulfide (H₂S) and other corrosive substances. The alloy’s superior corrosion resistance makes it perfect for downhole tubing, wellhead parts, and valve accessories in deep well environments.

Marine equipment lasts longer thanks to Inconel 718’s resistance to seawater corrosion. Propeller blades, pumps, and other marine hardware use this alloy where saltwater would quickly damage regular materials. This outstanding performance helps parts last longer and cuts maintenance costs while boosting reliability.

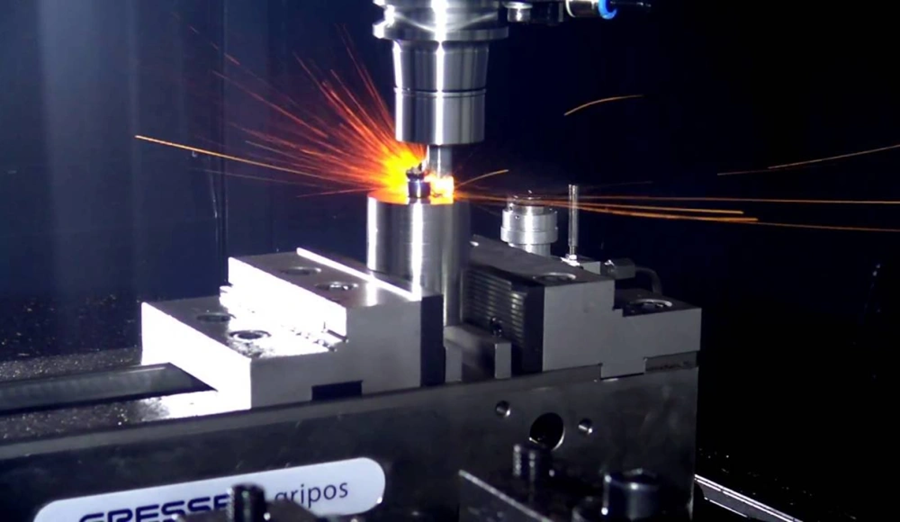

Machining and Forming Challenges of Inconel 718

Manufacturing Inconel 718 components comes with major challenges that arise from the same properties that make this superalloy valuable for high-performance applications. These manufacturing difficulties need specialized approaches and advanced tooling to get acceptable results.

Work Hardening and Tool Wear Issues

Inconel 718 shows high work hardening during machining operations. The work-hardening layer can go deeper than 60 μm beneath the machined surface when using chamfered tools. This hardened layer makes cutting forces increase and causes tools to deteriorate faster in later passes. The alloy’s low thermal conductivity (11.04 W/m°C) leads to heat buildup at the cutting edge. Regular machining methods cause quick temperature spikes that make tools break down through diffusion and adhesive wear. Hard intermetallic precipitates are what give the alloy its strength, but they also wear down cutting tools through abrasion.

Recommended Tool Materials: CBNs and Ceramics

Several materials work well for machining Inconel 718. Ceramic tools, especially whisker-reinforced alumina and TiC-added alumina ceramics, work better at high cutting speeds. SiC whisker tools are great at managing notch wear when speeds stay under 300 m/min. TiC-added alumina ceramics do their best work at speeds over 400 m/min. Polycrystalline cubic boron nitride (PcBN) tools with low cBN content (≤75 vol.%) and ceramic binders are a better choice for finishing work at cutting speeds between 200-450 m/min. Ceramic tooling brings its own set of challenges. These materials are harder than carbide options but don’t handle mechanical shocks well, which limits their use in interrupted cutting.

Cooling and Lubrication Strategies

The right cooling and lubrication methods make a big difference when machining Inconel 718. Tests comparing regular flood cooling, minimum quantity lubrication (MQL), and dry machining show clear performance differences. Cryogenic cooling with liquid CO₂ or N₂ is a great way to improve surface quality. High-pressure coolant at 200 bar reduces cratering better than standard low-pressure delivery. Chilled MQL strategies help reduce cutting forces, particularly at lower cutting speeds. These advanced cooling techniques help solve heat dissipation and work hardening problems. They help tools last longer while keeping the dimensional accuracy and surface integrity needed for metal injection molding post-processing operations.

Welding and Joining Techniques for Inconel 718

Welding Inconel 718 components comes with unique metallurgical challenges that need specialized welding techniques. The chosen welding process affects the mechanical integrity and performance of the final assembly.

GTAW, EBW, and LBW Process Comparisons

Gas Tungsten Arc Welding (GTAW) stands as the most accessible technique for Inconel 718, but achieves only 70% joint efficiency due to its inferior tensile properties. The formation of coarse Laves phases in the fusion zone creates this limitation. Electron Beam Welding (EBW) brings substantial advantages through its high-energy-density and lower heat input. This creates narrower fusion zones and reduces distortion. Laser Beam Welding (LBW) gives exceptional control over the welding process. Both EBW and LBW keep niobium segregation (10-12%) and Laves phase formation (4-6%) in check within the fusion zone. These processes come with their own challenges, particularly porosity-related defects.

Gas Tungsten Constricted Arc Welding (GTCAW) has shown remarkable progress lately. It achieves up to 99.20% joint efficiency that matches more expensive EBW and LBW processes.

HAZ Microfissuring and Laves Phase Control

Heat-Affected Zone (HAZ) microfissuring remains a persistent challenge in Inconel 718 welding. Liquid films form at grain boundaries during the weld thermal cycle and cause this issue. Minor alloying elements like C, P, S, and B segregation, combined with constitutional liquation of MC carbides, make microfissuring more likely.

Compound current pulsing with helium shielding gas helps control Laves phase formation. This technique speeds up cooling rates and reduces microsegregation. The result is refined fusion zone microstructures with less Laves phase content. Solid solution filler wires with higher molybdenum content boost heterogeneous nucleation and equiaxed dendritic solidification.

Post-Weld Heat Treatment Requirements

Post-weld heat treatment (PWHT) is crucial to optimize Inconel 718 weldment properties. Standard treatments combine 980°C solution treatment with precipitation hardening. Higher temperatures at 1065°C can completely dissolve the Laves phase. The two-step aging process takes 8 hours at 718°C, followed by cooling to 621°C for another 8 hours.

PWHT reduces residual stress and promotes strengthening phase precipitation. Optimal treatment at 650°C distributes fine-scale γ″ strengthening phases evenly throughout the weldment. This boosts strength and corrosion resistance. Treatment temperatures above 850°C can trigger δ phase precipitation along Laves phase boundaries. These create stress concentration points that weaken mechanical integrity.

Metal Injection Molding and Additive Manufacturing

Modern manufacturing methods have reshaped the scene of Inconel 718 production. These methods now enable complex components with exceptional properties that cost less than traditional techniques.

Suitability of Inconel 718 for MIM

Metal Injection Molding serves as a cost-effective alternative to investment casting and machining for Inconel 718 components. European and American manufacturers now produce MIM automotive turbocharger components at scale. The master alloy route creates a homogeneous fine-grained microstructure that matches cast Inconel 718’s mechanical properties. Heat treatment substantially improves tensile properties, especially when temperatures reach 540°C. MIM Inconel 718 parts’ room temperature mechanical properties are a big deal as they mean that they surpass AMS 5383 (Cast), AMS 5662 (Wrought), and AMS 5917 (MIM) standards. The MIM process can produce parts with sufficient elongation without expensive HIP consolidation if controlled properly.

SLM and EBM Process Parameters

Selective Laser Melting of Inconel 718 needs precise control of processing parameters. Research has analyzed various laser powers, scan speeds, and hatch spacings. The results show that 99.5% density, 2 μm surface roughness, or 248 MPa residual stress can be achieved individually. Parameters of 320 W power, 600 mm/s scan speed, and 0.12 mm hatch spacing create 99.2% density with relatively low roughness of 3.5 μm. Mixed grain structures appear at 600-1000 mm/s scan speeds, which points to reduced anisotropy.

Post-Processing: Heat Treatment and Surface Finishing

Post-processing reshapes MIM and additively manufactured Inconel 718’s properties completely. Standard heat treatment consists of solution annealing at 980°C for 1 hour. This is followed by two-step aging: 8 hours at 720°C, furnace cooling to 620°C, and aging for 8 hours. This treatment lifts mechanical properties substantially, especially at 650°C. Hot Isostatic Pressing improves density from about 98% to nearly 100%, which improves elongation properties. Surface finishing techniques can reduce Ra values by 57-88% to get surface roughness below 2.5 μm. Research shows that post-aging finishing improves high-cycle fatigue life more than pre-aging finishing.

Conclusion

Inconel 718 represents a breakthrough in materials engineering with performance features that put other alloys nowhere near its capabilities. This superalloy shows unique properties that stay stable up to 650°C, thanks to its special chemical makeup. The perfect mix of nickel, chromium, iron, and key trace elements creates a material that handles extreme conditions in many industries.

The internal structure of Inconel 718, especially when you have γ″ and γ′ precipitate phases, gives it amazing strength at high temperatures. These tiny formations block atomic movement and keep the material strong in conditions that would destroy regular metals. On top of that, it forms protective oxide layers at high temperatures that shield the metal from breaking down, which makes parts last by a lot longer.

This material is a big deal as it means that it outperforms others, but it’s not easy to work with. The metal gets harder as you work it and doesn’t conduct heat well, which makes machining tough. In spite of that, better cutting tools, cooling methods, and special welding techniques have made production easier. Engineers now make use of this amazing material’s full potential while keeping costs down.

Metal injection molding has become a real game-changer for making Inconel 718 parts. You can create complex shapes that match the strength of cast and forged parts, often without expensive finishing. New 3D printing methods like Selective Laser Melting also let you make designs that were impossible before, while keeping all the great properties that make Inconel 718 essential.

The aerospace industry remains this material’s biggest user. Its properties help make jet engines and gas turbines more efficient, reliable, and safe. Beyond flying machines, this metal is a great way to get better performance in oil and gas wells, nuclear power plants, and ocean equipment, where regular alloys would break down faster.

Scientists and engineers keep finding better ways to work with this superalloy. Though it’s tough to shape and machine, nothing matches its combination of high-temperature strength, corrosion resistance, and stability. That’s why it stays the top choice to handle the toughest jobs in modern industry.

Key Takeaways

Inconel 718 represents the pinnacle of superalloy engineering, combining exceptional strength with thermal stability for the most demanding industrial applications.

• Exceptional High-Temperature Performance: Inconel 718 maintains 980 MPa yield strength at 650°C, making it ideal for jet engines and gas turbines where conventional materials fail.

• Complex Strengthening Mechanisms: The alloy’s strength comes from γ″ and γ′ precipitate phases that block dislocation movement, providing superior creep resistance up to 700°C.

• Manufacturing Challenges Require Specialized Approaches: Work hardening and low thermal conductivity demand ceramic tools, cryogenic cooling, and precise welding techniques for successful fabrication.

• Metal Injection Molding Enables Cost-Effective Complex Parts: MIM produces Inconel 718 components with properties exceeding cast standards, offering economical alternatives to traditional manufacturing.

• Protective Oxide Layers Ensure Longevity: Chromium and nickel form dense oxide films that shield components from corrosion in seawater, acids, and high-temperature environments.

The strategic combination of precise chemical composition, controlled microstructure, and advanced manufacturing techniques makes Inconel 718 indispensable for aerospace, energy, and marine applications where failure is not an option.

FAQs

Q1. What are the key applications of Inconel 718? Inconel 718 is widely used in aerospace turbines, automotive components, medical devices, and chemical processing equipment due to its exceptional strength and corrosion resistance at high temperatures up to 700°C.

Q2. What gives Inconel 718 its remarkable strength? The strength of Inconel 718 comes from its unique microstructure, particularly the γ″ and γ′ precipitate phases that impede dislocation movement within the alloy’s matrix.

Q3. Why is Inconel 718 challenging to machine? Inconel 718 is difficult to machine due to its rapid work hardening and low thermal conductivity, which causes excessive tool wear and heat buildup during cutting operations.

Q4. How does Metal Injection Molding (MIM) benefit Inconel 718 production? MIM allows for cost-effective production of complex Inconel 718 components with mechanical properties that can exceed cast standards, often without requiring expensive post-processing treatments.

Q5. What makes Inconel 718 resistant to corrosion in harsh environments? Inconel 718 forms protective oxide layers, primarily composed of chromium and nickel oxides, which shield the base material from corrosion in seawater, acidic media, and high-temperature environments.